Are You in Need of Stainless Steel Spiral Duct?

KDM provides high-qaulity selections for you.

Premier Stainless Steel Spiral Duct Supplier in China

To avoid a wide range of caustic incidents, KDM stainless steel spiral ducts provide extreme resistance. It has great elevated temperature possessions and good toughness at deathlike state temperatures.KDM Stainless steel spiral ducts can be with/without duct adhesives. They are available with corrugation options, which have a high rigidness. Whatever the option you need, KDM is very glad in giving you full support.

At our factory in China, the best qualities of stainless steel spiral ducts are waiting for you. We will provide you with high-quality services as well. Our dedication to you is the success of our team! Give us now the opportunity to provide your business needs.

- Strengthened Stainless Steel Spiral Duct

- Glossy & Good-quality Finish

- Superior Constructional Strengths

- Long-lasting Spiral Duct Assembly

Contact Us As Soon As Possible.

KDM Stainless Steel Spiral Duct Series

KDM Air conditioning stainless steel spiral duct is good for HVAC parts & systems. Available with custom sizes, shapes, and characteristics. Discuss your detailed specifications to KDM and we`ll make the rest process.

KDM high-quality double-wall stainless steel spiral duct is one complete line of HVAC systems. It is an appropriate ducting for important air conditioning assembly.

This is most required for durable and long-lasting ducting and fittings. It makes sure the airflow velocities be finely utilized. This is the best option for duct constructions and assemblies.

Rigid stainless steel spiral duct from the KDM market has round shapes. It has a great smoothness effect that helps to improve efficient energy. Spiral ducts made by rigid stainless steel are proven long-lasting.

KDM Round stainless steel spiral ducts are the most common type of spiral duct we can offer. You can select different quality selections from our market. All the round stainless steel spiral duct selections are highly guaranteed.

KDM provides stainless steel spiral ducts to be used in huge areas same as workshops, warehouses, or even factories. On any maximum orders you need, we make our best efforts to supply you.

Related Products of Stainless Steel Spiral Duct

KDM Stainless Steel Spiral Duct

KDM Stainless steel spiral duct is manufactured in a combination with light gauge metals with a spiral lock seam assembly. This completely assures maximum durability and strength for ductwork applications.

KDM manufactured stainless steel spiral duct with a number of excellent features and drawing characteristics. KDM is the best manufacturer that can provide you a high-quality stainless steel spiral ducts for business.

KDM makes sure to produce durable stainless steel spiral ducts for your business solutions. They are featured with superior constructional strength and high rigidity. As a result, ductworks and projects will fulfil as soon as possible. To make a long spiral duct lengths diameters, 4 metal pins must form a constant interlocked and strengthen ribs on the outside part.

However, these long-lasting stainless steel spiral ducts are very versatile for some applications. In the fabrication process, our skilled team used authentic grades materials together with our state-of-the-art facilities. So as you can see, they are very glossy and made eye-catching to catch customers` attention.

For over 10 years of industrial experience, our spiral ducts made with high-quality stainless steel are guaranteed efficient in reducing leaks. This is very compatible with any commercial or industrial ductwork application. They are made fully mold resistant. KDM team will help you lessen your stainless steel spiral ducts fabrication costs and installation costs. We know what is the most right one for you.

Ultimate FAQ Guide to Stainless Steel Spiral Duct

- What Is A Spiral Duct?

- What Grade Of Stainless Steel Is Used For Ducts?

- What Other Materials Are Used Besides Stainless Steel?

- What Gauge Of Stainless Steel Is Used For Spiral Ducts?

- How Are Stainless Steel Spiral Ducts Made?

- What Types Of Stainless Steel Ducts Are There?

- What Are Perforated Spiral Ducts?

- What Are Corrugated Stainless Steel Spiral Ducts?

- How Do Stainless Steel Spiral Ducts Compare To SS Rectangular Ducts?

- What Are Standard Spiral Duct Sizes?

- What Connectors Are There For Stainless Steel Ducts?

- What Air Terminals Are There For Stainless Steel Spiral Ducts?

- What Accessories Control Airflow Inside The Stainless Steel Spiral Ducts?

- What Additional Features Can Stainless Steel Spiral Ducts Have?

- Where Are Stainless Steel Spiral Ducts Used?

- What Are Some Assembly Methods For Stainless Steel Ducts?

- Do Stainless Steel Spiral Ducts Need To Be Insulated?

- What Is Used To Install Stainless Steel Spiral Ducts?

- How Are Stainless Steel Ducts Maintained?

- What Coatings Are There For Stainless Steel Ducts?

What Is A Spiral Duct?

The ducting system is designed to supply rooms with conditioned air, and to circulate the same volume of air back to the heating, ventilation, and air conditioning (HVAC) equipment.

Among stainless steel ducts, there are spiral ducts.

These are great to prevent energy loss since the spiral design self-seals, which also ensures a lesser pressure change.

Interestingly, spiral ducts are also easier to maintain and are cheaper to make.

Stainless steel spiral duct

What Grade Of Stainless Steel Is Used For Ducts?

Stainless steel ducts can be made with steel grades 304 and 316.

Stainless steel is created by adding chromium, nickel, and molybdenum in different proportions to the iron-carbon alloy.

Steel grades differ in the content of all additives.

Grade 316 is slightly stronger and resistant to saline and acidic water because of molybdenum.

Stainless steel

This is why 316 is used more for ducts in harsher, industrial environments.

However, grade 304 is cheaper and more common in general use.

This is why most stainless steel spiral ducts use 304 steel.

Stainless steel is durable to all kinds of conditions, like temperature changes, humidity, impact, and other.

Plus, stainless steel is non-porous, meaning that mold and bacteria will not proliferate inside the spiral ventilation ducts.

What Other Materials Are Used Besides Stainless Steel?

Besides stainless steel, spiral ducting can use fabric.

Stainless steel ducts expand and contract as they heat and cool.

So, fabric joints are often used to absorb this change, especially if the ducting network has spiral flex ducts.

Fabric joints should also be used where the duct connects to the air conditioner, serving as a filter.

Also, spiral ducts are often made from aluminum or galvanized steel.

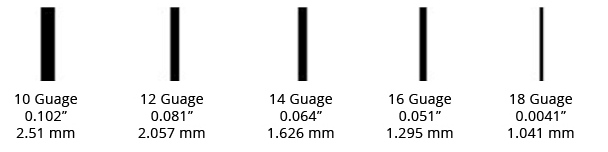

What Gauge Of Stainless Steel Is Used For Spiral Ducts?

Lower steel gauges are stronger, thicker, and more expensive.

Stainless steel ducts usually have a gauge of 26-16, or 0.5-1.5 mm in thickness.

You can specify the thickness of stainless steel either in gauge or in millimeters, or even inches.

Stainless steel gauge

How Are Stainless Steel Spiral Ducts Made?

Firstly, metal strips are turned into coils.

These coils are then processed into slit coils, which are narrower coils cut from a larger master coil.

Stainless steel slit coils

Then, the slit coil is placed on an uncoiler and sent through a rough leveler to flatten the material.

The metal is often 4-ply, meaning that it has 4 layers, consisting of aluminum or other types of steel.

Layered metal

It is then sent through an edge trimmer and a forming process.

This process sends the strip through an inner and outer welding stage that moves it in a circular motion to form a spiral.

The edges are welded or pinched together to form the duct piece.

Forming stainless steel spiral duct

Finally, it is cut from the machine at the desired length, inspected, tested, and then shipped.

Sometimes, the duct may be insulated or coated/painted as well.

What Types Of Stainless Steel Ducts Are There?

Ducts commonly used for carrying air are of a round or of an oval shape.

The most efficient duct shape is round, based on the volume of air handled per perimeter distance.

Round and oval spiral ducts

This is because less material is needed for the same capacity as a square or rectangular duct.

Oval spiral ducts are designed for restricted spaces where a round duct will not fit.

What Are Perforated Spiral Ducts?

Perforated ducts have holes all over the duct surface.

The holes may be small or big, depending on the effect you need.

These are used as air dispersion systems for even dispersion of conditioned air throughout a room.

It is basically a big diffuser.

Perforated spiral duct

Such ducts do not have a lot of throw, which is the distance air travels after leaving the duct.

This means that the pressure is also low, however, the air is distributed evenly.

Usually, perforated ducts are spiral to counteract the structural fragility of perforations.

What Are Corrugated Stainless Steel Spiral Ducts?

Spiral ducts combine the strength and structural rigidity of corrugated metal with the smooth inner surface or a round duct, resulting in high-quality versatile stainless steel ducts.

Corrugations are just grooves in a surface.

Corrugations are measured and categorized by the depth and spacing.

As for ducts and pipes, corrugations can be annular or spiral.

Corrugations

Annular corrugations are mostly used for hoses and flexible ducts and pipes, whereas spiral corrugations are more often used for rigid ducts.

Sometimes, the end edges of spiral ducts are re-corrugated to adapt to a connector.

Thus, spirals are slowly spun into rings.

However, this does not need to happen.

Re-corrugation permits the use of a regular round or rectangular coupling band or adapter for a stronger, leak-resistant connection.

End corrugations

Re-corrugation involves making a lock seam that crumples sheet metal enough for it to change corrugation direction.

You can also request the distance between the corrugations.

The more there are (the more densely packed together they are), the stronger is the duct.

However, corrugations also use up more metal, so there needs to be a balance between strength and cost.

Re-corrugation

How Do Stainless Steel Spiral Ducts Compare To SS Rectangular Ducts?

Spiral ducts leak less than regular ducts do, because of their spiral self-sealing design.

Spiral ducts have better pressure drop characteristics that reduce fan speed.

They are also more rigid than rectangular ducts.

This reduces the drum effect from duct vibration in comparison to a rectangular duct, which can transmit excessive noise if not properly supported.

As for insulation, spiral ducts are easier to insulate, but they only can be insulated on the outside, whereas regular ducts are more versatile.

Stainless steel spiral and regular ducts

All in all, the choice depends on your custom needs.

If you need ducting to be quiet, easy to install and maintain, and cheap, then stainless steel spiral ducts are a better fit for your requirements.

However, rectangular stainless steel ducts retain air conditioning energy better, meaning that you will not have to spend extra time and money on heating and cooling.

Plus, regular ducts are more versatile and easier to install if your building has strict structural restrictions.

What Are Standard Spiral Duct Sizes?

The size of a stainless steel spiral duct depends on the size of the unit, system installation design, and other considerations.

Local building and residential code requirements also provide sizing guidelines.

The duct size must adequately handle airflow supply and return in order for an HVAC system to operate at optimal levels.

The correct sizing of ducts is determined by the optimal airflow based on cubic feet per minute (CFM) as well as the velocity of air provided by other components of the HVAC system.

Spiral duct sizes

Different dimensions of ducts, as well as their shape changes the CFM, which you have to look up.

What Connectors Are There For Stainless Steel Ducts?

Stainless steel spiral ducts can be connected with elbows, boots, collars, reducers, and increasers.

Elbows can be spiral or segmented, and they provide a smooth curve for round ducts.

Spiral elbow

Boots connect a duct to the final opening, such as a register.

Stainless steel boot

Collars are used to transition from one duct to another.

They can be used between 2 round, 2 oval, or even 1 oval and 1 round ducts.

Some collars can also transition between a solid duct and a flex duct.

Stainless steel spiral duct collar

Collars can serve as size adapters as well, functioning as reducers or increasers.

These adapters can be eccentric or concentric.

Eccentric means that only one side is sloped, while concentric means that both sides are sloped.

Concentric adapters usually force air to transition faster, creating more pressure.

Starter collars are specifically used to connect the main plenum duct with branching ducts.

Another connector is a ball joint, the angle of which can be changed according to need.

Stainless steel ball joint

Besides these connecting accessories, there are various ways of connecting the spiral ducts together.

To split up airflow, the ducts can be connected as a V, a T or as a crossroad, depending on how many directions you need to split the airflow into.

Plus, the ducts can just branch out laterally, at different angles: 30, 45, 60, as well as any angle in between depending on your specifications.

Connecting stainless steel ducts

What Air Terminals Are There For Stainless Steel Spiral Ducts?

Room openings to ducts have several accessories that control the airflow and keep large objects out of the duct.

These are called diffusers, grilles, and registers.

Diffusers deliver fan-shaped airflow into a room.

Grilles control the distance, height, spread of air-throw, and amount of air.

Registers are also vented covers for ceilings and floors, but they have their own dampers to open and close the vent to control airflow.

Diffuser, register, grille

What Accessories Control Airflow Inside The Stainless Steel Spiral Ducts?

Dampers balance airflow and shut off or open certain ducts for zone control.

Dampers can be located in the terminal or in the duct itself.

There are three types of dampers: butterfly, split, blast gate, and fire dampers.

Butterfly dampers have a bifold construction and are also called throttle valves.

Stainless steel butterfly damper

Split dampers are mostly used at duct junctions.

They help split the airflow before it gets to the junction, creating a smoother and more efficient transition.

Split damper

All these dampers can be manual,pneumatic, or electric.

Another damper is a blast gate damper, which is mainly for manual use.

Blast gate damper

Furthermore, there are automatic fire dampers, which should be installed in all vertical ducts to prevent the spread of toxic fumes and fire—should a fire happen.

These either have fusible links that get melted and close the damper, or they have thermal sensors, which also close the damper.

Fire damper

Another mode of controlling airflow are turning vanes, which are, essentially, small dampers used to help airflow turn at corners and curves more smoothly and to avoid turbulence.

They are especially useful for bigger ducts.

Stainless steel turning vane

What Additional Features Can Stainless Steel Spiral Ducts Have?

There can be false air valves, which introduce unconditioned air into the duct to balance the system pressure.

They are inconspicuous and are perfect for wall or ceiling installation.

Another feature is a stainless steel mesh that protects the spiral duct from insects, mice, and small birds.

Insect-proof mesh and bullnose hood

Such mesh is often coupled with a bullnose hood that directs airflow 90 degrees from the surface of the duct.

Because spiral ducts are useful for duct collection, some may have a dust sweep-up.

This feature is a portion of the duct that lies on the floor, and you can sweep the dust and debris from your floor into the duct.

Stainless steel dust sweep-up duct

Similarly, there are duct sputniks, which are suction units that combine multiple suction ducts.

Stainless steel duct suction sputnik

Some ducts can have access doors, which are used to maintain the ducts.

The doors can have handles, screws; doors themselves can be flat or curved, oval, or rectangular.

This is similar to a spiral duct take-off.

Take-offs are anything where air changes direction.

So, these include diffusers, starting collars, branches, and more.

Take-off diffuser

Typically, they are cut into a spiral duct and welded in place.

Where Are Stainless Steel Spiral Ducts Used?

Stainless steel ducts are needed everywhere.

More specifically, spiral ducts are used as dust collectors, industrial ventilation, spray booth stacking, welding booths, paper trim, pharmaceutical clean rooms, some home wall vents, heat transfer and ventilation systems, gas electric dryers, cooker hood extractors, and the list goes on.

Commercial applications for spirals ducts include schools, malls, sports facilities, venues, restaurants, churches, offices, and hospitals.

As for industrial applications, stainless steel spiral ducts can be used for factory HVAC, removal of toxic fumes, removal of dust and various byproducts like sawdust.

What Are Some Assembly Methods For Stainless Steel Ducts?

Some assembly parts that are used for stainless steel ducts include pull rings, and flanges.

Pull rings have a groove in the middle—usually with a rubber insert—, where the edges of two connecting ducts are placed.

Pull-ring assembly

Then, the pull ring is tightened and it keeps the edges closed.

A flange is an extended edge of a duct.

Flange assembly

It has holes for screws; connecting ducts both should have flanges, and they are tightened together with screws.

As well, there are rubber flanges, which are resistant to oils, petrol, acids, and bases—perfect for industrial spiral ducts.

Do Stainless Steel Spiral Ducts Need To Be Insulated?

Typical air-duct systems lose 25-40% of the heating or cooling energy via the duct itself, so through leaks.

Thus, bad ducting makes the HVAC system work harder, thus increasing your utility bill.

As already mentioned, as the air travels along the duct, it loses its heat of coolness, so insulating a duct prevents that.

Moreover, duct insulation helps prevent not only energy waste, but also leaks, temperature drops, and condensation buildup on the outside of the duct.

Spiral ducts are easier to insulate because they are rigid, but they can only be insulated on the outside, which is more expensive than the inside insulation of regular ducts.

However, spiral ducts can be lined with fiberglass strips in a special way.

This insulation stops heat transfer, but also has sound-proofing qualities.

Spiral duct liner

A good duct insulation should have an R value of about 5-8.

R value measures how well a layer of insulation resists the conductive flow of heat.

Duct insulation usually consists of foil-faced fiberglass and metallic tape.

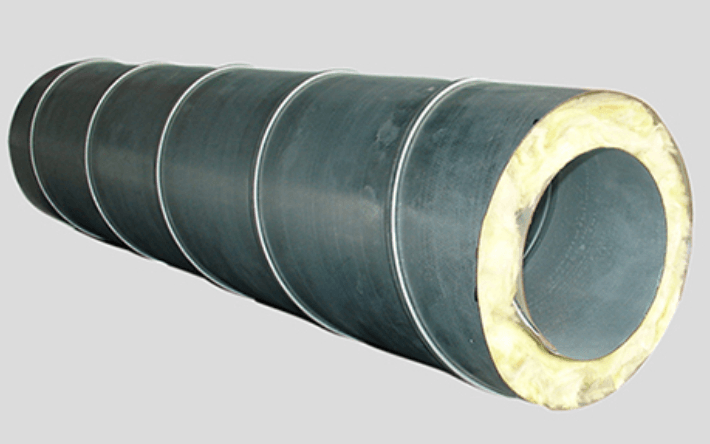

Furthermore, spiral ducts can be insulated with a double wall.

Dual-wall spiral ducts consist of two ducts of slightly different diameters, which differ in 2-5 cm. in diameter.

This space between the ducts has insulation filling.

While it is more expensive, this solution offers several advantages over other insulation methods.

Unlike external, blanket-type insulation, dual-wall insulation is factory installed, eliminating the need for additional fabrication and installment.

Since the outer pipe is metal, it protects the inner parts of the duct, and forms a durable barrier.

Dual-wall stainless steel spiral duct

Unlike with single-wall, interior insulating duct liners, the inner pipe protects the insulation from gradual erosion from the air stream and contains any such eroded particles from entering the air stream.

This allows for higher airspeeds, and makes duct maintenance easier.

What Is Used To Install Stainless Steel Spiral Ducts?

Stainless steel ducts use various clips for installment.

Single rod clips, also called stainless steel spiral duct hangers, are attached to the ceiling, with the duct looped into or attached to.

Single rod hangers

Double rod hangers can also be used to attach the ducts to the ceiling, or lay them on something.

Finally, there are wall-mount brackets that pin the duct to a vertical surface.

Installing options

For additional support, there are stainless steel stands that support the duct from the bottom.

Stainless steel support

How Are Stainless Steel Ducts Maintained?

In commercial applications, regular inspection of ducting is recommended by several standards.

According to most standards, ducts should be cleaned once every few years because ducts can become very dusty and have insects.

What Coatings Are There For Stainless Steel Ducts?

Stainless steel spiral ducts can have a variety of specialty coatings.

For example, a common inner coating is a fluoropolymer.

It is cheaper than some other coatings and provides additional protection against fire, corrosion, high temperatures, and various chemicals.

Fluoropolymer coating

Such coating is great for industrial applications.

Another coating is fiberglass-reinforced plastic, which is impact-resistant and relatively cheap.

For the outer side, there are PVC and PP coatings, which are even better at chemical resistance, but after a while they become brittle, and harbour a smoke hazard.

Plus, it is possible to powder coat the spiral ducts any colour to make them more aesthetic.

Powder-coated stainless steel spiral duct