- Custom Ip55 or Any IP rating Enclosure

- IP65/IP66 Certification

- Fast Sample Production within 3 days

Custom Metal Enclosure Box Manufacturer in China

KDM metal enclosure box is designed to house electrical, electronic, pneumatic controls/ instruments, and automation industries.

At the same time, they are compact and suitable for providing additional protection components against many adverse environmental conditions such as dust, oil, and water.

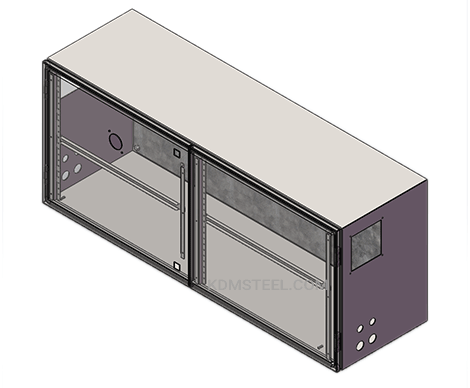

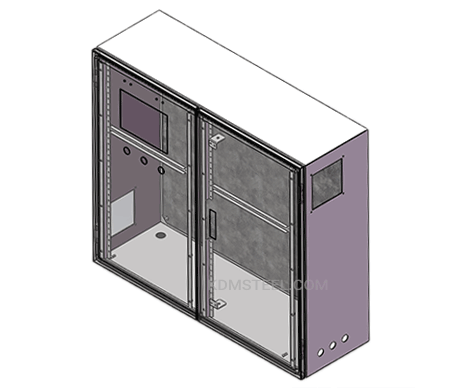

KDM Metal Enclosure Box Series

Send your Inquiry on KDM Metal Enclosure Box

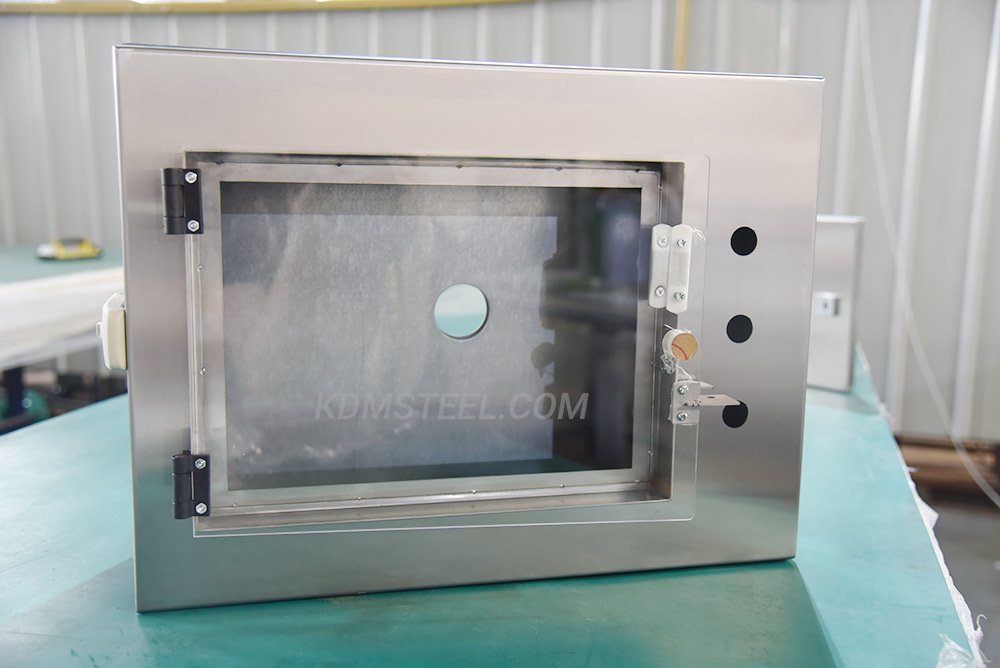

Our mild steel enclosures are manufactured using high-strength materials like galvanized steel, 304 and 316 grades stainless steel, and steel, allowing them to have a strong and rigid construction. Thus, you can be sure that our cabinets are built to last longer.

Moreover, this enclosure is available in a range of different sizes with a spectrum of accompanying accessories. These enclosures are finished with a highly durable powder coat paint that provides corrosion resistance and enables both indoor and outdoor use.

- Manufacturing Capacity

- Buying Guide

4000W high-performance laser cutting machine, +/- 0.05mm accuracy. No burr, no scratching.

Multi-Functioning flexible welding equipment, high accuracy, no deformation.

+/- 0.5mm bending precision, smooth surface without bending marks.

10+ welding experienced workers, perfect overall appearance.

High speed and accuracy foaming machines, fast and qualified Gasket

The expert assembling team, consistent assembly quality on every KDM enclosure

KDM Metal Enclosure Box

Our metal enclosure box goes through rigorous testing procedures and conforms to the highest international standards. You can assure that you will get guaranteed-quality enclosure box for your project. And that it will provide excellent protection against all atmospheric elements for electrical and electronic components installed within.

Metal Enclosure Box

KDM metal enclosure box is available in a broad selection of sizes (ranging from small to large), materials and styles, with a variety of covers, latching options, doors, and mounting configurations. These enclosures are continuously updated and enhanced as it may offer a scale of variations and sizes. Further, optional surface mount and wall mount styles are available. These enhanced products are competitively priced.

Depending on a given application, KDM metal enclosure box may be composed of nothing but a single layer of metal, or it can feature several layers of metal insulated with another material and fitted with interference-resistant shielding.

Metal Enclosure Box Accessories

We, at KDM, we also provide robust finishing solutions including an environmentally friendly powder coating technique that allows our products to stand the test of time. We guarantee that these outstanding enclosures will last you for a longer period of time.

At KDM, we are also able to manufacture NEMA rated metal electrical enclosu

res that can be customized for a wide range of indoor and outdoor applications. Our custom sheet metal enclosures include a variety of doors, drawers, and panel, including electrical cabinets, precision panels, control boxes, and enclosures. You can make any required modifications for cutouts. Furthermore, your custom metal enclosures can be finished to any powder coat color you desired.

Whether your applications for metal enclosure box is for commercial, architectural, industrial & mining applications, our high-quality units are best fitted to your facility. At KDM, we strive to offer the unique needs of our clients and provide it on schedule.

Metal Enclosure Box Manufacturing

With over 10 years of innovation, design and our experience, we are able to offer our client’s a metal enclosure box that will meet their exact performance requirements. Our strong design capability enables us to produce state-of-the-art product modifications that are designed, built and delivered on-spec, on-budget, and on-time.

Combining our vast expertise and experiences in the industry, our engineers have the knowledge, capability, and flexibility to design and manufacture a superb metal enclosure box. We at KDM can provide the best and the right solution for our clients’ needs in the most cost-effective way.

If you have any questions and need assistance choosing a metal enclosure box for your application, please give us a call today!

Metal Electrical Enclosures – The Definitive FAQ Guide

- What does a metal electrical enclosure do?

- What is the metal electrical enclosure design like?

- What is the difference between stainless steel and carbon steel for a metal electrical enclosure?

- How can a metal electrical enclosure be rated for use?

- What types of NEMA metal electrical enclosures can you use?

- What electrical metal enclosure works best in IoT environments?

- Is there a difference between UL and NEMA standards for metal electrical enclosures?

- Many metal electrical enclosures feature galvanized steel. What does this mean?

- Is there a chance that the steel on a metal electrical enclosure could develop deep stains or wear?

- What are the knockouts on a metal electrical enclosure?

- How can you get a metal enclosure designed for the specific layout of your electric components?

- Where can you buy metal electrical enclosures?

- Can a fan work on the inside of a metal electrical enclosure?

- Can an enclosure be wall-mounted, or does it have to remain freestanding?

Q: What does a metal electrical enclosure do?

A: A metal electrical enclosure is a cabinet used for protecting electric equipment.

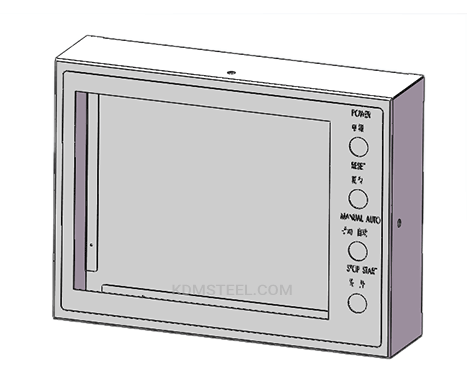

The enclosure will help you with mounting switches, displays, and knobs for electric controls.

The enclosure ensures users are protected from any hazardous issues when controlling these electric features.

More importantly, the enclosure protects the components from outside threats.

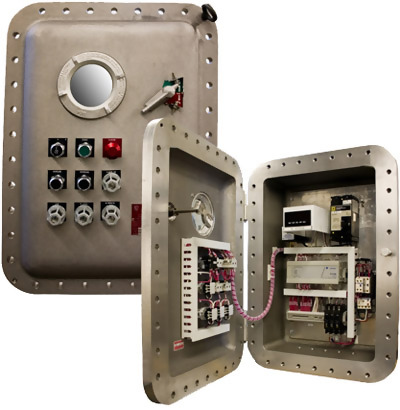

Q: What is the metal electrical enclosure design like?

A: An enclosure will feature a solid body that opens and closes like a door.

The inside includes the numerous electrical components that provide energy to a local site.

The outside part will include switches and other controls.

Some lights or gauges will also appear on the outside to help you identify how well certain items are functioning.

Q: What is the difference between stainless steel and carbon steel for a metal electrical enclosure?

A: Stainless steel resists fires and can handle moisture.

However, the stainless steel surface is exceptionally heavy.

Stainless steel can be found in varying alloys with each having a different quantity of certain metals in the body.

These include nickel, carbon, and chromium.

Each alloy is also different; a 201 or 202 alloy does not resist corrosion well, but a 304 alloy is highly durable.

Carbon steel is lightweight, but it can experience corrosion unless a powder coating is applied to protect the surface from general harm.

Carbon steel is ideal in environments where an X rating is not necessarily on the enclosure type.

Q: How can a metal electrical enclosure be rated for use?

A: The National Electrical Manufacturer Association (NEMA) and Underwriters Laboratories (UL) both use distinct ratings for metal electrical enclosures.

These ratings identify how well different enclosures operate and how they can protect electric components from various outside threats.

The specifics for each enclosure varies, so you would have to review the quality of your environment to figure out what works for you.

Q: What types of NEMA metal electrical enclosures can you use?

A: There are multiple types of NEMA metal electrical enclosures that you can utilize.

These include the following:

Type 1 – For indoor conditions. The enclosure protects the electric components from falling dirt and other solid foreign items.

Type 2 – For indoor use. The enclosure has trays to prevent water from entering.

The unit protects against drips and light splashes but may be vulnerable to corrosive compounds.

Type 3 – For indoor or outdoor needs. Extra shielding prevents dust from entering the enclosure.

The enclosure will not be at risk of harm due to the formation of ice, but the unit must still be sealed.

Type 4 – For indoor and outdoor use. The enclosure can repel hose-directed water.

Type 4X – Includes extra protection against corrosion.

Q: What electrical metal enclosure works best in IoT environments?

A: A Type 7 metal electrical metal enclosure is suitable for use in the Internet of Things environments.

The Type 7 enclosure protects equipment from explosions triggered by combustible gases.

The design is ideal for warehouses and other hazardous environments that IoT systems are often found in.

Q: Is there a difference between UL and NEMA standards for metal electrical enclosures?

A: Although the specific type designs that are recognized by UL and NEMA have similar functions, there is a difference between how the two standards for a metal electrical enclosure work.

UL requires compliance testing to ensure enclosure functions accordingly.

Such tests are not necessary for NEMA enclosures.

The manufacturer has the option to perform one’s own compliance testing efforts.

In many cases, a manufacturer’s testing work will be more comprehensive than what UL uses, not to mention with higher standards that must be met for success.

Q: Many metal electrical enclosures feature galvanized steel. What does this mean?

A: A galvanized steel surface features a zinc coating on its body.

The covering can work for carbon and stainless steel surfaces alike.

Zinc prevents corrosion from developing along the steel body of the metal electrical enclosure.

The coating can be applied through a liquid, although it may also be electromagnetically applied in the building process.

Q: Is there a chance that the steel on a metal electrical enclosure could develop deep stains or wear?

A: The steel on your metal electrical enclosure is naturally porous and should be safe to use.

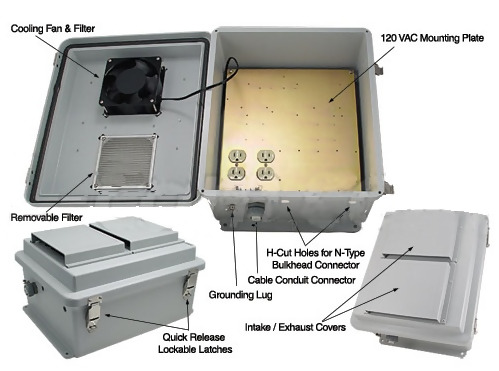

Q: What are the knockouts on a metal electrical enclosure?

A: A knockout is an opening on a metal electrical enclosure that has been partially punched out.

A knockout will feature enough room to allow cables or connectors to go through among other things.

You’d have to ensure the enclosure has enough room in its knockouts to allow your cables to go through, but not too much to where the inside part of the enclosure could be exposed for whatever reason.

You would also have to ensure any knockouts you want to use are appropriately opened.

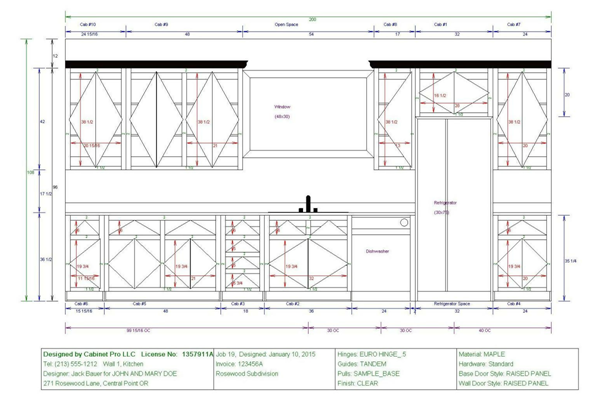

Q: How can you get a metal enclosure designed for the specific layout of your electric components?

A: A computer-aided drawing or CAD can help.

The CAD file format entails a design that features a specific diagram of how your metal electrical enclosure is going to work.

You’ll need to produce the CAD to the precise measurements and layouts possible to ensure you’ll get the enclosure you want.

Q: Where can you buy metal electrical enclosures?

A: You can buy an enclosure from various electrical service providers and manufacturers.

You’d have to ask any of these entities about their standards for producing quality standards to ensure you are buying a quality model from a trustworthy provider.

Q: Can a fan work on the inside of a metal electrical enclosure?

A: A fan can be installed on the inside part of the door.

Q: Can an enclosure be wall-mounted, or does it have to remain freestanding?

A: Metal electrical enclosures are available in many designs.

A smaller enclosure can be wall-mounted.

A much larger model might need to be freestanding depending on the quality of whatever is being used.

Recent Mild Steel Enclosure Order

FAQS Guide

What is Metal Enclosure Box?

Metal Enclosures

Metal enclosures are rugged and sturdy electrical cabinets. It provides outstanding protection for your electronic device. This cabinet is the workhorse of electrical repairs and remodels.

What is Metal Enclosure Used?

Metal enclosures are used to in-house various electrical cables and switches, ceiling lights, ceiling fans, outlets, etc. It protects its contents from a harsh environment and unfavorable elements.

It’s easy to find the perfect metal enclosure box for any project. Due to a variety of styles, materials, sizes, and finishes available in the market.

What are the types of metal enclosures?

Metal enclosures include:

- electrical and electronic enclosures

- battery cabinets and boxes,

- traffic control enclosures,

- server enclosures,

- telecommunications cabinets,

- industrial enclosures.

Metal Enclosures Prevent Sensitive Components From?

Metal enclosures ensure excellent protection against hydraulic oils, gasoline, alcohol, solvents, rain, snow, sleet, and extreme weather fluctuations, etc.

What are the Advantages of Metal Enclosures?

Metal enclosures obtain many advantages compared to other materials. Some are the following:

- Outstanding resistance to low and high temperatures

- High resistance to impacts

- Long-lasting and deliver durable performance

- difficult to damage or break

- Fireproof and waterproof

- Ideal for industrial applications

- Reduce emissions

- Protect against outside external noises.

- Low maintenance

Does Metal Enclosures Rust?

Metal enclosures can be made out of rust-resistant or corrosion-proof metals, such as aluminum, stainless steel, copper, bronze, or brass.

Stainless steel material is an excellent alternative to prevent corrosion. Aluminum materials also afford the strength of metal and do not corrode.

What to Consider in Buying Metal Enclosures?

There are various factors in play in selecting metal enclosures. Consider some of these:

- Determine the environmental hazards your device will encounter

- What NEMA rating or IP rating does it requires

- How big is your metal enclosure is.

- Consider other component options such as hinges, a lock, or mounting flanges

What are the Material Options for Metal Enclosures?

- Aluminum Enclosures

Aluminium Enclosures

These enclosures are made from pure aluminum or mixed alloys such as copper, magnesium, zinc, manganese, silicon. It has a tensile strength approaching 100,000 pounds per square inch. This type of enclosure features extreme durability, lightweight and corrosive resistance. It is available in 8’ (H) x 4’ (W) x 4’ (D) to 8’ (H) x 15’ (W) x 10’ (D) dimensions. Diecast aluminum enclosures and extruded aluminum enclosures are great choices for metal enclosures.

- Stainless Steel Enclosures

Stainless Steel Enclosures

Stainless steel is a durable material. It is versatile and easily customized for specific uses. Enclosure made from stainless steel features corrosion resistance and aesthetic appeal. It also has excellent fire/heat resistance features and low maintenance. It protects internal hardware from exposure to corrosive materials and extreme temperatures. Widely applied various industries such as oil production, traffic control, electronic, solar, and industrial applications.

- Carbon steel enclosures

Carbon Steel Enclosures

The carbon steel enclosures are made from 16-gauge steel. It is coated with a gray powder. This is widely used in both indoor and outdoor industrial environments. Strong metal is high in carbon. When exposed to moisture, it can rust quickly.

What is the Metal Enclosures Door Types?

You can get single door metal enclosures, double door metal enclosures, and transparent door metal enclosures.

What are Powder Coated Metal Enclosures?

Powder-coated metal enclosures are boxes with a powder coating finish. Powder coating can make metal enclosures attractive and durable. It is a cost-effective finishing option for most metal surfaces.

It provides more resistance to temperature changes and rain, dust, snow, ice.

Which Industries Use Metal Enclosures?

Metal enclosures are made for both indoor and outdoor environments. It is suitable for almost any industry including:

- Automotive industry

- Building Automation

- Utilities

- Food and Beverage

- Printing and Publishing

- Pulp and Paper

- Energy and Communications

- Electrical controls for mining equipment

- Textiles

- Wastewater Treatment

- Factory automation controls

- Petrochemical

- X-ray machines

- Factory process controls

- Golf course electrical controls for irrigation

What are the Installation Options of Metal Enclosures?

- Freestanding

- Pad mount

- Wall mount

- Pole mount

- Walk-in steel enclosures

Is Custom-Design Metal Enclosure Available?

Yes of course.

Custom Metal Enclosures

Manufacturers can custom-build metal enclosures to exceed your specifications and requirements. Here are the few aspects they consider to provide excellent custom-design enclosures:

- Special components for tough environments

- Paint requirements

- Holes and cutouts

- Quality manufacturing standards

- Installation of accessories

- Environment ratings

- Custom dimensions to match internal space of enclosures

- Special Human interface applications

Can Metal Enclosure Be Waterproof?

Yes, definitely.

Metal enclosures that feature waterproof are available in the market. It is an enclosure specifically designed to meet NEMA and IP requirements. It has a watertight gasket, sealed enclosures. Waterproof metal enclosures assure safe internal electrical and electronic equipment.

It is commonly used in oil & gas, food & beverage, marine, alternative energy, agriculture applications, and more. This is ideal for both indoor and outdoor uses.

How are Metal Enclosures Produced?

Manufacturing a metal box can be finished in various ways. It includes:

- CNC Machining

- Sheet Metal Process

- Die-Casting

- 3D Printing

- Turret press

- CNC press brakes

- Cutting, bending, and assembling processes

- Metal Finishing

What are the Different Metal Enclosure Finishing Technologies?

Metal enclosure finish improves the qualities of the metal you’re working with. Using this method, you can achieve no flaws, be durable, and not prone to rust metal enclosures. Here are a few common finishing solutions:

- Grinding process

- Bead blasting and sandblasting

- Polishing/Buffing

- Heat Treating

- Anodizing

- Electroplating, electroless plating, and immersion plating

- Wet or powder coat painting

Metal Enclosures Vs Plastic Enclosures?

Enclosures are classified into 2 categories: plastic boxes or metal boxes. Which is better? Here are some of the metal enclosures advantages compare to plastic enclosures:

- Metal is stronger than most plastics

- incapable of being melted

- It is electrically conductive, groundable

- Metal enclosure block radio frequency and electromagnetic interference

- It provides shock protection

- Ultra-strong, and fireproof

- Virtually impossible to bend or crush

- Longer life than plastics

What are the Disadvantages of Metal Enclosures?

- Difficult to work with

- Heavier than plastic boxes

- Have sharp edges that can scratch hands

- Difficult to remove

- Not built-in clamps need separate clamps

- More expensive than plastic

How to Choose the Right Material Thickness for Metal Enclosures?

You can decide gauge or thickness depending on your specifications and needs. Some are the starting point to select the gauge/thickness of metal enclosures:

- Take inventory of your product needs

- Evaluate material type

- Determine allowable flex, weight, and strength requirements

- Discuss your program needs (installation sites, transportation, climate, requirements, etc.)

How to do Quality Testing on Metal Enclosures?

To test the quality and durability of metal enclosures, use advanced sheet metal testing machines. It is designed to conduct quality checks for sheets made from various types of metal. The cupping test is one of the best processes. Here are some of the advantages of the Cupping test on sheet metal:

- evaluate the sheets thoroughly

- provide accurate result

- helps access the quality of paint applied to metallic substrates

- Determine how resistant sheets can handle harsh climatic conditions

Get the Exact Metal Enclosure for Your Project

A metal enclosure will protect your electronics from indoor hazards and external environments. It also gives outstanding security to your personnel.

It is not complicated to choose the right metal enclosures. Just make sure you settle with a reputable manufacturer and supplier for a better product.

For more information about metal enclosures, contact us immediately.