Impact protection (IK) outlines the test you can conduct on systems to establish their resistance to external impact. Usually, we use this for most electronic casings.

It is represented by two-digit numbers ranging from 0 to 10; lowest to highest.

What is IK Rating?

IK stands for “Impact Protection”, with the “K” referring to Kinetic.

It is therefore an extent to which electrical equipment or housing guard against mechanical damage to their enclosed materials.

The scale of measurement ranges between IK00, which is the “unprotected level” to IK10 which is completely secured.

We measure IK rating in joules. Like other standards, the IEC 62262 dictates the test guidelines and specifications.

The level of protection is determined through Charpy impact tests using a pendulum hammer. The impact level (energy and number of impacts) is adjusted upwards until the product fails or attains its maximum IK measurement.

Benefits of Understanding Impact Protection Rating

Understanding Impact protection rating has its benefits some of which are listed below.

· Choice of Material

Products with high IK ratings are made from hard materials such as steel which can tolerate certain mechanical impacts. Understanding impact protection rating therefore will enable you to select the right material for your electrical product depending on its application.

· Saves Cost

Knowing the mechanical stress level of an environment helps you determine the best IK rating for a product. This therefore saves on the cost of repairing damaged products due to unsuitable IK rating choices.

· Product Suitability

Before installing electrical products such as lights in various environments, it is crucial to understand the environment and the mechanical impact. This will help you determine the correct IK rating for your product depending on its environment. For instance, an intercom within a building will require less IK rating compared to one installed in a school.

How IK Rating compare to IP Rating

IP rating and IK rating are quite different. That is to say:

- IK rating focuses on protection from mechanical force

- The IP rating is concerned with protection from liquid and solid elements

Like IK, IP is also controlled by the international standards of codes; IEC60529 which dictates the measure of protection of the enclosures.

Unlike IK scale which ranges between IK00 to IK10, IP rating has a two-digit value representing solid and liquid protection levels respectively. The IP scale varies from IP00 to IP68 with IP00 indicating zero protection while IP68 is the highest protection level.

When an electrical casing has IP00 mark on it, it simply means it is not protected against solid or liquid elements. An Ingress Protection of 68 (IP68) offers the highest protection against the entry of solid or liquid agents.

When selecting products such as biometric fingerprint machines that are installed outdoors, IP rating is an important factor to consider. This is because the reader is exposed to solid and liquid elements which are likely to impact its functionality.

An IP rating of IP65 and above is ideal to protect them from solid and liquid agents in the environment.

Interpreting IP Chart Rating

| IP Level | First Number (Solid Entrance) | Second Number (Liquid Ingress) |

| 0 | Not Protected against solid agents. | Not Protected against liquid or moisture. |

| 1 | Shielded from solid agents above 50mm like accidental hand touch | No liquid infiltration from a height of 200mm from the object when falling at 3-5mm cubic per minute for 10 minutes. |

| 2 | Shielded from solid agents above 12mm like fingers. | Shielded against direct vertical sprays up to 150mm. |

| 3 | Shielded from solid agents above 2.5mm like tools and wires. | Shielded against direct vertical sprays up to 600mm at a speed of 11L per minute and 800-100kN/square meter pressure for not less than 5 minutes. |

| 4 | Shielded from solid agents above 1mm like tools, small wires, etc. | Shielded against all directionsprays at a speed of 10L per minute and 800-100kN/square meter pressure for not less than 5 minutes-limited inflow allowed. |

| 5 | Shielded from dust. | Jetted water from a 6.3mm diameter spout must not ingress from any angle. Average jetting speed of 12.5L per minute and 30kN/square meter pressure for 3 minutes from 3 meters distance-limited inflow allowed. |

| 6 | Completely secured against dust entrance. | Jetted water from a 12.5mm diameter spout must not ingress from any angle. Average jetting speed of 100L per minute and 100kN/square meter pressure for 3 minutes from 3 meters distance. Limited inflow allowed, e.g. equipment mostly used in ship decks. |

| 7 | Protection from inflow with complete immersion of between 15cm to 1m for half an hour. | |

| 8 | Shielded from extended liquid exposure like pressurized liquid immersion. |

Interpreting IK Chart Rating

The IK chart is meant to be a general guide on values required to attain specific levels of IK ratings.

| IK Rating Standard | Meaning or Interpretation of IK Rating |

| IK00 | Unprotected from external mechanical force. |

| IK01 | Safeguarded against 0.14 joules force (same as dropping a 0.25kg weight on product surface from 56mm height). |

| IK02 | Safeguarded against 0.2 joules force (same as dropping a 0.25kg weight on product surface from 80mm height). |

| IK03 | Safeguarded against 0.35 joules force (same as dropping a 0.25kg weight on product surface from 140mm height). |

| IK04 | Safeguarded against 0.5 joules force (same as dropping a 0.25kg weight on product surface from 200mm height). |

| IK05 | Safeguarded against 0.7 joules force (same as dropping a 0.25kg weight on product surface from 280mm height). |

| IK06 | Safeguarded against 1 joules force (same as dropping a 0.25kg weight on product surface from 400mm height). |

| IK07 | Safeguarded against 2 joules force (same as dropping a 0.5kg weight on product surface from 400mm height). |

| IK08 | Safeguarded against 5 joules force (same as dropping a 1.7kg weight on product surface from 300mm height). |

| IK09 | Safeguarded against 10 joules force (same as dropping a 5kg weight on product surface from 200mm height). |

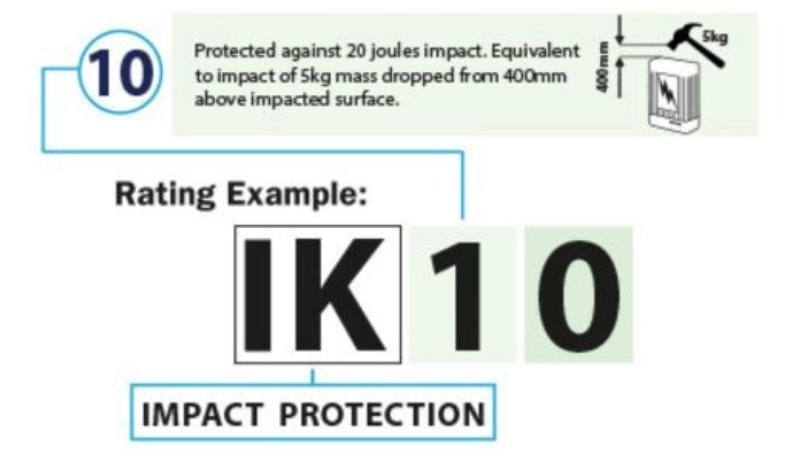

| IK10 | Safeguarded against 20 joules force (same as dropping a 5kg weight on product surface from 400mm height). |

How to Measure IK Rating

IK Rating is measured using the Charpy pendulum impact tester method. This method involves hitting an electrical object with a swinging pendulum hammer of known weight from different distances.

The pendulum strikes the object from all directions (front, back, top, corners, and sides) to imitate the normal impacts it may encounter.

The test is started from a low energy level and the pendulum hammer weight and height are adjusted gradually. Pendulum-object striking continues until the object’s breaking point or maximum IK level.

The more an object can resist the mechanical impact the higher the IK rating; IK10-shielded against 20joules. On the other hand, the least resistance degree to impact yields low IK rating; IK0-zero impact protection.

IEC 62262Vs IK Rating

IEC62262 is the “International Electrotechnical Commission”, a body that manages the protection rating system for electric equipment enclosures. This international standard body was effected in 2002 by the European Union to provide standard guidance on IK rating.

While the IK rating defines the degree of mechanical force resistance, its system of rating IK00 to IK10 is guided by IEC62262.

According to IEC62262, the lowest rating is IK00 denoting “zero protection” with IK10 representing “maximum protection” of up to 20 joules.

As per IEC62262 standards, IK10 is the maximum protection. However, some products require greater protection from mechanical impact and can be rated beyond IK10 by the Charpy impact test. IEC62262 does not go beyond IK10 rating, therefore, IK10 is the maximum impact rating there is for all electrical enclosure equipment.

Importance of IK Rated Products

IK rated products are important because they give an idea of how much mechanical impact they can withstand.

Different electrical products have different IK rating scales which determine where they can be suitably installed.

For instance, high-traffic and busy areas, public parks, schools, hospitals, etc. require high IK rated products due to vandalism. As a result, the electrical product will require maintenance or replacement if completely damaged at an extra cost.

In some cases, it may pose as a risk or even lead to inconvenience to users should the damage be hazardous.

Knowing the potential impact exposure to an electrical object in an area is therefore important in determining the IK rating before installation.

Secondly, some electrical objects such as intercoms can be designed for aesthetics thus making them a target of vandalism. A high IK rating is then important for such to protect them from mechanical damage.

Why IK Rating for Light is Important

Lights are used in different environments ranging from parking spaces, construction sites, factories, stadiums, etc. These environments may be the most unfriendly of places thereby exposing the lights to several harsh mechanical impacts.

IK rating is then important because it will determine the level of impact the light fixture will be able to withstand. For example, light fixture at a construction site will require IK10 rating to protect it from falling objects, heavy impact, etc.

Additionally, IK rating in lights helps save on cost and time that would otherwise be spent repairing or replacing damaged lights.

Choosing the correct IK rated light for its area of use improves security by ensuring there’s light throughout.

IK Rating vs Vandal Resistance

IK rating directly affects vandalism resistance an electrical equipment such as light fixtures or intercoms.

This is because IK ratings dictate the level of mechanical stress an electrical object is able to resist. The higher the IK rating of an electrical object, the less likely it is to be vandalized either intentionally or accidentally.

Objects that are installed in areas that expose them to vandalism like public parks or commercial places need higher IK ratings.

On the contrary, intercoms installed inside a building do not need a higher IK rating because they are less likely to be vandalized.

Conclusion

Impact Protection rating is important for electric enclosure products as it determines mechanical impact level resistance.

It is therefore important to understand the IK rating for products as well as the area of application before installing them.