KDM manufactures an empty enclosure for Ex p, Ex d, and Ex e types of protection. We offer a huge range of KDM Ex enclosures with a selection of various materials and sizes that fit all your requirements.

With KDM, you can find the perfect solution for you!KDM Ex enclosure has cutting-edge production processes and sophisticated design that ensures all KDM Ex enclosure offers lasting protection. We are supplying a wide range of high-quality Ex enclosures in various types and sizes for service-temperature ranges and the various gas group uses.

KDM is an Ex enclosure expert from China who provides the industry with a wide array of solutions for reliable and safe encapsulation of electrical equipment.KDM Ex enclosure covers a diverse and extremely large range of industrial environments requirements. Whether as simple distribution boxes for sensor signals, energy, or complex control systems.

- Certified with ATEX and IECEx

- Exceptional free sample program

- Industry leader of authentic design

- Outstanding on-time delivery performance

KDM Ex Enclosure Series

KDM is offering a wide range of pressurized cabinets to fit every customer’s specifications. All of our pressurized cabinets are offered at the lowest price guaranteed trusted quality.

KDM aluminum Ex carries a NEMA rating. It is manufactured using excellent quality materials through KDM’s modern types of machinery.

This polyester Ex is particularly designed guaranteed by our top-notch engineers. You can purchase polyester ex at single or bulk orders.

KDM Ex d enclosure has cutting-edge production processes and sophisticated design that ensures all KDM Ex d enclosure offers lasting protection.

KDM can provide Ex stainless steel to our valued customers to suit their application needs. These are available in various sizes and shapes. Contact us now!

Send your Inquiry on KDM Ex Enclosure Now

All KDM Ex enclosure complies with the IP66 protection degree in accordance with DIN EN 60529 signifying that they are water-tight and dust-tight.KDM Ex enclosure is widely used in the processing industry, gas and oil, pharmaceutical, and chemical companies.KDM manufactures Ex enclosure that is used in instrumentation and control applications.

We are supplying both aluminum and stainless-steel Ex enclosures to our valued customers. We can also customize the surface finishes or modifications including the paint system and sight glasses. It can be implemented depending on the specific type of enclosure. At KDM, we can also fabricate a special enclosure as the customer request.

- Guaranteed excellent quality Ex enclosure

- On-time delivery and reasonable prices

- Certified and approved by NEMA, UL, IEC, etc.

- Manufactured using high-class raw materials

Related Products with Ex Enclosure

防爆外壳

KDM Ex enclosure is specifically made for hazardous environment uses. It is particularly manufactured, designed, and tested to various international standards.

All of our KDM Ex enclosure is certified to ATEX/IECEx under the license from the testing authority.

Our wide range of Ex enclosure is made of either polyester or polycarbonate and aluminum.

It is ideally suited for control, instrument housing, automation, connection, protection, or interruption use.

KDM Ex enclosure provides complete protection for various applications in process technology and industrial environments.

Our offered product range is consisting of a standardized enclosure in a variety of sizes. The entire Ex enclosure range is available pre-assembled and processed upon request.

For more information about our Ex enclosure, please don’t hesitate to contact us now!

What are Ex Enclosures?

The ex enclosure is intended to confine an explosion while also containing sparks, flames, or hot gases.

Ex enclosures are enclosures built of various materials, including aluminum, stainless steel, and metal sheets.

Should an internal explosion occur, it will escape onto the surrounding atmosphere.

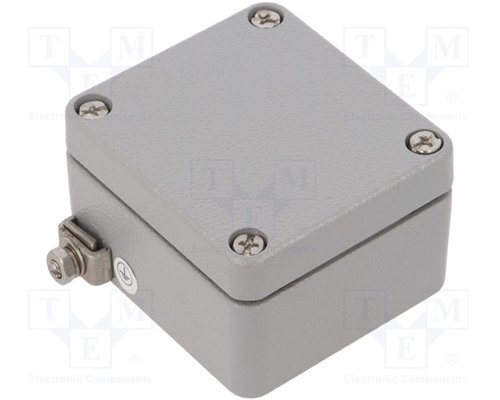

Figure-1 Ex Enclosures

What is the Purpose of Ex Enclosures?

The primary purpose of these enclosures is to protect the surrounding environment by limiting the number of sparks or explosions inside the chamber.

The cage itself must be heat-resistant to high temperatures to prevent fire from escaping.

What is the Advantage of Ex Enclosures?

Some advantages of ex enclosure are listed below:

- Installation is simple.

- Appearance is pleasing.

- Cut-off switch for safety.

- Safe use outdoors

- Efforts to assemble and approve are reduced.

- Protection of a higher level.

- Components that are readily available and less expensive.

- It is capable of containing an internal explosion and preventing it from spreading to the surrounding environment.

Figure-2 Ex Enclosures

What are the Essential Considerations While Using Ex Enclosures?

The ignition gap in the ex enclosure prevents sparks, flames, and hot gases from spreading, guaranteeing. That every hazardous buzz surrounding the device is just not triggered.

There are some essential considerations while using ex enclosures:

- An Ex enclosure’s primary purpose is to keep an internal explosion from spreading.

- It also protects the installed equipment from external influences such as moisture, filth, dust, or water.

- An Ex enclosure is built to survive an inside explosion mechanically.

- Must not harm the so-called ignition protection gap in Ex enclosures.

What are the Applications of Ex Enclosures?

Ex Enclosures application that especially designed:

- Automation in industry processes.

- Chemical and refinery industries.

- Pharmaceutical.

- Maritime.

- Stations in the field.

- Beverages and food

- The printing industry.

- Air travel is available.

- Both nuclear and renewable energy sources are available.

Figure-3 Ex Enclosures

What are the Other Types Of Ex Enclosures?

The following are examples of several sorts of ex enclosures:

- Enclosures that are flameproof “d.”

- Enclosures with oil “o”

- I for intrinsic safety

- Enclosures with pressure “p”

- Increased safety “e”

- Enclosures with sand “q”

- Enclosure “t” provides protection.

- “m” encapsulation

- The letter “n” is a non-sparking letter.

- Op “Optical radiation” is a term used to describe a phenomenon in which light is emitted.

- “h” that isn’t electrical

- “s” for special protection

Where Do Ex Enclosures Suitable For?

Ex enclosures would thus act as a safety precaution, preventing any defective equipment from generating sparks that could ignite any external flammable gases in potentially dangerous situations.

Besides, ex enclosures are suitable for use in chemical and petrochemical industries and coastal sites.