KDM is your #1 provider of custom sheet metal fabrication in China.

We cut, bend, form, weld, joined sheet metal to meet your custom sheet metal requirements. Message us today!

- Works with various types of materials

- Personalized service for your needs

- Tested and precisely made products

- Durable, great appearance, and long-lasting

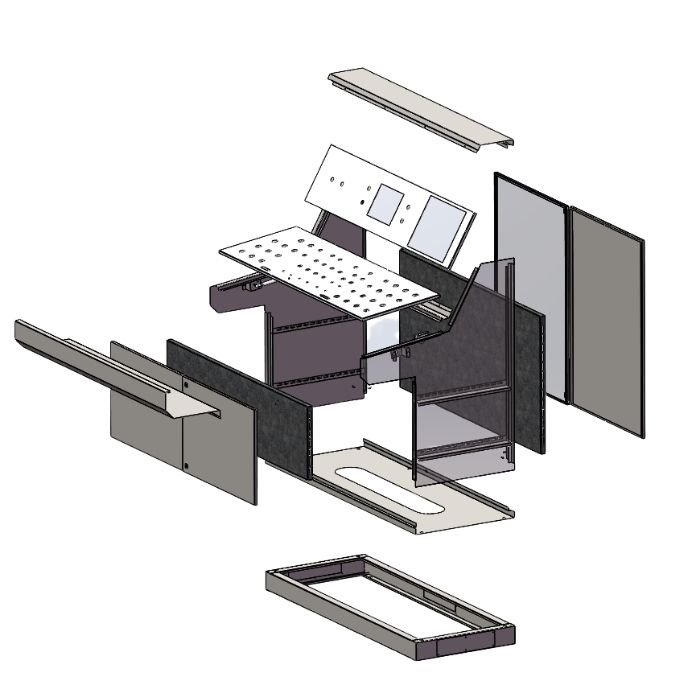

KDM Custom Sheet Metal Fabrication

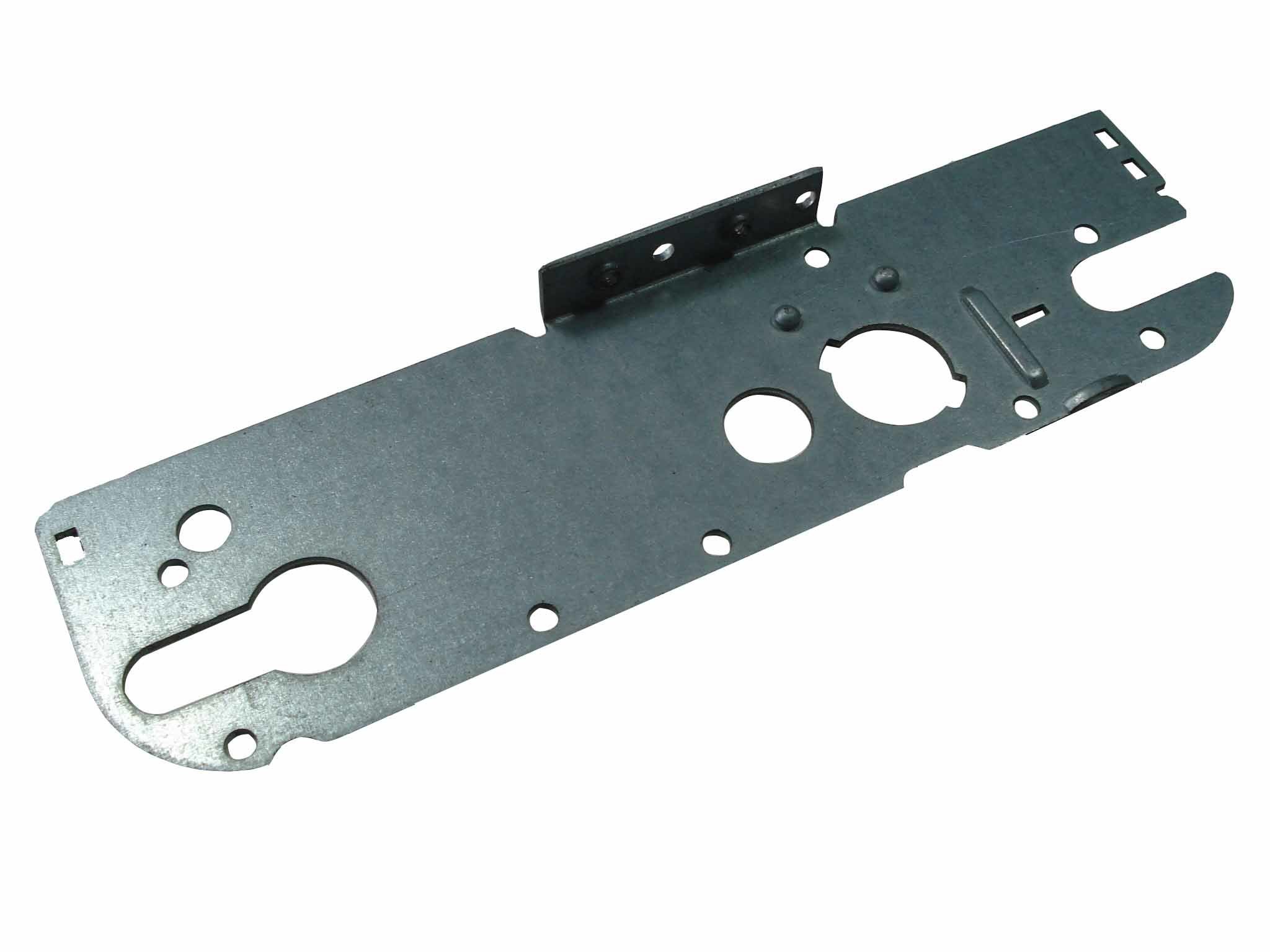

KDM sheet metal fabrication employs a broad range of industrial tools and manufacturing processes to produce high-quality products. The sheet metal can be rolled, bent, cut, folded, formed, engraved, and join into complex designs and assemblies. We can work with all metals such as stainless steel, copper, brass, aluminum, carbon steel, etc.

From initial design to full production, KDM will support you along the way. We have advanced machinery with Up to +/-0.005mm or +/- 0.0002-inch tolerances. Our custom manufacturing professionals provide rapid response across a wide range of sheet metal products and industrial applications such as aerospace, electronics, appliances, HVAC, medical equipment, architectural roofing, etc.

Custom sheet metal fabrication in all sorts of materials, sizes, thicknesses, designs, finishes, and applications. Just send your specifications immediately and we will create your idea into reality. Contact us now!

Custom Sheet Metal Fabrication Series

Aluminium Sheet Metal is available in various grades to meet your specific needs. It includes 1100, 3003, 5052, 6061, etc. These are stronger and more formable. It is easy to weldable, chemical & weather-resistant, and affordable.

Sheet Metal Brass has strong acoustic features. Thus, it is perfect for manufacturing metal products in many instruments. We can also produce doorknobs, nuts, bolts from brass sheet metal.

Copper Sheet Metal responds well in the bending process and can create amazing-shaped finish products. This material does not rust. A strong conductor of electricity material used in producing fixtures and electronic equipment.

Galvanized steel sheet is stronger and more durable compared to regular steel. KDM can create parts using galvanized steel sheets depending on your applications, thickness of the coating layer, shapes, etc. It can be used for a long period of time.

Stainless Steel Metal has great corrosion-resistant while maintaining its high strength at high temperatures. It is available in 316, 304 grade, etc. They offer good formability and weldability.

Titanium Sheet Metal offers resistance to corrosion. It also carries a very high power to weight ratio, flexible, with aesthetic designs. These are material friendly to the environment and humans.

KDM Custom Sheet Metal Projects (6)

KDM Custom Sheet Metal Advantages

Sheet Metal withstands greater pressure, strong and durable. It is also resistant to corrosion, wear, and tear.

Sheet metal can be bent into multiple shapes. It maintains its strength and structural integrity for a long time.

Sheet metal is an environmentally and economically strategic material. It can be recycled and turned into other parts.

Custom sheet metal fabrication provides an overall reduction in costs and material waste. You can save money while boosting your business.

Custom Sheet Metal Materials and Finishes

KDM sheet metal can be custom according to your material requirements. These materials have their own features and advantages in sheet metal fabrication. We match materials precisely to customer engineering drawing requirements.

- Stainless steel – 304, 304L, 316, 316L stainless steel grades are commonly used in sheet metal fabrication. It is available in 0.025” to 0.187” thicknesses range or customized.

- Aluminum – 5052-H32, 2024, 6061, 7075 aluminum sheet is commonly used. Available in 0.032” to 0.250” thicknesses. Thinner or thicker material is accessible to meet your needs.

- Copper sheet – We use soft and varying hardness coppers based on your demand.

KDM sheet metal products can be coated with various surface finishes such as anodizing, electroplating, painting, powder coating, and more. You can request a custom logo to skyrocket your business. We can use laser engraving, CNC engraving, screen printing, etc.

Custom Sheet Metal Applications

Our custom sheet metal can be utilized in multiple applications and industries. We can manufacture various structures such as sheet meat chassis, brackets, enclosures, cabinets, housings, and other parts from raw sheet metal materials according to your request. Regardless of the industry, you are using fabricated sheet metal for, KDM got your back. Here are some of the industries KDM cooperates with:

- Telecommunications

- Lighting and energy

- Construction Industry

- Transportation Industry

- Electronic Industry

- Agriculture

- Military and aerospace

- Automotive applications, etc.

Custom Sheet Metal Fabrication

KDM is your one-stop solution for any custom sheet metal fabrication needs. Using advanced technology and machines, KDM can offer customers unique product design, rapid prototyping, reliable engineering, and manufacturing services. The main processes include riveting, welding, forming, shearing, cutting, etc.

Sheet metal fabrication is also known as metal plates processing. We can design an extensive range of products out of sheet metal. Whether you need elbows, squares, ventilation pipes, computer cabinets, iron barrels, fuel tanks, oil tanks, or telecommunication boxes, KDM is able to produce them quickly and accurately.

Why KDM Custom Sheet Metal Fabrication

KDM is a professional custom sheet metal supplier with 10+ years of manufacturing experience. We are a CE, ISO9001, ISO14001 certified company in China. Our company strives to fabricate superior quality products and offer reliable sheet metal services. At every stage of the project, our expert team serves customers with honesty, dedication, and integrity.

Our manufacturing facility has highly or fully automated machines to ensure efficient production. This equipment improves product quality and processing speed. We are able to produce extremely complex and high-precision sheet metal parts at a reduced cost.

Message us for your next custom sheet metal sheet projects.

KDM is an industry-leading custom metal fabrication provider in China. We work with a large variety of metals and can provide small, large, and heavy components. Our expert team offer numerous sheet metal fabrication services to provide your custom needs.

- Bending

- Cutting

- Forming

- Punching

- Stamping

- Stitching

- Welding, etc.

KDM can do multiple surface treatments for different types of metal sheet. Our skilled and qualified staff contributes to the highly efficient process of our surface coatings for aluminum, steel, stainless steel, titanium, brass and copper. Below are some of the metal surface coatings KDM offer:

- Anodizing

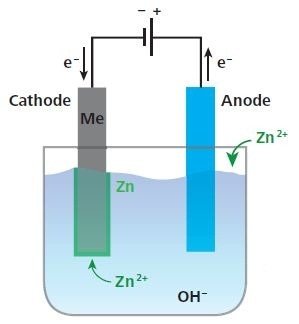

- Zinc coating

- Nickel coating

- Blackening

- Glossy tinning, etc.

OEM & ODM Sheet Metal for Various Applications

KDM is reliable in aerospace sheet metal fabrication. We can manufacture precise, long-lasting, and versatile parts for reliable, safe aircraft.

You can trust roofing sheet fabrication from KDM. We serve residential, industrial and commercial roofing. Our company own a custom roofing sheet metal fabrication at our advanced facility.

Get high quality, high-strength architectural roofing. KDM has the quality and skill to guarantee every part of the roofing system lasts. We provide high-grade Architectural Sheet Metal materials such as galvanized, stainless steel, copper, and numerous prefinished metal flat sheets.

KDM produce high-quality ductwork project. Working with KDM will ensure quality system infrastructure and will reduce overall project costs.

For your automotive projects, KDM can support you using various materials such as mild steel, aluminum, and stainless steel. We will construct your products with your exact specifications.

Why KDM is Trusted By Over 1000 Global Clients

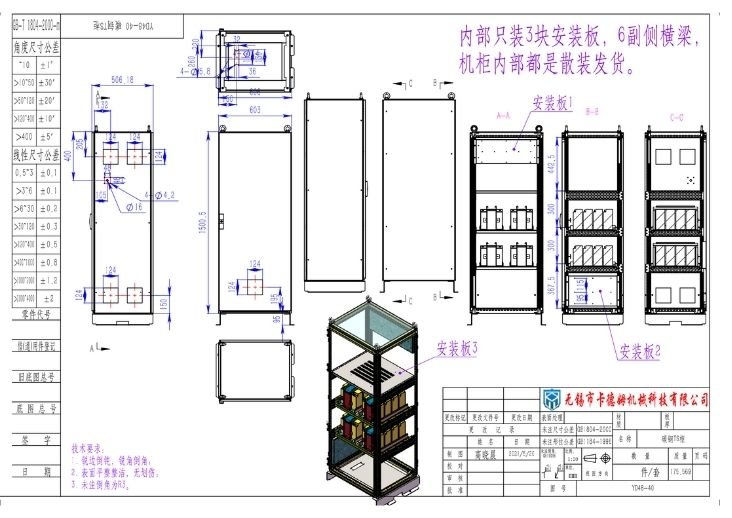

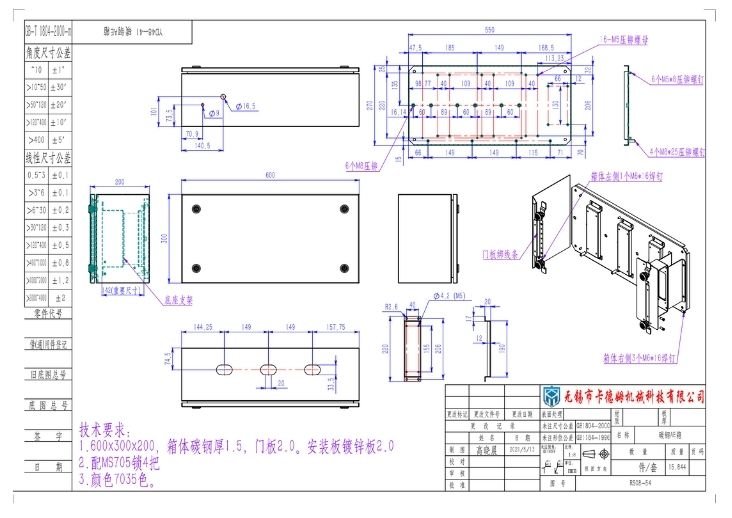

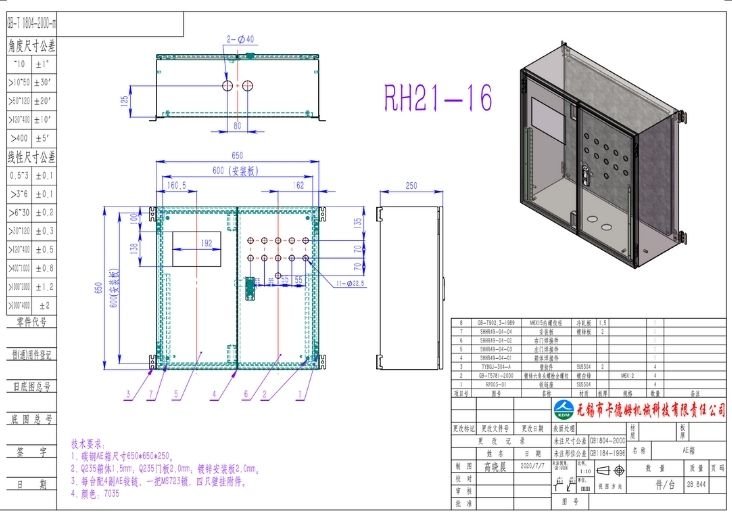

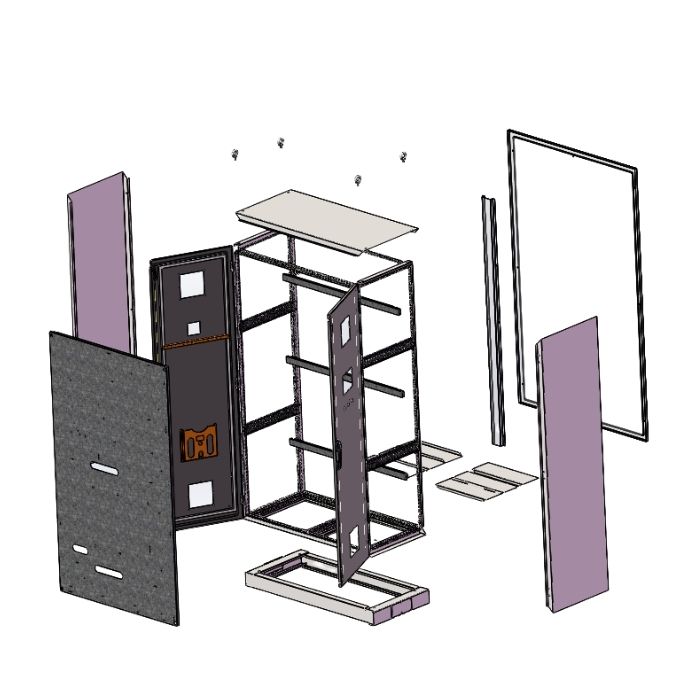

- Enclosure Manufacturing

- 2D Drawing

- 3D Drawing

4000W high performance laser cutting machine, +/- 0.05mm accuracy. No burr, no scratching.

Multi-Functioning flexible welding equipment, high accuracy, no deformation.

Expert assembling team, consistent assembly quality on every KDM enclosure

Related Products

KDM Custom Sheet Metal Fabrication

Are you in need of a manufacturer that can deliver your desired custom sheet metal fabrication services within the budget that you have set? Don’t go far! KDM is the right choice. Make the right and wise investment with every fabricated metal, component or feature that your business required.

KDM Custom sheet metal fabrication is a manufacturing procedure where pieces are generated by detaching material from sheets. We transform flat sheets of sheet or aluminum into metal structures used in a variety of applications.

With custom sheet metal fabrication, you can decide on the right product you obtain. Custom sheet metal fabrication here in KDM requires cutting materials in a particular way to exceed the needs of every customer.

KDM can bend, stretch, or cut sheet metal into almost a piece of shape by burning or cutting it. These methods will be utilized to design your custom fabricated metalwork. Perfect fabrication increases the durability and versatility of the metal being employ, making it suitable for a wider range of applications. So, what are you waiting for? No need to go further.

We can also design and create custom sheet metal that’s lightweight. That`s why you can ensure that your customers will feel comfortable using it. Choose a sheet metal that suits your needs and budget.

One of the biggest advantages of using a sheet metal product that has been customized for your specific application is that this assures that it is built to endure the stresses of your applications. Plus, it can increase function life, increases process efficiency and are compatible with your component solutions.

KDM produced sheet metal baskets or other products with the generalized standards. In a customized metal process, the sheet metal will be manufactured from different materials that are particularly resistant to the temperatures, chemicals, and forces related to your process.

You can make many things from custom sheet metal fabrication. Things such as electronic enclosures, jewelry, models, signs, art, toys, robots, lighting, office items, housewares, kitchen products, and whatever other extraordinary design and ideas you can dream up utilizing our KDM custom sheet metal parts.

In China, KDM is one of the leading manufacturers of custom‐engineered products from steel wire and sheet metal. These are industrial raw material handling enclosures that serve many industries including defense, aerospace, medical, etc. KDM is a manufacturer with a cost-efficient manner and used high-quality long-lasting materials in fabrications.

You can trust KDM. We acquired all necessary international standards such as ISO 9001, CE, UL, and more. In short, KDM for more than 10 years of expertise is an expert on manufacturing your custom sheet metal fabrications.

We can provide your needs even you’re a supplier, distributor, or a custom factory. Execute something different for you, to your customers, and to their customers. The success of your business will definitely 100% possible.

For more details about KDM custom sheet metal fabrication, please feel free to contact our friendly and professional team. We are happy to serve you 24/7.

The Complete FAQ Guide to Custom Sheet Metal Fabrication

- What is Sheet Metal Fabrication Process?

- Machining vs. Fabrication – What’s the Difference?

- What are the Benefits of Custom Sheet Metal Fabrication?

- How do Custom Sheet Metal Fabrication Work?

- What is Precision Sheet Metal Fabrication?

- What are the Main Products of Sheet Metal Fabrication?

- Which Types of Sheet Metals are Available for Fabrication?

- What is the Best Metal Fabrication Design Software?

- What are the Design Considerations in Sheet Metal Fabrication Process?

- What is DFM (Design for Manufacturability)?

- Sheet Metal Fabrication Tolerance; Why is it Important?

- What are Sheet Metal Fabrication Safety Procedures?

- How Can You Choose Sheet Metal Cutting Technique?

- What are the Capabilities of Sheet Metal Laser Cutting?

- When Can You Use Punching Press for Sheet Metal?

- What is Photo-chemical Machining?

- What is Sheet Metal Laser Cutting?

- How do you Calculate Sheet Metal Bending Allowance (BA)?

- What is K-factor in Sheet Metal Bending Fabrication Technique?

- What are the Defects in Drawn Sheet Metal Parts?

- What’s the Difference in TIG and MIG Welding?

- What’s the Best Welding Technique for Metal Sheet Fabrication?

- Can you Prevent Weld Distortion in Sheet Metals?

- What is Sheet Metal Hemming and Seaming?

- What is Deep Drawing Metal Sheet?

- What is Sheet Metal Hydroforming?

- Punching Sheet Metal vs. Blanking Sheet Metal; What’s the Difference?

- How Does Sheet Metal Spinning Work?

- When Can You Use Single and Progressive Sheet Metal Stamping?

- Electro-Galvanized vs. Hot Dipped Galvanized; What’s the Difference?

- Powder Coating or Liquid Painting; Which one Should You Choose?

- What are the Benefits of Sheet Metal Sand Blasting?

- What are the Benefits of Sheet Metal Polishing?

- What’s the Difference Between Coating and Plating Sheet Metal?

- What is the ASTM Standard Practice for Metal Fabrication?

- Why is ISO Certification Important in Sheet Metal Fabrication?

- Are there Material Testing Standards for Sheet Metals?

- Can you Recommend Acceptable Sheet Metal Testing Methods?

- Why Work with KDM Steel in Custom Sheet Metal Fabrication?

- How Fast will KDM Steel Finish Your Custom Fabricated Metal Sheet Parts?

What is Sheet Metal Fabrication Process?

It is a broad term referring to various manufacturing processes you can use to manipulate or transform sheet metal into a useful product or structure.

Normally, it is these manufacturing processes that we call fabrication techniques.

The fabrication techniques include cutting sheet metal, bending sheet metal, shrinking sheet metal, assembling sheet metal, etc.

Sheet metal fabrication

Resources:

Machining vs. Fabrication – What’s the Difference?

First, machining is a subset of metal fabrication operations.

However, machining is a more specific process, which refers to subtractive operations in the metal fabrication industry.

Meaning, it is the cutting away or removing material from the workpiece (main material), using different techniques such as grinding, cutting, drilling, etc.

For example, laser cutting sheet metal is a machining technique:

Resources:

What are the Benefits of Custom Sheet Metal Fabrication?

The main benefits include:

- Ability to make virtually anything, from unique designs to sizes, ranging from small to large products.

- An effective way of controlling quality, from dimensional tolerance, design to shape

- Cost effective since the final product meets the specific requirements of your applications. There will be no further adjustments needed.

- You have a say over the entire fabrication process since you will be working with a team from the custom sheet metal fabrication company

- With your team working closely with the custom sheet metal fabrication company, the job can be done faster

- Increases product usefulness and durability – the sheet metal will be fabricated to meet your unique environment and working conditions, such as temperature, chemicals, stress, vibrations, etc.

- Increases efficiency and productivity – through custom sheet metal fabrication, you can optimize your design, making them compatible and suitable for your specific needs. This will increase efficiency and productivity.

How do Custom Sheet Metal Fabrication Work?

Step 1: Define the type of product you want to fabricate – clearly state every aspect of the product you need. It should include the type of material, design, structure, type of finish, etc.

Step 2: Identify and hire a custom sheet metal fabrication company. It should be based on their sheet metal fabrication capability, experience, expertise, customer support, and reputation.

Step 3: Developing technical drawing and listing requirements for custom sheet metal fabrication

Step 4: Prototyping – making the first sample for you to check and verify whether they conform to your requirements.

Step 5: Mass sheet metal fabrication and finishing operations

Step 6: Quality inspection and verification

Step 7: Shipping finished parts or structures.

What is Precision Sheet Metal Fabrication?

It is the use of modern and computerized manufacturing capabilities to transform a metal sheet into a useful end product accurately.

Here, the precision sheet metal fabricating companies use CAM/CAD software for design, then incorporate computer numerically controlled machines (CNC) in the fabrication process.

Furthermore, it also involves the use of modern finishing and quality testing operations.

With precision sheet metal fabrication, a manufacturer can achieve tight tolerances.

Resources:

What are the Main Products of Sheet Metal Fabrication?

You can make thousands of products through sheet metal fabrication such as:

Sheet metal fabrication products

i. Metal tank

ii. Machine parts

iii. Ventilation systems

iv. Metal mailbox

vi. Metal cabinet

vii. Portable shops

viii. Electronic parts, etc.

Which Types of Sheet Metals are Available for Fabrication?

i. Stainless steel sheet metal – comes in different grades such as 304, 316, 410, 430, etc.

ii. Aluminum sheet metal – available grades include 1100-H14, 3003-H14, 5052-H32, and 6061-T6.

iii. Copper sheet metal

iv. Brass sheet metal

As you can see, the above classification is based on the type of material.

Again, the type of sheet can be classified depending on specific requirements.

Furthermore, you can classify these metals depending on the manufacturing process.

For instance, you can have corrugated sheet metal, galvanized sheet metal, cold rolled sheet metal, hot rolled sheet metal, etc.

Resources:

What is the Best Metal Fabrication Design Software?

Choosing a specific metal fabrication design software will depend on your preference.

For instance, if you want automatic bend calculations, SolidWorks can be a perfect choice.

https://youtu.be/pUgPjj3RjJo

Still, you can consider the following:

- SolidWorks

- CAD/CAM

- FabCAD

- IntelliCAD

- IRONCAD

- Rhinoceros 3D

- SolveSpace

- DesignSpark Mechanical, and many others

What are the Design Considerations in Sheet Metal Fabrication Process?

i. Type of product you want to fabricate, such as electrical enclosure, letterbox, tanks, etc

ii. Metal sheet fabrication technique, it can be bending, welding, cutting, etc.

iii. Type of material

iv. Chemical and physical properties of the material

v. Sheet metal fabrication machinery and equipment

vi. Technical drawing for product to fabricate

vii. Dimensions such as bending radius, minimum flange width, wall thickness, etc.

viii. Tolerance

ix. Finishing operations such as painting, galvanizing, etc.

x. Compliance with set quality standards

What is DFM (Design for Manufacturability)?

It is where the metal sheet fabrication team, together with the client, examine the part design, manufacturing capability, and resources, to ensure the manufacturing will be cost effective and efficient.

Of course, it also takes account of the production needs (quantity), conforming set quality standards and clients requirements. Therefore, it examines:

- Part specifications

- Quality compliance

- Material type

- Environmental compliance

- Quality testing compliance

Sheet Metal Fabrication Tolerance; Why is it Important?

It ensures that parts you fabricate parts fit and function properly.

Mostly, people use it to illustrate the quality of custom sheet metal fabrication process.

Please note: Tighter tolerances makes custom metal sheet fabrication more challenging hence, may require more advanced machine and equipment.

Besides, it may increase the cost of the sheet metal fabrication process.

Also, a single part that requires more fabrication cycles may compromise tolerance.

Therefore, it requires a strict and meticulous custom sheet metal fabrication procedure.

Moreover, in custom sheet metal fabrication, the tolerances mainly focus on:

- Thickness of the metal sheet tolerance

- Dimension range tolerance

- Edge to edge tolerance

- Hole to hole tolerance

- Edge to hole tolerance

- Edge or hole to bend tolerance

- Bend to bend tolerance

- Angular tolerance, etc.

Resources:

What are Sheet Metal Fabrication Safety Procedures?

In sheet metal fabrication, the safety procedures must focus on the following key aspects:

1. Safety of the technician, engineers, worker, or any person within the fabrication environment. You must wear all protective safety gear.

Welding safety gear – Photo courtesy: Policaros arc welding

2. Safety of the fabrication machine or equipment – you must follow the correct operation procedure, handling mechanism, etc.

3. Safety of the workpiece and fabricated part

4. Safety of metal fabrication workshop

Resources:

How Can You Choose Sheet Metal Cutting Technique?

You should consider the following before cutting sheet metals:

- Know the thickness of sheet metal

|

Sheet Metal Cutting Technique |

Average Metal Sheet Thickness in inches (″) |

|

Laser cutting sheet metal |

< 0.080 |

|

Oxyfuel cutting |

> 8 |

|

Plasma cutting |

< 0.125 |

https://youtu.be/ajwYtXSwRqM

i. Type of metal sheet you want to cut

ii. Quality of the cut surface – for instance, plasma cutting produce better finishing

iii. Design of the cut – cutting complex metal sheet parts will require an advanced machine

iv. Cost – will you get the value for your money?

Remember, you can choose from laser cutting sheet metal, plasma cutting sheet metal, water jet cutting sheet metal, punching sheet metal, shearing sheet metal, and blanking sheet metal, among other processes.

Resources:

What are the Capabilities of Sheet Metal Laser Cutting?

Sheet metal laser cutting technique is suitable for:

i. Precise metal sheet cutting

iii. Cutting complex shapes and sizes

iii. Thickness of sheet metal will depend on the cutting power of the sheet metal

Laser cutting sheet metal

Of course, the good thing with the laser cutting machine is that you can set it to achieve virtually unlimited cutting options.

Even with that, pay attention to the following for a specific laser cutting machine configuration:

- Maximum sheet metal thickness

- Cutting head position tolerance

- Type of material

- Cutting pattern and software

- Power supply specifications

Resources:

When Can You Use Punching Press for Sheet Metal?

You can use punching press to make holes or indents in sheet metal.

Of course, you will need the right punch and dies, which is the primary tool system for the punching press.

Resources:

What is Photo-chemical Machining?

It is a sheet metal fabrication technique that uses chemical etchants and photoresist to mill sheet metal surface chemically.

The process does not interfere with the mechanical properties of the sheet metal, and the part does not require further processing.

Photo-chemical machining (PCM), is also called photo-etching or photomechanical milling.

Resources:

What is Sheet Metal Laser Cutting?

It is the process of using a laser machine to cut sheet metal into desired shapes.

With laser cutting sheet metal, you can achieve precise designs and cut complex shapes easily.

Laser cutting steel sheet

Resources:

How do you Calculate Sheet Metal Bending Allowance (BA)?

Whenever you are bending a metal sheet, there will is a neutral axis that lies between any two bend lines.

That is what we call the bending allowance (BA).

Bend allowance – Photo courtesy: CustomPartNet

The formula for calculating bend allowance is:

Bend Allowance – Photo Courtesy: Wikipedia

Where;

- BA is bending allowance

- A is bend angle

- R is bend radius of the inner section

- K is the distance between the neutral line and inside face divided by material thickness

Resources:

What is K-factor in Sheet Metal Bending Fabrication Technique?

K-factor is the neutral axis divided by the sheet metal thickness, where the neutral axis is the distance between the inside face and the neutral line.

Resources:

What are the Defects in Drawn Sheet Metal Parts?

Common defects may include surface scratches, wrinkling, tearing, and earing.

Of course, there could be other defects, but these four are the most common.

What’s the Difference in TIG and MIG Welding?

|

Tungsten Inert Gas Welding (TIG Welding) |

Metal Inert Gas Welding (MIG Welding) |

| Uses non-consumable electrode |

Uses consumable electrode |

|

The electrode is tungsten, alongside other alloys |

An electrode made from any suitable element |

| Welding requires experience |

Simple welding technique |

|

Low filler deposition rate |

Fast filler deposition rate |

| Best for thin metal sheet |

Suitable for thick metal sheet |

|

More expensive |

Less costly |

| Suitable for a beautiful and clean finish |

It produces a better finish, but not as TIG |

Resources:

What’s the Best Welding Technique for Metal Sheet Fabrication?

Depending on the type of metal, desired surface finish, welder’s experience, sheet metal specifications, and budget, you can choose any of the following:

- Gas welding (oxy-acetylene)

- MIG welding

- TIG welding

Resources:

Can you Prevent Weld Distortion in Sheet Metals?

Yes, you can.

But you must have an in-depth understanding of what causes weld distortion.

Besides, you need to master the welding technique you’re using.

Remember, the expansion (due to heating) and contraction (due to cooling) cycles, causes the weld distortions.

Depending on the situation at hand, you can prevent weld distortions by:

Weld distortion – Photo Courtesy: Metal Arts Press

i. Avoiding over welding

ii. Adoptingthe intermittent welding technique

iii. Welds should be in neutral axis and balance it around this axis

iv. Few weld passes can prevent distortion

v. Trying back step welding technique

vi. Reducing welding time

vii. Preparing well for the welding sequences

viii. Peening and thermal stress relieving will prevent shrinkage

ix. Adopting strongback and water-cooled jig techniques

Resources:

What is Sheet Metal Hemming and Seaming?

It is a custom sheet metal fabrication technique where you will roll the edge of a metal sheet onto itself.

You can use it to hide rough edges or reinforce the edge of the sheet metal.

Hems and seams

Resources:

What is Deep Drawing Metal Sheet?

It is the process of applying a reasonable threshold of mechanical force on a punch, thereby drawing metal sheet in a die with a preformed shape.

Resources:

What is Sheet Metal Hydroforming?

Hydroforming technique uses a flexible diaphragm subjected to pressurized hydraulic fluid, thereby shaping metal sheet against tooling, to form various geometrical shapes and designs.

Resources:

Punching Sheet Metal vs. Blanking Sheet Metal; What’s the Difference?

Both sheet metal punching and sheet metal blanking involve removing some sections of the metal.

However, the difference is:

- Sheet metal blanking – the section removed from the large metal sheet will be the final product.

Sheet metal blanking – Photo courtesy: SMLEASE

- Sheet metal punching – the final product is the large metal sheet from which a small section or part has been removed.

Sheet metal punching – Photo courtesy: SMLEASE

Resources:

- Difference Between Metal Piercing, Punching and Blanking

- Punching and Blanking Processes

- Sheet Metal Shearing

How Does Sheet Metal Spinning Work?

Spinning is a fabrication technique where you can make cylindrical and circular parts from flat metal.

In this sheet metal cold working technique, you will form the shapes over a rotating mandrel about a predetermined axis.

Metal spinning -Photo courtesy: Research gate

Resources:

When Can You Use Single and Progressive Sheet Metal Stamping?

Stamping is a sheet metal fabrication technique where you use die to convert a flat sheet into various shapes.

A single sheet metal stamping technique involves only one processing technique.

However, progressive sheet metal stamping involves the use of a series of press techniques to get a suitable shape.

It may involve coining, punching, embossing, etc.

Metal stamped door part

Resources:

Electro-Galvanized vs. Hot Dipped Galvanized; What’s the Difference?

Electro galvanized, also referred to as electroplating; is the process of adding zinc layer to a metal surface such as steel sheet.

Here, the process depends on electrodeposition.

In electro galvanized technique, it is easier to control the zinc layer.

Therefore, the process is accurate.

Hot dip galvanizing is the processes of immersing already fabricated sheet metal component in a bath of molten zinc at a temperature of 449 °C.

With a hot dip galvanizing process, the entire surface is covered, making it corrosion resistant.

Hot dip galvanizing process -Photo courtesy: Research gate

Electro galvanizing process – Photo courtesy: Azom

Resources:

Powder Coating or Liquid Painting; Which one Should You Choose?

Whether to choose powder coating or liquid coating will depend on the nature custom sheet metal fabrication at hand.

Powder coating – it involves the use of electrostatic principle to apply the powder paint.

Liquid painting – here, you will use pressurized paint applicant to deposit paint on the surface.

Whether to choose powder coating or liquid painting will depend on the following advantages and disadvantages.

|

Powder Coating Technology |

|

|

Advantages |

Disadvantages |

| · Coating is tough

· Ensures a thick finish · Durable than most paints · Fast, easy and efficient coating since you’ll only need a single coat · It is easier to achieve custom color and texture finish · Produces minimal VOC hence, eco-friendly |

· Producing thin finish is virtually impossible

· The production process is complex · Relatively expensive for small scale use |

|

Liquid Painting |

|

|

Advantages |

Disadvantages |

|

· Best for parts that cannot be heated · Allows for custom surfaces · Ability to produce a thin finish |

· Not durable like the powder coating · Requires repeated painting to achieve even finish |

What are the Benefits of Sheet Metal Sand Blasting?

- It is an affordable sheet metal finishing operation

- Cleans surfaces better and faster

- Effectively prepares sheet metal part surfaces for additional finishing operations

- An easy process, as long as you have the right sandblasting accessories

- Environmentally friendly

Resources:

What are the Benefits of Sheet Metal Polishing?

- Produces easy to clean surface

- Aesthetically pleasing surface finish

- Improves the durability of the sheet metal surface

- Produces high gloss surface finish

- Acts as metal surface beautification

Resources:

What’s the Difference Between Coating and Plating Sheet Metal?

Plating is the process of depositing protective substrates of metals on fabricated parts.

Depending on the nature of the process, you can choose sputter deposition, electroplating, or vapor deposition.

Remember, plating is also a process of coating metal surface.

For other processes like painting or powder coating, you focus on applying non-metallic substances.

So, you have to specify the type of sheet metal coating technique you need – it can be plating, powder coating, or painting.

Resources:

What is the ASTM Standard Practice for Metal Fabrication?

- ASTM metal coating standards

- ASTM welding standards

- ASTM standard for testing coating powders

- ASTM steel standards

- ASTM standard for galvanization

- ASTM standards for electroplating

Please visit ASTM International, to explore various standards on sheet metal fabrication.

Why is ISO Certification Important in Sheet Metal Fabrication?

It ensures that the custom sheet metal fabricator makes components or products that meet the specific needs of customers.

Besides, it affirms that the company forms the international acceptable manufacturing standards.

You can visit the official website to learn more: International Organization for Standardization (ISO).

Are there Material Testing Standards for Sheet Metals?

Quality control in custom sheet metal fabrication starts from testing the quality of the raw material.

The sheet metal testing machines examine the physical and chemical properties of sheet metals.

Of course, the testing procedure will depend on the metal fabrication technique and finishing operations.

Normally, the sheet material testing standards are stipulated by the European Norms/European Standard (EN), American Society for Testing and Materials (ASTM), and Japanese Industrial Standards (JIS), just to mention a few.

Can you Recommend Acceptable Sheet Metal Testing Methods?

Normally, the testing method will depend on the type of custom sheet metal fabrication technique.

Some of the most common tests include:

- Erichsen cupping tests (EN ISO 20482

- Forming limit curve test

- Hole expansion test

- Sheet metal square cup tests

Choose a testing machine that can determine the mechanical and physical properties of the sheet metals.

Resources:

Why Work with KDM Steel in Custom Sheet Metal Fabrication?

- 2D and 3D drawings will be ready within a day

- KDM Steel makes samples within 3 days

- Ability to customize electrical enclosures, metal cabinet, mailbox, etc.

- An ISO 9001 Certified custom sheet metal fabricator

- Over 10 years of manufacturing experience

- Trained and experienced engineers, technicians and support team

- 24/7 online support to help you

- Ultramodern sheet metal fabrication machines and testing equipment

- A range of custom sheet metal fabrication capability such as casting, forging, plating, polishing, etc.

How Fast will KDM Steel Finish Your Custom Fabricated Metal Sheet Parts?

You will get the CAD drawing within a day.

KDM steel will send you a sample within three days.

From here, the lead time will depend on the quantity of your order.

You can contact KDM Steel technical support who are available 24/7.

KDM Steel guarantees short lead time on all custom fabricated steel metal parts.