- Customized NEMA Enclosure Solution

- IP65/IP66 Certification

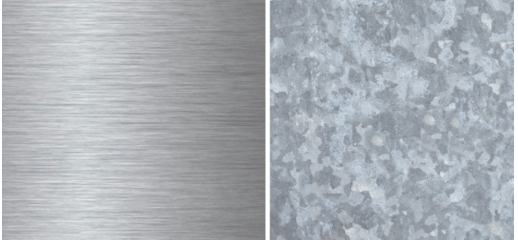

- Stainless Steel, Carbon Steel, Galvanised Steel Material

Custom NEMA 3 Enclosure Manufacturer in China

KDM NEMA 3 enclosure is weather-resistant at the same time equipped to protect against leaking pipes, which makes it suitable for both indoor and outdoor usage. It provides additional protection to users against access to hazardous parts and even to the equipment inside the enclosure towards ingress of solid foreign objects such as falling dirt and windblown dust.

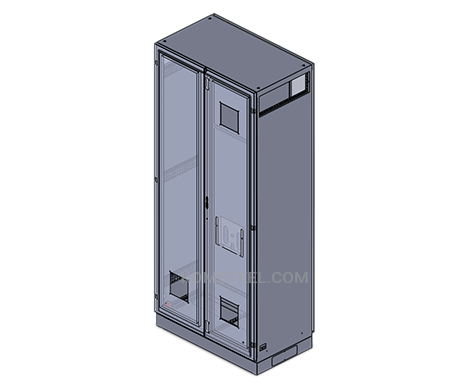

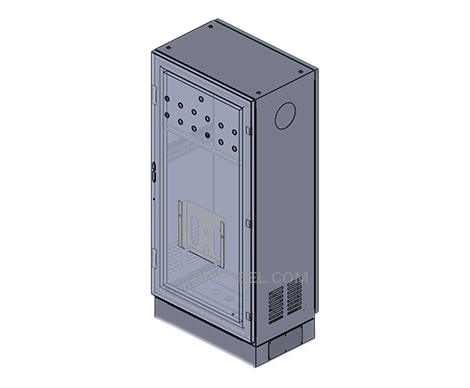

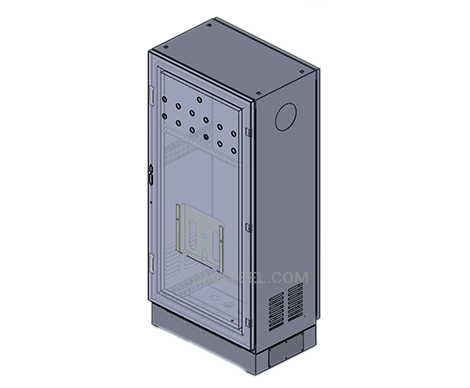

KDM NEMA 3 Enclosure Series

Send your Inquiry on KDM NEMA 3 Enclosure

KDM manufacture NEMA 3 enclosures that are compatible with both indoor and outdoor applications and hold the least demanding rating for outdoor use. We produce top-quality metal enclosures in a variety of types and materials, all at competitive prices; quick delivery is our specialty. Get an instant quote for your next NEMA enclosure order.

- Manufacturing Capacity

- Buying Guide

4000W high-performance laser cutting machine, +/- 0.05mm accuracy. No burr, no scratching.

Multi-Functioning flexible welding equipment, high accuracy, no deformation.

+/- 0.5mm bending precision, smooth surface without bending marks.

10+ welding experienced workers, perfect overall appearance.

High speed and accuracy foaming machines, fast and qualified Gasket

The expert assembling team, consistent assembly quality on every KDM enclosure

KDM NEMA 3 Enclosure

KDM NEMA 3 enclosure, if used in outdoor, provide more protection to harmful effects on the equipment due to the ingress of water in the forms of rain, sleet, snow, etc. NEMA 3 enclosure from KDM will also remain undamaged from the formation of ice in the enclosure.

For indoor applications such as industrial structures or labs the metal structure, KDM NEMA 3 enclosure is generally stored in a dry environment but would be equipped to protect against dripping pipes.

Our NEMA 3 enclosures are fabricated to house electrical controls, generator skids, or rotating equipment and protect these electrical components aboard ship docks, on constructions sites, inside tunnels or in subway systems.

While KDM NEMA 3 enclosure may not be suitable for extreme weather conditions, these enclosures can function as outdoor electrical junction boxes to protect wiring and cables. Also, it’s important that engineers should consider the exact location and material of their enclosure.

NEMA 3 Enclosure

With KDM NEMA 3 enclosure, you can find durable, cost-effective and UV-resistant enclosures. These qualities make them a much safer choice for outdoor environments in both commercial and industrial applications.

With a variety of styles and sizes available, it’s easy to find the NEMA 3 enclosure solution at KDM. For even more options, you can choose from our wide range of products. If you want to custom NEMA 3 enclosure for your own industry, our professional team of engineers and technicians will help you in custom your design which is based on your detailed application. In addition to this, we can handle your urgent orders in short lead time.

KDM with more than 10 years of NEMA 3 enclosure manufacturing experience, we are fabricating both standard and custom NEMA 3 enclosures for our client’s. All of our enclosures, meet the requirements of our customers. At every stage in the manufacturing process, we always collaborate with them. Also, we had passed the IP65/IP66 certification. KDM, with the very LOW MOQ, you can order NEMA 3 enclosure for as low as 1 pc.

At KDM, we manufacture high-quality electrical boxes that meet the NEMA standards. We assure quality, competitive price and a range of NEMA 3 enclosures that are right for your enclosure needs.

With the KDM NEMA 3 enclosure offer, we are sure you can choose the right NEMA 3 electrical enclosure for your unique applications. Send us your inquiry and let us solve your NEMA 3 enclosure problems.

The Ultimate FAQ Guide to NEMA 3 Enclosures

- What does NEMA Type 3 mean?

- How is NEMA 3 different from NEMA 3R, 3S, 3X, etc?

- Are NEMA 3 enclosures used outdoors?

- Do NEMA 3 enclosures protect from explosions and arc flash?

- Do NEMA 3 enclosures protect from corrosion?

- What are common applications for NEMA 3 enclosures?

- How are NEMA 3 enclosures tested?

- How can I be sure of the quality of NEMA 3 enclosures?

- What is NEMA 3 in IP standards?

- How else are NEMA ratings represented?

- What are common designs for NEMA 3 enclosures?

- What additional features are often included?

- Do knockouts, vents, fittings, etc. affect the rating of the enclosure?

- How do NEMA 3 enclosures maintain thermal environment?

- What materials are used for NEMA 3 enclosures?

- What paints and coatings can be used for NEMA 3 enclosures?

- What are some ways to put symbols on a NEMA Type 3 enclosure?

- What else should I be aware of when ordering an enclosure?

What does NEMA Type 3 mean?

NEMA stands for National Electrical Manufacturers Association.

It is an electrical industry trade association that does not certify products, but rather develops standards, and government guidelines.

NEMA 3 complies with certain specifications.

NEMA 3 can be broken down into 3 variations, or levels of protection.

All of these also carry a corrosion-protection option, making Type 3 have altogether 6 subtypes.

Overall, Type 3 provides protection of personnel against accidental contact with live electrical parts.

It is also meant for use both indoors and outdoors, as it is fairly rain-proof, as well as dust-proof.

Also, the enclosure protects inside equipment from snow and sleet, and guarantees that everything will work even if the enclosure is covered with ice.

How is NEMA 3 different from NEMA 3R, 3S, 3X, etc?

NEMA 3R is the same as NEMA 3, except it does not offer as much protection against windblown dust, so it is better for cold inside applications like freezer rooms.

This is because 3R usually lack a few gaskets that other NEMA 3 enclosures have.

NEMA 3S is the same as NEMA 3, but also ensures that any external mechanism is still operable when laden with ice.

NEMA 3X includes added protection against corrosion.

There could also be enclosures with subtype ratings NEMA 3RX and NEMA 3SX.

Subtypes of NEMA 3

Are NEMA 3 enclosures used outdoors?

Yes, NEMA 3 enclosures do protect against water ingress and dust ingress, as well as snow and sleet.

Thus, it is perfectly suitable for outdoor applications.

Do NEMA 3 enclosures protect from explosions and arc flash?

No, NEMA 3 enclosures are not strong enough to withstand an external explosion or contain an internal one.

If you need that kind of protection, you should consider NEMA types 7-10, which are made specifically for hazardous locations.

NEMA enclosures do not protect against arc flash incidents, so it is the responsibility of personnel to be prepared for them.

Do NEMA 3 enclosures protect from corrosion?

Per se, NEMA Type 3 enclosures do not protect against corrosion well.

However, you can increase the enclosure’s resistance to corrosion with the material you choose to use.

As such, galvanized steel and stainless steel 316 are the best options.

Also, paint coatings can help deter corrosion.

Especially, enamel paint is great for corrosion resistance.

Also, you can order NEMA 3X enclosures, which include protection against corrosion.

What are common applications for NEMA 3 enclosures?

NEMA 3 enclosures are great for indoor and outdoor commercial uses.

These may be junction boxes, utility boxes, outdoor meter cabinets, transformers, generator skids, frequency converters, power conditioners, and rotating equipment.

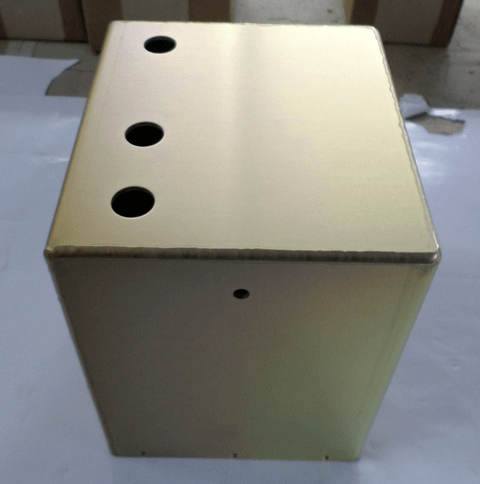

Typical NEMA 3 box

Because of this type’s resistance to water and ice, such enclosures are great for commercial freezer rooms, ship docks, subway systems, outdoor construction sites, and anywhere else where it gets cold.

If you need an enclosure for a cold indoor location, you can use NEMA 3R.

For more information, check out our NEMA enclosure FAQ!

How are NEMA 3 enclosures tested?

NEMA enclosures are not tested by NEMA, but by third-party laboratories.

NEMA labels can be used to self-declare enclosure ratings.

NEMA 250 outlines all the extensive tests that enclosures undergo to achieve a NEMA label.

For NEMA 3, one of the tests is the rod entry test, which involves inserting a rod of different diameters into openings and vents of the enclosure in an attempt to reach live parts of the circuit.

NEMA 3 enclosures also undergo a rain test for 1 hour.

Rain test chamber

The test is considered passed if there is no significant water accumulation inside the enclosure.

NEMA 3 enclosures are further tested with an external icing test, outdoor dust test, and outdoor corrosion test.

External icing test involves spraying the enclosure with water and then cooling down the room until 20mm of ice has formed over the enclosure.

Outdoor icing test

The enclosure should be undamaged and operable at the end of the test.

Outdoor dust test involves blasting the enclosure with general-purpose dry cement dust at a rate of 5 pounds (2.3 kg) per minute.

The inside of the enclosure is then inspected for white cement residue

Outdoor corrosion test is included for NEMA Types 3X, 3RX, and 3SX.

It involves making a 5% saline solution (using sodium chloride) and spraying it continuously for 600 hours (25 days).

How can I be sure of the quality of NEMA 3 enclosures?

At KDM, we have the ISO9001 certification that you can look through.

Also, you can do independent third-party testing of the enclosures if you want confirmation of quality and conformity assessment.

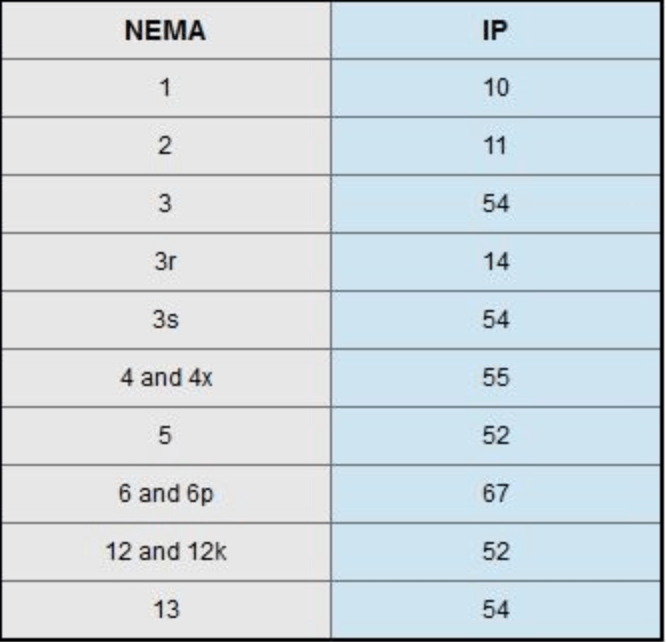

What is NEMA 3 in IP standards?

Although it is difficult to translate one set of standards into another, NEMA Type 3 is roughly comparable to IP54 and IP64.

Both provide good protection against dust and water.

NEMA and IP

How else are NEMA ratings represented?

NEMA 250 standards are also represented as UL 50E and CSA C22.2 No. 94.2.

This is because different certifying agencies use different standards – UL or CSA – so NEMA guidelines can be understood in terms of either one.

CSA is used in Canada, while UL is mostly used in the US.

CSA and UL

What are common designs for NEMA 3 enclosures?

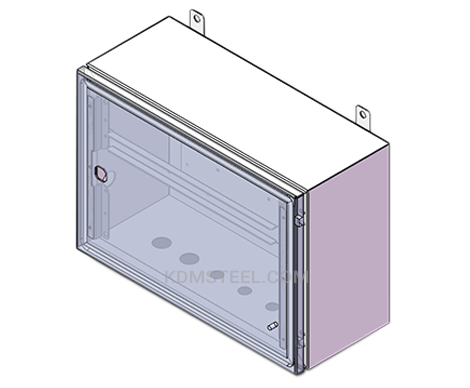

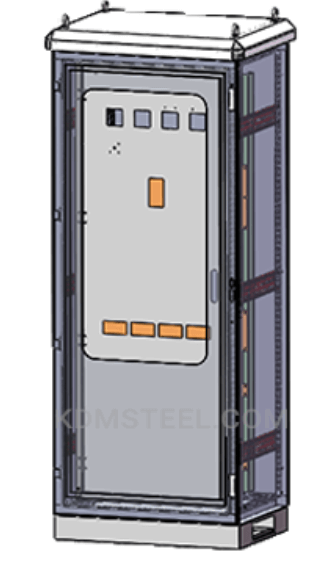

Some common designs for NEMA 3 enclosures include free-standing, floor-mounted, wall-mounted, and pole-mounted.

Free-standing, floor-mounted, and walk-in enclosures are used for bigger equipment.

They can have one or multiple doors, depending on your requirements.

Such enclosures can also have pedestals, casters, leveling feet, and lifting eyes to help install and move it around.

Free-standing enclosure

Wall-mounted and pole-mounted NEMA 3 enclosures are typically small and house fuses and switches.

These are less mobile, but take up less space as well.

They are installed using special brackets that can be just external or have internal elements too.

Wall-mounted enclosure

Overall, higher NEMA ratings benefit from U-shaped designs since those require less seam welding, which works well with ice and corrosion protection.

U-shaped enclosure (top part)

Of course, we also offer custom enclosures.

What additional features are often included?

You can request vents, windows, hinged doors, locks, cable management systems, and much more.

Vents, as well as radiating fans, provide a path for heat to escape through, cooling electrical components of the enclosure.

Vents provide a more passive flow of air, whereas fans actively move air and are used to cool down equipment that heats up quickly.

This prolongs their life and decreases the possibility of malfunctions.

If you want to include a drainage opening, there should also be a removable plug.

Radiating fan in an enclosure

These also stabilize air pressure inside the enclosure, preventing condensation which can damage the electrical components of the enclosure.

Plus, vents and fans can be further upgraded to air conditioners and heat exchangers.

Windows help personnel examine the electrical components in a quick and non-invasive way.

And if something goes wrong, a window helps to see what is happening right away.

Plus, infra-red windows help protect workers from arc flash accidents by letting them see heat buildup.

Enclosure with a window and a lock

Hinged doors control how and how much the door or cover of the enclosure opens.

This also includes a variety of handles that you can request as well.

You can choose between continuous, offset, and other types of hinges.

Locks, latches, and clamps add a layer of security to your NEMA 3 enclosure, making sure no one tampers with it or accidentally accesses its electrical components.

Cable management systems may involve hooks, racks, and other organizing features.

We also offer secondary features like casters, lifting eyes, file pockets, drip caps, switches, lights, and anything else you request.

File pocket

Casters help move the enclosure around; lifting eyes are for heavy enclosures that need to be lifted to be carried around; file pockets store operating manuals; drip caps protect the enclosure from splashing water; solar shields protect against UV rays; switches and lights help operate the equipment inside the enclosure.

Do knockouts, vents, fittings, etc. affect the rating of the enclosure?

Individual fittings, vents, knockouts, etc – ideally – should have a better NEMA rating than the enclosure.

But generally this is not possible, so these features should have the same rating as the overall structure.

How do NEMA 3 enclosures maintain thermal environment?

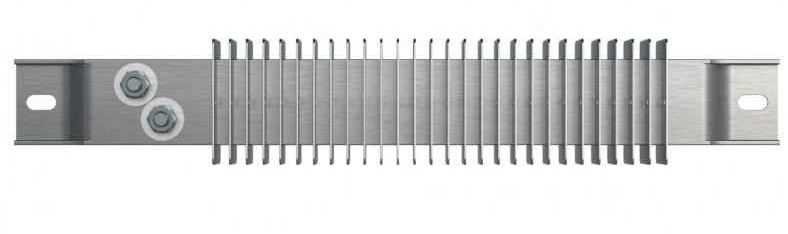

Generally, enclosures can have air conditioners, coolers, heat exchangers, and heater strips to control the temperature inside the enclosure.

This is done to prevent overheating, but also freezing of equipment.

If cold environments are your concern, then heat exchangers and heater strips may be of interest to you.

Heat exchangers are closed loop systems that are easy to maintain.

They push hot air in colder compartments, which results in an equalized temperature and pressure.

Heat exchanger

Heater strips use electricity to heat up the air inside the enclosure to protect its contents from low temperatures, condensation, and subsequent corrosion on the inside.

Heater strip

There can also be fan filters and small positive temperature coefficient heaters.

Enclosure heaters range in performance from 50 to 1200 Watts, depending on the size of your enclosure.

What materials are used for NEMA 3 enclosures?

The materials used for NEMA 3 enclosures aren’t different from materials used for other types of enclosures.

They can be made from carbon steel, galvanized steel, and stainless steel – usually of the grades 304, 316, or 316L.

Carbon steel is usually duller than stainless steel.

It is also magnetic and more malleable since it only has iron and carbon.

This steel is also prone to corrosion, so it is not recommended for NEMA types that are designed for the outdoors.

Stainless steel is created by adding chromium, nickel, and molybdenum to the iron-carbon alloy.

Stainless steel vs. galvanized steel

Steel grades 304 and 316 differ in the content of all additives.

For NEMA Type 3 enclosures, stainless steel grade 304 is most recommended.

Galvanized steel is coated with a protective layer of zinc that prevents corrosion.

This type of steel is more expensive and heavier than stainless steel.

Another type of steel that can be used is cold-rolled steel, which is thinner and more dense than normal steel – and thus, it is stronger.

When using steel, the manufacturer should keep in mind a certain gauge, or thickness, of the sheet metal that is necessary to comply with NEMA standards.

NEMA 3 enclosures use 12-14 gauge steel, which is about 1.9-2.6 mm.

Fiberglass is very strong, can dissipate heat, and insulates electricity, lowering the effect of interference and the possibility of shock.

It is made from glass fibers placed in plastic.

Fiberglass enclosure

Enclosures can also be made from aluminum alloys.

They are not necessarily better than steel alloys, but can be depending on what you are going for and what are your needs.

Just like steel grades, aluminum alloys can be either of the 5052 or the 6061 series.

Aluminum vs stainless steel

Both are lightweight, but 5052 is more weldable, whereas 6061 has a higher resistance to corrosion. Also, 6061 is more expensive.

Aluminum has a layer of oxide on top that prevents any corrosion.

This material is especially good for enclosures exposed to solvents, petrochemicals, some acids, most sulfates and nitrates.

But NEMA 3 enclosures are not made for these environments, so aluminum is not common for them.

Also, our windows are made from polycarbonate and ABS.

Polycarbonate is more resistant to corrosion, whereas ABS is cheaper.

If you would like to learn more, send in your inquiry now for a consultation!

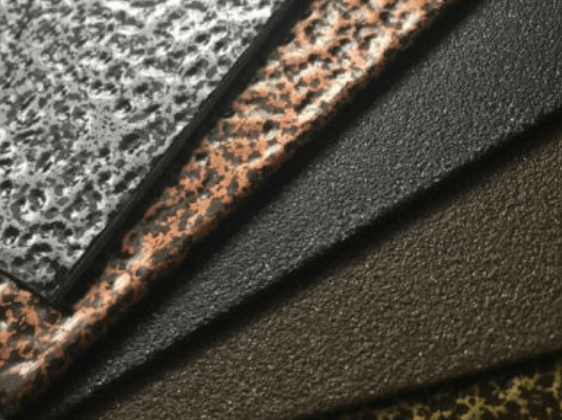

What paints and coatings can be used for NEMA 3 enclosures?

Our enclosures are well-protected, but the right coating can add its protection as well.

You can choose enamel or powder paint coats in any color.

Enamel paint has a glossy finish and is resistant to different weather conditions.

Specific enamel paints like epoxy enamel and PU enamel are commonly used for industrial enclosures since they are resistant to corrosion.

Powder paint is deposited with the electrostatic force, and is quicker and easier than enamel.

It is also more flexible in appearance, giving you the option of glossy and matte finishes.

Powder coating finishes

We also offer anodizing and alodining coatings.

Anodizing coating uses anodes to oxidize a metal, usually aluminum, to increase its thickness for better corrosion resistance.

Steel is not typically anodized because it can actually speed up the corrosion of the metal.

Alodine coating, also known as the chromate conversion coating, is used to prime steel and aluminum for paint, as well as prevent corrosion.

Alodine coating

This is a cheaper process than anodizing, and can be recognized by its characteristic greenish-yellow hue, unless it is painted over.

There can also be anti-graffiti and anti-poster coatings to protect your enclosure from vandalism.

NEMA 3 enclosures most often use powder coating.

We can provide any coating in any color and finish, so contact us today!

What are some ways to put symbols on a NEMA Type 3 enclosure?

Our customizing services include engraving and silk-screening.

Silk Screening is the easiest and most affordable method of customization.

Any flat side of the enclosure can be silk-screened with labels, warnings, serial number, your company name and logo.

However, silk-screening on metal like stainless steel or aluminum can be worn off or scratched off, but a clear powder coat helps to prevent that.

Silk screening

Engraving the enclosure is another method of customizing your enclosures.

This option is more costly and takes more time, but it is also more long-term than silk-screening.

A little bit of metal is removed from the surface of the enclosure in the design of the logo or symbol.

Usually, about 0.005 inches or 0.010 inches of metal is removed from the surface.

Once the metal has been removed, it is filled in with epoxy paint of any color to match your requirements.

Engraving

Besides symbols, there should be other markings.

If the equipment has to be installed in a particular orientation, this has to be marked on the enclosure.

Also, areas where live parts will be also has to have a mark.

Any warning or danger signs should also be engraved or silk-screened onto the enclosure as well.

What else should I be aware of when ordering an enclosure?

There are some common mistakes that people make.

These include choosing the wrong NEMA type, wrong material, wrong size, wrong design, and disregarding features.

NEMA types have certain environments they are suited for.

NEMA 3 is built for non-hazardous, indoor and outdoor locations with normal air pressure, rain or dripping water, some dust, snow, sleet, and ice.

NEMA 3 usually uses stainless steel 304 or galvanized steel to increase resistance to corrosion.

The size and the design of the enclosure depending on the specific electrical equipment you plan to house there.

However, NEMA 3 enclosures are usually medium-sized or big.

As for the design and features, these are case-specific, so consult your manufacturer for advice.

Recent NEMA 3 Enclosure Order

FAQ Guide

What is NEMA 3 Enclosure?

A NEMA 3 enclosure is designed for outdoor use only.

It protects from water ingress such as snow, sleet, and rain.

NEMA 3 enclosure also protects from windblown dust and ice formation.

What is the Purpose of NEMA 3 Enclosure?

NEMA 3 enclosure is manufactured to house rotating equipment, generator skids, and electrical controls.

It protects the equipment in the subway system, inside tunnels, or on construction sites.

What Are the Accessories To Add On NEMA 3 Enclosure?

Most NEMA 3 enclosures can be fully customized by your manufacturer.

It maintains the functionality and your protection requirements by adding the following accessories:

1. Temperature and Air Control

- Thermostats

- Vents and air filters

- Sun shields

- Axial fans

- Enclosure breathers

- Air conditioner

- Insulation

- Heaters

2. Lighting and Interior

- Power supply

- Slide-out drawers

- Enclosure lights

- Shelves

- Light switches

- EIA racks

- Viewing windows

3. Mounting and Exterior

- U-bolts

- Sub-panels/backplates

- Lifting eyes

- Vibration control

- Caster and wheels

What Are the Finish Options for NEMA 3 Enclosure?

NEMA 3 Aluminum Enclosures

NEMA 3 aluminum enclosure has a unique combination of lightweight, strength, and corrosive resistance.

They are suitable for industries like oil & gas, solar, traffic, and telecommunication application.

NEMA 3 Carbon Steel Enclosure

The fabrication of the NEMA 3 carbon steel enclosure is categorized by three typical configurations.

It is galvanized, cold-rolled, and hot-rolled.

Most of the NEMA 3 carbon steel enclosure is not corrosion resistant.

NEMA 3 Stainless Steel Enclosure

This enclosure offers a high level of corrosion protection.

It also provides exceptional strength, outstanding heat/fire resistance, consistent long-term value, and durability.

What is the Difference Between NEMA 3 Enclosure and NEMA 3R Enclosure?

NEMA 3 enclosure has the same protection as NEMA 3R.

However, NEMA 3R subtracts the windblown dust protection.

The NEMA 3R has the same protection as NEMA 3 regarding the formation of ice, snow, sleet, and rain.

This enclosure is often used for protected structure enclosure.

What is the Advantage of NEMA 3 Enclosure?

A NEMA 3 enclosure offers protection from solid outdoor grade.

It comes in numerous feature sets and styles.

Below are the primary advantages of NEMA 3 enclosure:

- Protection against dirt particles and airborne dust

- Protection against dripping and splashing water

- Protection against precipitation, including snow, rain, and sleet

- Protection against contact from personnel

What is the Disadvantage of NEMA 3 Enclosure?

NEMA 3 enclosure does not protect against:

- Explosions

- Prolonged or temporary submersion

- Hose-directed water jets

- Impact