KDM is a leading manufacturer in China that offers custom galvanized sheet metal fabrication services according to your required specifications. We can provide fabrication of galvanized sheet metal using a variety of materials such as steel, iron, etc.

- Ideal for both indoor & outdoor projects

- Excellent durability under harsh conditions

- With rust & corrosion protection

- Wide range of galvanization process

KDM Galvanized Sheet Metal Fabrication

Galvanized sheet metal fabrication is a process of using various galvanized materials such as iron and steel to produce a wide range of metal parts and other products.

Galvanizing sheet metal is a process of adding a protective zinc coating to metal to prevent rusting and corrosion. An iron or steel that is galvanized has excellent resistance to corrosion, rust, oxidation, moisture, and scratches. Also, galvanized sheet metal has excellent resistance to various harsh weather conditions. As a result, they can be used for both indoor and outdoor applications.

The galvanized sheet metal is fabricated with many features such as long lifespan, environ-mentally friendly, versatility, sustainability, and great durability under harsh conditions. They are widely used in many industries such as construction, transportation, agriculture, electronics, and other industries.

Furthermore, KDM has the ability to custom fabricate the galvanized sheet metal according to your specifications. We are equipped with expert engineers, advanced manufacturing equipment, detection machines, and more. Therefore, you can rest assured that we can satisfy your business needs.

If you want KDM galvanized sheet metal fabrication services, please contact us!

KDM Galvanized Sheet Metal Fabrication

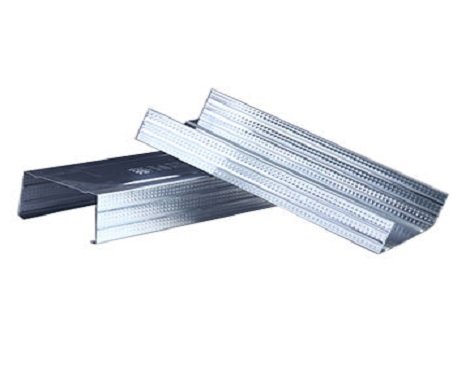

KDM can manufacture U-channel guide tracks using galvanized steel sheets. The U-channel guide track galvanized sheet metal is water-proof, rust-proof, fire-proof, and corrosion-resistant. It can be used as a floor guide on the systems of multi-slide doors.

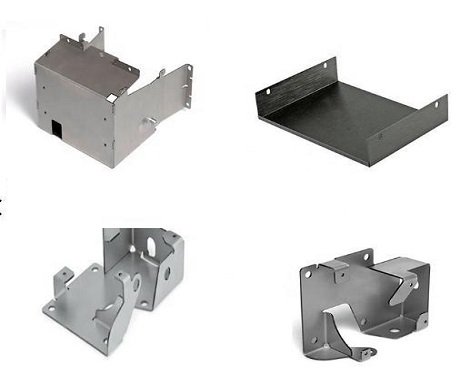

KDM can produce various types of U-shaped brackets galvanized sheet metal. Fabrication of U-shaped brackets galvanized sheet metal includes bending, forming, etc. They are highly resistant to scratches, corrosion, rust, oxidation, and chemicals. Also, they are widely used in the construction industry.

KDM can custom fabricate different types of elevator brackets and parts such as guard rail brackets, wall-mounted brackets, angle brackets, and many more. The processes of fabricating elevator brackets and parts include forming, stamping, bending, etc. They have excellent resistance to corrosion, rust, weathering, etc.

The galvanized sheet metal can be fabricated into various types of support brackets such as L-shaped angle brackets and other brackets for furniture, fences, walls, post, buildings, automobiles, and more. The galvanized sheet metal support brackets are highly durable and resistant to corrosion.

KDM can produce different types of perforation of galvanized sheet metal such as round, slotted, square, hexagonal, bar, and other shapes. The perforated galvanized sheet metal is commonly used for computer cases, brackets, automotive parts, machinery parts, building components, and more.

KDM is capable of customizing the different types of galvanized sheet metal according to customers’ requested sizes, materials, thickness, designs, and other specifications. The galvanized sheet metal is designed to withstand corrosion, weather-related degradation, scratches, rust, etc.

KDM Galvanized Sheet Metal Fabrication by Materials (3)

KDM Galvanized Sheet Metal Fabrication Advantages

Galvanized sheet metal has excellent resistance to rust and corrosion. That is due to the addition of a protective zinc coating. They will not rust when exposed to any oxygen or moisture. A sheet metal that is galvanized will be fully protected including their recesses and sharp corners, unlike other coatings.

Galvanized sheet metal is expected to last for over 50 years in normal environments. When exposed to severe water conditions, it can last for more than 20 years. Also, galvanized sheet metal requires little or even no maintenance, repairs, or replacements. They have increased durability and reliability.

In comparison to other types of coated metals, galvanized sheet metal is one of the least expensive options. That is because they are not as labor-intensive and do not need extra preparations such as surface coatings, painting, inspections, and more. So, when the galvanized sheet metals are delivered, they are ready to use.

The galvanized sheet metal can be fabricated for a variety of applications such as construction materials, electrical appliances, fixtures, frames, and other complicated shapes. All finished products from the galvanized sheet metal fabrication are designed to offer excellent performance for each application.

KDM Galvanized Sheet Metal Fabrication Materials

KDM uses a lot of materials when fabricating galvanized sheet metals. However, the most common galvanized sheet metals that are used are:

Galvanized Steel Sheet – The galvanized steel sheets are regular steel sheets that are coated in zinc to make them highly resistant to corrosion and rust. Regular steel sheets will corrode when exposed to humidity. On the other hand, galvanized steel sheets will not rust or corrode. They are known for their excellent formability and shiny surface.

Galvanized Iron Sheet – The galvanized iron sheets are basically iron sheets that are coated with a protective zinc layer. Regular iron sheets are prone to degradation caused by weather. However, galvanized iron sheets are protected from corrosion, rust, and weather-related degradation. The iron sheets are commonly galvanized using electro-galvanization and the hot-dip galvanization processes.

KDM Galvanized Sheet Metal Fabrication Benefits

The finished products of galvanized sheet metal fabrication are one of the most popular products in many fabrication facilities all over the world. That is due to their great benefits such as:

Less Expensive – Galvanization is one of the least expensive choices since it is not as labor-intensive.

Long-Life Expectancy – Galvanization is the ideal choice for many companies due to its long-term investment. Unlike other protective coatings for metal, galvanized sheet metal can last for about 50 years in rural environments. They have a long life expectancy and can also last for about 20 to 25 years in coastal and severe urban exposure. Also, they need almost no maintenance, replacements, or repairs.

Most Durable Protective Coating – One of the most durable and popular types of galvanization processes is hot-dip galvanization. Hot-dip galvanization is the process of immersing the metal in a bath of molten zinc to protect the iron or steel from corrosive substances. It also serves as a sacrificial anode. The latter means that if the protective coating is scratched, the remaining zinc will protect the exposed metal. Every inch, sharp corners, recesses, and other parts of the sheet metal will be protected from scratches, corrosion, rust, and weather conditions when galvanized.

KDM Galvanized Sheet Metal Processes

There are a lot of processes of galvanizing the metal sheets. However, the most common processes are electro-galvanizing and the hot-dip galvanizing process.

Hot-Dip Galvanizing Process – The hot-dip galvanization is a process done by continuously immersing the metal in a bath of high-grade molten zinc. The zinc will protect the metal from corrosion, rust, oxidation, moisture, scratches, and weather conditions. Also, the molten zinc has a minimum content of 99.95% zinc. The hot-dip galvanization can coat all parts of the metal including hard-to-reach parts such as corners.

Electro-Galvanizing Process – In the electro-galvanizing process, the coating is not usually as thick as that formed by the hot-dip galvanization. The coating is uniform, thick, and has excellent adhesion. It also does not contain the zinc crystals found on hot-dip galvanized metal sheets. The coating has a homogeneous structure and is made of pure zinc. But it’s also possible to produce electro-galvanize coatings using zinc-iron or zinc-nickel. In this process, the layer of zinc is coated on the metal using electroplating. One benefit of electro-galvanization is that it can be done in a cold environment and does not affect the mechanical properties of the metal.

Choose KDM to Custom Galvanized Sheet Metal Fabrication Needs

KDM is leading for more than 10 years as a result of providing quality galvanized sheet metal fabrication services. We have a highly skilled team, a 3000 square meters facility, state-of-the-art manufacturing equipment such as 3000W optical laser cutting machines, 3D flexible welding platforms, and other advanced technology which enable us to provide custom fabrication of galvanized sheet metal.

When producing galvanized sheet metal, we use the most durable and finest raw materials. The galvanized sheet metal is tested, inspected, and meets the standards in the industry and international including ISO, JIS, ASTM, AISI, and more. As a result, you can rest assured that our products have excellent quality, durability, and performance in various applications.

Our fabrication methods include bending, CNC machining, curving, forming, pressing, sawing, stamping, welding, and assembling for the final product.

For custom galvanized sheet metal fabrication, KDM is the ideal choice! You can contact us if you want to know more about KDM galvanized sheet metal fabrication.

KDM Galvanized Sheet Metal Fabrication

The galvanized sheet metal can be used for a variety of applications and industries such as:

- Construction Industry – The construction industry needs galvanized sheet metal fabrication for building frames, support beams, fences, railings, guardrails, ladders, handrails, ductwork, and many more.

- Transportation Industry – The transportation industry, specifically cars, and aircraft, uses galvanized sheet metal for oil pans, fenders, hoods, roofing, and other complex shapes.

- Electronic Industry – The electronic industry uses galvanized sheet metal since they are resistant to rust and moisture. The galvanized sheet metal is used for precision instruments, computer casings, and more.

Other industries that need galvanized sheet metal fabrication services are agriculture, recreation, agriculture, utility, bridge & highway, and so on.

KDM is fabricating the galvanized sheet metal with a lot of features and advantages such as:

-

- Excellent resistance to corrosion, rust, moisture, oxidation

- Long-life expectancy

- Anti-fingerprint characteristics

- Good lubrication characteristics

- Excellent weather resistance

- Environmentally friendly & chromate-free

- Outstanding paintability

- Recyclable

- Easily formable

- Suitable for indoor & outdoor applications

- Great durability

- Water resistance

Galvanized Sheet Metal Fabrication for Various Industries & Applications

KDM fabricates galvanized sheet metal for construction industry. The galvanized sheet metal can be fabricated into support beams, door brackets, ductworks, building frames, fences, guardrails, and other metal parts that are used in construction. They have great resistance to corrosion and weathering.

The galvanized sheet metal is highly workable and can be used in the fabrication of a wide range of automotive parts such as car DVD frames, car bodies, oil pans, roofing, fenders, hoods, and other vehicle parts. They are featuring superior resistance to corrosion, chemicals, temperatures, oxidation, and more.

KDM galvanized sheet metal is ideal for the fabrication of kitchen and home appliances components such as fan blades, refrigerator decorative panels, washing machine components, and so on. The zinc particles, wrinkles, wave edges, can’t be found on the galvanized sheet metal for home appliances.

The galvanized sheet metal is widely used in the electronic industry for the fabrication of computer chassis, brackets, audio amplifier enclosures, EMI shielding boxes, and other electronic parts. It has a lot of great features such as better moisture resistance, excellent corrosion resistance, and high durability.

KDM galvanized sheet metal can be used for the fabrication of various furniture parts such as cabinet frames, cabinet door brackets, table legs, shelf brackets, chair frames, and many more. They have great durability, long service life, excellent resistance to rust, corrosion, degradation, and scratches.

Why KDM is Trusted By Over 1000 Global Clients

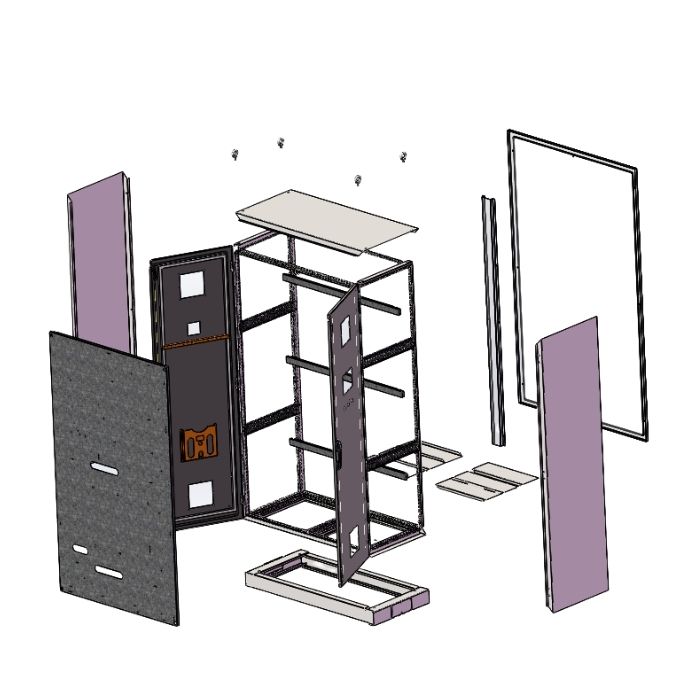

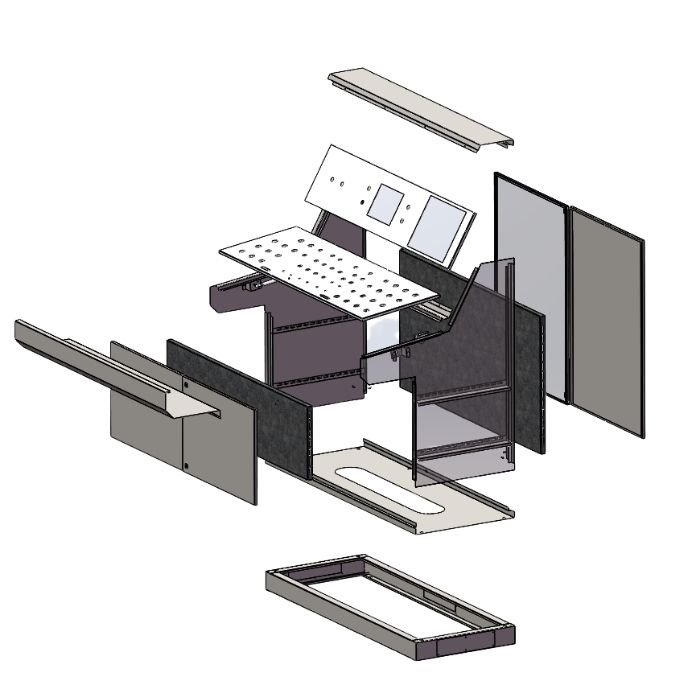

- Enclosure Manufacturing

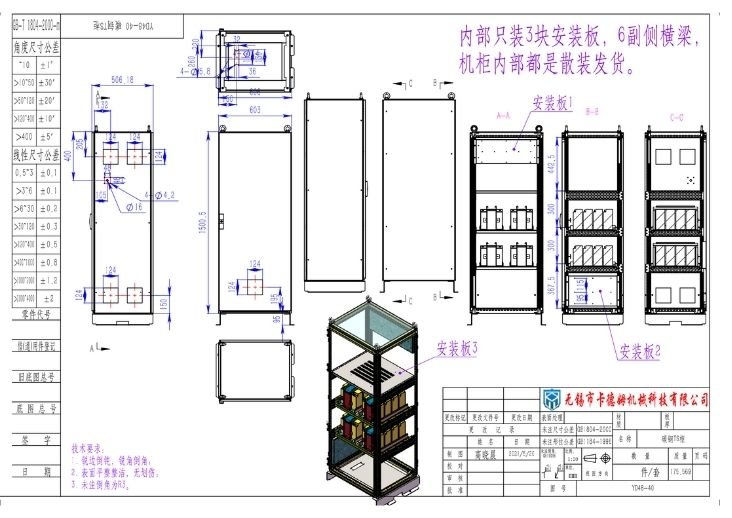

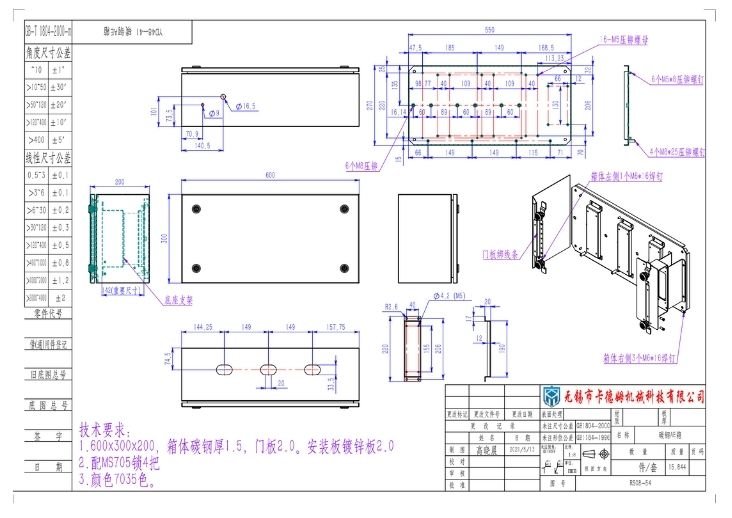

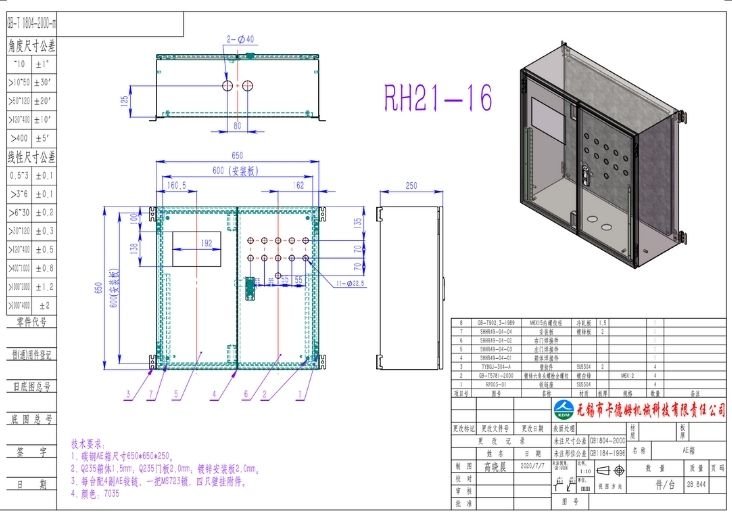

- 2D Drawing

- 3D Drawing

4000W high performance laser cutting machine, +/- 0.05mm accuracy. No burr, no scratching.

Multi-Functioning flexible welding equipment, high accuracy, no deformation.

Expert assembling team, consistent assembly quality on every KDM enclosure