Looking for High-Quality Paralleling Switchgear for your Business?

KDM is Professional Paralleling Switchgear Manufacturer in China

Premier Paralleling Switchgear Supplier in China

In KDM, we offered complete service solutions to our valued customers. Our clients comes across various industries, business provide customers, end-to-end products.

Our state-of-the-art paralleling switchgear system design evolved and adopts the increased electrical infrastructures. By reason of, we are able to optimize our units independent, advances and robustness. All switchgear components are engineered intended for their application and optimized to meet specifications.

- KDM Paralleling Switchgear offers advanced, reliable, flexible, and independent power management.

- Increased productivity, cost-efficiency, installed quickly to any project

- Highly trained professionals to manage your requirements

- On-time delivery

Send Your Inquiries Now!

KDM Marshalling Box Series

Our Generator Paralleling Switchgear enhances the safety, reliability, and instinctively of the power distribution system. KDM’s team of experts takes every project seriously to meet every customer’s needs.

Automatic Paralleling Switchgear designed and manufactured tested and listed UL, CE., etc testing. Their robust design brings added flexibility, authenticity, and cost savings to any project.

Our range of low voltage paralleling switchgear is available in both indoor and outdoor installations. This is the switchboard and control switchgear ultra-solution.

KDM Medium Voltage Paralleling Switchgear delivers comprehensive solutions that meet the need and requirements – field of needs. We are dedicated to offering the highest standard of product quality.

KDM manufactures oil and gas paralleling switchgear which serves complies and is approved of many different standards such as ANSI, IEEE, NEMA, and more. Whether used for indoor or outdoor applications, our paralleling switchgear offered the best solution for you.

Our APT Paralleling Switchgear was designed with the new system which evolved and adapted to the changing technologies of the electric system. We have a variety of product which is customizable in order to meet the required standard.

Send your Inquiry on KDM Paralleling Switchgear

We have constructed and developed different paralleling switchgear suitable for any particular specifications. At the same time, we are eager to design units based on your layout or even your idea. Custom paralleling switchgear is processed through our advanced machines and is supervised by our highly-trained professionals.

In every stage of the project, from engineering, production to transporting, we can do all this responsibility and more others.

- Constructed from finest quality material

- Multiple selections of Paralleling Switchgear Units

- Tested and proven by international standards

- Safety, reliable, and versatile product to meet your specification

Related Products of Paralleling Switchgear

KDM Paralleling Switchgear

KDM Paralleling Switchgear designed and manufactured to the highest safety levels.

All electrical system, power distribution and among others, our kind of paralleling switchgear is the solution for them.

To enhance safety, reliability, and efficiency, we carry a wide array of upgraded paralleling switchgear.

Accessible and operational equipment which require minimal maintenance, functional design available in KDM.

Our Paralleling Switchgear comes in different dimensions, designs, and special functional features.

All our Paralleling Switchgear designed to offer optimum solution from simple to very complex switchgear controls, monitoring system, and other electric protection.

It will help ensure the reliability, protection, controls to the power source.

Unquestionably, our paralleling switchgear is the best automation and control solutions for all the power distribution components.

Each and every paralleling switchgear fully complies with internal testing and is rated by diverse authoritative authorities.

With improvement on dimensional flexibility and finishes, our equipment deliver full control to the power generation system.

Whether you need Paralleling Switchgear for prime power, emergency, or any electric cover applications, KDM team of talented engineers can custom-engineer switchgear to back it up.

Guaranteed-quality paralleling switchgear for any project requirements can be built to support you need to get the job done.

KDM, as one of the leading manufacturer and supplier of Paralleling Switchgear, we had extensive experience when it comes to providing numerous types of units.

As your optimum paralleling switchgear partner, KDM have done it all for you.

We are glad to help you find the best solution right for your needs.

In every detail of the production, we pay more attention with it to provide reliability, technically tested- quality product. Here in KDM, we professionally manage your projects at all stages.

Over the last 10 years, we pride ourselves to manufacture quality product, plus we had achieve customers’ satisfaction to prove it.

KDM paralleling switchgear contains a circuit breaker section and controlling sections.

These can consolidate into 1 assembly or individually attached.

An operation in which triple energy sources are contemporized and associate with the usual bus.

These have important function requires two or more extra paralleled generators with viability.

Also, these able to enlarge authenticity, the pliability in charge control, continuous maintenance activity and cost-effective throughout peak cost inducement times.

These are switchgear types that functional for security, metering, management, and converting union.

And then acts as a unified electrical system.

These help to manage well dispersal of electricity power for urgent systems, lawfully necessitate understudy systems, hypercritical utilization capacity system, etc.

These all kinds of systems, paralleling systems are very functional.

The generator meets near to assess voltage and persistence linked to a dead bus.

Even without waiting to integrate and must ordinarily categorize at minimum power energy to censorious and life security charges.

Before paralleled, frequentness, voltage energy, phase perspective, and rotary must be counterpart within the authorized maximum.

And triple generators required to be paralleled into usual bus finer set out evaluative charges.

Thus, the foremost generator equipment that meets automatic utilizing parameters will energize evaluative charges with harmonizing outstanding generators.

The load control program is so simple to direct when charge requests paired all separated generator proportions.

Taking one generator disconnected for sustenance and allows others to choose losing up is very easy with this paralleling switchgear product.

All generators will operate with their fullest regulation level when almost complete charges.

But when only have lightly charged generators, paralleling switchgear will be vulnerable to moistened assemble, where temperature engine operates not sufficiently inflated to expertly burn all fuels.

All these safety functions surely obtained with well-structural paralleling switchgear from KDM.

Paralleling switchgear has many purposes and advantageous effects to demonstrate.

For your business, including well-built paralleling switchgear is very worthwhile and serviceable.

Much benefits for both clients and for your business especially.

With qualified system-checked, significant specifications for standby institutions.

And no stacking examination was implemented.

Though, generators in parallel switchgear are well organized and link to extremity bus even without loads taken.

These run across both offload and on load tests, just to ensure the quality of service and quality of the product.

We make quality ensured productions.

Not just paralleling switchgear, but there`s a lot more.

We, KDM are the top choice of everyone when talking about the reliable value of manufacturing abilities.

We provide customized electrical enclosures, cost savings, and huge industrial purposes.

We, as responsible suppliers received international certification such as ISO9001 and IP 66.

With more than 10 years showing good rated services, we become known as one of the trusted enclosure manufacturers worldwide.

Designers and engineers that operate on behalf of KDM institution have exercising skills and proven professionals.

They are assigned to help make inventions with the highest quality.

To keep you updated, contact us and receive appropriate answers to your questions.

We fully support your business.

Paralleling Switchgear: The Complete FAQ Guide

Are you looking for an independent power source, robust protection or monitoring solution integrated in one system?

Then you need to start thinking of implementing paralleling switchgear.

And, today’s guides will take you through all the fundamentals of paralleling switchgear:

- What is Paralleling Switchgear?

- Is Paralleling Switchgear the same as Momentary Paralleling?

- What are the Advantages of Paralleling Switchgear?

- Are there disadvantages of Paralleling Switchgear?

- When should you use Paralleling Switchgear?

- Where can you use Paralleling Switchgear?

- How does Paralleling Switchgear work?

- What are the Methods of Paralleling Switchgear?

- What is Droop?

- What are the Metering Parameters for Paralleling Switchgear?

- What is the Quality Standard Specifications for Paralleling Switchgear?

- How does On-board Paralleling Switchgear compare to Traditional Paralleling Switchgear?

- Does Paralleling Switchgear have a Voltage Limit?

- What are the Specifications for Paralleling Switchgear?

- What is Distributed Generation Switchgear System?

- When should you Synchronize Generators?

- What is the difference between Kilowatt Load and Kilovar Load?

- How do you Test Paralleling Switchgear?

- What are the Common Paralleling Switchgear Types?

- What are the Building Blocks of Paralleling Switchgear?

- What are the Components of Parallel Switchgear?

What is Paralleling Switchgear?

Paralleling Switchgear refers to a combination of metering, control, protection, and switching components that act as an integrated system.

Its function is to control power distribution to systems like:

- Critical Operation Power Systems (COPS)

- Optional Standby Systems

- Emergency Systems

Paralleling switchgear

Is Paralleling Switchgear the same as Momentary Paralleling?

No.

They are not the same.

You achieve momentary Paralleling when there is a change in the use of switchgear from one type to another. While this happens, there is no tripping downstream of the loads.

Paralleling Switchgear is the synchronization of two or more switchgear to ensure optimum performance.

In this case, all the switchgear operate.

While Momentary Paralleling involves a change of the switchgear, paralleling switchgear, continue to function until each reaches an optimum level.

At this point, the others continue functioning.

What are the Advantages of Paralleling Switchgear?

The following are the advantages of using Paralleling Switchgear:

Paralleling switchgear

· Reliability

Paralleling Switchgear allows for continuous operations even when one switchgear reaches optimum operating parameters.

This also allows for the repair and maintenance of one switchgear while the other continues operating.

· Flexibility

You have a wide of energy to select when using paralleling switchgear.

This is because it can accept either direct currency or Alternating currency.

You, therefore, don’t have to worry over which source of energy to use when operating a Paralleling Switchgear.

· Ease of Maintenance

During maintenance, there is no need for switching off the entire paralleling switchgear.

You can repair one while the other still operates.

· Cost-efficient

It is cheaper to operate and maintain parallel switchgear than the other types of switchgear.

First, it is cheaper to purchase paralleling switchgear than to purchase separate switchgear.

Also, you have a lower maintenance cost than the other types of switchgear.

This is because maintenance does not reduce the operating cost and operational time.

· Complexity

Paralleling switchgear eliminates the complexity associated with switchgear.

Paralleling switchgear is easier to learn and operates with little know-how.

Are there disadvantages of Paralleling Switchgear?

Yes, there are disadvantages of using Paralleling switchgear including:

· Incompatibility

All the switchgear that you use should be compatible with each other.

This may pose a challenge especially when you have different types of switchgear.

Also, you can experience different energy requirements, which necessitates the use of different switchgear.

· Cost

The overall cost of the Parallel switchgear installation is high compared to traditional switchgear.

· Space

Paralleling switchgear requires a lot of space for installation and proper functioning.

This can be a limiting factor if you don’t have enough space.

When should you use Paralleling Switchgear?

Paralleling switchgear is ideal for a Critical operating system that requires a standby source of energy.

Where can you use Paralleling Switchgear?

You can use Paralleling Switchgear in the following areas:

- Critical Operation Power Systems (COPS)

- Optional Standby Systems

- Emergency Systems

- Legally required standby systems.

How does Paralleling Switchgear work?

Paralleling switchgear involves simultaneously functioning of the switchgear until each reaches an optimum level.

The operation depends on the parts of Paralleling switchgear namely the relay and the circuit breaker.

When a fault occurs, the relay swings into action by closing the circuit trip.

This is through the automatic disconnection of the fault line.

Next, the healthy and operative sections ensure there is a flow of the required normal supply load.

Through this, there is a smooth electrical supply throughout the equipment, ensuring there is no damage.

Overloading of the line inhibits the current from making an electromagnetic release action.

However, it initiates the production of heat by the thermal element.

The heater heats the bi-metal sheet causing it to bend upwards.

This pushes the lever upwards, making the hook to lock off.

This breaks off the primary contact, cutting power supply off.

By doing this, when there is an overload, it exceeds the set current causing the electromagnetic tripper to produce suction.

A combination of the suction and the impact lever results in the lap hook to rotate upwards around the

Shaft seat, thereby releasing the lock.

What are the Methods of Paralleling Switchgear?

The common methods of paralleling switchgear include:

Paralleling switchgear – Photo courtesy: IEEE

1. Island Method (Isolated from the utility)

In this method, when there is a power blackout, the paralleling switchgear disconnects from the main power source.

The Parallel switchgear consists of relays which detect a change in voltage and frequency of the individual utility connection.

A change in the voltage or frequency means that there is a collapse in the utility.

This causes the relay to trip incoming utility in the circuit breaker.

The disconnection of the utility from the paralleling switchgear initiates the operation of the generator.

When a generator reaches the optimum operating level, it automatically disconnects to a dead bus.

The disconnections allow for the provision of emergency power and life safety loads within a couple of seconds.

2. Manual Method

The manual method allows for system operations when there is a failure on other components.

It consists of a predefined sequence of events that allows for efficient operations by an operator.

The operator starts operating the switchgear manually and initiates their synchronization process.

Manual operation implies that the user initiates all the functions as opposed to system initiation.

3. System Testing Method

This is an important requirement during standby/emergency applications.

It is a protective requirement for commercial buildings.

When carrying out the monthly and yearly tests, the system testing method helps in ensuring that the switchgear passes the necessary tests.

4. No-load Testing Method

You use the no-load testing method when you have started synchronizing the paralleling switchgear.

You then have to connect them to the switchgear bus without accepting any load.

This method aims to determine if the switchgear can start if they are signals for them to start. It also determines if the switchgear can carry any load during operations.

5. On-load Testing Method

You can carry this method during a gradual transfer of a load from a source of power to the paralleling switchgear.

This is through a closed transition.

You need to check on the operating conditions of the different compartments before using this method.

What is Droop?

A Droop refers to a control mode whose application in AC electrical equipment is to reduce the power output while the line frequency increases.

Droop functions by controlling the power rate that is produced by prime movers as per the grid frequency.

What are the Metering Parameters for Paralleling Switchgear?

The following are the Metering Parameters for paralleling switchgear:

- Speed control. The paralleling switchgear needs to have the same final speed to ensure efficient working.

- Load balance. All the Parallel switchgear should share the load equally as per the capacity of the individual switchgear.

- There is a need to synchronize the Parallel switchgear to ensure efficient and proper working. This includes having the same voltage and frequency and load compatibility.

- Voltage regulation. This is the need for having proper regulation of the voltage to ensure effective working.

What is the Quality Standard Specifications for Paralleling Switchgear?

The quality standard specifications for a Paralleling Switchgears include:

- American National Standards for Insulators (ANI) standards.

- International Electrotechnical Committee (IEC) standards.

- National Electrical Manufacturer Association (NEMA) standards.

- Institute of Electrical and Electronics Engineers Standards Association (IEEE-SA)

- ISO standards which check on the quality and safety of the LV switchgear.

How does On-board Paralleling Switchgear compare to Traditional Paralleling Switchgear?

Traditional Paralleling – Photo courtesy: IEEE

Onboard paralleling

Traditional Paralleling switchgear utilizes a lot of space as compared to an On-board Paralleling switchgear.

Both On-board Paralleling switchgear and traditional paralleling switchgear allow for customization.

This enhances its usability and application.

Both Traditional Switchgear and On-board switchgear guarantees efficiency and less maintenance during the operation duration.

This ensures optimum productivity.

It is easier to integrate the different components of Traditional paralleling switchgear than those of On-board switchgear.

Traditional paralleling switchgear has a longer lead time to manufacture than an On-board Traditional Switchgear.

Traditional paralleling switchgear is relatively expensive when you compare to an On-board Paralleling switchgear.

Does Paralleling Switchgear have a Voltage Limit?

Yes.

There is a specific voltage limit for each specific paralleling switchgear.

Generally, there are three types of Paralleling switchgear based on the voltage limit.

That is, low voltage Paralleling Switchgear, Medium voltage switchgear, and high voltage paralleling switchgear.

Low voltage Paralleling switchgear connects and disconnects, distributes, and interrupts current flow with a voltage of up to 600V.

Medium voltage Paralleling switchgear interrupts, connects and disconnect and distributes current with a voltage between 600V and 69kV.

A High Voltage Paralleling Switchgear connects and disconnects, interrupts and distributes current with a voltage of between 69kV and 230kV.

What are the Specifications for Paralleling Switchgear?

The specifications for a Paralleling Switchgear include Voltage drop, Application type and the model of the Parallel switchgear.

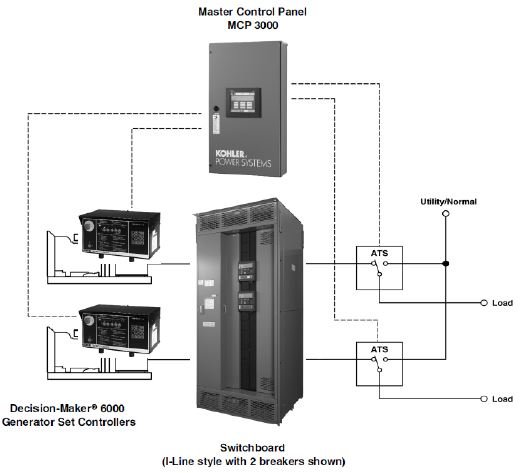

What is Distributed Generation Switchgear System?

Distributed Generation Switchgear system refers to the parallel operation of either a single or numerous Switchgears on an isolated bus or to a utility grid.

Such a system offers power factor control, automatic synchronization, and soft load closed transition transfer.

You can use this system for continuous parallel operations using utility when carrying out load testing, cogeneration applications, and load demand management.

When should you Synchronize Generators?

You can achieve Generator synchronization under the following conditions:

i. Phase Sequence

As a requirement, the phase sequence of the alternator’s three phases that you connect to the power grid should be equal to the bus bar’s three-phase.

You will encounter this condition during the installation process of your paralleling switchgear.

ii. Phase Voltage

The phase voltage, an incoming alternator needs to be equal to the phase voltage of the electric grid or bus bar.

A high reactive power occurs in the case of a higher incoming alternator than the voltage of the bus bar.

This power flows to the grid from the switchgear

iii. Phase Angles

The incoming switchgear voltage and the bus bar voltage should have a phase angle of zero.

You can check this through a comparison of the zero-crossing occurrence.

iv. Frequencies

The incoming switchgear frequency needs to be the same as the bus bar frequency.

A mismatch in the two can result in high deceleration and acceleration in the prime mover.

This increases the transient torque.

What is the difference between Kilowatt Load and Kilovar Load?

Kilowatt Load refers to the measure of working power that switchgear uses while operating.

All loads that use real power are called resistivity loads.

Kilovar Load is a measure of the reactivity power necessary for the generation and sustenance of the magnetic field. This field is necessary for the operation of the switchgear.

Kilovar Load is the same as non-working power.

In direct current, the Kilowatt load is equal to the Kilovar load.

This is because the current and the voltage do not go out of phase.

In Alternating current, the current and voltage are at times out of phase, which means the Kilowatt and Kilovar are not the same.

In a practical sense, only a portion of the Kilovar is available for work while current stores the rest as excess.

How do you Test Paralleling Switchgear?

The following are the tests that you need to conduct on a Paralleling Switchgear:

· Creepage and Clearance distance

You need to carry out this test between the live parts of the paralleling switchgear and also its exposed conductive parts.

You measure the distance between the live parts using the different polarities.

Bolted connections, joints, unsuitable connectors minimize the initial insulation values.

· Protective Circuit Effectiveness

This helps in determining the safety of the Parallel switchgear.

This test also determines the occurrence of high fault current in case the conductor detaches accidentally.

Effective protective circuits need to withstand optimum short-circuit thermal stress, which happens as per the supply current.

· Short-circuit Resistance

This test determines the resistance of the busbars and their breaking, supports, and protective devices to the electrodynamic and thermal stress.

· Temperature Rise Limits

Temperature rise limits help in determining the appropriate operating temperature for the low voltage switchgear.

High temperature has the effect of components aging prematurely, leading to the failure of the Parallel switchgear.

· Checking Operational Degree

This test determines the operational safety of the low voltage switchgear.

It also helps in preventing solid and liquid contaminants from getting in contact with the switchgear.

· Current Transformer Core Test

You need to test the ration and polarity of the current transformer core and compare the results to the primary current injection.

You need to perform this test phase by phase.

· Dielectric Test

The dielectric test is on the auxiliary circuits.

For this test, apply 500 voltage DC between the terminal blocks and the earth point.

· Low Voltage Tests on the Main Circuit

You need to check on the dielectric strength to remove causes like damage during handling, wrong fastening, and presence of foreign bodies.

Such issues may result in an internal malfunction of the switchgear of not addressed

What are the Common Paralleling Switchgear Types?

The following are the main types of Paralleling Switchgear types:

- Generator Paralleling Switchgear offers reliability and accuracy to the power distribution system while enhancing safety. You can get a customized generator paralleling switchgear.

- Automatic Paralleling Switchgear complies with tests and standards such as UL and CE. They have a unique design that enhances authenticity, flexibility, and cost-saving.

- Low Voltage Paralleling Switchgear is available for both indoor and outdoor installation. It is ideal for low voltage requirements.

- Medium Voltage Paralleling Switchgear offers comprehensive solutions that meet your average power requirements. Its quality is unmatched, and you can rely on its productivity as it certifies all the necessary tests and safety standards.

- Oil and Gas Paralleling Switchgear complies with international tests and standards such as ANSI, IEEE, and NEMA. You can use this switchgear either for your outdoor or indoor requirements.It features a sleek and compact design that enhances performance.

- APT Paralleling switchgear features a new design that can handle the changing electronic technologies. You can easily get a customized APT Paralleling switchgear that fits your application requirements.

- Digital parallel switchgear prioritizes reliability and flexibility in its operation. It is ideal for applications with a wide range of applications from simple to complex power systems.

- Indoor parallel switchgear is suitable for indoor applications and can manage load with maximum efficiency and reliability. It is an effective power management system that offers trustworthy and advanced independent management.

- 15kV Paralleling switchgear comes either for indoor or outdoor applications. It features a compact size that enhances safety and flexibility, which meets your power system requirements.

- Marine Paralleling switchgear maximizes on the controlling and monitoring capabilities on your electric system. This paralleling switchgear is available in different types that can manage any load.

- Utility Paralleling switchgear offers reliability and flexibility for your utility application.; we have a wide range of paralleling switchgear that fits your application needs.

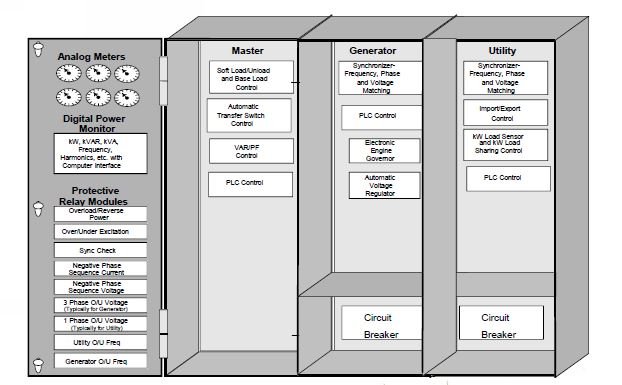

What are the Building Blocks of Paralleling Switchgear?

The main building blocks of paralleling Switchgear are:

- Utility Breaker Compartment. The utility source feeds this breaker.

- The Generator source feeds the generator Breaker Compartment directly.

- Tie Breaker Compartment is between the same source breakers. For instance, between a generator tie and a utility tie.

- Generator Main Breaker Compartment connects the utility bus to the generator bus. Its function is to transfer controls between two points.

- Distribution Breaker Compartment/ Feeder directly transfers switches or feeds loads.

What are the Components of Parallel Switchgear?

The main components of parallel switchgear are:

· Protection

The protection component is dependent on the size of your parallel switchgear.

The protective functions of common use are 25, 27, 32, 40, 46, 49, 50P, 50/51G, 51V, 59, 67G, 81O/U and 87G.

· Load Management

Load management helps in the efficient operation of the parallel switchgear.

The classification of load depends on the number of switchgears.

Load addition is through a pre-designed priority depending on the line capacity availability.

Block shedding starts in case the switchgear fails.

· Master Control

The master control consists of load add/shed transfer switches.

The Master control connects all the protective metering display and control devices.

· Engine Control

Paralleling switchgear requires two main generators for it to function properly.

An engine governor controller helps in controlling the output and speed of the engine.

A voltage regulator helps in controlling the reactive power and voltage of the generator.