Looking for a World-class Solid insulated Switchgear for your Business? KDM is Leading Solid insulated Switchgear Supplier in China

- Long working life, reliable for heavy operations Solid Insulated Switchgear

- Offer maximum control and protection on electrical equipment

- All in one packaging solution for any industrial electric system needs

- Raw materials selected carefully according to the intended application

For inquiry, contact KDM!

As one of the leading Switchgear manufacturer in China, KDM supply wide variety of 12kV Solid Insulated Switchgear. Thus, as a reliable supplier certified with ISO 9001 certification, you can ensure with the quality product we deal with.

All Solid insulated MV Switchgear solidly manufactured with our advanced technology. We are able to offer compact, reliable, less-maintenance and type-tested units.

Our 35kV Solid Insulated Switchgear is applicable in wide array of industrial electric power system applications. If you want an economical kind of product yet highly reliable and efficient, you can count on KDM 35kV Solid Insulated Switchgear.

Are you looking for a guaranteed-safe, quality-tested 5kV Solid insulated MV Switchgear? KDM is your top choice. We have an extensive range of stated products that fully comply local and international standards.

KDM, as a professional manufacturer, we design compact solid insulated switchgear along with the customer’s preferences. It includes where they installed units, the area so that in the production our engineers pay more attention with the main features.

Solid insulated Ring Main Unit made by KDM is highly compact and environmentally-friendly. The units stand as the best solution for any power distribution.

SVP Solid insulated Switchgear well-built design makes it eliminate quickly the power shortage interruption duration and any other power deficiency. KDM highly trained engineers fabricate product into the customer specification.

38kV solid insulated switchgear offered by KDM delivers long-lasting functionality. You can benefit from low maintenance costs with this reliable switchgear. Thus, you can ensure a safe facility as a unit enhance the safety of the plant.

KDM SF6 Solid insulated Switchgear comes in different sizes, shapes, and configurations. We have up to date units for your specific requirements. KDM can help you find a reliable yet cost-effective products right for your needs.

Related Product with Solid insulated Switchgear

Send Your Inquiry on KDM Solid insulated Switchgear Now

- Custom Solid insulated Switchgear to meet your specification

- Well-trained engineers expert in project designing and engineering

- Built from high-grade raw materials and modern technology

- Cost-effective yet functional products

KDM Solid Insulated Switchgear

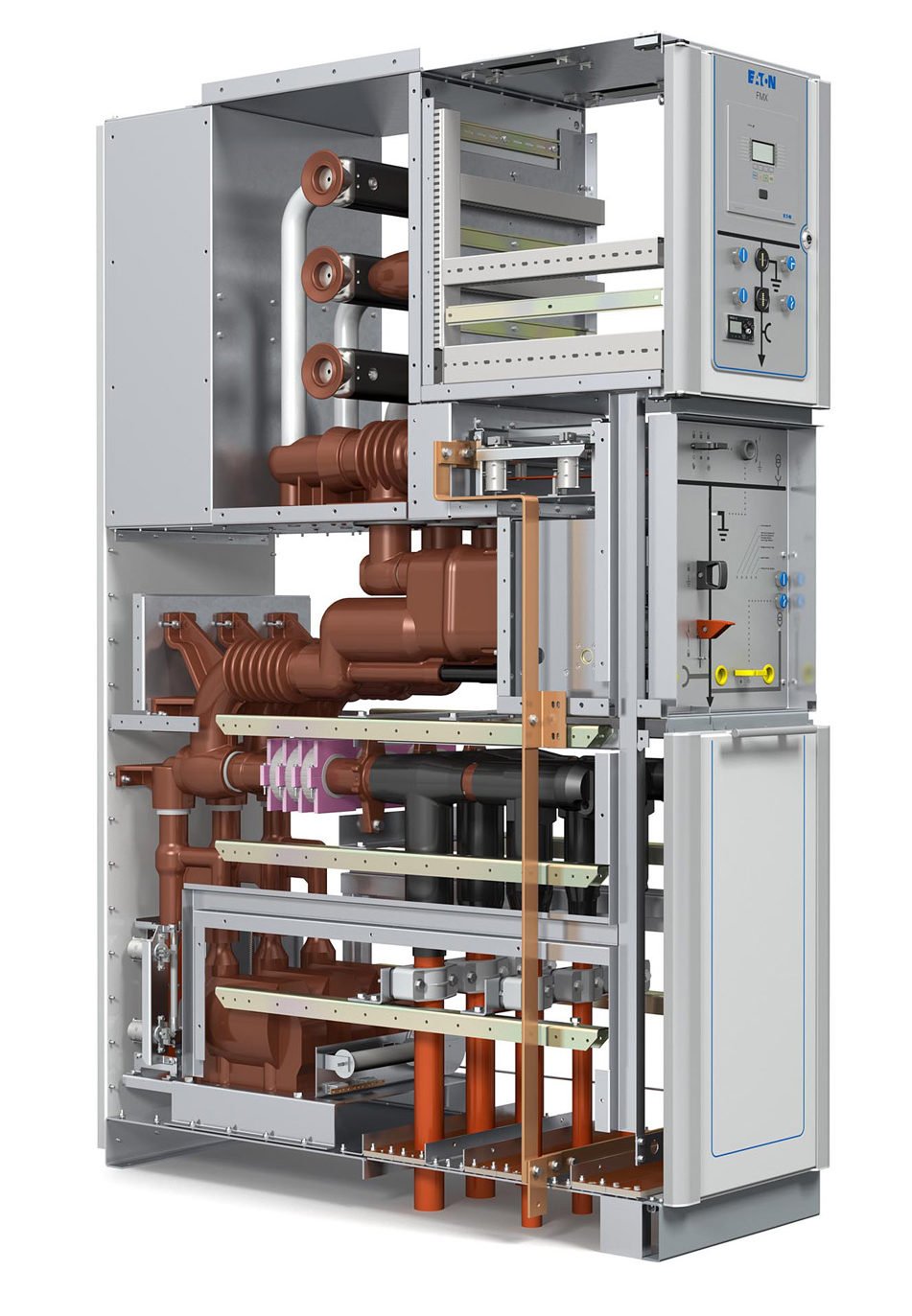

KDM solid insulated switchgear is designed were space-saving and safety required. It is fully loaded with functional features that make it highly meet the modern and upgraded systems. This is built using high-grade raw materials and modern technology. Consequently, we are continuously providing highly reliable solid insulated switchgear into the increasing range of applications.

All Solid insulated switchgear are constructed specifically based on environmental and person-in-charge safety. The unit is truly nature-friendly, thus it provides high performability. Our solid insulated switchgear is compact-in-size, ultra-functional, safe, robust and highly meets the main testing. Plus, it requires less maintenance in maintaining safety and performance. In any substation or distribution boards, we have solid insulated switchgear meet your standards.

KDM solid insulated switchgear is manufactured and developed by our team of experienced and knowledgeable experts that is skilled with this domain. They pay more attention to the project designing and its intended applications. Over a decade in the production, our engineers gained rich understanding and a higher level of mastery to provide world-class electric units. Together with our modern types of equipment and manufacturing techniques, we are able to produce innovative, upgraded products. With all the responsibility, from engineering, production to delivery, you can rely on KDM. We have equipped with a skilled and dedicated team that are expert with their area of responsibility.

Our solid insulated switchgear comes in a broad range. We have solid insulated switchgear intended for indoor and outdoor applications. Also, we have units that come with various voltage ratings. Offered items, individually outstand with their particular applications. Any standard testing you require, our solid insulated switchgear is your choice. It meets the necessary certifications and passed the internal tests during production. In KDM, our range of solid insulated switchgear comes in various sizes, styles, materials, and unique features.

Whether applied in the industry or utility sector, KDM solid insulated switchgear is great solution to reduce space usage and save cost. Under the increasing market technology, KDM design solid insulated switchgear which are technology-tested and time-tested. Since the last 10 years, our development of authentic solid insulated switchgear rides on with increasing market standards. KDM built a reputable and trusted relationship over our customers in different fields. Our main goals are to fully aim every order sent on us. With excellent services, we are able to build long-lasting relationships with our clients.

Through more than a decade of experience and expertise in solid insulated switchgear technology, we are able to develop products to meet any required configuration. Compared to any other switchgear, our solid insulated switchgear outstands of its efficiency, weightless, environmental-friendliness, higher reliability. KDM is not just professional with solid insulated switchgear but also leading when it comes to manufacturing such related products. This includes high voltage switchgear, sf6 switchgear, outdoor switchgear, double-ended switchgear and among others. KDM is truly your reliable manufacturer and supplier in China.

Do you have any technical question, or are you looking for an offer? Don’t hesitate to contact us today!

Solid Insulated Switchgear: The Complete FAQ Guide

Are you looking for solid insulated switchgear integrated with vacuum circuit breaker, switch for load break or any other electrical accessory?

This guide covers all the basic and advanced concepts of solid insulated switchgear.

And by reading until the end, you’ll definitely by an expert in switchgears components.

- What is a solid insulated Switchgear?

- What should you consider when purchasing a Solid Insulated Switchgear?

- What is the function of a Solid Insulated Switchgear?

- What are the Applications of a Solid Insulated Switchgear?

- What are the benefits of using a Solid Insulated Switchgear?

- Are there any drawbacks of using a Solid Insulated Switchgear?

- What is the voltage rating for a Solid Insulated Switchgear?

- How does a Shielded Solid Insulated Switchgear compare to a Normal Solid Insulated Switchgear?

- What are the Insulation Materials for Solid Insulated Switchgear?

- What are the Components of a Solid Insulated Switchgear?

- How does a Solid Insulated Switchgear work?

- What are the Safety features of a Solid Insulted Switchgear?

- What are the Quality Standards for a Solid Insulated Switchgear?

- What are the Test requirements for a Solid Insulated Switchgear?

- What are the types of a Solid Insulated Switchgear?

- How do you Troubleshoot Solid Insulated Switchgear?

- What are the Specifications of a Solid Insulated Switchgear?

What is a solid insulated Switchgear?

A solid insulation switchgear is a type of switchgear that uses epoxy resin as its main insulation material.

Insulated switchgear

What should you consider when purchasing a Solid Insulated Switchgear?

You need to consider the following factors when purchasing a solid insulated switchgear:

· Efficiency

Your solid insulated switchgear should perform efficiently with minimal interference.

Efficiency involves maximum productivity and continuity in your application.

You can enquire from your manufacturer on the efficiency of the solid insulated switchgear.

· Manufacturer’s Reputation

The reputation of your manufacturer determines the quality of the solid insulated switchgear.

A reputable manufacturer can offer you all the relevant information you may need concerning your switchgear.

They are also ready to repair and maintain your solid insulated switchgear in case of a breakdown.

· Future Allowance

The average operating duration for a solid insulated switchgear is 30 years.

It is therefore critical that your solid insulated switchgear is able to handle any development that occurs during this period.

Such developments may include expansion of your production.

· Solid Insulated Switchgear Material

You need to consider the material that the manufacturer used for your solid insulated switchgear.

This is because of the availability of different material in the market with different applicational areas.

· Safety

An effective solid insulated switchgear should offer safety to both the operator and the electrical equipment.

Safety ensures that there is minimal hazard occurrence during the operation of the Solid Insulated Switchgear.

You can check this by going through the specifications and consulting an expert.

· Space

For the effective performance of your solid insulated switchgear, there is need to ensure you have enough space.

Also, the size of the switchgear should guarantee that it will fit your space for optimum performance.

Space should allow for maintenance movements of the solid insulated switchgear.

· Warranty

A warranty from your manufacturer guarantees you of the quality production process and offers you a peace of mind.

It allows you to return the switchgear to your manufacturer for repair and maintenance in case of a breakdown as per the warranty conditions.

What is the function of a Solid Insulated Switchgear?

The functions of a solid insulation switchgear include:

Solid insulated switchgear

- It has devices that help in the distribution and control of electric current.

- Electrical faults and general maintenance.

- Connection and disconnection of electric induction motors

- Performing quantitative and qualitative power supply measurements.

- It has devices that offer protection against overloading and short circuits. This helps in ensuring the safety and functionality of the electrical equipment.

- Isolation of electrical circuits from the main power source, which helps in safe clearance

What are the Applications of a Solid Insulated Switchgear?

The applications of a Solid Insulated Switchgear are:

· Urban Installations

Solid Insulated Switchgear appeals for use in the real estate industry where the price is a critical component.

· High Voltage Installation

In installations where high voltage is a requirement, solid insulated switchgear is a critical element.

This is because it does not utilize a large space.

· Environmentally Sensitive Installation

The features of a Solid Insulated Switchgear allow for its use in environmentally sensitive installation.

Such features include resistance to lightning due to the quality material used.

The enclosure is another feature that makes it ideal for this use.

· Underground Stations

They are ideal for use since they allow for a metal enclosure.

What are the benefits of using a Solid Insulated Switchgear?

The following are the benefits of a Solid Insulated Switchgear:

· Environmentally Safe

A solid Insulated Switchgear is environmentally safe.

This is because it does not emit poisonous gases to the environment.

It also does not react with the environment.

· Reliable

The use of a Solid Insulated Switchgear offers reliability.

This is due to the fewer outages time and maintenance procedures that you will incur when using it.

Its maintenance procedures do not take much of the time which ensures there is continuity of its operation.

Also, maintenance is not a regular procedure since it takes time before you perform one.

· Less Maintenance Cost

A Solid Insulated Switchgear has less maintenance cost due to the occurrence of fewer blackouts.

Also, the components of the Solid Insulated Switchgear do not react with each other or with the environment.

This increases their durability and reduces the overall cost.

· Minimizes on Space

Solid insulated switchgear uses less space for installation than other types of switchgear.

This makes it ideal for use in areas where space is a limiting factor.

· Easy to Assemble

Solid Insulated Switchgear is easy to assemble and requires less skilled experts.

This ensures you can start using it as soon as you purchase it.

Are there any drawbacks of using a Solid Insulated Switchgear?

Yes. There are drawbacks to the use of a Solid Insulated Switchgear including:

· High Initial Cost

The initial cost of purchasing a solid insulated switchgear is relatively higher compared purchasing other types of switchgears.

· Requires Maximum Care

You need to take maximum care for your Solid Insulated Switchgear.

This prevents dust contamination of the live parts of the Solid Insulated Switchgear.

Maximum care can be quite tedious and time-consuming.

· High Outage Time

It takes a lot of time to identify and diagnose a fault when it occurs.

This results in high power outages, which affect the plant operation.

What is the voltage rating for a Solid Insulated Switchgear?

Solid insulated switchgear

The voltage rating for a solid insulated switchgear are:

Low voltage switchgear connects and disconnects, distributes and interrupts current flow with a voltage of up to 600V

Medium voltage switchgear isolates, distributes, connects, and disconnects power system with a voltage range of between 600V and 69kV

High voltage switchgear connects and disconnects, interrupts, and distributes current with a voltage of between 69kV and 230kV.

How does a Shielded Solid Insulated Switchgear compare to a Normal Solid Insulated Switchgear?

A shielded solid insulated switchgear offers superior operating capability when you compare to a normal solid insulated switchgear.

The shielding reduces the electromagnetic effect associated with electrical current flowing through cables.

The electromagnetic effect reduces the performance of your solid insulated switchgear.

What are the Insulation Materials for Solid Insulated Switchgear?

A solid insulated switchgear uses either of the following insulation materials:

· Air Insulation Material

Th advantage of air as an insulation material is that it is easily available and relatively cheaper.

Also, it has a relatively lower maintenance cost when you compare to other insulation material.

However, it requires a large space for installation.

This can be a challenge when there is no enough space.

· Gas Insulation Material

The gas Insulation material is a reliable option for your Solid Insulated Switchgear.

This is because there are fewer maintenance procedures that necessitate switchgear shutdown.

Since there is less maintenance, you can rely on this switchgear to maximize your productivity.

Also, it does not require a large installation space making it ideal for most applications.

However, the epoxy resin material is costly.

The installation process requires an expert which can be a challenge and costly.

What are the Components of a Solid Insulated Switchgear?

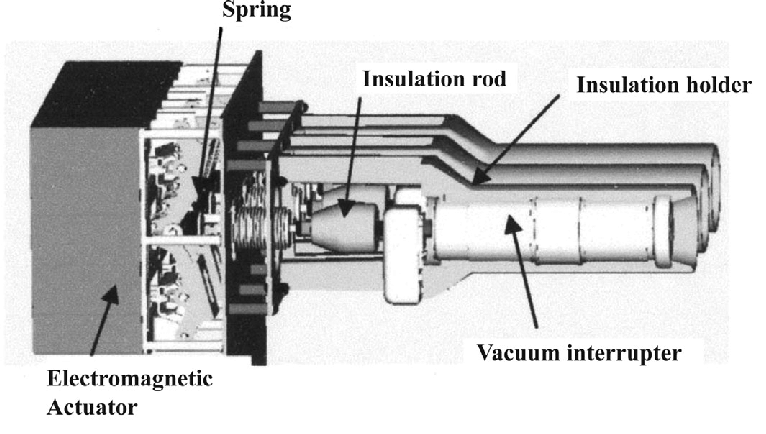

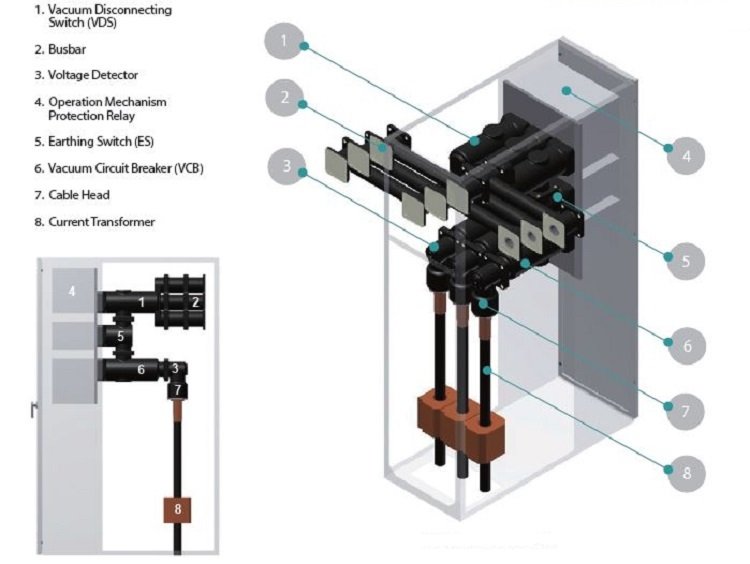

Parts of solid insulation switchgear

The components of a Solid Insulated Switchgear include:

· Disconnecting Switch/ Isolator

The function of a disconnecting switch in a Solid Insulated Switchgear is to interrupt small currents which are capacitively coupled or induced.

They are a crucial part, especially during maintenance of the Solid Insulated Switchgear.

· Air Break Switches

They help in the sustenance of two lines or equipment of the solid insulated switchgear, thus minimizing electrocution.

This is through isolation of circuit and equipment within the switchgear.

· Busbar

A busbar is a metallic bar or strip whose function is to connect voltage equipment to the switchgear.

They carry the current within the switchgear.

They are uninsulated and stiff enough to hang in the balance with support from insulated pillars.

· Current Transformer

The function of a current transformer is to multiply or reduce the electrical current in a solid insulated switchgear.

It helps in maintaining the current between the primary and secondary circuits of the switchgear.

· Step-down Transformer

They help in the conversion of voltage from high to low, which the Solid Insulated Switchgear can use.

· Earthing Switch

Earthing switch helps in directing excess electrical current in the switchgear to the ground.

This helps in reducing electrical overload and the occurrence of electrical faults.

· Circuit Breaker

A circuit breaker helps in stopping excess current flow in the electric circuit.

This helps in preventing faults from occurring withing the switchgear

It is a metal-clad that uses SF6 gas for fault interruption and Insulation

How does a Solid Insulated Switchgear work?

The functioning of a Solid Insulated Switchgear depends on working of its components.

When a fault occurs, the relay swings into action by closing the circuit trip.

This is through the automatic disconnection of the fault line.

Next, the healthy and operative sections ensure there is a flow of the required normal supply load.

Through this, there is a smooth electrical supply throughout the equipment, ensuring there is no damage.

Overloading of the line inhibits the current from making an electromagnetic release action.

However, it initiates the production of heat by the thermal element.

The heater heats the bi-metal sheet causing it to bend upwards.

This pushes the lever upwards, making the hook to lock off.

This breaks off the primary contact, cutting power supply off.

By doing this, when there is an overload, it exceeds the set current causing the electromagnetic tripper to produce suction.

A combination of the suction and the impact lever results in the lap hook to rotate upwards around the shaft seat

This results in the release of the lock.

What are the Safety features of a Solid Insulted Switchgear?

The safety features of a Solid Insulated Switchgear include the following:

· Lock-out/Tag-out

It allows for permanent or temporary lockout Tag-out procedures customization as per the client’s application

· Remote Tracking

Remote tracking enables the removal or installation of circuit breakers from the outside of an arc flash boundary.

· Remote Switching

Remove switching allows for remote charging, closing or opening of the switches and circuit breakers from a within a safe distance.

What are the Quality Standards for a Solid Insulated Switchgear?

The quality standards for a solid insulated switchgear are:

- American National Standards for Insulators (ANI) standards.

- International Electrotechnical Committee (IEC) standards.

- National Electrical Manufacturer Association (NEMA) standards.

- Institute of Electrical and Electronics Engineers Standards Association (IEEE-SA)

- ISO standards

What are the Test requirements for a Solid Insulated Switchgear?

A Solid Insulated Switchgear has to pass the following tests:

· Checking Operational Degree

This test determines the operational safety of the Solid Insulated Switchgear.

It also helps in preventing solid and liquid contaminants from getting in contact with the switchgear.

· Creepage and Clearance Distance

You need to carry out this test between the live parts of the Solid Insulated Switchgear and also its exposed conductive parts.

You measure the distance between the live parts using the different polarities.

Bolted connections, joints, unsuitable connectors minimize the initial insulation values.

· Protective Circuit Effectiveness

This helps in determining the safety of the Solid Insulated switchgear.

Also, this test also determines the occurrence of high fault current in case the conductor detaches accidentally.

Effective protective circuits need to withstand optimum short-circuit thermal stress, which happens as per the supply current.

· Current Transformer Core Test

You need to test the ration and polarity of the current transformer core and compare the results to the primary current injection.

You need to perform this test phase by phase.

· Dielectric Test

The dielectric test is on the auxiliary circuits.

For this test, apply 500 voltage DC between the terminal blocks and the earth point.

· Voltage tests on the main Circuit

You need to check on the dielectric strength to remove causes like damage during handling, wrong fastening, and presence of foreign bodies.

Such issues may result in an internal malfunction of the switchgear of not addressed.

· Short-circuit Resistance

This test determines the resistance of the busbars and their breaking, supports, and protective devices to the electrodynamic and thermal stress.

· Temperature Rise Limits

Temperature rise limits help in determining the appropriate operating temperature for Solid Insulated Switchgear.

High temperature has the effect of components aging prematurely, leading to the failure of the Solid Insulated switchgear.

What are the types of a Solid Insulated Switchgear?

The main types of Solid Insulated Switchgear include:

· Solid Air Insulated Switchgear

This is one that uses air as its main insulation material.

It requires a large area for installation though it is relatively cheaper than other types of solid insulated Switchgear.

· Solid Gas Insulated Switchgear

It is a relatively costly type of Solid Insulated Switchgear.

However, it offers reliability and efficiency since it does not require regular maintenance.

· Low Voltage Solid Insulated Switchgear

It is a type of Solid Insulated Switchgear that connects and disconnects, distributes and interrupts current flow with a voltage of up to 600V

· Medium Voltage Solid Insulated Switchgear

This type of Solid Insulated switchgear isolates, distributes, connects, and disconnects power system with a voltage range of between 600V and 69kV.

· High Voltage Solid Insulated Switchgear

It connects and disconnects, interrupts, and distributes current with a voltage of between 69kV and 230kV.

How do you Troubleshoot Solid Insulated Switchgear?

Solid insulation switchgear

The following are the main causes of Solid Insulated Switchgear failure and the ways of troubleshooting them:

· Internal Noise

The cause of your switchgear producing internal noise is due to the electromagnetic induction screws that are on the partitioning plates.

Cable touching gland plates are another source of the internal noise.

Ensure that you have tightened the screws on the portioning plates and applying a layer of sealant on the cable.

· Overheated Connections

This is a result of having bolts that are overhead and loose.

To solve this, ensure that you use the rated current value.

Also, tighten any loose bolt and replace the busbar if necessary.

· The Switchgear Fails the Dielectric Test or Ground Fault

Cracked insulators cause this. Such insulators are prone to moisture or foreign contaminants.

To solve this, you need to replace the insulators.

You can also clean using an appropriate cleaning agent and dry the moisture parts.

· Shutters not Closing

The main reason why the shutter is not closing is due to damaged shutters.

To solve this, you need to repair the shutters and clean the adjustable parts.

You can also apply a lubricating oil in these parts to facilitate the closing.

· Indicating Light Extinction

Indicating light extinction may be as a result of the following: Fuse or resistor burnt, broken bulb filament, faulty limit switch contactor poor contact of the auxiliary switches.

You need to check on the following to fix this: change the bulb, replace the fuse or resistor, cleaning of the auxiliary contacts, or monitor the MCCB of the fuse terminals.

· You Cannot Lock the Handle

This problem arises from the rusting of the internal locking mechanism or a faulty locking mechanism.

It may also be that you are using the wrong key to open up.

To solve this problem, ensure that you use the correct key.

You need to lubricate the locking mechanism or replace it altogether.

· Poor Control Unit Operation

Poor control unit operation maybe because of unfastened screws of the terminal blocks.

Alternatively, it can be due to an improper connection of the control plug.

You need to tighten the screws for the terminal blocks.

You can also connect the control plugs appropriately.

· Shutters are not Opening

If your shutters are not opening, it may be due to poor adjustment of the moving parts or lack of lubricating in these parts.

Also, it can be due to deformed shutters.

To solve this, you need to adjust and lubricate the moving parts and check on the shutters to ensure they are incorrect shape.

What are the Specifications of a Solid Insulated Switchgear?

The specifications of a solid insulated switchgear refer to the details of a specific Solid Insulated Switchgear.

They include;

i. Manufacturer details

ii. Installation process

iii. Areas of application

iv. Voltage rating

v. Protection level

vi. Standards specification and compliance

vii. Dimensions and weight

viii. Material type

In short, before you invest in a new solid insulated switchgear, it is important to know the specification, working principle, installation process and troubleshooting procedures, amongst others.

It is only through this that you will get the best solid insulated switchgear.

Contact us today for inquiries on solid insulated switchgear.