Avail Our High-Grade Stainless Steel Ducting KDM will be Your Stainless Steel Ducting Reliable Manufacturer.

- Durable Stainless Steel Ducting

- Excel in Extreme Temperature Environments

- Designed for Optimum Sealing

- RoHS Certified

Contact us now.

90 Degree Elbow, 10″ Stainless Steel Ducting has the measured width of 22-1/4″, and duct fitting size of 10″. Also, we can tailor it based on your specifications. These are safe and sturdy that comply with standards.

100mm Stainless Steel Air Vent Ducting is a smooth, fully welded item ideal for most fume, mist, dust collection applications. They are easy to relocate and uninstall as your needs change. A quick-fit ducting is easy to clean, remove, and reinstall without devices or tools needed.

150mm Stainless Steel Wall Air Vent Ducting designed with insect-proof mesh effectively prevents insect,mouse birds from entering. KDM offers a large selection of stainless steel ducting to exceed both safety regulations and your job’s requirements.

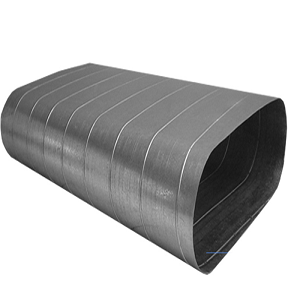

Rectangular Stainless Steel Ducting has acquired the VDI 3803 or the Optimised Airflow Ability to withstand pressure compliance. These are manufactured from 0.5mm-1.5mm thickness.

Spiral Stainless Steel Ducting is available from 80 to 1600mm diameter. These round spiral ducts have an excellent smooth effect. KDM is expert in manufacturing all your needs.

Stainless Steel 16inch Duct Fitting Diameter provides an easy connection to other components with the use of a barrel-type clamp. You can easily and quickly take it apart for cleaning.

Stainless Steel Ducting Elbow is a draft-free and energy-efficient solution. The materials utilized are sustainably ventilated and fire approved. It is good for indoor climate conditions. Designed with hemispherical hood, rainproof and windproof features,

Stainless steel Fire-Rated Duct is manufactured from high-standard stainless steel. This has been fully assessed and tested. It is significant to use fire-rated ducts to reduce the risk of fire.

Related Products of Stainless Steel Ducting

Send Your Inquiry on KDM Stainless Steel Ducting Now.

- 100% High-Quality Stainless Steel Productions

- Standard Proven Solutions

- Reliable and Authentic Management System

- ISO9001 Certified Supplier and Manufacturer

Stainless Steel Ducting

You must be more observant especially when sourcing the accurate and functional stainless steel ducting to assist your project business.

Worries no more! KDM a designer and manufacturer of industrial ducts made from high-grade stainless steel. We have the capabilities including layout, cutting, drilling, forming, restoration, grouting & engineering.

For all we know, stainless steel materials indicated with high-corrosion resistance, low moisture absorption, high chemical resistance, and excellent insulating and electrical properties. These have a better dimensional length and compressive strength.

KDM stainless steel ducts are ventilation commonly utilized for transporting gas. These are the municipal infrastructure which essentially allows air circulation and lessens the concentration of disadvantageous gases.

Our series of KDM stainless steel ducting mostly used in construction and industrial projects.

Usually utilized in the field of application such as in the purification system for the sterile workshop of medicine or food; purification systems for a dust-free plant of electronics industry; the central air conditioning systems for hotels, shopping malls, hospitals and many more.

Many industrial sectors used our high-standard finishes. You can employ it also to your healthcare, automotive, and other commercial applications.

As a premier manufacturer of stainless steel ducts, KDM can masterly produce the various types, different thicknesses, dimensions and color finishes of these stainless steel ducts. Many styles for your choices.

KDM stainless steel ducts are available in a wide variety of selection. Like T-branches, in-cuts, and tap in ducts. It is also obtainable in cut-to-length, slit-to-size, polished, blanked or sheared measurement.

Also, we can custom your specifications to meet your standard and demands on stainless steel. Just send it to us, and expect the 100% perfect assembly.

For the finish options, we highly offered our 90 Degree Elbow, 10inch Stainless Steel Ducting, Rectangular Stainless Steel Ducting, Stainless steel Fire-Rated Duct, and much more. Shop here! And experienced the best products.

All of the KDM stainless steel ducts undergo strict quality examining and inspections prior to the shipping process. KDM stainless steel ducting includes shearing, bending, punching, welding, powder coating and finishing. KDM knows all about your needs!

All of the KDM stainless steel exceeds the various industry-standard like (VDI 3803) optimized airflow ability to withstand pressure, DIN EN 1507 or the tightness class, and the hygiene requirements (VDI 6022).

For your orders, we offer a free sample for you to check the quality. Our factory has the full stock of KDM stainless steel ducting ready to deliver within a short period on time and on budget. ODM and OEM orders are also accepted.

All of our outputs are produced by our skilled and professional engineering team. Although we achieve brand name products, our rates are very competitive and affordable. Because of this, clients from all over the world encouraged to purchase our excellent products, because of our best price.

Aside from offering stainless steel ducting, we can also accommodate Stainless steel Flame Diffuser, Stainless steel Air Louver, Stainless steel Ventilation Damper, Stainless Steel Grilles, and more.

When choosing the right manufacturer, you can always count on KDM for your stainless steel solutions.

Talk to our expert stainless steel ducting team now. We provide 24/7 online assistance.

Ultimate FAQ Guide to Stainless Steel Ducting

- How Does A Duct System Work, And Why Is It So Important?

- Why Use Stainless Steel For Ducts?

- What Grade Of Stainless Steel Is Used For Ducts?

- What Gauge Of Stainless Steel Is Used For Ducts?

- What Types of OfStainless Steel Ducts Are There?

- What Ducting Supply Systems Exist?

- What Are Standard Duct Sizes?

- How Can Stainless Steel Ducts Be Connected?

- What Air Terminals Are There For Stainless Steel Ducts?

- What Do Stainless Steel Duct Dampers Do?

- What Additional/Miscellaneous Features Can Stainless Steel Ducts Have?

- Where Is Stainless Steel Ducting Used?

- What Rainproof Solutions Are There For Stainless Steel Ducts?

- What Are Some Assembly Methods For Stainless Steel Ducts?

- Should I Insulate Stainless Steel Ducts?

- What Is Used To Install Stainless Steel Ducts?

- How Are Stainless Steel Ducts Maintained?

- What Coatings Are There For Stainless Steel Ducts?

How Does A Duct System Work, And Why Is It So Important?

The duct, or air distribution, the system used in cooling and heating a building or home.

It is a collection of tubes that distributes the heated or cooled air to the different rooms.

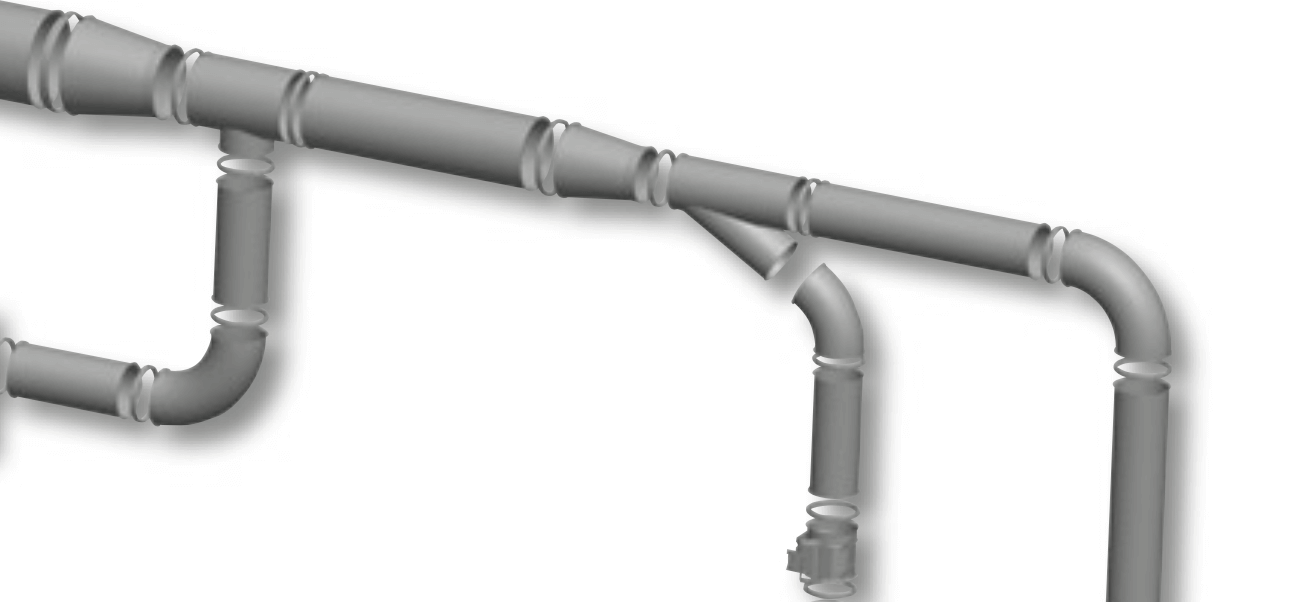

The duct system—of round or rectangular tubes—is designed to supply rooms with conditioned air, and to circulate the same volume of air back to the heating, ventilation, and air conditioning (HVAC) equipment.

Stainless steel ducting model

Typical air-duct systems lose 25-40% of the heating or cooling energy via the duct itself, so through leaks.

Thus, bad ducting makes the HVAC system work harder, thus increasing your utility bill.

The duct system has two main air-transfer systems, which are supply and return.

The supply side delivers the conditioned air to the home through individual room registers.

The return side withdraws inside air and delivers it to the air handler of your central system.

All of the air drawn into the return duct(s) is conditioned and should be delivered back through the supply registers.

Ducts work on the principle of air pressure difference.

If a pressure difference exists, air will flow from an area of high pressure to an area of low pressure.

Stainless steel ducting

The larger this difference, the faster the air will flow to the low-pressure area.

This pressure difference may be achieved with vents and other mechanisms.

Ducts are thus important to keep air circulating and room temperature optimal and comfortable.

Why Use Stainless Steel For Ducts?

Stainless steel is durable to all kinds of conditions, like temperature changes, humidity, impact, and other.

Stainless steel will not rust, serving you for a long time.

Although, it can get stained with heat, salt, smoke, and mineral deposits—these will not shorten its life.

Plus, stainless steel is non-porous, which means that mold and bacteria will not proliferate in the material.

Thus, stainless steel ducts are safe against spreading mold and bacteria through the ventilation.

What Grade Of Stainless Steel Is Used For Ducts?

Stainless steel ducts can be made with steel grades 304, 302, and 316.

Stainless steel is created by adding chromium, nickel, and molybdenum in different proportions to the iron-carbon alloy.

Steel grades differ in the content of all additives.

316 stainless steel provides the best protection against salt spray, certain acids, and high temperatures.

Grade 316 is slightly stronger and resistant to saline and acidic water because of molybdenum.

Stainless steel

This is why 316 is used more for ducts in harsher environments.

But grade 304 is cheaper and more common in general use.

This is why most stainless steel ducts use 304 steel.

This grade is durable as well.

Grade 302 has the same corrosion-resistant qualities as grade 304, but grade 302 is slightly tougher and more impact resistant because it has a higher concentration of carbon.

There is also 316L or 304L.

Grades 316L and 304L have a lower carbon content, making it a little bit stronger.

However, they are not very frequently used on the market.

Stainless steel is great for ducts because it is a durable material resistant to corrosion and most other conditions.

Besides stainless steel, ducting can use fabric.

Stainless steel ducts expand and contract as they heat and cool—respectively.

Fabric joints are often used to absorb this change.

Fabric joints should also be used where the duct connects to the air conditioner.

What Gauge Of Stainless Steel Is Used For Ducts?

Lower steel gauges are stronger, thicker, and more expensive.

Stainless steel ducts usually have a gauge of 26-16, or 0.5-1.5 mm in thickness.

Stainless steel gauge

What Types of OfStainless Steel Ducts Are There?

There are three common classifications of ducts: conditioned air ducts, recirculating-air ducts, and fresh-air ducts.

Conditioned stainless steel ducts carry air from the air conditioner and distribute it around.

Recirculating air ducts take air from the conditioned space and distribute it back into the air conditioner system.

Fresh air ducts bring fresh air into the air-conditioning system from the outside.

Typical stainless steel duct system

Ducts commonly used for carrying air are of a round, square, or rectangular shape.

The most efficient duct shape is round, based on the volume of air handled per perimeter distance.

This is because less material is needed for the same capacity as a square or rectangular duct.

Square or rectangular ducts fit better for building construction.

Duct shapes

They fit above ceilings and into walls and are much easier to install between construction elements like joists and studs.

Plus, there are spiral ducts.

These are great to prevent energy loss since the spiral design self-seals, which also ensures a lesser pressure change.

Interestingly, spiral ducts are also easier to maintain and are cheaper to make.

Another type of duct is the exhaust duct, which dumps air from the inside to the outdoors.

Spiral duct

However, rectangular and round designs are usually sturdier.

Furthermore, ducts can be categorized based on air velocity and pressure: high, medium, low.

Low velocities include up to 2000 CFM, high velocities go above 2500 CFM, while medium velocities are between those.

High-velocity ducts are cheaper upfront but will require friction maintenance.

Small buildings 2-3 stories/floors high typically use low-velocity ducts, while tall buildings use high-velocity ducts.

What Ducting Supply Systems Exist?

Some of the supply systems include the following: individual round pipe, extended plenum, reducing trunk, and a combination of multiple systems.

Individual pipe ducts are just regular pipes.

The extended plenum supply system is when there is a box-like main duct with many smaller ducts extending from it.

Extended plenum system

Reducing trunk systems are similar to plenum systems, but it narrows the duct width as it goes.

Reducing trunk systems are commonly used in commercial applications.

Reducing the trunk system

What Are Standard Duct Sizes?

The size of ductwork for HVAC systems depends on the size of the unit, system installation design, and heating or cooling space considerations.

Local building and residential code requirements also provide sizing guidelines.

The duct size must adequately handle airflow supply and return in order for an HVAC system to operate at optimal levels.

The correct sizing of ducts is determined by the optimal airflow based on cubic feet per minute as well as the velocity of air provided by other components of the HVAC system.

Rectangular or square ducts come in standard sizes that typically range from 3-by-7 inches (7-by-18 cm.) to 35-by-40 inches (89-by-102 cm.).

Meanwhile, round ducts come in standard sizes ranging from a diameter of 4.9 inches to 41 inches (12 to 104 cm.).

Duct sizes

Ducts have their own sizing measurements, which are called CFM, or cubic feet per minute.

Different dimensions of ducts, as well as their shape changes the CFM, which you have to look up.

For example, a 4×6 inch rectangular duct will have the same CFM—of 100—as a round duct with a diameter of 5.33 inches.

Moreover, if you need a complex ducting network, where the parts will range in size and diameter, then you can request adapters.

Furthermore, when stating your requests for duct dimensions, there are certain limitations.

If you are ordering 30- or 45-degree branches, then the values should be as follows: A=C≥B.

Duct scheme

How Can Stainless Steel Ducts Be Connected?

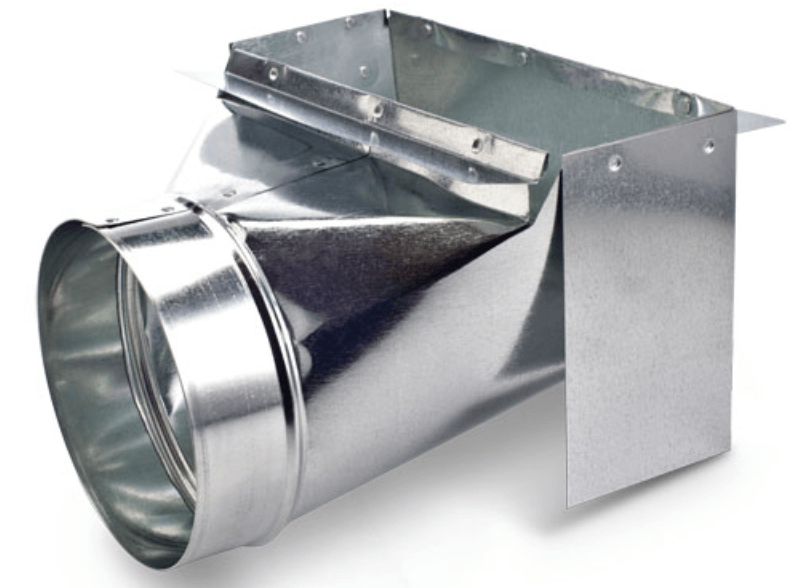

Besides adapters, the ducts can be connected with elbows, boots, collars, reducers, and increasers.

Elbows can be pressed or segmented, and they provide a smooth curve for round ducts.

Segmented elbows allow a more fine-tuned curve.

Segmented elbow

Boots connect a duct to the final opening, such as a register, being a sort of adapter between openings and ducts.

Stainless steel boot

Collars are used to transition from one duct to another.

They can be used between 2 round, 2 rectangular, or even 1 rectangular and 1 round ducts.

Some collars can also transition between a solid duct and a flex duct.

To do this, collars have different edges for different purposes.

Stainless steel duct collar

Collars can serve as size adapters as well, functioning as reducers or increasers.

These adapters can be eccentric or concentric.

Eccentric means that only one side is sloped, while concentric means that both sides are sloped.

Choosing which depends on how quickly you need airflow to be adapted.

Starter collars are specifically used to connect the main plenum duct with branching ducts.

Another connector is a ball joint that is useful for connecting flexible ducts.

Plus, a ball joint is a versatile connector, the angle of which can be changed according to need.

Stainless steel ball joint

Besides these connecting accessories, there are various ways of welding ducts together.

To split up airflow, the ducts can be connected as a V, a T or as a crossroad, depending on how many directions you need to split the airflow into.

Plus, the ducts can just branch out laterally, at different angles: 30, 45, 60, as well as any angle in between depending on your specifications.

Connecting stainless steel ducts

What Air Terminals Are There For Stainless Steel Ducts?

Room openings to ducts have several accessories that control the airflow and keep large objects out of the duct.

These devices are called diffusers, grilles, and registers.

Diffusers deliver fan-shaped airflow into a room.

Grilles control the distance, height, spread of air-throw, and amount of air.

Grilles cause some resistance to airflow because their bars block about 30% of the air.

Registers are also vent covers, but they have dampers to open and close the vent to control airflow.

Registers are used to deliver a concentrated air stream into a room, and many have one-way or two-way adjustable air stream deflectors.

Diffuser, register, grille

If you need to adjust vent airflow, then a register is helpful.

If you need a simple generic vent cover, then a grille is perfect, but if the vent cover is for a system vent, then air return should be used.

Registers are also usually placed on floor vents, whereas other vent covers go on the walls and ceilings.

What Do Stainless Steel Duct Dampers Do?

Dampers balance airflow and shut off or open certain ducts for zone control.

Dampers can be located in the grille or in the duct itself.

There are three types of dampers used in air-conditioning ductwork.

These are: butterfly, multiple-blade, and split damper.

Butterfly dampers have a bifold construction, and are mainly used in round ducts.

They are also called throttle valves.

Butterfly damper

Multiple-blade dampers allow more fine-tuned airflow control, and are perfect for rectangular ducts.

Multiple-blade damper

Finally, split dampers are mostly used in ducts that are branching out.

They help split the airflow before it gets to the duct junction, creating a smoother and more efficient transition.

Split damper

Split dampers also have adjustable handles on the side.

These dampers can be regular—manual—,pneumatic, or electric.

Another damper is a blast gate damper, which is a very simple damper, mainly for manual use.

Blast gate damper

They are suitable for any type of duct or connector and are easy to install.

Furthermore, there are fire dampers.

Automatic fire dampers should be installed in all vertical ducts, which can carry toxic fumes and fire.

Fire dampers are usually fail-safe units.

Some are spring-loaded to close, while others are weight-loaded to close; both are held open with a fusible link.

The heat from a fire will melt this link, letting the damper close under gravity, weights, or springs.

Fire damper

Some dampers can also have a thermal sensor with an actuator instead of a fusible link.

Fire dampers must be inspected and tested at least once a year to be sure they are in proper working order.

Similar to dampers, ducts have turning vanes, which are basically small dampers used to help airflow turn at corners and curves more smoothly and to avoid turbulence.

Stainless steel turning vane

What Additional/Miscellaneous Features Can Stainless Steel Ducts Have?

There can be false air valves, which introduce unconditioned air into the duct to balance the system pressure.

Various air intake and exhaust valves are considered to be a part of the false air valve system.

They are inconspicuous and are perfect for wall or ceiling installation.

Stainless steel false valve

Another feature is a stainless steel mesh that protects the duct from insects, mice, and small birds.

Insect-proof mesh and bullnose hood

Such mesh is often coupled with a bullnose hood that directs airflow 90 degrees from the surface of the duct.

Vertical ducts can also have a dust sweep-up, which is a portion of the duct that lies on the floor, and you can sweep the dust and debris from your floor into the duct.

Stainless steel dust sweep-up duct

This is great if you have a garage or a workshop that needs frequent cleaning, and you have/plan to install a separate dust duct.

If you want a kitchen vacuum duct, then you may be interested in stainless steel duct sputniks.

A duct sputnik is a suction unit that combines multiple suction ducts.

Stainless steel duct suction sputnik

Another interesting feature that some ducts can have are access doors, which are used to maintain the ducts.

The doors can have handles, or just screws.

Plus, they can be flat or curved, oval, or rectangular.

Duct access door

Where Is Stainless Steel Ducting Used?

Stainless steel ducts are needed everywhere.

All buildings have vents and air circulation systems, so ducts are used in every building, be that residential, industrial, or commercial.

More specifically, ducts and their various features are used in tumble dryer vent pipes and hoses, bathroom vent extractors, air conditioning units, commercial kitchen fan vents, all home wall vents, heat transfer and ventilation systems, gas-electric dryers, cooker hood extractors, and the list goes on.

What Rainproof Solutions Are There For Stainless Steel Ducts?

If a portion of your ducting is exposed to the outdoors, or can be susceptible to condensation, there are a few design features for that.

Vertical discharge cowls, or jet caps, are done for vertical ducting that goes outside.

This entails various pipes and such.

Stainless steel vertical discharge cowl

These jet caps have an inner funnel that collects rainwater, letting it out through a tube, while air bypasses this funnel.

Besides jet caps, there are other kinds of caps for both vertical and horizontal ducts.

Horizontal ducts have caps to direct airflow, but also protect the duct from any drippings.

Stainless steel duct cap

With the caps, there are also louvers that protect from drippings and direct airflow.

Plus, louvers protect from some debris entering the duct or getting flown out of it.

Stainless steel louvers

What Are Some Assembly Methods For Stainless Steel Ducts?

Some assembly parts that are used for stainless steel ducts include spigots, pull rings, and flanges.

Spigots are basically collars and connect ducts by just fitting them together.

Pull rings have a groove in the middle—usually with a rubber insert—, where the edges of two connecting ducts are placed.

Pull-ring assembly

Then, the pull ring is tightened and it keeps the edges close together.

A flange is an extended edge of a duct.

Flange assembly

It has holes for screws; connecting ducts both should have flanges, and they are tightened together with screws.

Furthermore, we can include rubber gaskets if you need them.

As well, there are rubber flanges, which are resistant to oils, petrol, acids, and bases.

Should I Insulate Stainless Steel Ducts?

As already mentioned, as the air travels along the duct, it loses its heat of coolness, so insulating a duct prevents that.

Moreover, duct insulation helps prevent not only energy waste, but also leaks, temperature drops, and condensation buildup on the outside of the duct.

Ducting insulation

A good duct insulation should have an R value of about 5-8.

R value measures how well a layer of insulation resists the conductive flow of heat.

Duct insulation usually consists of foil-faced fiberglass and metallic tape.

Ducts can also be insulated with fiberglass, but this harbours a health concern.

What Is Used To Install Stainless Steel Ducts?

Stainless steel ducts use legs and clips for installment.

Legs can be V-shaped, attaching to the duct along the midline.

Legs can also be straight, so you can use 2 legs attaching to the sides of the duct.

Ducts can be either standing, or they can be wall-mounted, or hanging.

Clips are versatile in use—they can also be used to strengthen connections of ducts—but they can also be used to install ducts to a wall or ceiling.

Stainless steel clip

How Are Stainless Steel Ducts Maintained?

In commercial applications, regular inspection of ducting is recommended by several standards.

One standard recommends inspecting both supply and return ducts every 1–2 years.

Air-handling units should be inspected annually.

Another standard recommends visual inspection of internally-lined ducts annually as well.

Inspections are typically visual, looking for water damage, mold, or dust.

When visual inspection needs to be validated numerically, a vacuum test (VT) or deposit thickness test (DTT) can be performed.

A stainless steel duct with less than 0.75 mg/100m2 is considered to be clean according to the NADCA standard.

There are many different standards as well.

However, according to most standards, ducts should be cleaned once every few years because ducts can become very dusty and have insects.

What Coatings Are There For Stainless Steel Ducts?

Stainless steel ducts can have a variety of specialty coatings.

For example, a common inner coating is fluoropolymer.

It is cheaper than some other coatings and provides additional protection against fire, corrosion, high temperatures, and various chemicals.

Fluropolymer coating

Such coating is great for industrial applications.

Another coating is fiberglass-reinforced plastic, which is impact-resistant and relatively cheap.

For the outer side, there are PVC and PP coatings.

These are even better at chemical resistance, but after a while they become brittle, and harbour a smoke hazard.

Plus, it is possible to powder coat the ducts any colour to make them more aesthetic.

Specifically, airflow terminals are usually painted.