KDM ATEX Enclosures have potentially been certified for use in both indoor and outdoor risky environments.

These provide protection from any hazardous atmosphere to any electronic and electrical equipment.

Facilities with high absorption of gas, dust, or at levels that can cause explosion or fire should utilize ATEX enclosures. These offer the advantage of flexibility in accordance with environmental conditions. If the time comes that customer needs to replace their electrical equipment because of its malfunctioning, they can do it without replacing the enclosures.

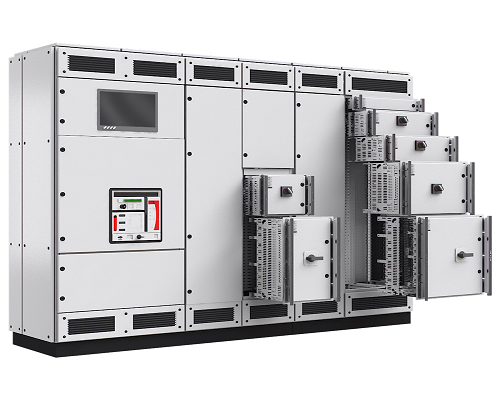

Our enclosures are fabricated with a robust-compact design to ensure durability and to withstand dangerous atmospheres. This guarantees the safeness of every application with ready-to-use features. KDM ATEX enclosures are assembled with ATEX electrical, hydraulic, and pneumatic components to form ATEX-certified solutions that can suit your need in explosion-proof enclosures.

- ATEX Certified Flameproof Enclosures

- Ingress protected up to IP66-67 rating

- Made up of high-quality components

- Totally comprehensive solution

KDM ATEX Enclosures Series

Battery-Holder ATEX Enclosures are utilized for potentially hazardous location atmospheres. Designed with robust exterior compact to remain undamaged despite the harsh environment.

Indoor ATEX Enclosures are ideal in various applications. These contain so many advantages that give flawless characteristics that suit your demand. Different high-standard optional items are available in KDM.

Camera-flameproof ATEX Enclosures provides the camera with weatherproof protection. Fabricated from high-quality substances to increase the functionality features.

Control ATEX Enclosures manufactured to control or monitor the electrical equipment with the assurance of flexibility and workability management. Tested-qualified for better application.

Crouse hinds ATEX Enclosures guarantee the safeness and reliability solution provider. Features sturdy exterior that provides long-lasting utility.

Junction box ATEX Enclosures in KDM are well-developed from excellent quality materials. Provides rust-resistant enclosures.

Send your Inquiry on KDM ATEX Enclosures

Ideal application in many various industries and sectors like in facilities that used inflammable materials such as in power stations, foundries, chemical plants, gas stations, and many more. They employ ATEX enclosures because their establishment is prone to any possible explosion. Additionally, being ATEX compliant is a legal procedure that needs to comply.

- Robust and rugged structural construction

- Professional engineers to manage designing and engineering

- Custom structure length, width, height, and other features

- ISO9001:2015 certified aluminum extrusion enclosure supplier

Related Products of ATEX Enclosures

KDM ATEX Enclosures

KDM ATEX enclosures feature a waterproof and dustproof application.

With above NEMA 4x standard certified to provide the best yet cost-effective enclosures.

Manufactured using high-grade stainless steel, polyester, and steel to deliver the fully-assembly application.

A comprehensive solution that comes complete with a set of wall brackets and heavy-duty mounting plates.

Our ATEX enclosures confirmed IP65/IP66 certified in the international rating industry.

That’s why when it comes to your needs in highly explosion-proof enclosures, KDM is the best choice.

KDM ATEX enclosures are a budget-friendly alternative for anyone that can ensure the success of your business.

With 10 years of expertise and professionalism in manufacturing, KDM built integrity and competency in this field industry.

We developed a certified reliable source for your necessities.

Our electrical enclosures are committed to well-tested quality processes.

We can customize your desired design and can implement it just within a few days.

KDM provides the most efficient products that meet the standard of every customer.

We provide 24/7 online assistance that assures 100% support for your business.

We have a wide range of various ATEX enclosures.

Feel free to message us with your requirements now.

ATEX Enclosure: The Ultimate FAQs Guide

Nowadays, you might need an ATEX enclosure that meets and exceeds your specific IP and NEMA requirements.

But it is not an easy task.

This guide will answer all the possible questions about ATEX enclosures that may come up in your mind.

You will learn all the information about the ATEX enclosure.

Let’s begin!

What is ATEX Enclosure?

ATEX enclosure complies with the ATEX Directive of the European Union’s safety standard.

The ATEX enclosures are designed for the electrical enclosure to be safe in probably hazardous areas.

Furthermore, the ATEX enclosure is durable and rugged.

It can provide security and safety in the exact size, shape, and other specifications you want.

What is ATEX?

The term ATEX is derived from French “ATmospeheres EXplosibles.”

ATEX is protection equipment and system standards that describe probably explosive atmospheres.

Two European Directives integrate with EN European standards, including:

- International standards IEC 61241 and IEC 60079

- ATEX 94/99/CE and ATEX 99/92/CE

What is Potential Atmosphere According to ATEX?

The flammable substances mixed in the structure of dust (cloud deposit), vapor, and gas are called the potentially explosive atmosphere.

The air with normal atmospheric conditions wholly or partially catches fire through an explosion when exposed to an ignition source.

The use of verified equipment, assembly, or component must comply with ATEX 94/9/CE European Directive.

It is considered for use in gaseous, dusty atmospheres and potentially explosive zones.

What Are the Materials Used for ATEX Enclosure?

There are three material types to construct ATEX enclosure, including:

- Aço

- Aço inoxidável

- Polyester

ATEX Steel Enclosure

ATEX enclosure made from steel can protect its content from corrosive materials, exposure to moisture, and extreme temperatures.

It is easily customized and versatile for unique industrial applications, including wastewater treatment.

ATEX Stainless Steel Enclosure

The stainless-steel enclosure will provide complete protection for in-process technology and industrial environment applications.

It is available in many different sizes, like 1000mm x 1000mm x 300mm.

Additionally, stainless steel enclosure is safe for extreme conditions because of its thick enclosures.

It is also safe for outdoor use due to its IP66 rating compliance with NEMA 4X and EN 60529.

The stainless-steel enclosure has ready-equipped junction boxes for approval effort and reducing assembly.

ATEX Polyester Enclosure

Polyester enclosures are helpful for industrial environments.

It has high impact strength, superb temperature resistance, and sturdy construction.

What Are the Applications of ATEX Enclosure?

ATEX enclosures bring ideal conditions for the following sectors and industries:

- Offshore sector

- Food industry

- Gas station

- Grain drying area

- Flour mill

- Petrochemical and chemical industry

- Aluminum and wood workshops

What is the Difference Between IECEx and ATEX?

The European Union Directive, ATEX, can cover protective systems and equipment.

It is widely used in working environments like “potentially explosive atmospheres.”

It can protect the equipment where mists, flammable gasses, combustive dust, or vapors might be present.

Potential combustible substances might happen.

If that’s the case, the electrical equipment must install in the safety areas.

It may be enclosed in the cabinets.

Therefore, the dust, gases, mists, or vapors will not contact electrical equipment and penetrate the cabinets.

Explosion or fire is the result of an electrical spark or arc.

All protective systems and equipment must comply with ATEX safety and health requirements.

This European Union Directive, ATEX, is similar to United States standard’s NEC or OSHA.

Whereas IECEx is a minimum requirement for explosive and hazardous environments.

The IECEx is short for “International Electrotechnical Commission for Explosive Environments.

The IECEx standard is complied with globally.

What is ATEX Certification?

When all the equipment and protective system has ATEX certification, it is safe to use in explosive and hazardous atmospheres.

ATEX enclosure can resist the cold, withstand the heat, and keep the dust and dirt out.

How to Get ATEX-IECEx Certifications?

To get the ATEX-IECEx certifications, enclosures must endure strenuous tests like:

- Frozen to less than 60 degrees

- Baked to 375-degree

- Battered by heavyweights

- High-pressure water hoses must be blasted

The process of ATEX certifications requires substantial effort and time.

It ensures the ATEX enclosure can exceed the performance requirements demand of increased safety environments.

What Are the Features of ATEX Enclosures?

There are different sizes of ATEX enclosures.

It is highly customizable according to the customer’s exact specifications, such as brackets and cutouts.

- ATEX-IECEX approved

- Safe for harsh and hazardous areas

- Constructed from 316 and 304 stainless steel

- With stainless-steel earth grounding

- Working temperature: -58°F to 329°F

- NEMA 4X protection and IP 66 standard

What is an ATEX Zone II?

An explosion atmosphere place, zone II, is consists of air flammable substance mixture in the form of vapor, mist, or gas.

It is not likely to happen in regular operations. And if it happens, it will persist temporarily.

What is the Difference Between EX P Pressurized Enclosure and ATEX Enclosure?

The EX P protection is an explosion protection method.

This method ensures the interior EX P enclosure’s pressure is enough to prevent flammable gas, dust, vapor, or fiber entry.

It also ensures the possible ignition to prevent.

The EX P pressurized enclosures are helpful for large control cabinets or sizeable electric motors containing circuit boards or switchgear.

The ATEX cabinet enclosures demand more considerable ATEX enclosures floor standing.

The ATEX cabinet enclosure’s material gauge and build quality have enough durability and rigidity to withstand physical and environmental impact.

What Are the Advantages of ATEX Enclosure in the Gas & Oil Industry?

ATEX enclosures are critical in the gas and oil industry.

They are helpful for downstream, midstream, and upstream facets integration.

Below are the examples of why ATEX enclosures are implemented in the gas and oil industry:

- Process control system

- Pressure and purge system

- Sampling and testing system

- Safety for Zone 1 and 2

- Blow out preventers

- Transformer and battery crates

- Shut down system

- Foundation Fieldbus

- Turbocompressor unit

- Distribution and high voltage solution

- Gas and fire system

- Wellhead system

- Instrumentation and control system

- Process system and control of shale gas fracking

What is the IP Rating of ATEX Enclosure?

ATEX has a minimum IP rating of IP54.

The standard index enclosure is IP66.

The IP66 is the arduous test of dust protection and tightness from dominant water jets.

The IP68 and IP67 are on request.

What is the Difference Between Explosion Proof and ATEX?

The explosion-proof and ATEX both help manufacturers to install and choose equipment for probably explosive atmospheres.

The explosion-proof is employed in Canada and North America, while ATEX is utilized in Europe.

The material properties and process environment that are present must be ascertained.

Therefore, the dust and gas atmospheres ignition risks are classified.

Ex-Proof

The ex-proof employs class 1 and class 2 to determine between dust atmospheres and explosive gas.

The categories of gas (A, B, C, D) and dust (E, F, G) are subdivided.

For applications like grinding and milling, the subdivision is G because it covers grain, food, and general dust.

Vapor/Gas/Mist: Class 1

Dust/Powder: Class 2

ATEX

ATEX employs zones for classifying dust atmospheres and potentially explosive gas.

Zone 2 and zone 22 are the classifications from ignitable conditions to present zone 0 and zone 20.

Vapor/Gas/Mist: Zone 2, Zone 1, Zone 0

Dust/Powder: Zone 22, Zone 21, Zone 20

Why is ATEX Enclosure Rated with NEMA and IP Ratings?

ATEX enclosure must be standard rated for safety use.

NEMA is short for National Electrical Manufacturers Association. IP is scarce for Ingress Protection.

NEMA and IP grade ATEX enclosure is suitable for industrial applications.

An IP rating is employed in Europe.

It considers the protection against water ingress and solid foreign object ingress.

NEMA is employed in North America.

It considers the construction and corrosion details.

Does ATEX Enclosure is IP68 Rated?

IP66 to IP68 is used for compressing, holding, and passing cables in the middle of two compartments.

It includes cabinets, junction boxes, devices, or electrical boxes that require sealing against dust.

What is the Benefit of ATEX Certifications for Enclosures?

All enclosures with ATEX certifications ensure that the equipment can be used in explosive environments with safe.

It will not cause an accident with each recommendation of the manufacturer.

The equipment must be ATEX certified if intended for explosive atmospheres in EEA (European Economic Area and EU (European union).

If you’re looking for the best ATEX enclosure manufacturer in China, KDM is the right place to come.

We can customize your ideal ATEX enclosure according to your specific requirements.

For more information about ATEX enclosure, please don’t hesitate to drop us your message!