KDM is an expert in steel sheet metal fabrication for aerospace, automotive, construction, and many industries. Our capabilities include custom steel sheets to ensure your future projects are successful.

- High-strength and durable

- Flexible design for custom configurations

- Heat resistant – not easily degradable

- Numerous surface finish: powder coating, plating, painting, etc.

KDM Steel Sheet Metal Fabrication

KDM steel sheet metal fabrication is a process of producing steel parts using a secondary manufacturing process. Fabrication of custom steel sheets includes welding, punching, bending, and cutting. Heat treatment and finishing are the additional technique to impart its characteristics.

We work with numerous types of steel such as carbon steel, stainless steel, and galvanized steel. Most steel sheet fabrications are crucial in transportation, construction, agriculture, consumer goods manufacturing, and mining.

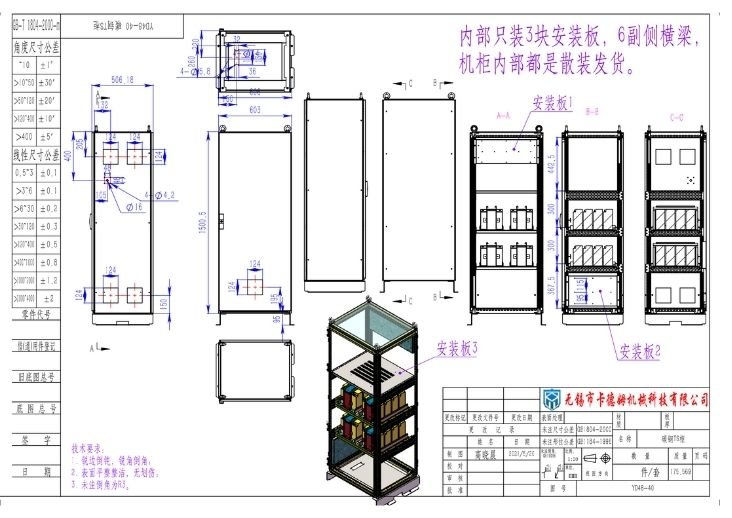

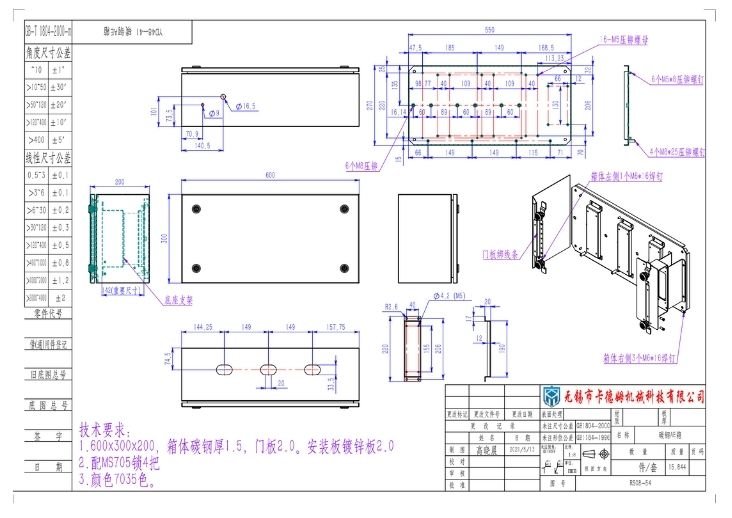

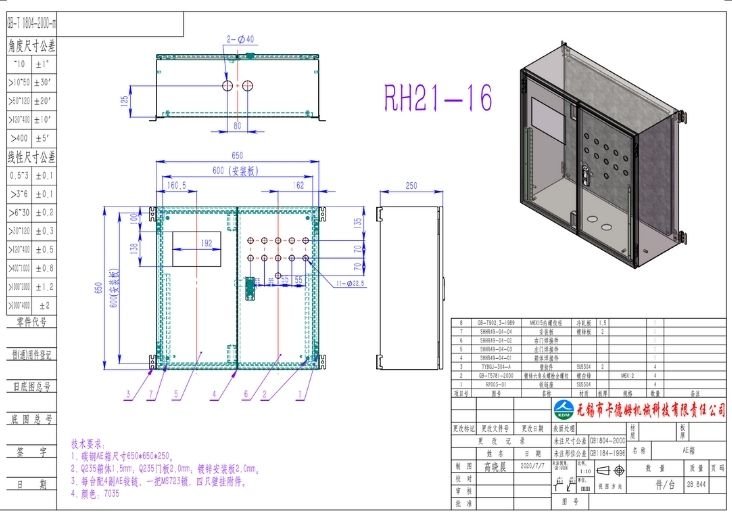

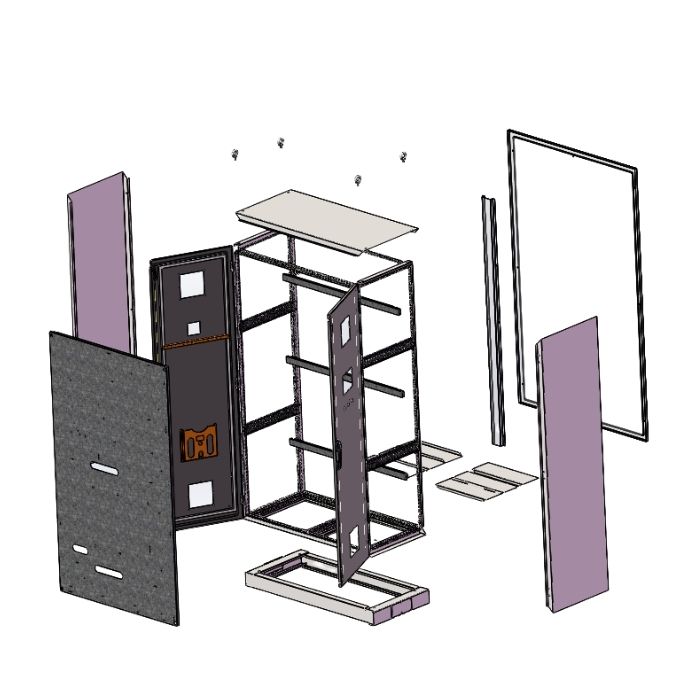

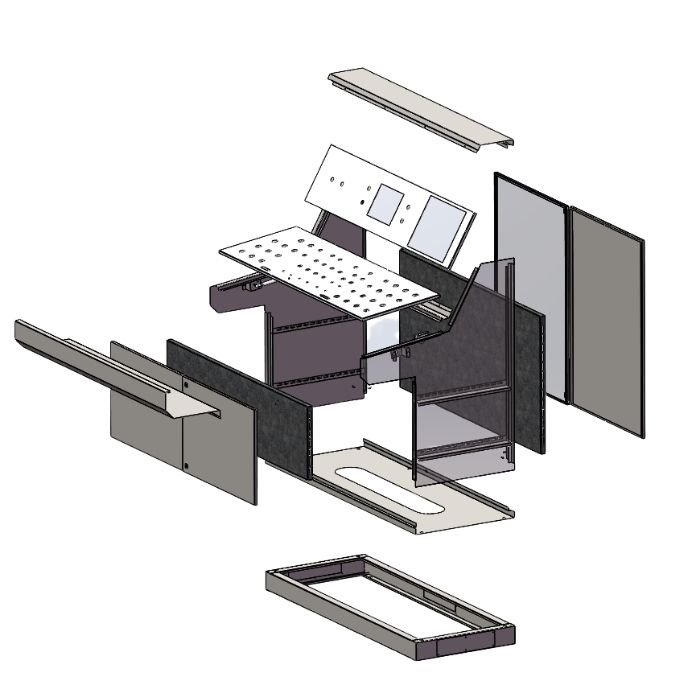

KDM steel sheet metal fabrications include steel trusses, automotive chassis, storage tanks, enclosures, and many more. We are using high-tech manufacturing equipment and machines to produce custom steel sheets according to your specifications.

Send us your inquiry now!

KDM Steel Sheet Metal Fabrication

KDM auto precision steel sheet fabrication is made through welding, stamping, bending, and cutting process. You can request a custom finish for steel fabrication such as anodized, plated, and more.

KDM provides mass production of stainless-steel bending parts fabrication. Stainless steel parts can be anodized, brushed, plated, and many more surface treatments.

KDM automotive steel case fabrication includes bending, welding, and stamping process. It can guarantee tight tolerance, precise quality, and a beautiful finish.

KDM high-precision steel stamping parts can be manufactured according to your specific material thickness. It is widely utilized in electric appliances, toys, medical, furniture, and many more.

KDM provides expert fabrication services to produce galvanized steel sheet enclosures such as stamping, laser cutting, bending, punching, turning, and many more.

KDM custom steel sheet metal component is manufactured based on the client’s drawing. Custom steel sheet fabrication includes bracket, box, frame, enclosure, and many more.

Steel Sheet Metal Fabrication By Process (6)

Why KDM Steel Sheet Metal Fabrication

Steel is easy to install, making it effective to save time in the construction industry. It is lighter and more robust.

KDM steel sheet metal fabrication improves the durability of steel due to its zinc-coated technique. It protects the steel from corrosion, withstanding harsh conditions.

KDM steel sheets metal fabrication is eco-friendly since it is recyclable. Old tools may be formed into another product that helps reduce pollution.

The steel sheet metal fabrication acquires various finishes such as painting, powder coating, plating, galvanizing, and many more.

Steel Sheet Metal Fabrication Technique

KDM steel sheet metal fabrication involves numerous techniques. The basic techniques are cutting, bending, welding, machining, coating, and drilling. These capabilities ensure high-precision shapes and sizes of steel products based on our client’s requirements.

In machining, KDM uses mills, lathes, and drills to get rid the unwanted materials. Then, the custom steel sheet is formed into required sizes and shapes.

Custom steel sheets are sliced into required dimensions through the cutting process like a water jet, flame, or plasma. It can make the fabrication process easy.

In welding, the raw materials are melted using high heat levels and then combined together. And lastly, the steel sheet is covered with zinc to prevent corrosion. Different surface treatments are employed according to the customer’s requirements.

Steel Sheet Metal Fabrication Benefits

KDM steel sheet metal fabrication allows single prototypes to volume production. We use the 3D printing method to provide a well-aligned prototype in a quick lead time.

Additionally, the KDM custom steel sheet provides great benefits in surface finish options. We offer powder coating, galvanizing, painting, plating, and many more. These unique finishes allow different looks of custom steel sheets and offer various protections.

Steel Sheet Metal Fabrication Application

Custom steel sheets can be hot or cold rolled. These steel sheets in the hot and cold rolled process have specific uses. For instance, cold-rolled steel which is rolled at room temperature has a limited 3mm thickness. It is suitable for applications that need a beautiful smooth finish, such as lockers, cabinets, furniture, and home appliances.

However, hot rolled steel is suitable in applications in which specific dimension is not crucial, such as construction projects and railroad tracks. KDM offers a one-stop solution for your steel sheet metal fabrication needs. If you need a custom design, please don’t hesitate to contact us today!

Choose KDM to Custom Steel Sheet Metal Fabrication

KDM is expert in supplying custom steel sheet metal fabrication. We produce various steel sheet fabrication using our high-end manufacturing facility. They are produced in compliance with ASTM, JIS, AISI, and GB/T5231-2000 standards.

Our designers and engineers with great experience in metal fabrication can help you design your custom steel sheet. We utilize precision stamping machines, laser cutting machines, welding machines, and many more.

Skyrocket your business with KDM! For any inquiries, we can answer your concerns supported by our 24/7 online assistance. Message us now!

KDM Steel Sheet Metal Fabrication

- Thermal Cutting

- Mechanical Cutting

- Punching

- Bending

- Assembling

- Finishing

Steel Sheet Metal Fabrication Application

KDM steel sheet furniture can guarantee sturdy, precise cut, and high-quality. This furniture can be available in many surface treatments like anodize, powder coating, plating, and more.

KDM steel sheet enclosure is widely used in the electrical design industry. These enclosures are versatile, simple, and extremely tough.

KDM works with various steel sheet materials to produce fitness equipment. Mainly are CR-plated carbon steel, painted carbon steel, and stainless steel.

Steel sheet is resistant to high temperature and mechanical damage. These advantages make steel sheet metal fabrication suitable for the medical industry.

KDM has the skills to produce steel sheet fabrication for home appliances, such as parts and components required in refrigeration solutions, air conditioning units, dishwashers, and washing machines.

لماذا تحظى شركة KDM بثقة أكثر من 1000 عميل عالمي

- تصنيع العلبة

- 2D Drawing

- رسم ثلاثي الأبعاد

آلة قطع بالليزر عالية الأداء بقوة 4000 واط، بدقة +/- 0.05 مم. بدون نتوءات أو خدوش.