Need Help for Complete line of High-Quality Pad-Mounted Switchgear?

KDM is one of China Leading Pad-Mounted Switchgear offer Excellent Services

Premier Pad-Mounted Switchgear Supplier in China

KDM is a certified supplier who has been awarded many times because of the quality service we offered, especially for Pad-Mounted Switchgear. Our friendly staff who can handle any difficulties can make clients satisfied and feel convenient in dealing with us. Especially our best in quality Pad-Mounted Switchgear is not the only reason why many clients stay on dealing with us. It is also because of our eco-friendly cost offered. It is great for you because we can deliver our Pad-Mounted Switchgear worldwide. We are perfectly tested because we absolutely inspect our supplied products before we deliver.

- In the industry, KDM has experienced over 10 years Pad-Mounted Switchgear production

- Supply a wide range of Pad-Mounted Switchgear that is typically tested and proven technology

- KDM is a skilled manufacturing company of Pad-Mounted Switchgear

For inquiries, Contact Us Today!

KDM Pad-Mounted Switchgear Series

Our FTDF Fused Sectionalizer Pad-Mounted Switchgear is available in 15 and 25 kV voltage classes. It was designed to maintain electrical clearances, with expulsion type power fuses.

Our professional and well-trained staff produce PLD Live-Front Dead-Front Pad-Mounted Switchgear with flexibility and convenience desirable features for ensuring security.

PMDF Primary Metering Pad-Mounted Switchgears are most available here in KDM which has its high performance suited in many applications. A wide range of PMDF Primary Metering Pad-Mounted Switchgears that are reliable and upgraded can be provided.

Reliable PMH Pad-Mounted Gear that is tested by many from KDM is highly developed so it can be great for any use. We are certified in Manufacturing PMH Pad-Mounted Switchgear to meet all the special requirements.

All the ratings of our manufactured PSE Dead-Front were exceeded for both 15 and 25 kV. Featuring publicity, it eliminates the possibilities for standing water. Our professional and skilled staff fabricate PSE Dead-Front pad-mounted switchgear with the flexibility to supply all their client’s needs.

Live Front 6 Compartment pad-mounted switchgear is now performed in single switchgear fabrication. Live Front 6 Compartment pad-mounted switchgear needs four-compartment units. KDM produced pad-mounted switchgear with the help of their licensed team.

Send your Inquiry on KDM Pad-Mounted Switchgear

We are one of the substantial distributors and suppliers of Pad-Mounted switchgear with our very best and most modern machines. Our professional and well-trained staffs are perfectly able to manufacture Pad-Mounted Switchgear in its standard layouts with durability and efficiency. We handle no pressure services just to supply and meet the needs of your special requirement by dealing with us.

- KDM knows a lot of requirements on the enclosure

- Only focused on the electrical enclosure in more than 10 years

- Professional in supporting clients’ orders

- KDM provides the best enclosure solutions

Related Products of Pad-Mounted Switchgear

KDM Pad-Mounted Switchgear

KDM Pad-Mounted Switchgear conceived in detail by its different proportions. By our latest technology, KDM Pad-Mounted Switchgear was constructed and expands. We maintain different functions in a well-organized and also in a very competent way. KDM ensured their supplied products to all of their customer’s well package provided and safe. In more than 10 years in manufacturing Pad-Mounted Switchgear in the industry, we have been trusted and proven by many people in the business. Providing our very best services with our well-experienced staff, Pad-Mounted Switchgear is fabricated to supply all necessary requirements.

KDM Pad-Mounted Switchgear conceived in detail by its different proportions. By our latest technology, KDM Pad-Mounted Switchgear was constructed and expands. We maintain different functions in a well-organized and also in a very competent way. KDM ensured their supplied products to all of their customer’s well package provided and safe. In more than 10 years in manufacturing Pad-Mounted Switchgear in the industry, we have been trusted and proven by many people in the business. Providing our very best services with our well-experienced staff, Pad-Mounted Switchgear is fabricated to supply all necessary requirements.

Most of our customer’s value KDM products. We simply develop our strength in manufacturing Pad-Mounting Switchgear to help clients get their desired products. To provide the isolating requirements, Pad-Mounted Switchgear was designed. We have standard Pad-Mounted Switchgear that is accessible just to cover all the possible situations. KDM is highly offered its best manufacturing products that are applicable by many. Being successful in finding your desired quality products is the best and great help for your business especially in finding Pad-Mounted Switchgear.

Upon your request for your Pad-Mounted Switchgear, KDM can surely provide what you need. In manufacturing, we increased the protection of switch components to prevent any circumstances to limit exposures. Our very watchful and professional team makes great Pad-Mounted Switchgear in different features that are suited to our needs. We have our proficient engineering team who develop their way of the manufacturing of our products to serve their client’s tastes.

Any types of KDM Pad-Mounted Switchgear are available. You can always get what you wished for by dealing with us. Have a great deal with us and contact KDM with no other hesitation.

Pad Mounted Switchgear: The Ultimate FAQ Guide

In this guide, you’re going to learn everything about pad mounted switchgear – from technical specification, parts, working principle, and troubleshooting process amongst others.

So, if you want to be an expert in these switchgear panels, then read this guide.

- What is Pad-Mounted Switchgear?

- What are the Functions of Pad-Mounted Switchgear?

- What are the Components of Pad-Mounted Switchgear?

- What are the common Faults in Pad-Mounted Switchgear?

- How do you Test Pad-Mounted Switchgear?

- How does Pad-Mounted Switchgear Work?

- What is the difference between Pad-Mounted Switchgear and Pad-Mounted Transformer?

- What is Pad-Mounted Switchgear Specification?

- Does Pad-Mounted Switchgear have Arc Flash Hazard?

- How do you Troubleshoot Pad-Mounted Switchgear?

- What are the Advantages of Pad-Mounted Switchgear?

- Are there Drawbacks of Pad-Mounted Switchgear?

- Where can you Install Pad-Mounted Switchgear?

- What are the Pad-Mounted Switchgear Quality Standards?

- What are the Characteristics of Pad-Mounted Switchgear?

What is Pad-Mounted Switchgear?

Pad-mounted switchgear’s design intends to help in realizing the activities like the insulation and switching necessities of electrical supply systems.

They have over 15 switching formations which are pre-engineered.

The pad-mounted switchgear is of different types, namely:

- Live-front Pad-Mounted Switchgear

- Dead-front Pad-Mounted Switchgear

- Auto-Source transfer Pad-Mounted Switchgear- operates using the automatic mechanism.

- Manual Pad-Mounted Switchgear- operated manually.

The voltage ratings are in accordance with the IEC 6271-200, medium voltage up to 25 kV.

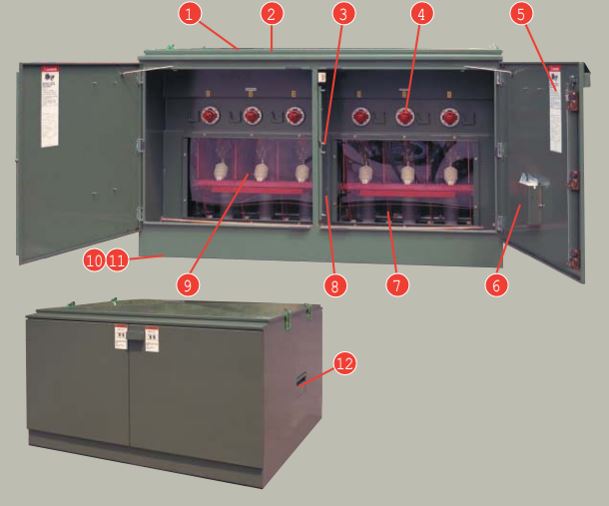

Pad mount switchgear

What are the Functions of Pad-Mounted Switchgear?

The functions of live-front pad-mounted switchgear:

· Pad-mounted Switchgear offers Insulation and Protects Fuses in Radial Systems.

The radial systems are applicable where service dependability and type of load do not permit the intensified investment of the further adaptable loop system.

In situations where there are numerous cables, the radial system becomes useful.

Every one of them serves a limited number of discrete loads.

Sample of radial system

· Pad-Mounted Switchgear delivers Sectionalizing in a Loop Feed Delivery System

It has a loop cable connected to the power supply at a “normally open”.

The two terminals, switch nearby the load midway-point, to offer outstanding physical sectionalizing.

Similarly, the auto-jet II switches close and open as per the requirement to insulate a cable fault or defected circuit condition.

They deliver comprehensive service restoration.

· Offers Service to Critical Load

It is a perfect way to offer services to critical loads through the selecting switches.

The selecting switches permit physical restoration of service in case there is a loss of the supply.

What are the Components of Pad-Mounted Switchgear?

Some of the main components of pad mounted switchgear include:

1. The Components of the Pad-Mounted Switchgear

Always ensure the checklist contains the required information about the equipment.

Therefore, the following components are vital in the build-up of the Switchgear to confirm that it meets the standards of IEC 6271-200:

Since pad-mounted switchgear comprises of varied types, there is little variation in the types of components.

For instance:

a) Dead-front Pad-Mounted Switchgear

The main components include the following:

Dead front pad mounted switchgear

- The roof of one-piece on all dead-front replicas

- No unprotected hardware, every part is covered

- The hand-positioned handle on overlapping doors -takes no apparatuses to function

- Shielding shipping protections on bushing well and bushings

- Phase identification, unit, rating labels, and hazard-alerting signs

- Instruction guide packing container

- Internally, walls offer phase seclusion

- Stiff, steel-panel walls fully insulate fuses, switches, and bus

- Clearcoat switch window of inspection

- Component sections sealed at the bottom by a galvanized sheet made of steel, at the top by a gasket

- Gasketing at the bottommost on inclusion flange

- Optional key meshes for fuse doors & switch handles

Pad mount switchgear

- Robust stainless-steel space stand

- Bushing shafts with detachable studs

- Watching window to detect blown fuse

- Ground bracket linked to enclosure

- Mesh handlebar regulates contact to fuses

- Gasketing amid compartment steel & fuse panel divider sheet

- Shutter walls hinged

- Hold-down clamp protects panel to insertion while eradicating fuse

- Articulated mesh moves and protects shutter wall

- Fuse panel houses fuses of all types

- Packing strut for fuse assemblages which is noncompulsory

- Incessant copper pulverized rod

- Cable guides

- Fuse compartment encompasses features to regulate access, limit cable movement. Besides, they offer safety to personnel.

Until the latch bar raised and the elbow parked, there is no lowering of the fuse panel to get access to fuses.

Cable leads at the bottom of the cover, amid fuse panels, retain cables adjacent and out of sight when fuse panel lessened.

- The shutter barrier routinely locks when the panel lessens to ensure the isolation of personnel from energized parts.

- The hold-down lock – located is to secure the fuse panel at a point.

Fuse is secluded from the high voltage at mutual ends.

Also, it lifted out either employing shotgun stick outfitted with the fuse-removal device or by hand.

Re-utilizable parts of fuse are indistinguishable whether the unit is dead-front or live-front.

The panels offered for all types of fuses.

- Bushing wells match ANSI 386/ IEC 6071-200 design standards.

All wells entail a detachable stud, non-load-break, or accommodating load-disrupting elbows.

Phase-to-phase arrangements permit the use of an array of standoff and insert bushings.

Dissolution-compartment complexity is ample to lodge all the elbow connectors.

Clear gap outspreads complete width of the enclosure at the bottom for simple cable termination and entry.

The bottom flange clamped to hold bolts to safeguard cover to the pad.

Other Vital Components for the Pad-Mounted Switchgear in General

Some of these components include:

Auto-Transfer Microprocessor

Some of the key features include the following:

- LCD of 40-character exhibition

- Incident log used for 2000 archives

- Keypad meant for straight access of field-selectable operations

The microprocessor offers software intellect to induce processes grounded in programming settings.

Field selectable operations entail timers used for:

- Return and loss of voltage

- Setting for usual, unbalanced and over-voltage

- Pick-up settings for locking out over-current

- Assortment of favored/ alternate supply, close/ open transition on return and auto/ hold return.

Status situations are accessible and testing functions provided for keypad, LCD, lamps, and to mimic lockout & loss of voltage.

Auto-Transfer Stored-Energy Switch Operator.

Some of the key features include:

- Operation Counter

- Decoupler

- Indicators for switching positions & charged position

- Close/ open pushbuttons

- Charging port with meshed cover

The accumulated-energy switch operative offers high-speed, controlled, shut-trip functionality of the load break switch to counter the indicators from the microprocessor control.

Transfer time from the first switch uncluttered to the second switch lock is ten cycles.

It is combined with any deliberate time delay to validate loss of supply voltage is not transient.

The rugged creation of the switch operator protects a longer life of the slipping mechanism.

SCADA Switch Operator: Remote Switch Function.

It’s key features are:

- Decoupler

- Weather-resistant closure

- Close/ open pushbuttons and indicator lamps

- Countering operations.

- Battery & battery charger

The SCADA-regulated switch operative is used in unification with the load-breaker switch to offer regulated, even process in response to indications from a remote terminal unit (RTU).

The battery size is to effectively energize the RTU, motor operator, and the user-chosen transmission equipment, landline, radio, fiber optic, or hardwire.

Isolated indication of switch point and other analogue & digital outputs are voluntary.

600-Amp Load Breaker Switch

It operates by securing the operators from the source when it opens an electrical circuit.

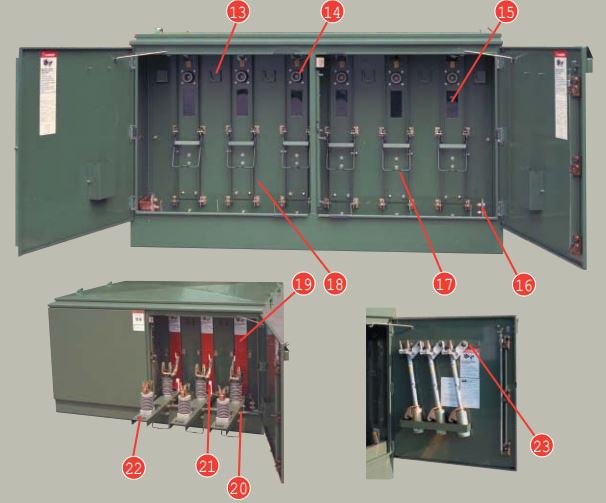

Load breaker switch

Features

- 600-amp consistent and load disrupt

- Side-function straight drive

- UL- Identified at 15kV

- Three-Phase power shifters

- Fault locking to 40kA irregular three-time obligation cycle

Non-Load Breaker Fuse Mountings & 200-Amp Load-break

Some of the key features include:

- 200-Amp, offer to switch in a single-pole with fuses

- Lodges all types of fuses in a wide array of Amp ratings

- Cycloaliphatic insulation

- Stable, firm pull/ push opens and locks load interrupter

- Heavy-gauge mounting plate made of steel makes comprehensive assembly rigid and rugged

- Defect locking to three times rated fuse.

Bushing Wells & Bushings, Cycloaliphatic Isolators

Some of the main features of this accessory include the following:

- UL identified at 15kV

- 1200 amp & 600 amp consistent and load breaking

- Three-phase & single-phase switches

- Defect locking to 40 kA irregular three-time obligation cycle

- Side-functioning straight drive

During the construction/ maintenance or installation of bushing wells, insulators, & bushings, the following conditions must apply:

- The insulators, bushing well & bushing, should have at least 20 years of functioning experience.

- An ablative act is to certify properties of non-tracking.

- Suitable leakage detachment recognized for every IEC standard 60507 of testing.

- Their power of resistance towards short-circuiting stress recognized by the test

- Validation to the appropriate ANSI/IEC standards

- The Cycloaliphatic epoxy balm should have consistency throughout every bushing, insulator, and bushing well.

The property provides maximum withstand to power arcs.

Any damaged surface to isolating components during maintenance or installation of the pad-mounted equipment exposes material of a similar property.

The isolating components with inconsequential surface damage do not require replacement.

The damages can be as a result of consistent exposure to high temperature from power arcs.

- Every bushing well, insulator, & bushing x-rayed to ensure it is fundamentally free from the void—an alternative method of testing used as well after the engineer’s approval.

- Bushing well and bushing conducting rods made of copper, and silver flash at looped studs.

What are the common Faults in Pad-Mounted Switchgear?

Since the installation of Pad-Mounted Switchgear is underground, it, therefore, faces failures like:

Pad mount switchgear

· Electrochemical Treeing of Cables

The main dependability worry relating to subversive cables is electrochemical treeing.

Treeing arises when moisture permeation in the existence of an electric field decreases the dielectric potency of cable isolation.

When the dielectric power reduces adequately, transients triggered by switching or lightning can lead to dielectric failure.

Electrochemical treeing typically alters extruded dielectric cable and is widely attributed to isolation contaminations and terrible manufacturing.

To lessen malfunctions associated with electrochemical treeing, a company can:

- Establish surge shield on riser poles,

- Can buy tree-retardant cable, and

- Can check cable reels before allowing them from the producer.

Animal Faults

The fire ants are the major causes of these faults.

They build nests in the equipment. When they make their nests, the materials can result in short-circuiting.

The ants can probably eat away insulating material, leaving the conductors bare.

The invasion of fire ants and other animals like rodents make the maintenance of the pad-mounted switchgear a challenge.

Invasion by ants

How do you Test Pad-Mounted Switchgear?

You should always conduct testing of pad-Mounted Switchgear by:

- Carrying out insulation resistance test, dielectric test, circuit interrupter test, and current test.

- You should always do an insulation resistance test by applying voltages ranging from 600 to 10, 00 V DC.

- The circuit interrupter test conducted by measuring the breaker connection resistance from bushing terminals when in a locked position.

A recommendation of 100 A, a higher value of current provide a more reliable outcome than low values.

How does Pad-Mounted Switchgear Work?

The pad-mounted switchgear has vital components like the Load Interrupt switches, interlocks, and fuses.

These devices essentially contribute to protection.

Here is how pad mounted switchgear works:

- When the equipment is in an ON position, the load interrupt switch interrupts the high current. The switch uses the fast interrupt spring-charged process.

Then the switch linkages become impartial of the speed at which the operative handle shifted.

The switchblades close and break the flow of current.

- The locking and unlocking mechanism happens when the interlocks avert the breaking of the locks.

- The fuses installed similarly play a pertinent role in protection. If a higher value of current passes across the circuit, the fuse heats up and melts.

After melting, the current stops from flowing; hence, protection of the electrical system.

What is the difference between Pad-Mounted Switchgear and Pad-Mounted Transformer?

A pad-mounted transformer is a piece of equipment mounted on a concrete pad in electrical power supply in a closed steel cabinet.

Pad mounted transformer

It is applicable in stepping down high voltages in the power supply system and distributing it to the consumers in lower and safe voltages.

While pad-mounted switchgear designed to help in the insulation and switching necessities of electrical supply systems.

The equipment offers protection to the operators and the electrical power system.

What is Pad-Mounted Switchgear Specification?

Some of the main specifications include the following:

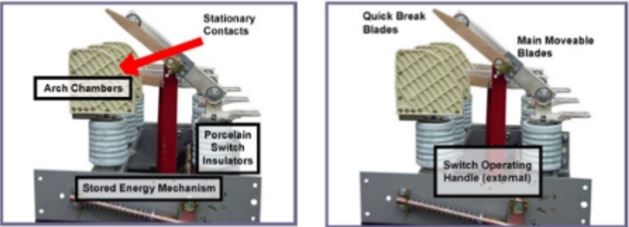

· Interrupter Switches

They encompass the load interrupt switches & interlocks.

Load Interrupt Switches

The load interrupt switches are essential in energizing/ de-energizing the electrical circuit that carries current.

The current can be from the mains or transformer or rather a captive current.

The Working Process of Load Interrupt Switch

- Two-positioned (locked/ open), three-pole switch

- Fast make/ fast interrupt spring-charged process for both completing & opening.

- Switch connection speed is impartial of the speed at which the operative handle shifted.

- They are controlled superficially from the opposite side of the switch cover.

- Switchblades unlock and disrupt the stream of electricity

Interrupter

Interlocks

- Door interlocks and automatic switch are standard.

- When the switching device is in the “ON” position, the interlocks avert the breaking of the locks.

- Block switch from locking when the door unlocks.

- There is a requirement of about six possible key interlocks.

They have a 3-time obligation cycle rating of locking defect.

Always ensure that the interrupter switches meet the standard rating of IEC.

The rating determines the capability to lock the switch when in combination or single with the applicable power fuses.

The interrupter switches utilize the mechanism of a fast break, installed by the manufacturer.

The mechanism is essential in locking and opening of the switch interrupter and independent of operational handle speed.

The switch interrupters work operationally based on switching operating hubs, located externally.

The operating hub indicates or targets the position of switches.

The interrupter switches have blades for contact and breakers for circuit closing.

Besides, the breakers also have interrupters for circuit breaking, continuous current-carrying, and fault locking.

For proper maintenance, to avert deterioration of moving parts, there should be maximum servicing.

The proper maintenance practices assist in various parts like pivots in handling fuse & latches.

Painting with stainless or zinc plating of the parts is appropriate for maintenance purposes.

Switch Compartments

The compartment operates by ensuring that the operators are safe from the source when it opens an electrical circuit.

Features

- Contains several of 600-amp consistent and load disrupt switches

- They have a side-function straight drive

- UL- Identified at 15kV

- Three-Phase power shifters

- Fault locking to 40kA irregular three-time obligation cycle

- Bushing wells and bushing have interfaces following IEC/IEEE standards.

- Windows for viewing are within the termination sections to enable visual certification and observation of the position of switches.

- The compartments have fuses and medium-voltage switches in the inner compartments grounded in steel. The components of the floor are 18-gauge, made of a galvanized sheet to seclude animals and foliage.

Fuse Compartments

This section of PM gear has the following features

- The compartment contains fuses of type E power.

- 200-Amp, offer to switch in a single-pole with fuses

- Lodges all types of fuses in various groups, with different Amp ratings

- The insulation type is Cycloaliphatic insulation

- Stable & firm push opening and locking load interrupters in the system

- The mounting plate is a heavy-gauge type, made of steel. Which makes comprehensive arrange so much rigid and rugged

- Defect locking to three times rated fuses.

The Working Mechanism of a Fuse

When you attempt to pass a very high amount of current across the circuit, it heats up until it melts.

When it burns, it interrupts the circuit that it’s attached to and prevents the current from flowing.

The fuse compartment is categorically essential for protection purposes.

The installed fuses assist in safeguarding the equipment and other parts of the electrical system.

The terminals of fuses equipped with bushing wells rated at 200 amp, a design to allow insertion of bushing rated at 200 amp.

Does Pad-Mounted Switchgear have Arc Flash Hazard?

The pad-mounted switchgear experience arc flash.

It is because this is medium voltage equipment but not infrequent occasions.

Normally, it is small animals such as rodents or snakes that may cause an arc flash.

How do you Troubleshoot Pad-Mounted Switchgear?

- Conduct the infrared inspection in the compartments of the equipment to check the connections.

- Always practice the maintenance of load interrupters, interlocks and fuses every year. The exercise is essential in ensuring that the operation of the system is consistent and limiting the chances of arc flash.

Moreover, you should always retain trend performance and good records of the operational unit.

What are the Advantages of Pad-Mounted Switchgear?

Pad mount switchgear

The pad-mounted switchgear is vital in offering high reliability in the maximum and consistent power supply.

It does not require a large space for installation hence economical.

The cross bus above the cover offers comfort during the inspection process.

Its design, flexible modular, prolongs its life cycle backing plus repairs and field upgrades.

Are there Drawbacks of Pad-Mounted Switchgear?

Disadvantages

- The pad-mounted switchgear can experience arc flash due to its place of installation. Some animals like rodents interfere with the insulation, leaving the conductors bare.

- It has limitations in place of installation, underground supply system.

Where can you Install Pad-Mounted Switchgear?

The pad-mounted switchgear installed in the underground distribution system.

Besides, in the substations with the need of medium voltages.

What are the Pad-Mounted Switchgear Quality Standards?

Pad mounted switchgears should conform for IEC, CE, RoHS, EMC, ANSI, IP, and NEMA rating.

All these will depend on where you intend to use the pad mounted switchgear.

What are the Characteristics of Pad-Mounted Switchgear?

Some of the main characteristics of pad mounted switchgear include:

- Most of the pad-mounted switchgear is of low and medium voltage rated at 0-6 kV and up to 25 kV.

- The Pad-Mounted Switchgear:

- Has stainless steel metal enclosure

- Has a flexible which is modular at the top.

- Has indicator lamps and ON & OFF buttons

- Its enclosure system is weather-resistant.

- It has an operational counter.

- Has three basic components namely,

- Switch compartment

- Fuse compartment

- Interrupter switches

Clearly, pad mounted switchgear is an assembly of many parts and components.

A clear understanding of every aspect will help you choose a suitable switchgear.

At KDMSteel, we are here to help you choose the best pad mounted switchgear – contact us now.