KDM is the perfect manufacturer of Pressurized Enclosure in China.

Assume all our productions are ATEX U certified and come from FM 3620, CSA E60079-2, FM 3620, NFPA 496, and more standards.

Let us know if you want bulking orders, we can`t wait to serve you!

KDM is fully capable of manufacturing your necessary designs.With KDM pressurized enclosure ease maintaining all the positive interior pressures of secured gases inside will become easy.

Our range of pressurizing enclosures are used to make a stop of environmental vapors` entry levels, for prior security.

Additionally, KDM pressurized enclosure necessarily supplies secured gases within the enclosure and make the constant running.

The enclosure lessens various combustible mechanical mixtures and is easily maintained.

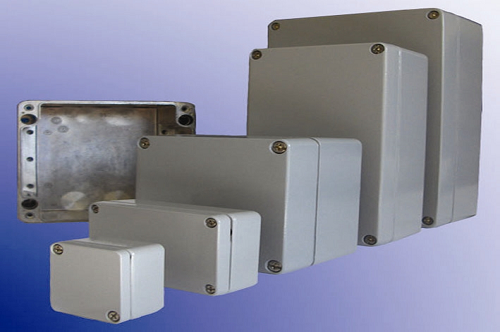

KDM Pressurized Enclosure

Aluminum Pressurized Enclosures are made of Si 12 Alloy Die Cast Aluminium with DIN EN 1706 AC-AlSi 12 (Fe). These features temperature and chemical resistance.

Elastomer Seals Pressurized Enclosures are finished with smooth gray color. These are always available unpainted and others prefer colors based on the client’s specifications.

Explosion-proof Pressurized Enclosures are suitable in risky area applications. These enclosures designed with excellent quality materials that can withstand various environmental conditions.

Hazardous area Pressurized Enclosures are available with external and internal mounting plates, hinges, wire lock screw, etc. These enclosures obtained ATEX compliance.

IEC-ex Pressurized Enclosures from KDM is suitable to utilize in hazardous areas where dust, gas or harmful substance are present. These are offered at an economical cost yet never compromise the quality.

Stainless Steel Pressurized Enclosures are available in fitted or empty enclosures. These have complete and safe permit operations of electronic equipment under hazardous conditions.

Acquire Our Excellent Quality Pressurized Enclosure

- Flame-retardant Pressurized Enclosure

- Corrosion-Resistant Enclosures

- Features Seawater-Proof Items

- NEMA and ATEX Compliant Enclosures

Send Your Inquiry on KDM Pressurized Enclosure Now.

- High-rated Materials Used in Fabrications

- Innovative and High-class Equipment

- ISO9001 Certified Manufacturer

- Trustworthy and Potential Supplier

Related Products of Pressurized Enclosure

Pressurized Enclosure

Wanting an advantageous Pressurized Enclosure for business?

KDM has the right answer! We have an experienced team of staff, equipped to provide customers` necessary needs.

KDM has full capabilities in manufacturing your specifications.

So, for next purchase schemes, consider KDM as your product solution provider. We know all you want!

KDM Pressurized Enclosure is useful for creating an artificial environment within the main enclosure.

This is a useful enclosure for housing the possible dismissal of operating types of equipment.

In general, KDM pressurized enclosure lessens pressurizations and provide apparatus security levels.

All hazardous consisting pieces of equipment in the enclosure can be controlled with the help of KDM pressurized enclosure.

This can make hazardous equipment to non-hazardous.

So, what else can you say? Aside from being a security provider, KDM pressurized enclosure has a great surface, very eye-catching for customers` eyes.

We highly recommend this kind of enclosure to be added to your business!

KDM has enough staff and designing team, helpful for creating your ideal pressurized enclosure designs.

This pressurized enclosure has a total protective gas offer, which allows the use of in-inclusive purpose enclosures.

Hazardous locations you may set this up to include certain Division 1 or 2, and class 1 dangerous settings.

Our team manufactured a pressurized enclosure with the right pressurization capacity and purge systems offer.

This has many advantages to bring for your business!

We made them explosion-proof, reliably protected, and flame-proof.

In actual design, KDM pressurized is weighted lighter and fine counterparts.

You may set them even in hazardous settings, they always work great!

Just send them us now and wait for a faster response.

What is A Pressurized Enclosure?

A pressurized enclosure is also called a hot work habitat or welding habitat.

It is a kind of chamber that offers safe work areas to perform hot work in vapors or explosive gases.

A pressurized enclosure is often used in combination with the requirement for welding.

Commonly, it is associated with offshore oil industries.

What is the Purpose of Pressurized Enclosure?

A pressurized enclosure forms pressurized rooms bases.

The pressurized methods can be elaborated and expanded to apply to built rooms.

It can also be applied to a whole building that consists of numerous rooms.

How Does Pressurized Enclosure Works?

The pressurized enclosures work by supplying a constant breathable atmosphere inflow.

It leads to the gas leak out of a chamber.

These gases outflow can prevent vapors or explosive gases ingress present in the work locations.

What is Pressurized Enclosure Made of?

The pressurized enclosure is made up of AISI 316L or AISI 304L stainless steel.

Most of the pressurized enclosure has a polished glossy finish.

What Are the Different Types of Pressurized Enclosures?

Px – Zone 1 Pressurized Enclosure

The enclosure offers Atex category 2 or EPL Gb protection.

It allows the consumer to use a standard industrial part in the control panel.

Moreover, this type of enclosure is individually certified as the test involving evacuation test.

It utilizes Argon and Helium which represents heavy gas and light gas.

Py – Zone 1 Pressurized Enclosure

For a higher degree of safety to your equipment, this type of protection is suitable.

Pz – Zone 2 Pressurized Enclosure

This type of enclosure is similar to Px.

It has a low degree of safety that protects ATEX category 3 or EPL Gc.

What is Pressurized Enclosure Used for?

A pressurized enclosure is built for aggressive or hazardous areas which are classified as Zones 22, 21, 2, and 1.

Pressurized enclosures are suitable for the following industries:

- Petrochemical

- Gas

- Pharmaceutical

- Maritime

- Field stations

- Air transport

- Print industry

What Are the Benefits of Pressurized Enclosures?

A pressurized enclosure provides the following benefits:

1. Quick Access

It allows easy open purged cabinets to maintain the hazardous areas.

- Class I Div 1 or Hazardous Area Zone 1: The power will automatically off when the internal air pressure falls or when the door is open. When the door will close, it’s automatically powered up, depending on the required purge cycle number.

- Class I Div 2 or Hazardous Area Zone 2: The low-pressure alarm will sound every time the door is open. But the equipment will work by the time you set.

2. Control Options

- Operator Interfaces: switches, lamps, pushbuttons, and annunciators.

- HMI Units

- Windows

3. Cooling & Heating

A pressurized enclosure includes the following local cooling or heating:

- Electric heating

- Thermostats

- Vortex coolers

- Fan-driven heat exchanger

4. Wheels

The purpose of the wheels is to move the equipment between points in hazardous areas.

Why I Need A Pressurized Enclosure?

A single unit such as a pressurized enclosure is cost-effective and purges numerous enclosures.

It also replaces interlinking conduit and explosion-proof boxes.

The pressurized enclosure is easy to upgrade and reconfigure when required.

What Are the Common Alternatives for Pressurized Enclosure?

Expensive alternatives to pressurized enclosures are the following:

- Explosion-Proof Junction Box (Exd Enclosure)

It can prevent internal ignition from reaching and can withstand internal explosions. However, explosion-proof junction boxes are heavy, general castings, solid metal boxes, and specially fabricated/welded.

- Increased safety Enclosure (Exe Enclosure)

It is widely used for equipment that does not spark or arc when having a fault or normal conditions.

This enclosure is insulated for keeping the temperature of the surface below incendive temperatures.

However, only approved Exe components are allowed to install inside the enclosure.