Sheet metal fabrication offers an inexpensive and efficient method of producing electronic enclosures.

Normally, these metal enclosures have considerably reduced material expenses in comparison to CNC-machined types.

This guide explores everything you need to know about sheet metal enclosure fabrication process.

Keep reading.

Sheet Metal Enclosure Fabrication Tools And Equipment

Sheet Metal Enclosure

Many tools and equipment are involved in the sheet metal enclosure fabrication process. Some of the commonly used machines and tools include:

- CAD design software

- Laser cutters

- CNC punch machinery

- Laser / punch combination machinery

- Robotic welders

- Folding machinery, like automated robotic folders, automated panel benders, and manual press brakes.

- CNC machine tools

- Precision turned parts machinery

- Co-ordinate measuring machines (CMMs)

- Powder coating plant

Fabrication Process Of Sheet Metal Enclosure

Step 1: Concept And Design For Sheet Metal Enclosure

This forms an integral stage of sheet metal enclosure fabrication process.

It can dictate influence the cost efficiency and best production approach of the fabrication process.

The stage involves determining the specifications of the sheet metal enclosure based on your design.

Rough sketches will be done to understand the extent of the fabrication process.

After finalizing on all the details, the engineering team will make the final sheet metal enclosure drawing.

Here, thorough calculations are done to establish the stress levels on the various parts of the enclosure.

This evaluation and calculation will dictate the subsequent process of sheet metal enclosure.

Step 2: Cutting

The initial step in any sheet metal fabrication process is cutting. In this procedure, you should make sure that all the drawings measurements are cut accurately to size.

It is among the most vital steps since when measurements are inaccurate the whole metal enclosure will not be fabricated properly.

The process of cutting sheet metal is performed applying a number of simple to advanced cutting tools.

For example, shearing is the common technique of cutting sheet metal for electronic enclosures.

Nonetheless, ultra-modern laser machines are employed to cut special hard materials, special alloys and precious metals.

1. Cutting With Shear

Here, a shearing force is exerted by 2 tools, one over and another under the sheet metal. Whether top and bottom blades or punch and die, the tool over exerts fast downward force to sheet metal resting on lower tool.

Normally, you leave a small clearance between the margins of the top and bottom tools.

This facilitates the separation of the enclosure material. The clearance size is typically 2 to 10 percent of the sheet metal thickness.

There are several processes of cutting sheet metal that employ shearing forces to separate material from a sheet metal block in various ways.

By applying many of the operations together, you can fabricate sheet metal enclosures with profiles and cutouts of any 2D geometry.

The common cutting by shear techniques used in the sheet metal fabrication process include:

2. Shearing

The terminology shearing by itself denotes a distinctive cutting procedure that give linear cuts to divide a sheet metal for electronic enclosure fabrication.

Usually, you apply shearing to cut a metal sheet aligned to an existing outline that is held square.

Nonetheless, you can equally make angled cuts.

For this matter, shearing is mainly employed to cut sheet metals into smaller sizes in readiness for other metal enclosure fabrication processes.

The shearing operation is carried out using a shear machine, commonly referred to as power shear or squaring shear.

You can operate the equipment manually, or by pneumatic, hydraulic, or electric power.

An ordinary shear machine consists of:

- A table having support arms for holding the sheet metal

- Guides or stops for securing the sheet

- Top and bottom straight-edge blades

- Gauging gadget to accurately position the sheet metal

The sheet metal is positioned between the top and the bottom blade. You then force the blades together against the metal sheet, cutting it into desired size.

In most shear machines, the bottom blade stays stationary whilst the top blade is pressed downward.

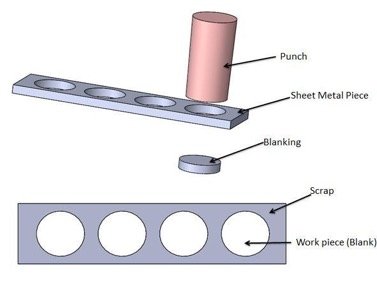

3. Blanking

Blanking refers to a cutting procedure where you remove a sheet metal piece out of larger stock piece by exerting sufficient shearing force.

The removed piece, known as the blank, is not waste but instead the desired sheet metal enclosure part.

Sheet Metal Blanking

You can apply blanking to cutout electronic enclosure parts in nearly any 2D shape.

However, this method is employed in cutting pieces having simple geometries which will undergo extra shaping during subsequent sheet metal enclosure fabrication processes.

The blanking operation needs a blanking press, blanking die and blanking punch. You place the sheet metal above the die within the blanking press.

Rather than having a cavity, the die has a cutout with the shape of the required metal enclosure part.

You must custom make the die unless you are forming a standard shape.

Above the sheet metal is the blanking punch that is a tool have the shape of the required enclosure part.

Both the punch and die are normally made using tool carbide or steel.

At high speed, the hydraulic press pushes the punch downward into the sheet metal.

There exists a small clearance, usually 10 to 20 percent of the sheet thickness, between the die and punch.

When the blanking punch thumps the material, the sheet metal within the clearance speedily bends and then separates.

The sheared blank from the sheet metal drops freely into the cavity in the die.

Also, the procedure is exceptionally quick, with certain blanking presses having the capacity to perform over 1000 strokes every minute.

4. Fine Blanking

Fine blanking refers to a specialized kind of blanking where you shear the blank from the sheet metal by exerting three separate forces.

The technique produces metal enclosure parts with smoother edge having minimal burrs, better flatness, and tight tolerance of ±0.0003.

For that matter, you can blank high quality electronic enclosure parts that don’t need any additional processing.

Nevertheless, extra tooling and equipment does add on to the inceptive cost, making fine blanking preferable for high volume sheet metal enclosure fabrication.

The majority of equipment and tooling used in fine blanking is the same as for conventional blanking.

Even so, as mentioned earlier, fine blanking involves the exertion of three forces.

The first one is a downward clenching force exerted to the upper surface of the sheet metal. A clamping mechanism clutches a guide plate securely against the sheet metal and is clasped in position by an impingement ring.

At times referred to as a stinger, the impingement ring surrounds the blanking location perimeter.

Fine blanking process applies the second force below the sheet metal, directly fronting the punch, through a “cushion”.

The role of the cushion is to offer a counterforce throughout the blanking operation and later release the blank.

These 2 forces minimize buckling of the sheet metal and enhance the blank flatness.

The third force is exerted by blanking punch acting on the sheet metal and cutting the blank in the die opening.

Clearance between the die and punch is smaller when applying fine blanking in sheet metal enclosure fabrication process.

The clearance is approximately 0.001 inches, and the process of blanking is carried out at slower speeds.

Consequently, rather than the sheet metal breaking to release the blank, the created blank flows and gets extruded from the sheet. This gives a smoother edge.

5. Punching

Punching refers to a process of cutting sheet metal where you remove a piece of the material by exerting sufficient shearing force.

Punching is the same as blanking other than the cut piece is scrap.

The discarded material, known as slug, leaves behind the required interior feature profile in the sheet metal, like a slot or hole.

You can use punching to create cutouts and holes of different shapes and sizes.

Typically, punched holes have simple geometric shapes (rectangle, square, circle, etc.) or blends thereof.

The margins of these punch sheet metal enclosure parts will feature some burrs due to shearing are of reasonably good quality.

Generally, you will need to perform additional finish operations to achieve smoother edges.

Applying punching in the sheet metal enclosure fabrication process needs a punch press, die and punch.

You place the sheet metal in the middle of the punch and die in the punch press.

The die, found below the sheet metal, features a cutout that is shaped as the desire enclosure part.

On top the sheet, the press grasps the punch that is also shaped as the desired part.

At high speed, the punch press thrusts the punch downwards against the sheet metal and in the die underneath.

There exists a clearance between the die and the punch margin, causing metal sheet to speedily bend and break.

The slug that you punch out from the sheet metal drops freely via the tapered die opening. You can perform this process of sheet metal enclosure fabrication using manual punch press, though CNC punch presses are common nowadays.

Sheet Metal Enclosure Punching

A typical punching process entails a cylindrical punch that pierces through the sheet metal, creating a single hole.

Nonetheless, there are a number of processes you can employ to create different features.

Here are the other punching techniques you can use in sheet metal enclosure fabrication process:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6. Cutting Without Shear

Here, the cutting processes use other mechanisms, such as abrasion or thermal energy.

This form of cutting is applied in industrial sheet metal enclosure fabrication processes, which require precision and quick processing times.

Some of the popular cutting without shear techniques employed during the process of fabricating sheet metal enclosure include:

7. Laser Beam Cutting

Laser cutting employs a high-powered laser beam to cut through the sheet metal.

A chain of lenses and mirrors direct and concentrate a high-energy light beam onto the sheet surface where you are supposed to cut.

When the bean of light hit the surface, its energy melts and evaporate the sheet metal underneath.

A jet of gas is used to blast away any remnant vapor or molten metal from the cut.

You precisely control the laser beam position corresponding to the sheet metal to enable the laser to take the required cutting path.

This cutting technique is performed on laser cutting machinery.

CO2 based laser having power of about 1000-2000 watts is the most common type of laser applied in sheet metal cutting.

Nevertheless, Nd-YAG and Nd are at times employed in very high-power sheet metal enclosure fabrication processes.

8. Plasma Cutting

Plasma cutting utilizes a concentrated stream of ionized gas (plasma) to cut across the sheet metal material.

The plasma streams at an exceptionally high velocity and temperature and a nozzle directs it toward the cutting spot.

The sheet metal melts when the plasma strikes the surface underneath. The ionized gas flow from the nozzle then blows away the molten metal from the cut.

There is need to precisely control the plasma stream position with respect to the sheet metal. This enables it to follow the required cutting path.

Plasma cutting is done using a plasma torch which can be handheld, or more popularly, computer controlled.

CNC plasma cutting machine enables you to make complex and accurate cuts during the process of sheet metal enclosure fabrication.

Different from laser cutting, this technique does not need any physical tooling.

As result, plasma cutting decreases the initial costs and facilitates cost-saving low volume sheet metal enclosure fabrication.

Moreover, plasma cutting capabilities differ modestly from laser cutting.

Although both methods can cut almost any 2D shape from sheet metal, you cannot attain similar precision and finish levels with plasma cutting.

You may have rough edges, specifically when using thicker sheet metals for enclosure fabrication.

Also, the material surface will form an oxide layer that can be eliminated through secondary processes.

Nevertheless, plasma cutting has the ability to cut through thicker sheet metals in comparison to laser cutting.

This allows its use in enclosure fabrication beyond sheet metal.

9. Waterjet Cutting

Water jet cutting applies a high velocity water stream to cut across the sheet metal.

Typically, the water consists of abrasive particles necessary for wearing the material and flows in thin jet at elevated speeds, about 2000 ft/sec.

Consequently, the water jet exerts exceedingly high pressure (approximately 60,000 psi) at the cut spot of the sheet metal. This speedily erodes the material.

Normally, the water jet position is computer controlled to make it move along the required cutting path.

You can use water jet cutting to cut almost any 2D shape from the sheet metal.

The cut widths often range between 0.002 to 0.06 inches and it produces edges of good quality.

Moreover, secondary finishing is not necessary since water jet cutting forms does not form burrs.

Furthermore, heat deformation is not an issue in water jet cutting of sheet metal.

This is because it does not apply heat for melting the material, as is the case in plasma and laser cutting.

Step 3: Bending Sheet Metal

Bending refers to application of force to sheet metal, making it to curve at a specific angle and create the desired enclosure shape.

Bending sheet metal operation leads to deformation along a single axis.

However, you can perform a series of various different procedures to form a complex enclosure part.

A sheet metal enclosure bend can feature several distinct parameters as exhibited in the diagram below.

Sheet metal Enclosure Bending

The operation of bending leads to both compression and tension within the sheet metal. Also, the external section of the material will experience tension and extend to a sizeable length.

Besides, the act of bending results in both tension and compression in the sheet metal, whilst the internal section endures compression and shrinks.

The neutral axis denotes the boundary line within the sheet metal, through which no compression or tension forces are existing.

Due to this fact, this axis length remains constant.

You can relate the length adjustment in the internal and external surface to the initial flat length by 2 parameters.

The two variables are bend deduction and bend allowance, which are illustrated in the diagram below.

bend Neutral Axis

K-factor denotes the neutral axis in the sheet metal. You calculate it as the ratio of the neutral axis to the thickness of the material.

The K-factor depends on a number of parameters, such as material, bend angle, bending operation etc.). Usually, it is greater than 0.25, though cannot surpass 0.50.

During bending of sheet metal, the stresses remaining within the material will make it springback moderately after the bending procedure.

Because of this elastic recovery, you should over-bend the metal sheet by a specific amount to attain the desired bend angle and radius.

You will have a greater final bend radius in comparison to the initially formed, this is in addition to smaller final bend angle.

Springback factor, KS is the ratio of the end bend angle to the starting bend angle.

The degree of springback relies on various variables, consisting of the material, bending process, and the starting bend radius and angle.

Springback in Bending of Sheet Metal

Typically, bending operation in sheet metal enclosure fabrication process is done on a machine known as press brake.

The operation of the equipment can be either manually or automatically.

A press brake consists of a bottom tool known as the die and a top tool referred to as the punch. You position the sheet metal between these 2 tools during the bending process.

You carefully place the sheet metal above the die and clutch it in position using the back gauge. The punch then lowers and compels the material to bend.

With automatic press brake machine, a hydraulic ram power forces the punch into the sheet metal.

The depth that the punch thrusts the sheet metal into the die determines the bend angle attained.

Standard tooling is commonly utilized for the die and punch. However, you can employ custom tooling for specialized bending processes but will incur additional cost.

Press Brake

Still, there exist several other techniques that you can use for bending during the sheet metal fabrication process.

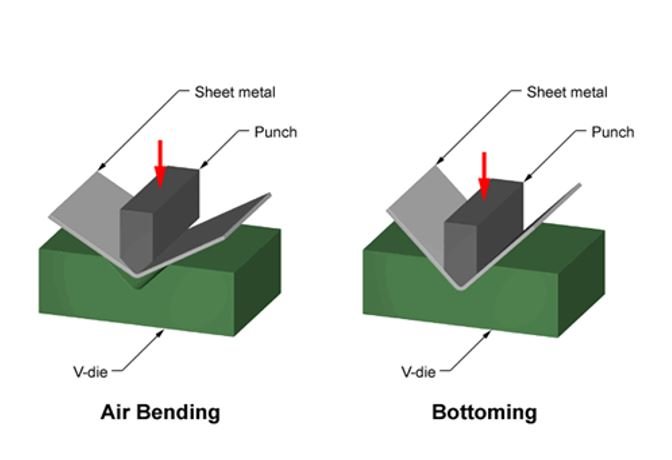

V Bending

In this method of bending sheet metal, where the die and punch assume a “V” shape.

The punch thrusts the sheet metal in the “V” shaped channel within the V-die, making it to bend.

In case the punch doesn’t push the material to die cavity bottom, leaving air or space below, it is known as “air bending”.

Consequently, the V-groove should feature a sharper angle with respect to the angle you are forming in the sheet metal.

When the punch pushes the sheet metal to the die cavity bottom, it is referred to as “bottoming”.

With this technique, you have more command over the angle since there is reduced springback. Nevertheless, you will require a weightier press.

In both methods, the width of die opening, or “V” shaped groove is normally 6-18 times the thickness of the sheet metal.

This figure is known as die ratio and is equivalent dividing the die opening by the thickness of the sheet.

V bending of Sheet Metal

Wipe Bending

At times referred to as edge bending, wipe bending is another common method of bending used in sheet metal enclosure fabrication process.

This bending technique requires that you hold the sheet against on the wipe die using a pressure pad.

The punch then pushes against the margin of the sheet metal that stretches beyond the pad and die.

The sheet metal will curve against the edge radius of the wipe die.

Wipe Bending

Step 5: Joining Techniques To Form Sheet Metal Enclosure

How do you pick the right metal joining method/s for your enclosure?

Here, we will help you decide on the suitable joining technique to apply during sheet metal enclosure fabrication process:

Welding Electrical Enclosure

There are several welding electrical enclosure options you can employ during sheet metal enclosure assembly.

The method you apply depends on the metal type, material thickness and the welding equipment.

Some of the common welding operations comprise of:

MIG Welding

This refers to an arc welding operation where you feed an endless wire electrode into weld pool through the welding gun. To guard the pool from pollution, you also feed a shielding gas via the gun.

TIG Welding

This welding method applies an infusible tungsten-based electrode and electric arc to produce welds. The welding technique is appropriate for sheet metals having a thickness of up to 8 to 10 mm.

Laser Welding

Laser welding utilizes high-powered, solid laser resonator to melt the sheet metal. The welding method allows you to produce consistent, top-quality welds.

Mechanical Joining

Mechanical joining or fastening is largely different from adhesive bonding or welding processes. This joining procedure entails various mechanical hardware to fasten multiple enclosure components together.

The common mechanical hardware used in this joining technique employed in sheet metal enclosure fabrication operation include:

- Screws

- Bolts

- Nuts, and

- Rivets

Also called threaded fastening, mechanical joining creates stronger joints compared to adhesives, though they are not as tough as welded joints.

Mechanical joining may be temporary or permanent. Fasteners like nuts, screws and bolts are temporary joining techniques, while riveting is a perpetual joining method.

Unlike welding process, you can replace or adjust hardware or fasteners utilized in mechanical joining if need be.

Moreover, different from welding technique, you do not need heat in the procedure, eliminating the risk of sheet metal deformation and discoloration.

Adhesive Bonding

Most manufacturers employ mechanical joining and welding methods for structural parts when it comes to sophisticated sheet metal enclosure fabrication process.

Adhesives are used aesthetically for add-on detail in instances where fasteners and welding should not be seen.

Similar to mechanical joining, adhesive bonding is ideal for this since it will not discolor or distort the metal, different from welding techniques.

Furthermore, it is effortless to conceal adhesive bonding.

This is because adhesives are basically concealed between 2 substrates, and this can give aesthetic enhancement over mechanical fasteners and welding.

However, there are disadvantages of adhesive bonding despite the great aesthetic solution it offers.

The main downside of using adhesive in sheet metal enclosure fabrication process is the joint strength.

Adhesive bonding makes the least durable among the three sheet metal joining techniques discussed.

Also, it is vital to properly test adhesives on the specific enclosure to prevent it from failure.

Moreover, certain adhesives need equipment having a special construction for appropriate application.

For instance, you must apply acrylic adhesives using stainless steel equipment. Also, while joining methods such as welding are instant, adhesives need curing time.

In summary, you can apply more than 1 joining technique during sheet metal enclosure fabrication operation. Most of the complex metal enclosure designs require all three.

Step 6: Grinding

Grinding refers to the operation where the grain strikes the sheet metal. Most precision sheet metal fabrication processes apply at least some degree of automation.

Grinding down a welded sheet metal part is an extensively manual process.

You need to exert sufficient pressure at the right angle to allow grinding disc grains eliminate the most metal within the shortest time.

At the same time, it is important to ensure that you do not prematurely wear the disc or run down the grinding tool.

There are a number of parameters that must be managed effectively for successful part flow.

Sheet metal Grinding

Step 7: Sanding

After grinding the entire sheet metal enclosure, sanding is the next step that ensures there is clean and polished surface before final finishing.

The process equally consumes some time and is essential in sheet metal enclosure fabrication process.

Step 8: Final Finish

Similar to material, surface finishes give distinct solutions for different sheet metal enclosure uses.

Not all surface finishes are proportionately fit to guard the sheet metal under different conditions.

Therefore, it is essential to consider the following factors during selection of the right finish to use in sheet metal enclosure fabrication process:

- Where the enclosure will be located; indoor or outdoor.

- Temperature the surface finish will be subjected to

- Kind of chemicals the finish might be exposed to

- Concerns relating to UV radiation

There are several surface finishes available to augment the corrosion resistance of a material. Let’s look at the common surface finish operations applied during the sheet metal enclosure fabrication process:

Powder Coating

Powder coating involves a dry thermoplastic powder that you apply electrostatically and bonded to the metal enclosure surface in an oven.

It is broadly considered as the industry standard for surface finish operation, and comes in a range of colors, textures and gloss levels.

One of the advantages powder coating is that it gives inexpensive high quality, exceptionally durable finish.

Also, it comes in various textures, for instance, rough finishes are excellent at concealing fingerprints, making it best choice for electronic enclosure.

The powder coat will put an additional layer on the metal enclosure.

Note that the drawing dimensions denote the underlying metal material and not the powder coating.

Therefore, it is advisable you assign an extra.003” to .005” on every side of your cutout dimensions.

If not, the cutouts might not be adequately big, and the enclosure components will not fit.

To specify the desired powder coat, simply select a powder coat with the right texture and color for your needs.

With the design for sheet metal enclosure fabrication, attach a note on the preferred powder coat.

Digital Printing And Silkscreening

This is a surface finish operation applied in sheet metal enclosure fabrication process that gives the design an excellent appearance and feel.

The techniques enable you to visibly mark your metal enclosure for identifying ports, switches, connectors and more.

Digital printing is as well a perfect choice for graphics, like artwork or company logo. It has turned out to be the default selection for most designers.

Nevertheless, each method features its own advantages. This makes each of them suitable for your distinct application.

Chemical Conversion Coating

This surface finish for metal enclosure is also known as chromate coating or chem-film. Applying chromate to the sheet metal surface provides a corrosion-resistant and long-lasting surface that displays stable electrical conductivity.

Anodizing

Anodizing refers to an electro-chemical procedure used in surface finishing of non-ferrous metals. It is commonly applied on aluminum surface to make it harder and corrosion resistant.

The anodized surface in effect becomes a part of the metal. As a result, it will not flake off, chip or peel and under ordinary application, will never wear out.

Anodized Sheet Metal Enclosure

Tin Plating

This is a simple immersion process that coats pure tin onto the sheet metal. The surface finishing operation is often applied to enhance solderability, electrical conductivity and corrosion resistance.

Bare Metal Finishes

Typically, bae metal finishes are provided in 3 basic forms:

No Finish

Here, you de-burr the electrical enclosure with no extra finishing, and might display small swirl marks or scratches. This is a cost-saving technique though only convenient for metal enclosures that will be used indoors.

Grained Finish

In this surface finish, you de-burr the metal enclosure surface then give it a distinct linear grain direction through brushing.

Tumbled Finish

Using tumbled finish during sheet metal enclosure fabrication process smoothens and provides non-directional finish through tumbling inside abrasive medium.

Complementing each other, the best material and surface finish for any metal enclosure aids in keeping delicate equipment safer and for longer duration. It is a solution that results in cost saving and better performance.

Step 9: Sheet Metal Enclosure Quality Inspection

Fully assembled electrical enclosure

After completing the sheet metal enclosure fabrication process, the product requires validation testing according to its operating requirements.

Here are the quality inspection tests that a metal enclosure will undergo before leaving the fabrication shop:

Salt Spray Test

Salt spray test acts as an accelerated mechanism of testing the capability of enclosure surface coating to endure atmospheric corrosion. It is also referred to as salt fog testing.

Scratch Test

Scratch testing determines the resistance to wear and abrasion of the metal enclosure material and coating. It is a simple and quick technique of characterizing coatings.

However, several variables affect the results, including substrate mechanical properties, coating thickness, and interfacial bond strength. The test conditions like indenter tip radius, scratch speed and load also influence the results.

Drop Test

This test is designed to access the structural integrity of the metal enclosure. Drop test normally entails dropping an object from a specific height onto the surface of the enclosure.

High Temperature Tensile Test

High temperature tensile testing helps in examining the metal material behavior when exposed to a blend of elevated temperature and tension.

Low Temperature Test

Low temperature testing accesses the impacts of reduced temperature on the performance, integrity and safety of metal enclosure material during use. This test is ideal for examining metal enclosures that will be subjected to low temperature conditions during its service life.

Ingress Protection Test

Commonly referred to as IP testing, ingress protection testing evaluates the metal enclosures capability to guard against “ingress”.

That is, protection against infiltration of dust, water and foreign objects.

For all your electrical enclosures from China, contact KDMSteel now.