KDM focused on stainless steel sheet metal fabrication for over two decades. We offer CNC machining, laser cutting, forming, welding, punching, engineering services, among other things.

- Manufacturing-friendly of OEM components

- Ideal for both large and small projects

- Weatherability, machinability, and sustainable

- Available in various finishes, sizes, thicknesses, and grades

KDM Stainless Steel Sheet Metal Fabrication

Stainless steel sheet metal fabrication is the process of transforming the material into a piece. It is used in various tasks, including structural projects, construction equipment, complex telecommunications, and electronics.

The stainless steel sheet metal is extremely machinable and adaptable to bespoke applications. In both small and large projects, KDM has a range of choices in stainless steel sheet form. Various sizes, thicknesses, finishes, and grades are available.

If you have any questions about stainless steel sheet metal fabrication material possibilities, please contact our staff right away!

KDM Stainless Steel Sheet Metal Series

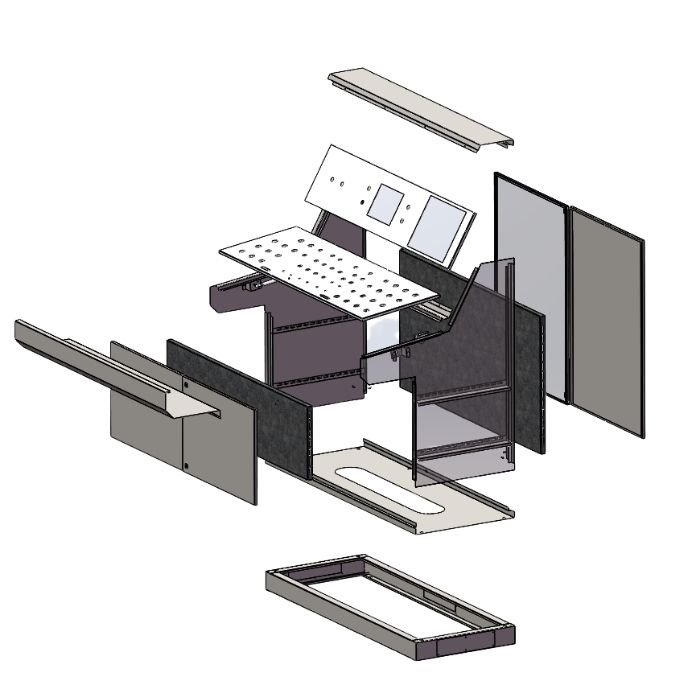

The stainless steel sheet metal box features a hinged cover with a keyed quarter-turn latch. It’s made of stainless 16-gauge steel and meets NEMA 1, 2, 4, 4x, 12, 13, and IP66 standards.

Stainless steel sheet enclosure can be used in various sectors, mainly engineering and electrical applications. Installation is simple. Plus, it provides an extensive range of capabilities, from small to large sizes.

The stainless steel 90° angle bracket features high stiffness and a secure grip. It has tapped holes for attaching industry-standard 25×25, 40×40, or 65×65-mm stages. Can build ultra-rigid multi-axis stage assemblies.

KDM decorative stainless steel sheet metal is resistant to rust, low intensity, dimensionally precise, and durable construction. It is long-lasting, up to 75% stronger than regular sheet metal.

The stainless steel sheet metal auto parts integral components are lightweight. High tensile strength, durability, fine finishing, reliability, and chemical resistance are all features of the series.

KDM stainless steel sheet milk can is made of food-grade stainless steel material. It promotes food safety and prevents contamination. It has no joints crevices and is easy to clean, making it hygienic.

Stainless Steel Sheet Metal By Materials (6)

Stainless Steel Sheet Metal By Finishes (3)

KDM Stainless Steel Sheet Metal Fabrication Advantages

Stainless steel sheet metal can be easily welded and cut. It’s stress and crack-resistant.

Because stainless steel sheet metal is corrosion-resistant, it has a long-term value and investment. Austenitic stainless steel, with type 316 stainless steel being the most often used grade in severely corrosive situations.

KDM stainless steel sheet metal can tolerate high temperatures. Its resistance to fire and heat adds even more value to long-term investment. They can be used efficiently in boilers, feedwater heaters, valves, and other heat exchangers.

The stainless steel sheet metal can be recycled indefinitely without losing quality. It is maintenance-free; therefore, you can concentrate on creating a fantastic process and product.

KDM Stainless Steel Sheet Metal Materials

KDM has a variety of stainless steel for sheet metal fabrication. Here are some of the quality stainless steel sheet metal for you.

Stainless Steel 301: It is a more affordable option than 304 stainless steel. This lower-cost variety is less corrosion-resistant. Train structural components and appliance enclosures are two of the most common uses.

Stainless Steel 304: It has outstanding formability and corrosion resistance properties, perfect for sheet metal components. Food processing equipment, such as structural bracketing and tanks, are examples of possible applications. Available in different versions: SS 304L & SS304H.

Stainless Steel 316: The addition of molybdenum to this austenitic stainless steel improves corrosion resistance. Furthermore, it is very formable and weldable.

Other material options include 302 Stainless Steel, 309 Stainless Steel, 321 Stainless Steel, 347 Stainless Steel, 400 series, 200 series, Ferritic, Martensitic, and Duplex.

For assistance in choosing the best stainless steel metal sheet for your needs, please contact us instantly!

KDM Stainless Steel Sheet Metal Fabrication Process

KDM offers a wide range of stainless steel sheet metal fabrication techniques. From the most basic to the most detailed made-to-order requirements, we can do it for you. The following list is our capabilities:

- Welding

- Bending

- Cutting

- Forming

- Stamping

- Threading

- Holemaking

- Machining

- Punching

- Bending, etc.

KDM Stainless Steel Sheet Metal Application

KDM supplies stainless steel sheet metal works best in different sectors and applications. Because it comes in various thicknesses and versions, it can be utilized in many industries. We cater:

- Architecture & Construction

- Consumer Goods Manufacturing

- Chemical Processing Industries

- Food and Beverages Manufacturing

- Marine Industry

- Aerospace

- Dairy Industry

- Automotive

- Medical

- Energy

- Heavy Industry

Whether it’s for residential, business, or industrial use, we’ve got you covered.

Choose KDM to Custom Stainless Steel Sheet Metal Fabrication Needs

KDM has specialized in stainless steel sheet metal fabrication for over 20 years. Laser cutting, CNC machining, forming, welding, and engineering services are among our capabilities.

Our fabrication process includes inspecting each component for safety. We can provide certificates of compliance upon request. Our staff can handle stainless steel sheet metal fabrication’s small, large, low, and high production volumes.

We at KDM can custom your stainless steel sheet metal suits best your project needs. From material grade, shape, sizes, surface treatment, and all other aspects, we can help you choose the right one. Whether it’s for business, industrial, or residential, KDM got you covered.

Contact KDM to find out how we can help you with your precision stainless steel sheet metal fabrication needs.

KDM Stainless Steel Sheet Metal Fabrication

For stainless steel sheet metal surfaces, KDM offers a wide selection of surface finishes.

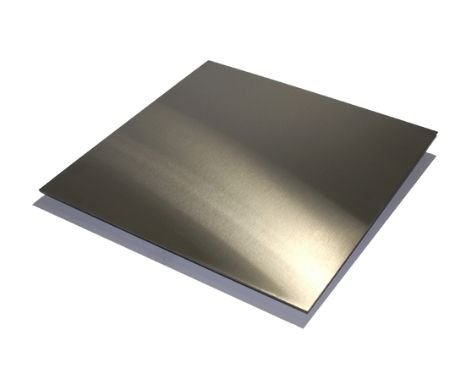

Standard Finish: After bending and shaping, the unit returns to its original state.

Powder Coating: Generates a high-quality, long-lasting surface finish.

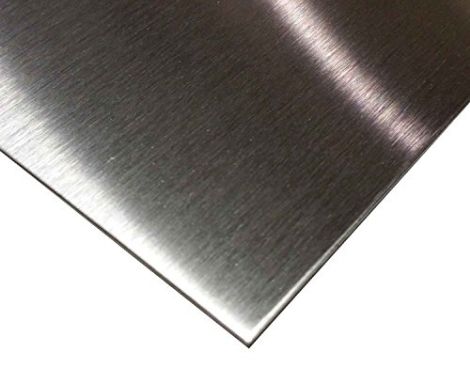

Bead Blasting: Produces a smooth and consistent surface.

Other surface treatments include:

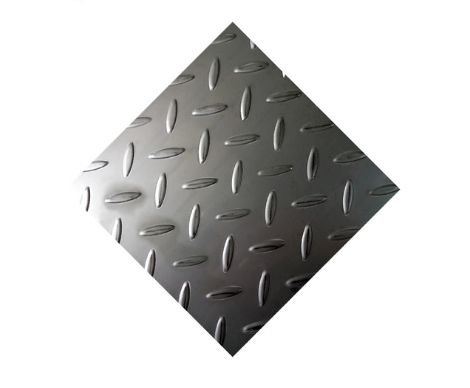

- Embossed

- Perforated

- Polished #4

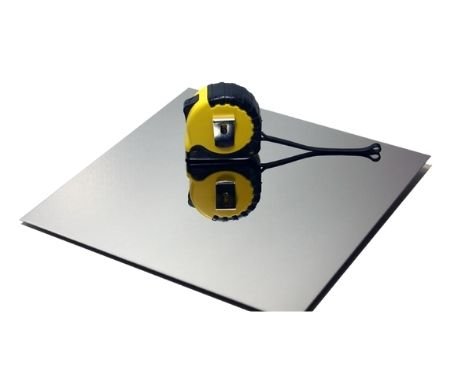

- No. 8 Finish

- Electropolish

- 2B Finish

- Manufacturing friendly

- Anti-corrosion and anti-staining

- Machinability

- Highly recyclable

- Weatherability

- Weldability

- Formability

- Durability

- Structural

- Conductive

- Reflective

OEM & ODM KDM Stainless Steel Sheet Metal Applications

Stainless steel sheet metal is employed in every architecture, building, and construction element. It’s both beautiful and functional, plus prominent.

The stainless steel sheets are corrosion-resistant and low-maintenance. Every part made has precise accuracy, high-quality, industrial-strength part performance, and reliability.

If you work in food production, you should consider food-grade KDM stainless steel sheets. It is made according to stringent international rules and compliance requirements.

Stainless steel sheet, specifically Stainless Steel 304, is one of the most often utilized materials in the fabrication of medical devices. There is a range of medical items in all shapes and sizes.

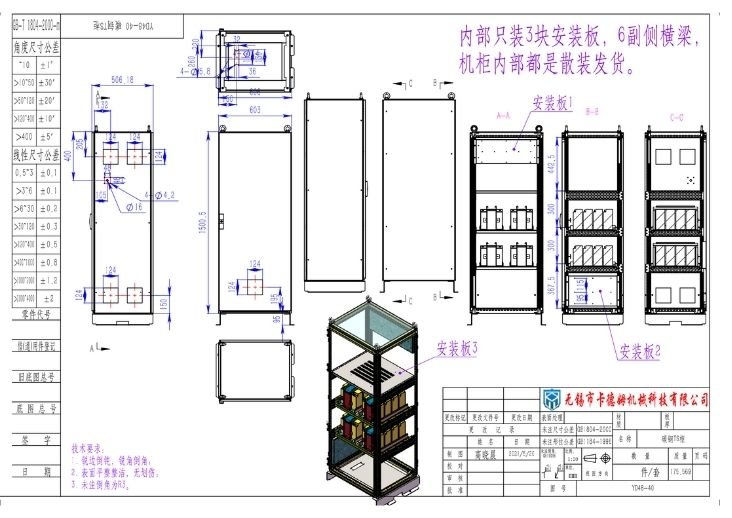

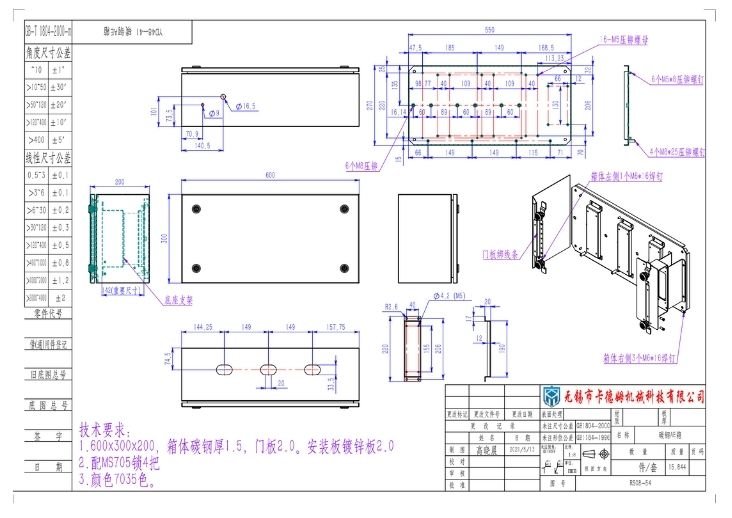

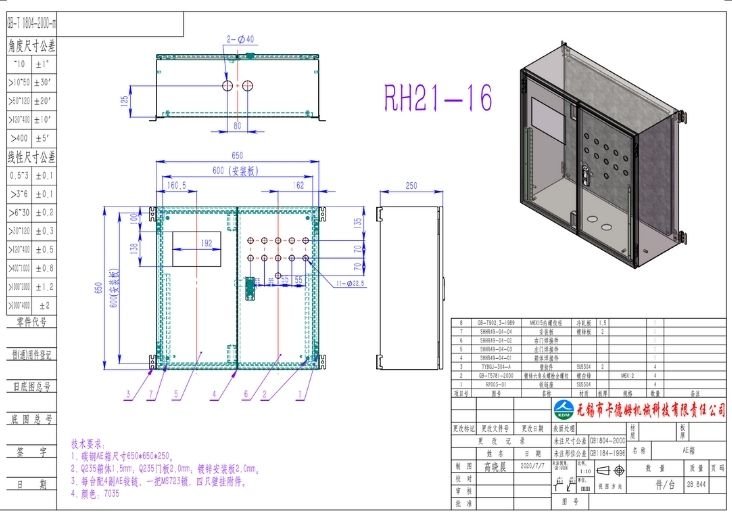

There are tons of electrical components and equipment made of stainless steel sheets. One of them is an electrical enclosure. The sheet exhibits superior corrosion resistance and other good mechanical properties.

Why KDM is Trusted By Over 1000 Global Clients

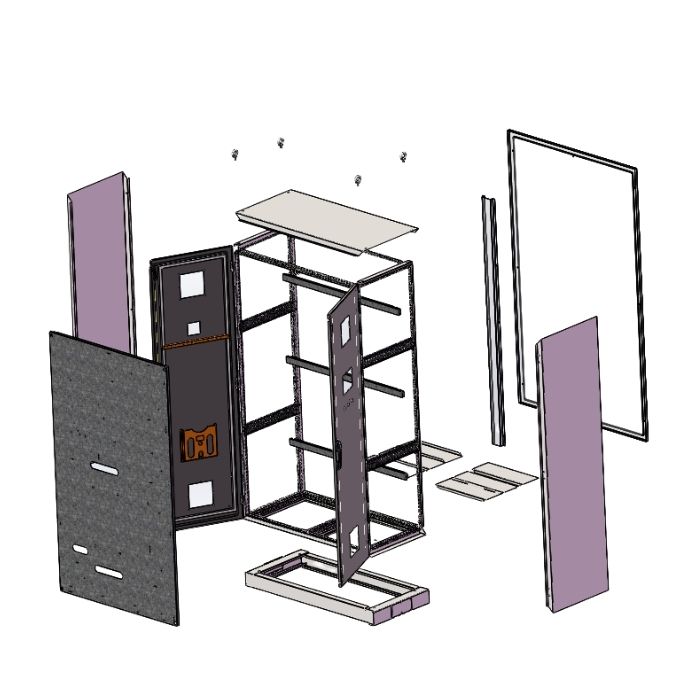

- Enclosure Manufacturing

- 2D Drawing

- 3D Drawing

4000W high performance laser cutting machine, +/- 0.05mm accuracy. No burr, no scratching.

Multi-Functioning flexible welding equipment, high accuracy, no deformation.

Expert assembling team, consistent assembly quality on every KDM enclosure