KDM is a professional manufacturer that fabricates high-quality, durable, and accurate metal components and accessories for the car industry! We are also offering custom fabrication services that allow you to create components that will be created exactly to your required specifications.

- Certified to ISO:9001 standards

- More than 10 years of fabricating experience

- Wide selection of metal materials

- Excellent quality at a low price

KDM Car Sheet Metal Fabrication

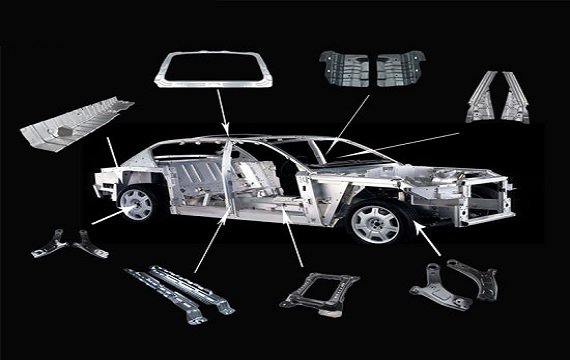

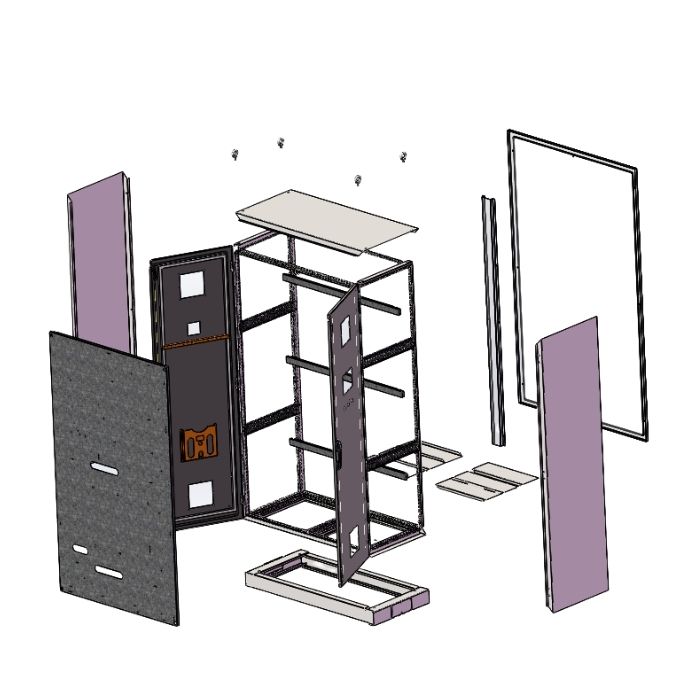

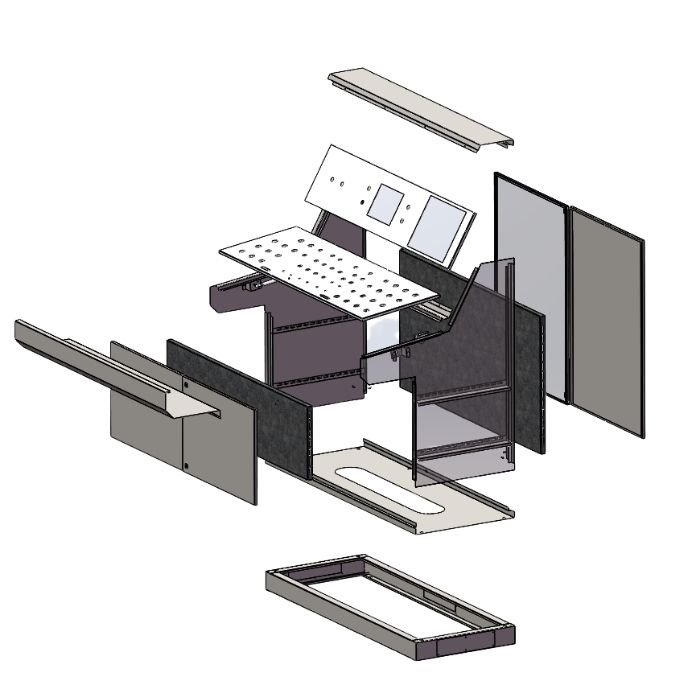

KDM is offering sheet metal fabrication services for the automobile industry, specifically for different types of cars. We can fabricate different types of metal parts for cars such as sound system enclosures, spare parts, metal brackets, inner door panels, sunroof frames, and other exterior and interior components of cars.

Moreover, KDM uses many different types of high-quality materials for the fabrication, materials such as aluminum, stainless steel, galvanized steel, copper, iron, carbon steel, and many more. The car sheet metal products are designed with features such as excellent corrosion resistance, lightness, high tensile strength, great durability, excellent weather resistance, etc. They have great and reliable performance in both interior and exterior applications.

We can also custom fabricate the car sheet metal according to your exact requirements. You can send us your designs or details, and we will fabricate them for you.

If you want to find out more about KDM car sheet metal fabrication services, feel free to contact us!

KDM Car Sheet Metal Fabrication Series

The car sheet metal brackets can be made using different types of materials such as stainless steel, aluminum, galvanized steel, and more. They come in different shapes or types such as T-brackets, shifter cable brackets, and many more. Also, they are resistant to corrosion, chemicals, and temperature.

The car stainless steel sheet metal mounting brackets are made from heavy-duty stainless steel. They have chemical resistance, corrosion resistance, and can withstand high temperatures without losing their rigidity. Also, they are available in various types and are easy to install on the surface of the car.

The car sheet metal tuning accessories can be fabricated using aluminum, stainless steel, or carbon steel. They have great durability, natural corrosion resistance, and a lightweight design.

The brushed stainless steel sheet metal heat shields are fabricated using 304-grade high-quality stainless steel. They are used for covering the turbo of the cars. Moreover, they are manufactured by laser cutting, welding, bending, etc. They have superior resistance to high temperatures and rust.

The car sheet metal door inner plates have features such as corrosion resistance, lightweight design, and great durability. To produce them, they have been deep drawn, bent, stamped, and punched. Aluminum metal sheets are commonly used for fabricating them due to their good formability.

The sheet metal can be fabricated into many different shapes, accessories, and parts of the car. Also, their sizes, shapes, materials, surface coatings, and designs are fully customizable. The custom sheet metal car parts are ensured to have corrosion resistance, high durability, and great quality.

KDM Car Sheet Metal Fabrication by Materials (5)

KDM Car Sheet Metal Fabrication Advantages

The car sheet metal parts have excellent resistance to corrosion caused by oxidation, pitting, moisture, and more. They are treated with different types of surface coatings to make them more resistant to corrosion and scratches. Some car sheet metal parts are also galvanized to prevent corrosion.

KDM fabricates the car sheet metal parts using high-quality materials to ensure their durability. They are hard to break, resistant to high impact, and will last for a long time. As a result of their high durability, they perform well in heavy-duty applications.

The car sheet metal parts have a lightweight design yet are extremely durable. They are made from lightweight materials such as aluminum and titanium to increase the efficiency of different types of cars. Also, using lightweight sheet metal parts will reduce the fuel consumption of the car.

KDM uses different grades and types of metal materials such as aluminum, copper, galvanized steel, titanium, stainless steel, brass, and many more. Aside from that, we are accepting custom materials based on the customer’s requests.

KDM Car Sheet Metal Fabrication Materials

KDM offers a wide range of high-quality materials for the fabrication of sheet metal for car parts and accessories. The common materials we have are:

Acero inoxidable – KDM uses different grades of stainless-steel sheets such as 316, 430, 304, and more. The stainless-steel sheets are popular for their excellent resistance to acidic environments, various types of corrosion such as intergranular corrosion, pitting corrosion, and more. They also have excellent weldability.

Aluminio – The aluminum metal sheets are known for their cost-effectiveness, electrical conductivity, weather resistance, high corrosion resistance, good formability, chemical resistance, lightness, and more. They are commonly used for car dash panels, car rear covers, fenders, inner door panels, bulkheads, etc.

Titanio – In comparison to other types of metals with the same density, titanium has the highest strength. That is why they are commonly used for the fabrication of parts in many luxurious cars such as Porsche. Also, titanium has superior resistance to saltwater, corrosion, weathering, and chemical.

Aside from these materials, KDM also uses other materials such as galvanized steel, copper, brass, carbon steel, and other materials based on the customers’ requirements.

Why Choose KDM Car Sheet Metal Fabrication for Your Needs?

At KDM, we are providing high-quality and custom sheet metal components and accessories for the car industry! We always ensure that the sheet metal components will be fabricated according to the highest quality standards and especially to your required specifications.

Moreover, we have a highly knowledgeable team that can fabricate not only the simple components but even the complex car components. We also ensure that the sheet metal is made from the highest quality materials. Aside from that, we are implementing a strict quality control system to ensure product quality.

As a reliable manufacturer, we always make sure that you get your exact requirements for your car project or business. We provide competitive pricing, dependable customer services, and excellent car sheet metal fabrication.

If you have questions regarding our services and fabrication of car sheet metal, contact us now!

KDM Car Sheet Metal Fabrication Processes

KDM is fabricating sheet metal by using many processes. Some of the processes include:

Doblado – Bending is a process of applying bending stress to form the sheet metal into the wanted shape.

Puñetazos – Punching is the process of cutting holes in the sheet metal using punching die and punch.

Dibujo profundo – Deep drawing is a process of forming the sheet metal into the wanted shape in many stages and by using a series of dies.

Corte por láser – Laser cutting is the process of precisely cutting the sheet metal using a laser. The laser can cut the metal sheets into complex shapes.

Rolling – There are 2 types of rolling processes such as cold and hot rolling. Rolling is a process of reducing the metal sheet’s overall thickness and making it uniform using a set of rolls.

Moreover, KDM also uses other methods of fabricating the sheet metal such as welding, foaming, stamping, riveting, surface treatment, assembling for the finished products, and more.

Choose KDM to Custom Fabricate Your Car Sheet Metal

For more than a decade, KDM has been leading and trusted for providing excellent services and quality fabrication of sheet metal in the car industry.

We have expert engineers that have the ability to custom fabricate the sheet metal using our advanced manufacturing machines and equipment such as 3000W optical laser cutting machines, detection machines, bending machines, and more. You can send us your drawing, design, and other specifications and we can fabricate them to your exact requirements.

Moreover, all of our sheet metal car parts are made using high-quality and carefully selected materials. They are inspected, tested, and comply with international standards such as ISO, AISI, JIS, ASTM, and more. Every process in the fabrication and to the final process are inspected to ensure the quality, reliability, and safety of the products.

At KDM, we guarantee you the reliability and quality of our car sheet metal parts. For your inquiries, kindly contact us!

KDM Car Sheet Metal Fabrication

KDM can fabricate the sheet metal into a variety of car metal parts and accessories such as:

- Bisagras

- Mounting brackets

- Body panels

- Seat belt tongue

- Engine oil pans

- Bumper reinforcement bars

- Sound system enclosures

- Brake backing plates

- Bolt-on parts

- Inner door panels

- Sunroof frames

- Catalytic converter housings

- ECU housings

- Battery cable & spring connectors

- Car radiator parts

The fabricated sheet metal parts for cars have a lot of amazing features and benefits such as:

- Ligero

- Excellent corrosion & rust resistance

- Alta durabilidad

- Long service life

- Excelente resistencia a la intemperie.

- Reciclable

- Temperature-resistant

- High tensile strength

- Good chemical resistance

- Wide range of material options

- Great impact resistance

- Suitable for interior & exterior applications

KDM Car Sheet Metal Fabrication for Various Applications

The custom perforated car sheet metal parts can be made using various materials such as stainless steel, aluminum, carbon steel, etc. They can be designed with different shapes of perforation such as round, squares, rectangles, bars, or custom perforation.

The triangle sheet metal car light bar brackets are an accessory that is installed on the exterior roof of the car. They are used for mounting LED light bars. Also, their surface is treated with powder coating or zinc plating to improve their resistance to weather conditions, corrosion, and scratches.

The sheet metal U-type car screw base fastener clips are made of high-quality galvanized iron. They are commonly used mounted on car bumper, fender, interior door panels, roof linings, door trims, and on other surfaces of the car. Also, they have anti-wear, anti-corrosion, long service life, and durability features.

The stainless steel sheet metal car body light clips can be used for installing car lights. They are made from durable, high-quality, and corrosion-resistant stainless steel. Also, they are produced by forming, stamping, bending, and perforating processes.

The steel sheet metal car bolt-on parts come in different types and designs. They are designed with perforation, anti-wear, and anti-corrosion features. Also, they can be installed on a car easily. Different types of bolts can be fitted into it.

Por qué más de 1000 clientes globales confían en KDM

- Fabricación de envolventes

- Dibujo 2D

- Dibujo 3D

Máquina de corte láser de alto rendimiento de 4000 W, precisión de +/- 0,05 mm. Sin rebabas ni rayones.

Equipo de soldadura flexible multifunción, alta precisión, sin deformación.

Precisión de doblado de +/- 0,5 mm, superficie lisa sin marcas de doblado.

Más de 10 trabajadores con experiencia en soldadura, apariencia general perfecta.

Máquinas de espumado de alta velocidad y precisión, empaquetadoras rápidas y calificadas.

Equipo de ensamblaje experto, calidad de ensamblaje constante en cada gabinete KDM