KDM is your trusted architectural sheet metal fabrication service provider. We form, bend, and trim sheet metals to fit architecture projects.

- Utilize architectural sheet metals such as aluminum, stainless steel, iron

- Provides precise architectural sheet metal fabrications

- Assures custom-tailored and accurate services

- Serves industries like institutional, industrial, commercial, etc

KDM Architectural Sheet Metal Fabrication

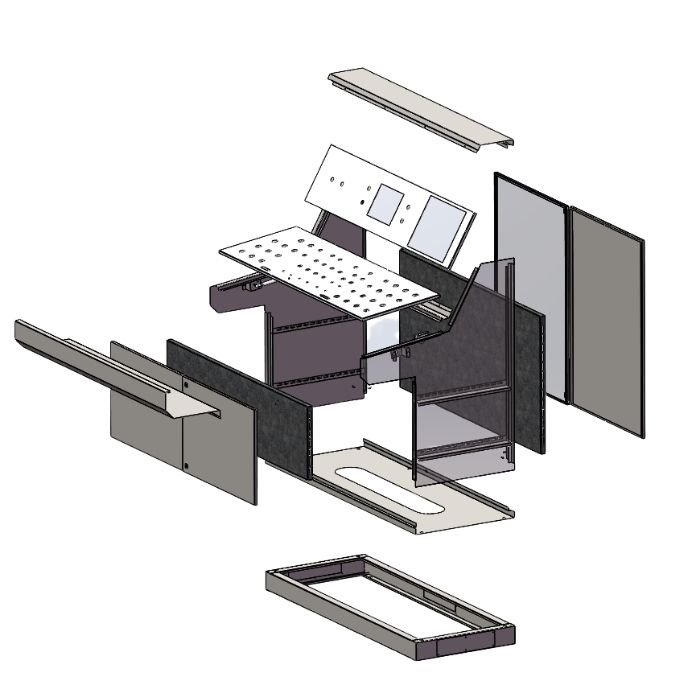

Architectural sheet metal fabrication is the process of forming metal sheets to produce architectural equipment and products. It is possible using bending technique, shearing, plating, welding, and more manufacturing methods. We also use different metals such as aluminum, copper, zinc, etc.

KDM has been supplying premium sheet metal to the architectural industry since we are founded. These sheet metals plays important role in multiple styles of building projects.

For many years, architectural sheet metal designs have been the preferred décor option for architects, building managers, property proprietors, and more. These designs are also found in universities, government offices, and more. Most produced architectural sheet metal designs include architectural soffits, ladders, stairs, roof designs, canopies, walkways, and so on. For more information, contact us!

Architectural Sheet Metal Series

Copper, zinc, and aluminum are the best metals suitable for creating architectural roofing sheets. Copper gives an aesthetic and appealing appearance. However, zinc is the most environmentally friendly because of its low melting point. While aluminum roofs are an inexpensive option.

Architectural gutters are used below the roof edge for carrying away rainwater. It is manufactured using sheet metals that are bent, cut, and surface coated. Sheet metals include copper, zinc, aluminum, steel, or vinyl.

Copings are curved sheet metals intended for the architectural industry. It forms a steady cap to cover the top of the fence wall. They are made of aluminum, copper, and other sheet metals to ensure leak-proof copings.

Counter flashing is an important part of architectural buildings. It is elastomeric metal sheeting fixed into a rooftop unit, pipe, curb, or wall. They are long-lasting, good quality, and multipurpose for architectural uses.

Louvers are window shutters or blinds with horizontal slatted. It is also angled to accept air and light while keeping out direct sunlight and rain. They are made of architectural sheet metals and totally adjustable.

Also known as vent stack, architectural vents are used to control airflow. It ensures water and waste flow through pipes. They are made of galvanized steel sheets, aluminum sheets, and other metals.

Architectural Sheet Metal By Materials (5)

Architectural Sheet Metal by Applications (4)

KDM Architectural Sheet Metal Advantages

All sheet metals for architectural purposes are durable, harder, and stronger, unlike other materials. When integrated into architectural designs, they supply excellent stability and strength.

KDM fabricates any sheet metal design with excellent heat resistance. Provided with higher melting points, sheet metals are unlikely to break down even the temperature climbs.

In the fabrication, we can form sheet metals in many sizes, patterns, materials, and styles. It makes it the most versatile choice for architecture.

KDM offers a cost-effective fabrication service. We used reasonable sheet metals to create architectural parts for any high-volume and long-term project.

Architectural Sheet Metal Designs & Materials

KDM manufactures a variety of architectural sheet metal which includes gutters architectural sheets, copings architectural sheets, architectural roofing sheets, and many more. We provide custom fabrication for each piece to match the specific needs of your applications.

As a leading fabrication provider, KDM is competent to work with any sheet metals for the architectural industry. We use copper, galvanized steel, aluminum, zinc, galvanized iron, stainless steel, and so on. All materials passed standard certifications, including AISI, EN, DIN, etc.

Additionally, each sheet metal went through rigorous testing and inspections right before the fabrication process. This is to assure you that we can meet your quality expectations and your fabrication needs. Reinforced with our skilled engineers, we guarantee high versatility and high strength architectural sheet metal fabrication.

KDM Architectural Sheet Metal Fabrication Capabilities

At KDM, we deliver outstanding fabrication services. Whether you need detailed architectural design or standard fabrication, we are confident we can meet any need. We have broad capabilities and skills to create advanced and long-lasting architectural parts. We perform processes including:

- Shearing

- Press brake (bending process)

- Custom forming

- Plating

- Solder

- Welding

- Powder Coating

- Painting

Why Choose KDM Architectural Sheet Metal Fabrication

In-depth Mastery

When you depend on KDM from the beginning of your project, we can assure that all your design perspectives and cost are sustained effectively. We will assist you with a successful project.

Action-Oriented Experience

For more than 10 years, our engineering team has been committed to some of the architectural buildings worldwide. We can provide you with perfect outcomes that include roofing sheets, canopies, ladders, anti-slip stairs, and more.

Beyond Compare Quality

If you need premium architectural sheet metal fabrications, KDM provides matchless quality services. Whether you are building owners, architects, or property managers, we are able to provide precise services.

Choose KDM for Your Architectural Metal Fabrication

KDM specializes in custom architectural sheet metal fabrication, making high-grade custom sheet metal parts for roofing, industrial components, commercial windows, and other applications. For your next custom sheet metal fabrication needs, please consider us!

During the fabrication, we create parts based on your drawings and technical specifications. All parts are high strength, heat resistant, versatile, and made from affordable yet quality sheet metals.

Our competent custom sheet metal fabrication staff are skilled to assemble end parts with pinpoint accuracy. Our machining and fabrication skills include coiling, press-brake shaping, folding, welding, and so on.

Choosing the exact corrosion resistance surface coating is important for a perfect architectural part design. Below we introduce the coating method with numerous advantages.

Anodising –This is the most familiar method of enhancing the corrosion resistance on sheet metal parts. It is an electrochemical procedure that transforms sheet metal surfaces into a rust-free, durable finish.

Plasma Electrolytic Oxidation PEO –Also referred to as micro-arc oxidation or electrolytic plasma oxidation is a surface coating process. It creates dense, thick coatings to improve corrosion and wear resistance.

Paints –The benefit of working with paints is that they can be applied, colored, or finished in multiple ways. Also, they can produce glossiness, temperature stability, and chemical resistance to any sheet metal parts used in architecture projects.

Many organizations and architects are realizing how effective and valuable architectural sheet metal designs are for architectural buildings, renovations, and the latest expansions. It includes canopies, walkways, vents, soffits, and roofs, to name a few. They offer features and benefits, such as:

- Improved ventilation and airflow

- Generating secured walkways

- Constructing privacy into an open domain

- Providing designs with aesthetic attraction

- Excellent durability and robust designs

- Extreme heat resistance

- Custom-made in various sizes, cuts, shapes, etc

- Corrosion-resistant finish

OEM & ODM KDM Architectural Sheet Metal Industries Served

The architectural sheet metals are carefully crafted for decorative construction and structural applications. These are extremely versatile, latest solutions for businesses and homes constructions today.

KDM used different sheet metals for commercial sheet metal fabrication. It includes aluminum, steel, stainless steel, copper, and other materials. They are used in wide commercial industries and buildings.

The institutional ceilings are processed using steel, aluminum, copper, etc. While these products are processed through decoiling, punching, bending, welding, and cutting.

The industrial bracket parts have a single side bracket structure. Materials used in the production are stainless steel 304 and steel. It is a welding and bending process.

Sheet metals are custom-fabricated, trim, and formed to fit architectural roofing projects. It is made in different materials, such as zinc, copper, stainless steel, with custom colored coatings.

Why KDM is Trusted By Over 1000 Global Clients

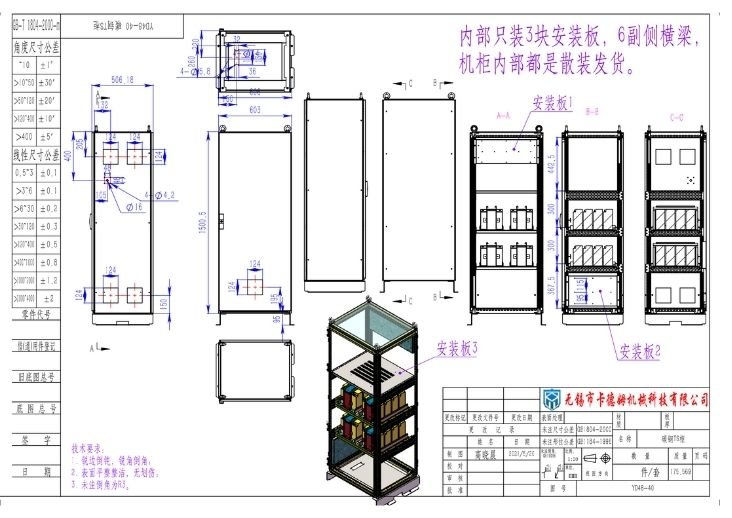

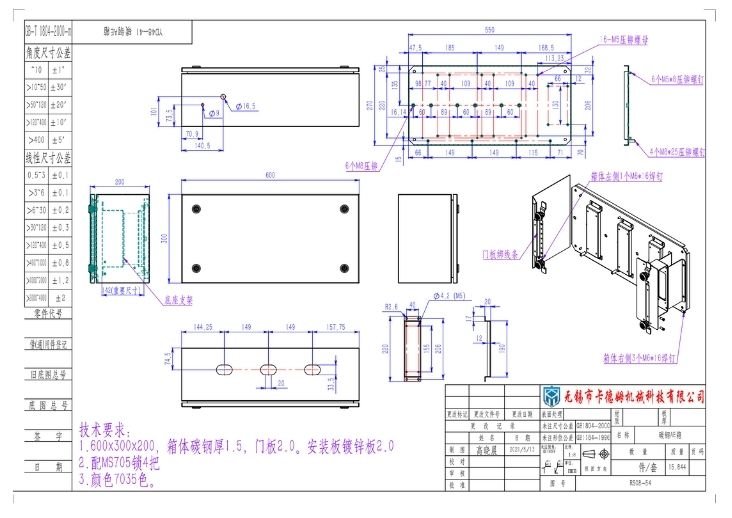

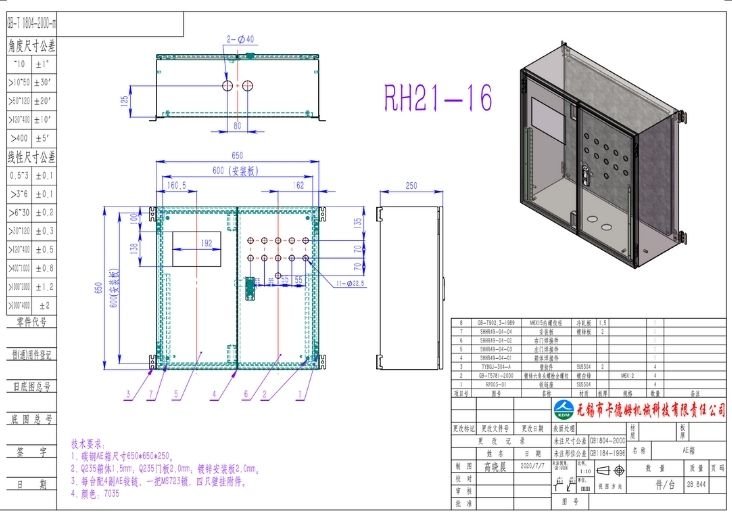

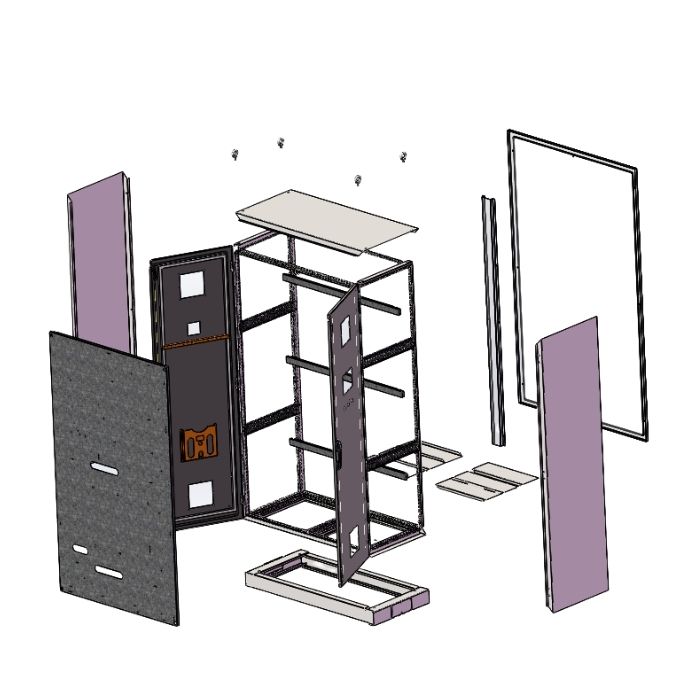

- Enclosure Manufacturing

- 2D Drawing

- 3D Drawing

4000W high performance laser cutting machine, +/- 0.05mm accuracy. No burr, no scratching.

Multi-Functioning flexible welding equipment, high accuracy, no deformation.

Expert assembling team, consistent assembly quality on every KDM enclosure