KDM is a trusted manufacturer that is providing titanium sheet metal fabrication services. We are offering titanium sheet machining, welding, fabricating, and other manufacturing-related services.

- Lightweight & high-strength material

- With excellent resistance to erosion, acid, & microbiological corrosion

- Cost-effective solution for many applications

- Offers superior rigidity & strength

KDM Titanium Sheet Metal Fabrication

Titanium sheet metal fabrication is a process of producing various forms, shapes, and components using flat sheets of titanium metal. The titanium sheet metal is extremely easy to fabricate and usually preferred by many industries such as chemical processing, automotive, medical, marine, aerospace, military, and more.

Many industries are choosing titanium sheet metal due to its superior strength, lightness, and rigidity in comparison to other types of metal. Also, they have excellent resistance to brackish water, salt corrosion, oxidation, rust, acid, chloride, and scratches without the need for coating or galvanization.

Other characteristics of titanium sheet metal also includes thermal conductivity, flexibility, nonmagnetic qualities, high melting points, excellent strength under high temperatures, and unique appearance.

Moreover, KDM can custom fabricate the titanium sheet metal to fully satisfy your business needs. If you have questions regarding KDM titanium sheet metal, you can contact us!

KDM Titanium Sheet Metal Fabrication

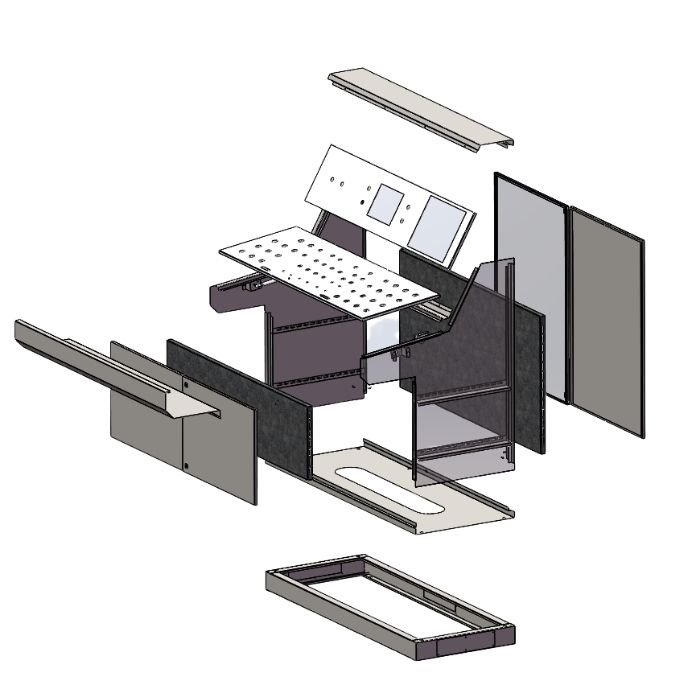

The titanium sheet metal speaker enclosure is fabricated by deep drawing, CNC turning, bending, forming, punching, and other processes. It is featuring lightness, extreme durability, and excellent corrosion resistance. It can be designed into various shapes and sizes.

KDM can produce various types of U-shaped brackets galvanized sheet metal. Fabrication of U-shaped brackets galvanized sheet metal includes bending, forming, etc. They are highly resistant to scratches, corrosion, rust, oxidation, and chemicals. Also, they are widely used in the construction industry.

The perforated sand scoop titanium sheet metal has excellent strength, lightweight design, and superior resistance to saltwater. It is designed with hexahedron-shaped holes. Also, it has excellent resistance to rust, chemicals, oxidation, etc.

KDM fabricates the plate heat exchangers or PHE using thin sheets of commercially pure titanium metal. The titanium sheet metal plate heat exchangers are commonly used for basement equipment rooms and marine vessels. It has great durability, favorable workability, and high corrosion resistance.

KDM can fabricate the titanium sheet metal into various types of flanges such as blind flanges, slip-on flanges, spectacle blind flanges, and many more. The titanium sheet metal can be produced using various grades of titanium such as Gr7, Gr5, Gr5, Gr2, and so on. It has high corrosion resistance and superior strength.

KDM is capable of providing custom fabrication of the titanium sheet metal. The titanium sheet metal can be fabricated based on your required sizes, designs, and other specifications. It is produced with features such as lightness, high resistance to various types of corrosion, and high temperatures.

KDM Titanium Sheet Metal Fabrication by Various Industries (5)

KDM Titanium Sheet Metal Fabrication Advantages

The titanium sheet metal is highly resistant to various types of corrosion including pitting corrosion, stress corrosion, microbiological corrosion, brackish water corrosion, and more. As a result of being resistant to various corrosion, it is suitable for both outdoor and indoor environments.

Titanium metal has 3 times more strength than aluminum. Also, it has 2 times more strength than low carbon steel. However, it is also lightweight in spite of its strength. Titanium metal has a mass of about 60% that of stainless steel and low carbon steel.

The stainless steel and low-carbon steel has a more expensive unit price per mass than the titanium due to the titanium’s low specific gravity. Moreover, due to its great corrosion resistance and high strength, its gauge thickness can be reduced, and this is advantageous to users when considering low life cycle costs because of fewer maintenance costs.

The titanium sheet metal has a strict management of oxide layer on its surface. It has a beautiful silver-gray color.

KDM Titanium Sheet Metal Fabrication for Various Industries

The fabrication of titanium sheet metal is very useful among many industries such as:

- Medical Industry

- Automotive Industry

- Aerospace Industry

- Marine Industry

- Chemical Industry

- Military Industry

- Building & Construction Industry

- Petroleum Handling Industry

- Food Service Industry

- Metallurgical Industry

KDM Titanium Sheet Metal Material Grades

When fabricating the titanium sheet metal, KDM uses various grades of titanium. The following are the most used grades.

Commercially Pure Grade 2 – This type of grade has high strength and great weldability making it ideal for cryogenic vessels, airframe components, heat exchangers, pickling baskets, architectural and medical applications.

Commercially Pure Grade 3 – The grade 3 titanium metal has more strength than the grade 2 and 1. However, they have similar ductility and a little less formability. This type of grade is ideal for medical equipment, aerospace structures, and chemical processing applications.

Commercially Pure Grade 4 – Among the 4 commercially pure grades of titanium, the grade 4 is the strongest. It has great weldability, good formability, and excellent corrosion resistance. Also, it is ideal for surgical hardware, airframe components, and more.

Ti-6AL-4V Grade 5 – The grade 5 is the most usually used titanium alloy. It has better resistance to high temperatures than the Grade 2. Moreover, it is commonly used in industries such as chemical processing, marine, medical, and aerospace.

Other grades of titanium also include grades 1, 7, 9, 12, 16, 17, etc.

KDM Titanium Sheet Metal Fabrication Process

KDM uses advanced manufacturing equipment when fabricating various titanium sheet metal components and products. Also, there are a lot of processes when fabricating them. Below are some of our manufacturing processes.

- Metal Stamping

- Laser Cutting

- CNC Machining

- Forming

- Bending

- Welding

- Punching

- Surface Treatment

Choose KDM to Custom Titanium Sheet Metal Fabrication Needs

At KDM, we have 3000 square meters facility with expert engineers, 3000W optical laser cutting machines, 3D flexible welding platforms, detection machines, high-speed PU foaming machines, and other advanced manufacturing equipment that enable us to provide custom fabrication of titanium sheet metal.

For more than 10 years, we have been fabricating titanium sheet metal products for various industries including chemical processing, medical, automotive, marine, etc. KDM has the ability to provide custom fabrication services that guarantee your satisfaction. Our machining capabilities include heat treating, welding, forming, drilling, shearing, punching, tempering, surface finishing, and many more. You can give us your required specifications or design and we will produce them for you.

All of the titanium sheet metal products that we are producing are made from durable and quality raw materials. They are all inspected, tested, and have passed international standards such as ISO, ASTM, JIS, and other quality standards.

If you want to know more information about KDM titanium sheet metal fabrication, you can contact us today.

KDM Titanium Sheet Metal Fabrication

KDM titanium sheet metal products are fabricated with many advantages and features such as:

- superior strength & rigidity

- extremely lightweight

- excellent temperature resistance

- good thermal conductivity

- ease of fabrication

- excellent wear resistance

- strong density

- unique appearance

- nonmagnetic qualities

- superior strength-to-weight ratio

- excellent mechanical properties

Moreover, the titanium sheet metal is featuring excellent resistance to stress corrosion, oxidation, brackish water, seawater, chemicals, microbiological corrosion, pitting corrosion, erosion, atmospheric corrosion, chloride, etc.

The titanium sheet metal can be used for a wide range of applications such as:

- airframe components, spacecraft frames, engines, etc.

- sporting goods equipment

- CPI equipment

- pickling baskets

- cryogenic vessels

- condenser tubing

- heat exchangers

- Missiles & other weaponry

- compressor blades

- gears

- automotive parts

- medical equipment

- hydraulic systems

- building material products

- submarine components & ocean-deployed surveillance devices

KDM Titanium Sheet Metal Fabrication for Various Applications

KDM is fabricating the titanium sheet metal into different types of brackets. Producing the titanium sheet metal brackets includes bending, CNC machining, punching, forming, and more. It is commonly used for windows, doors, furniture, and so on.

KDM can fabricate various types of spare parts for medical equipment. The titanium sheet metal medical equipment spare parts are made from high-quality, durable, and different grades of titanium metal. It has superior strength, rigidity, and high corrosion resistance.

The titanium sheet metal machine parts are made by laser cutting, folding, bending, stamping, punching, etc. It is designed with ventilation holes, rivets, and more. Also, it can be designed into different types of machine parts depending on the customers’ requirements.

The titanium sheet metal machine parts are widely used in the construction industry. It is stamped, bent, punched, etc. Also, it is produced with many features such as excellent durability, high temperature resistance, and resistance to different types of corrosion.

Why KDM is Trusted By Over 1000 Global Clients

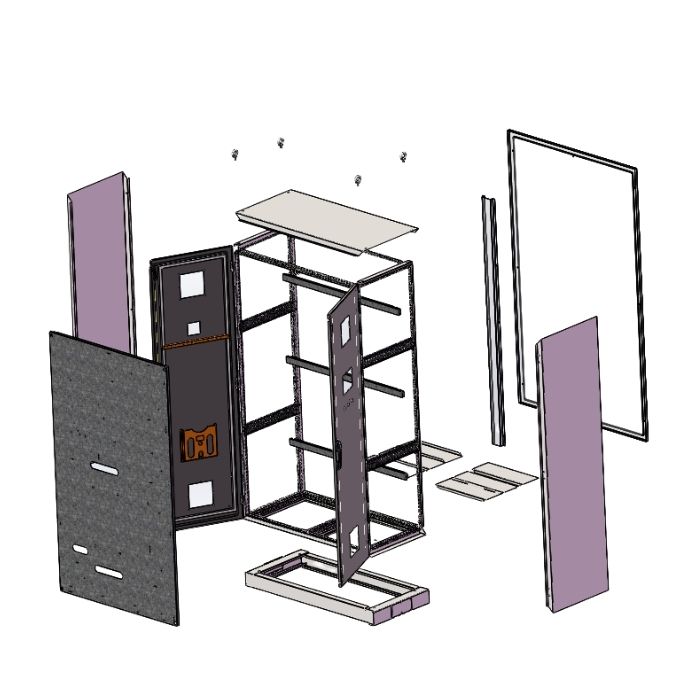

- Enclosure Manufacturing

- 2D Drawing

- 3D Drawing

4000W high performance laser cutting machine, +/- 0.05mm accuracy. No burr, no scratching.

Multi-Functioning flexible welding equipment, high accuracy, no deformation.

Expert assembling team, consistent assembly quality on every KDM enclosure