In need of a Metal Ceiling Access Panel for business?

Good news! KDM has the one you’re looking for

Premier Metal Ceiling Access Panel Supplier in China

Some industrial structural applications include schools, hospitals, hotels, apartments, etc, where you can see different kinds of metal ceiling access panels. We are happy to provide for your ultimate needs. Whether you need them for business or for personal applications, KDM is always here ready to provide you.

- 100% Sturdy Metal Ceiling Access Panel

- Great for Long-run Applications

- Available in Most Unique Designs

- Passed Fire-protection Codes

Contact Us Today And Send Inquiries!

KDM Metal Ceiling Access Panel Series

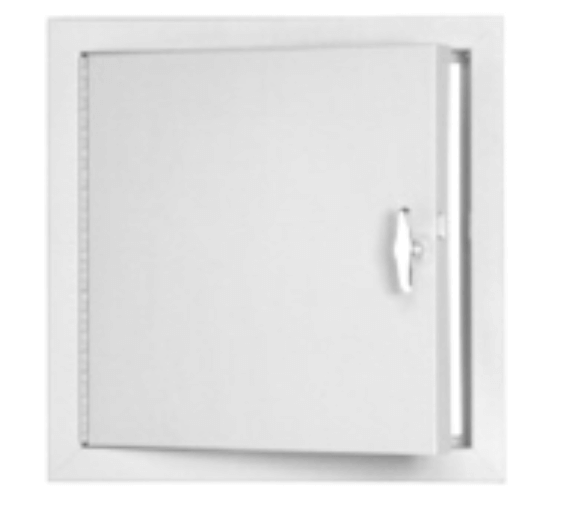

KDM Budget lock metal ceiling access panel is available with approximately 20mm standard sizes. It is paired with durable metal keys and locks for thief protection. It is perfectly installed on walls or ceilings.

KDM is a professional manufacturer of concealed frame metal ceiling access panels in China. It has a seamless appearance for interior ceilings and walls installment applications.

This Fire-rated metal ceiling access panel from KDM is made to strengthen and be fully protected from fires. Fire-rated for wall applications and ceilings. This can be easily installed at your intended wall positions. For exterior use only.

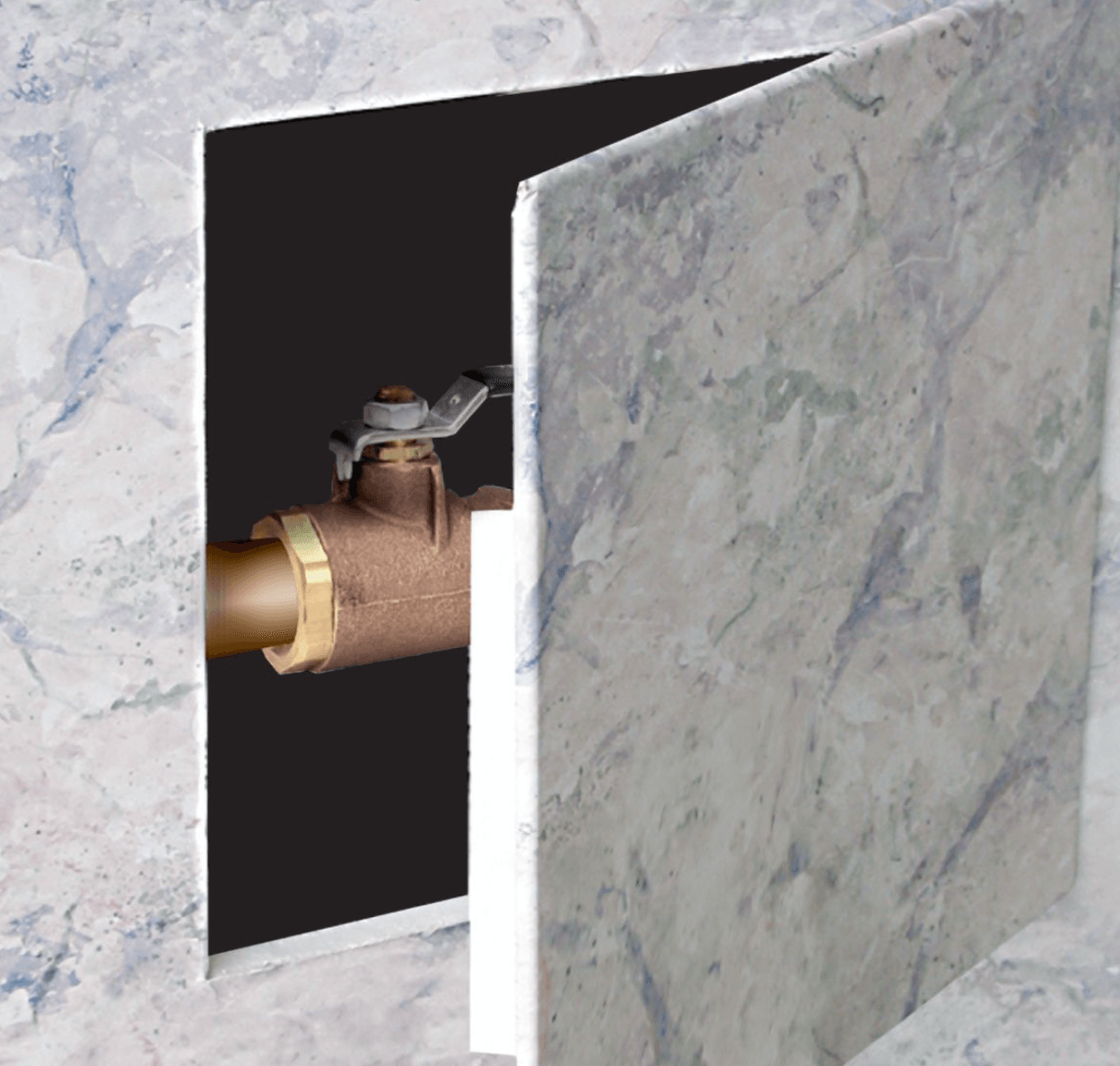

KDM Recessed flange metal ceiling access panel has high-quality functions and designs. It accepts drywall panels or ceramics tiles to match the outlook’s finish. This can be installed with studs.

These stealth metal ceiling access panels brought to you by KDM are great for hidden commercial and industrial building applications. This is one of the most cost-effective products from our factory.

KDM steel flush metal ceiling access panel is manufactured for global industrial applications. It is fire-rated and the safest type of metal ceiling access panel. It can be installed on roofs, ceilings, floors, and walls.

Send your Inquiry on KDM Metal Ceiling Access Panel

In our factory located in China, we offer a wide array of high-quality metal ceiling access panels. Not only them, but there are also high-valued pipes, ducting, wires, and valves available at competitive prices. They are the best and most appropriate materials for renovations, repairing, and even structural project applications. So when you are in need of our metal ceiling access panels, you know the right place We have the staff and representatives standby; ready to serve the best of the best services you deserve.

- Cost-effective Metal Ceiling Access Panel

- Reliable Manufacturers on Service

- Affordable Customized Designs

- Easy to Clean, and Maintenance-free

Related Products of Metal Ceiling Access Panel

KDM Metal Ceiling Access Panel

KDM Metal Ceiling access panel is great for any construction and building projects. All contractors or architecture want the best material to finalize building projects. That`s also the reason why KDM manufacture different kinds of metal ceiling access panels for open selections.

The metal ceiling access panels we produce control the longevity and functionality of the building. Whether the building is big or small, KDM metal ceiling access panel works the best on every task they are designated.

As the professional metal ceiling access panel manufacturer in China, KDM manufactures a model where has a high capacity to endure long-run of uses. There are different types of metal ceiling access panels we present which has the same quality functions- to avoid severe structural problems might happen later on. KDM has overall quality control for every metal ceiling access panel productions. Our finishes meet specific fire code standards, makes it the best choice for your upcoming projects.

For your business matters, if you are searching for the exact size and design of a metal ceiling access panel, no worries! Whatever the projects await you, we are sure you can find the best product at our honorable company.

At KDM, we can supply the stocks you require and the quality of every metal ceiling access panel for competitive rates. The metal ceiling access panels we offer pass certain structural code standards like fire protection codes, safety codes, etc.

We have the knowledge and capacity to supply your requirements. So if you are interested in our offers and have some concerns, contact us.

Ultimate FAQ Guide to Metal Ceiling Access Panels

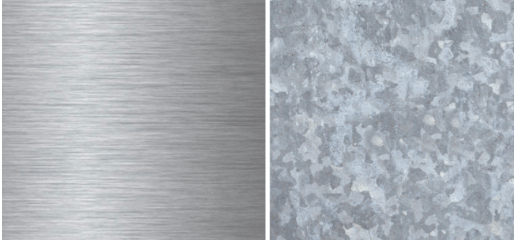

What Metals Are Used For Ceiling Access Panels?

Ceiling access panels can be made from carbon steel, galvanized steel, stainless steel, and aluminum.

Metal ceiling access panel

Carbon steel is usually duller than stainless steel.

It is also magnetic and more malleable since it only has iron and carbon.

This steel is also prone to corrosion, so it is not recommended for ceiling access panels in harsh conditions, such as humid industrial sites.

Stainless steel is created by adding chromium, nickel, and molybdenum to the iron-carbon alloy.

It had several grade series that have different properties.

Stainless steel vs. galvanized steel

Steel grades 304 and 316 differ in the content of all these additives.

Grade 316 is more resistant to salt and corrosion, whereas grade 304 is cheaper.

There is also 316L or 304L.

Grades 316L and 304L have a lower carbon content, making it a little bit stronger.

However, they are not very frequently used on the market.

Galvanized steel is coated with a protective layer of zinc that prevents corrosion.

This type of steel is more expensive and heavier than stainless steel.

Another type of steel that can be used is cold-rolled steel, which is thinner and more dense than normal steel—and thus, it is stronger.

NEMA 4 enclosures use 18-10 gauge steel, which is about 1-4 mm thick.

Enclosures can also be made from aluminum alloys.

They are not necessarily better than steel alloys, but can be depending on what you are going for and what are your needs.

Just like steel grades, aluminum alloys can be either of the 5052 or the 6061 series.

Aluminum vs stainless steel

Both are lightweight, but 5052 is more weldable, whereas 6061 has a higher resistance to corrosion.

Also, 6061 is more expensive.

Aluminum has a layer of oxide on top that prevents any corrosion.

This material is especially good for places exposed to solvents, petrochemicals, some acids, most sulfates and nitrates.

If you would like to learn more, send in your inquiry now for a consultation!

What Shapes Of Metal Ceiling Access Panels Are There?

There can be rectangular, square, and even round metal ceiling and wall access panels.

Most ceiling access panels are square because it is the simplest shape.

Sometimes, the design or the space does not permit a square panel, so a rectangular one is used.

It can have any dimensions of width and length.

Also, there are round access panels, which are used in commercial applications to suit the design of the room.

Round metal ceiling access panel

Plus, such access panels can be used on ships, which is common.

Besides the shape, the number of doors may vary.

There can be access panels with just a single door—as most access panels are.

However, there can be access panels with double doors.

These are big panels, which are perfect for industrial applications, or to use the access panel as a door to a residential attic.

Metal ceiling access panel with double door

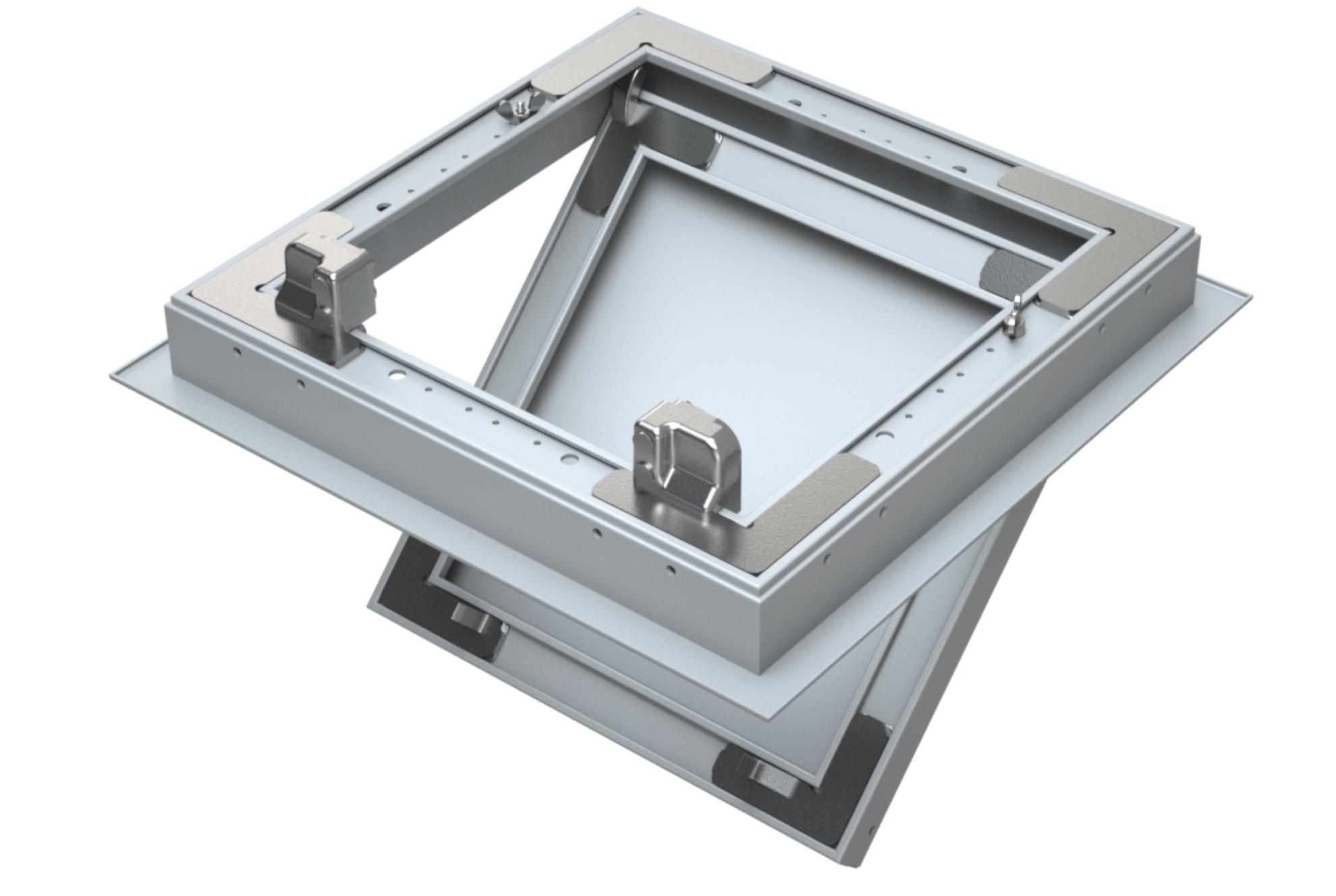

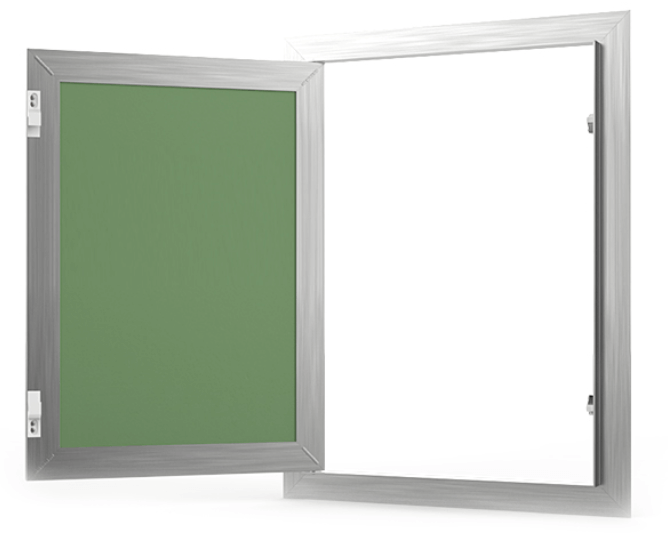

What Frames Can Metal Ceiling Access Panels Have?

Metal ceiling access panels can have concealed frames, recessed flange frames, flush frames.

Concealed frames and recessed flange frames are pretty much the same.

They have flanges that are recessed into the wall or ceiling, and are thus completely concealed, leaving only the access panel itself exposed.

Concealed frames are similar, but they do not have flanges, yet the frame is invisible.

Metal access panel recessed flanges

Flush frames are simple frames that do show along the sides of the panel, but these frames are flush with the mounted surface, so they mostly add a decorative element.

Which frame to choose mostly has to do with the aesthetics you need, and whether the access panel has to be concealed.

Flush frame

What Security Features Do Metal Ceiling Access Panels Have?

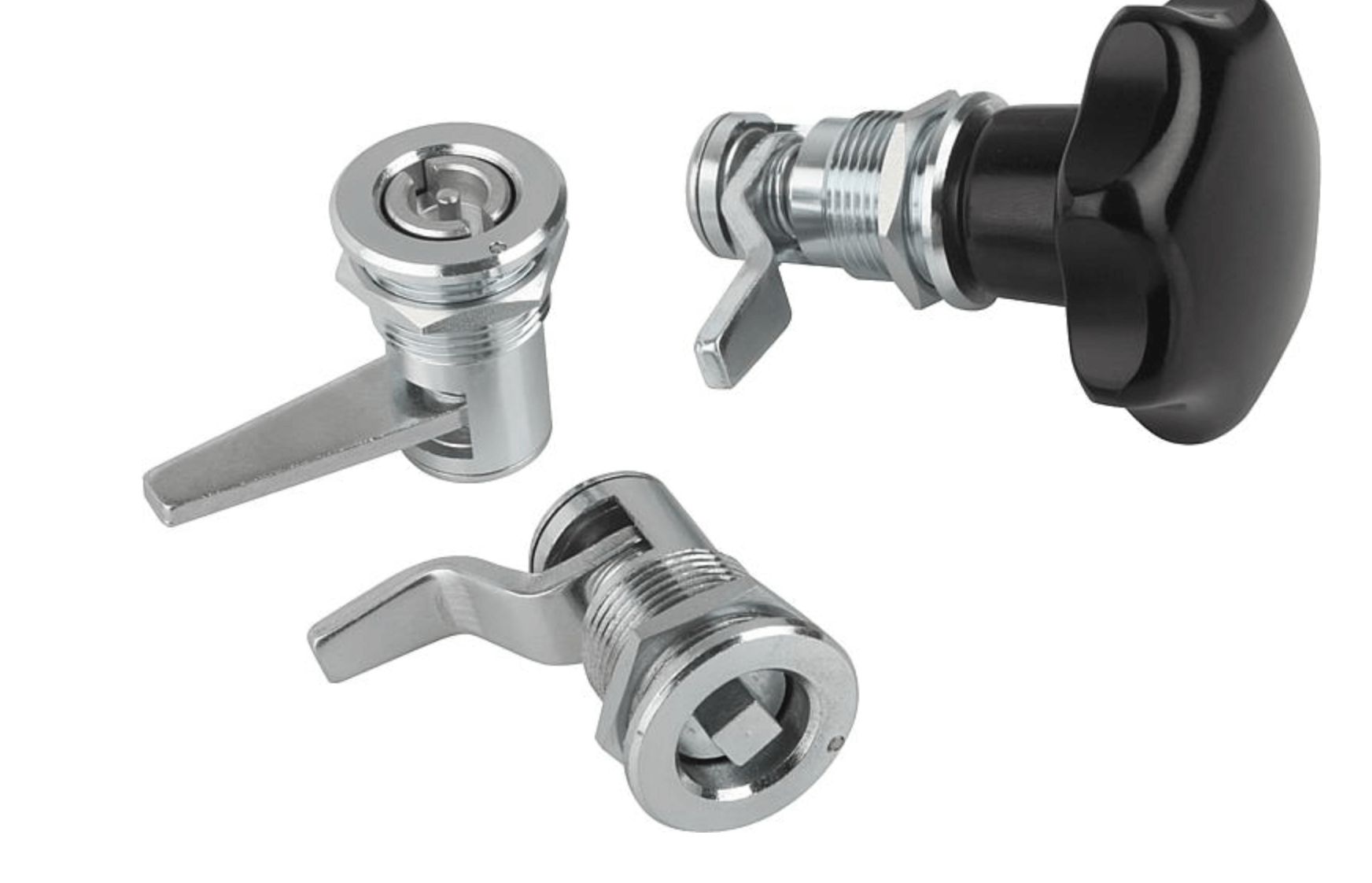

Among our designs, we offer many types of locks, including different cam locks, key-lock handles, key insert locks, T-handle locks, and deadbolts.

Cam locks are simple and affordable.

They can be of many types, such as cylinder cam, torx head cam, spanner head cam, knob cam, and hex head cam.

They differ in the type of tool used to turn and open them.

However, cam locks are not as secure as can be.

Cam locks are made of a cylindrical base and a cam, which is a metal piece that lets the cover open once a key pushes it up.

There are also multiple types of cams, such as straight, hooked, and offset, that offer different levels of complexity, and thus, different levels of security.

These locks can rotate clockwise and counter-clockwise, limited to 90 or 180 degrees.

Different cam locks

Plus, there are allen key locks, which are easy to open, so they are great for frequently used access panels.

Allen key lock

Key-lock handles fulfil the roles of a handle and a lock.

Usually, you need a key for these that unlock the handle, the turn of which unlocks the door.

It could also be the other way around – first the turn of handle, and then the key.

Key-lock handles

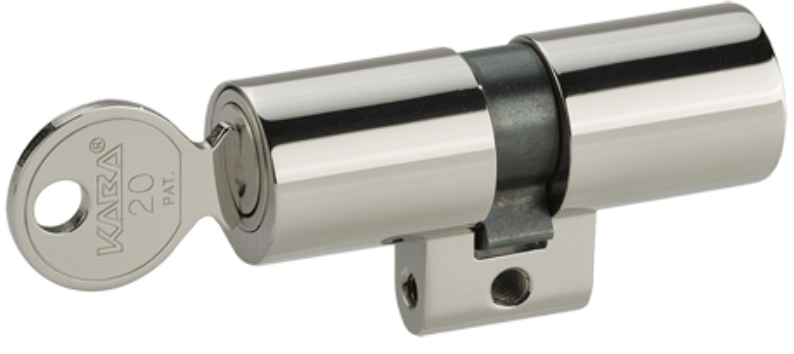

Insert locks just refer to any lock that needs a key to open it.

This includes cam locks, key-lock handles, but also euro profile locks.

Euro profile locks are popular in Europe, but are also sometimes used in North America.

They look like a circle with an oval on the bottom.

They are attached by one screw and are simple.

They are also called DIN cylinders.

Their disadvantage lies with that one screw since it is easy to break to open the lock.

Euro profile lock

T-handle locks are easy to install and replace since they are taken out every time the lock is opened.

They come in 2 types: spring latch and dead latch—one doesn’t need a key, while the other one does.

T-handle lock

There are also mortise locks, which require to be installed into the access panel.

They work with a key.

Metal mortise lock

Finally, deadbolts are some of the most reliable locks you can find.

A deadbolt lock has a cylinder for the key and a bolt that rests in the cover, preventing it from opening.

Once a key is inserted, the bolt moves, letting the cover open.

Deadbolt lock

Besides locks, there can also be latches, but they typically just keep the panel closed, not protecting from tampering.

Metal latch

What Hinges Are There For Metal Ceiling Access Panels?

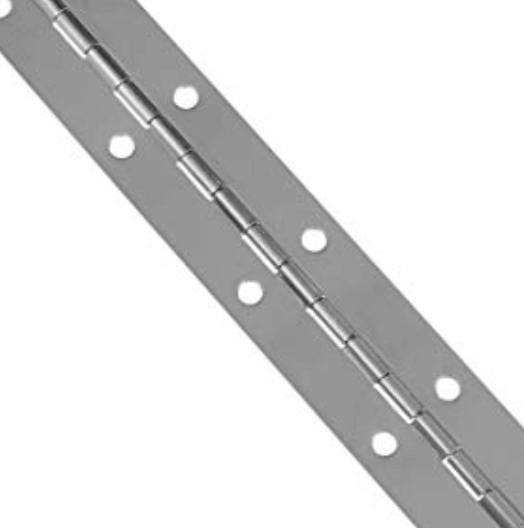

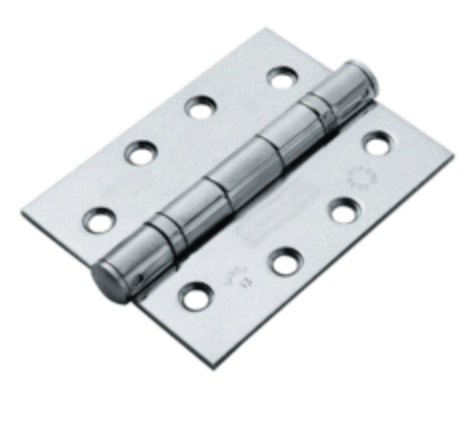

There can be continuous, piano, concealed, heavy-duty detention, and butt hinges.

Continuous hinges, or piano hinges, are long and are installed along the full length of a metal access panel.

They are aesthetic and provide a secure hold.

Continuous hinge

Piano hinges are another name for continuous hinges, so they are the same thing.

Concealed hinges come in two main types: the latch and the curved hinge.

There is not much difference functionally between the two, except the latch is more commonly used in residential applications, but this is not the rule.

This type of hinges connects to the access panel internally, being invisible externally.

Mainly, this serves an aesthetic purpose.

Concealed latch and hinge

Butt hinges are regular hinges with 2 leaves.

They are used for heavy-duty applications, such as double-door access panels and industrial sites.

Detention hinges are basically butt hinges, but with a thicker barrel, making them suitable for even heavier panels.

Butt hinge

How Can Metal Ceiling Access Panels Be Opened?

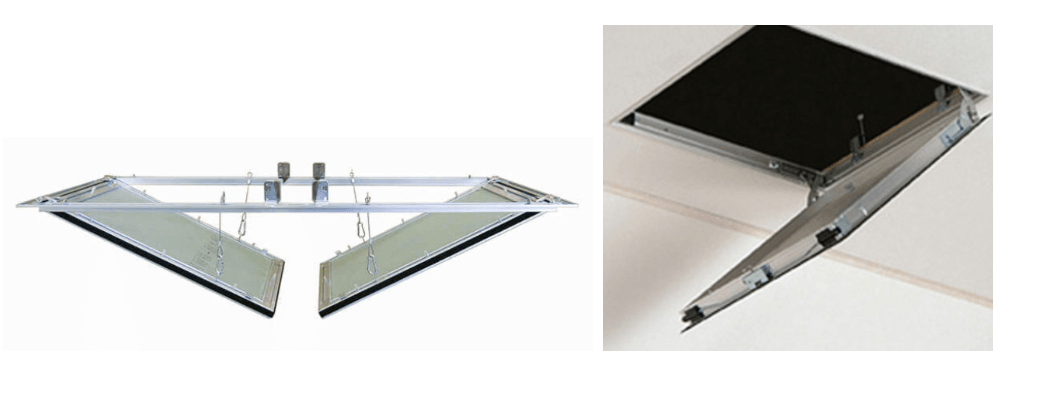

Metal access panels can be suspended, opened to the side—horizontally—, or opened up or down—vertically.

Suspended access panels are for ceilings, and they can be hinged or have ropes as well.

The ropes act as an additional safety measure that prevents the panel from hitting personnel on the head.

These are usually better for large and heavy panels.

Suspended metal ceiling access panel

Usually, they open down, but can be opened upwards.

Horizontally-opening access panels are used on wall access panels.

They are hinged and can be opened to the left or right, depending on your requirements.

Plus, there are removable access panels.

These do not have hinges or anything, the panels can just be popped out of their frames and pushed aside.

These are used for ceiling access panels.

Removable metal ceiling access panel

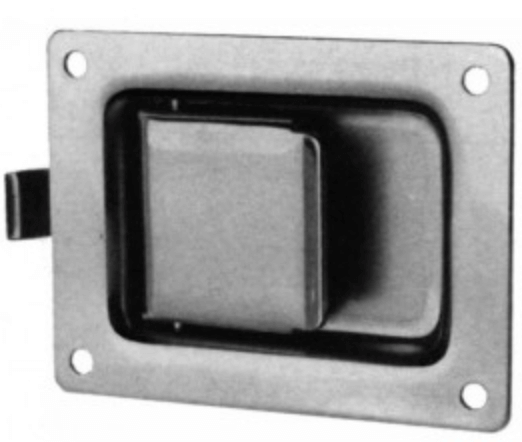

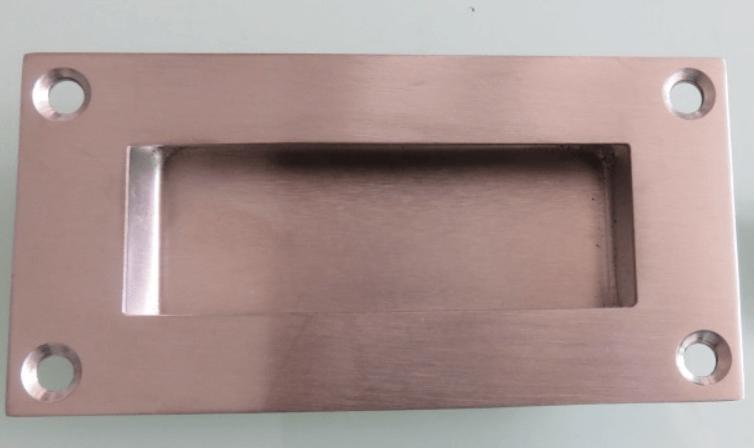

What Handles For Metal Ceiling Access Panels Can I Request?

The main types of handles that are available include paddle handle, pull handle, recessed handle, and swing handle.

Paddle handle allows a lock to be installed into the handle, saving space and providing a clean look.

Paddle handle

These handles are also easy to use.

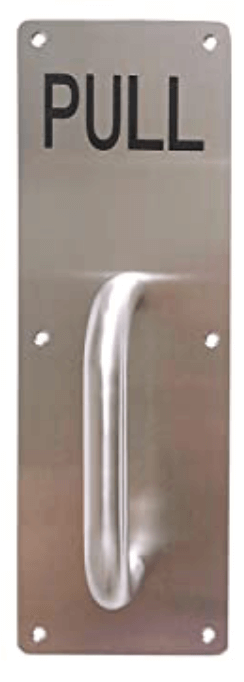

Pull handles are the standard simple handles versatile for any application.

Pull handle

Recessed handles can just be a dent in the surface of the metal access panel.

Recessed handle

However, these are not commonly used.

Swing handles, on the contrary, are more common.

Swing handle

These are versatile and comfortable to use, but cannot be concealed.

Of course, there are also t-handles mentioned in the previous question.

Also, it is common for metal access panels not to have any handles, but have keyed-entry locks.

That way, when the key is inserted to open the lock, it acts as a sort of pull handle as well.

What Ceilings Can Metal Access Panels Be Installed In?

Metal ceiling and wall access panels are perfect for masonry walls/ceiling, drywall, shaft walls, plywood ceilings, concrete, stucco, fire-rated walls, and much more.

Besides ceilings, metal access panels can be installed into walls and floors.

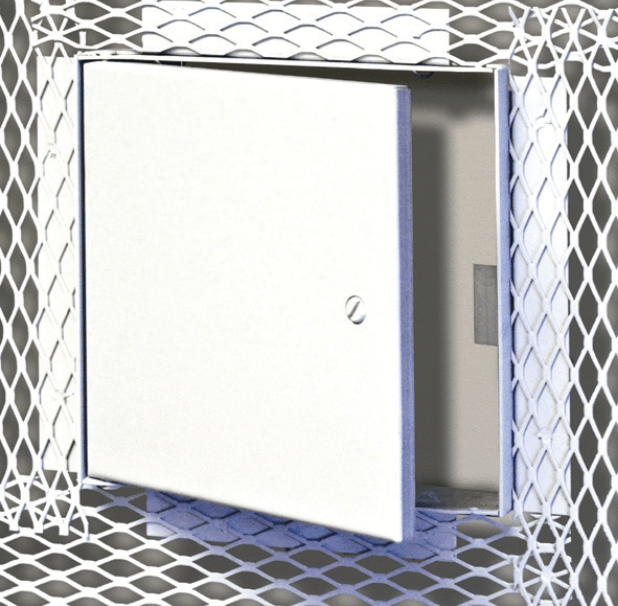

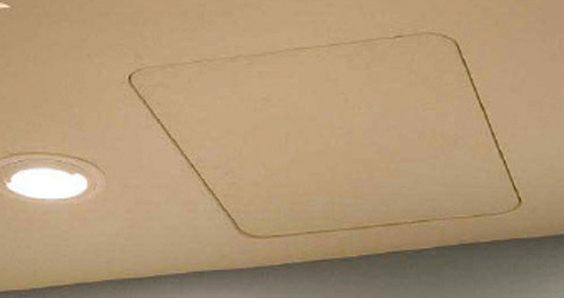

What Are Stealth Metal Ceiling Access Panels?

Stealth access panels are a design of access panels that lets it seamlessly blend into the ceiling or wall.

Stealth metal ceiling access panel

These can be masked to mimic drywall, and they are often small, so they will not be conspicuous.

Often, they are made from glass-reinforced gypsum.

Gypsum boards are also used to make metal ceiling access panels for drywall surfaces.

Gypsum-filled access panel

Are There Fireproof Metal Ceiling Access Panels?

We do offer fire-resistant metal ceiling and wall access panels.

There can be access panels with fire ratings starting at 30 minutes, an hour, and going up to 2-3 hours.

Wall access panels can also go up to 1 hour and a half in fire rating.

These may be required by law, so make sure your business has these!

They can be installed in office buildings, shops, warehouses, apartment buildings, and any other place.

Usually, lower fire ratings are required for less populated locations, like homes, whereas high fire ratings are required for locations with many people.

Fire-rated metal ceiling access panel

Are There Soundproof Metal Ceiling Access Panels?

Besides fire-rated metal ceiling and wall access panels, there are sound-proof ones as well.

Soundproof access panels are equipped with all-around gasketing and sound-blocking insulation, which can be made from vinyl, acoustic wool, drywall, and foam.

Such ceiling access panels are required in judicial settings, music rooms, performing spaces, and in hospitals for patient privacy.

Soundproof ceiling access panel

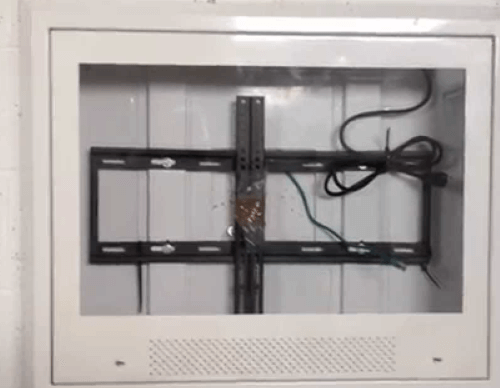

What Additional Features Are There?

You can request windows, vents, and rain/drip caps.

Windows help personnel look through the access panel and check things without having to open the door or cover.

This is useful for access panels that lead to gauges, electrical components, measurement units, etc.

The windows can be made from special glass or ABS.

Metal access panel with window

You can also request vents, such as louvered openings.

Vents help cool down electrical wiring, gauges, or anything that gives off excess heat as it works.

Vents also help with regulating air pressure beyond the access panel, and filter out various fumes and gases that may be produced, such as in industrial ducts.

Access panel with louvers

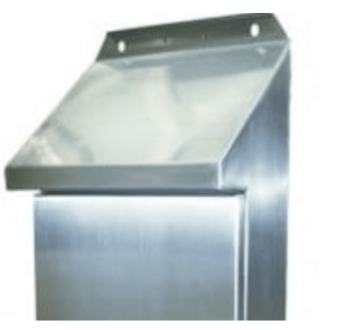

Rain or drip caps in metal access panels are basically protruding top panels that shield the rest of the door, as well as any locks and windows, from rain, snow, drips, etc.

They help protect the metal on the door and secure its longevity, as well as protect the locking mechanism from rusting.

Rain cap

What Coatings For Metal Ceiling Access Panels Are There?

You can request various polishes, paints, and coatings for decorative and functional purposes.

Satin polish is an abrasive polish that uses aluminum oxide as the abrasive substance.

This finish produces a fairly smooth surface.

There is also brushed finish, which shows lines and is rougher to touch.

Brushed vs satin polish

Mirror polish creates a very smooth mirror surface.

It is easier to clean, but any scratches, vapour condensation, and fingerprints are very prominent on such a surface.

A matte polish gives the surface a very soft, vintage, ceramic look.

This polish is great if you have ceramic tiles on the walls that you want the access panel to mimic.

It also guards against fingerprints and has a grainy texture.

Epoxy coatings consist of an epoxy resin and a hardener.

This type of coating is very durable and is suitable for harsher applications like outdoor vent covers, serving functionally as well as aesthetically.

Metal ceiling and wall access panels can also be powder coated, which has excellent edge coverage.

Powder coating is when powder paint is electrostatically sprayed onto a metal surface.

Painted metal ceiling access panel

Both coatings—epoxy and powder—can be of any colour.

We can also paint it according to your colour swatch, Pantone, RGB, or RAL colour request.

You can also request different decorative coatings that add colour to metal.

Such coatings are usually coloured metals that are electroplated on top of another metal.

Electroplating is a process that involves passing an electrical current through 2 metals, where one metal takes ions from the other metal.

For this, the 2 metals need to be chosen that will have such a reaction with each as opposed to a reverse reaction or no reaction.

Electroplated coatings

Metals can be electroplated with various metals that all have their own properties and colours.

For a yellow, orange, or warm brown color, you can request brass, bronze, or gold.

Copper goes for reddish and pink colors.

Chrome, nickel, cadmium, and pewter give cool-toned silvers and greys.

Steel is easy to electroplate.

It is possible to plate various metals onto aluminum alloys including nickel, tin, and precious metals such as silver and gold.

However, a common problem when working with aluminum and aluminum alloys is their tendency to form an oxide that can prevent proper adhesion of the coating.

If you need a custom polish, contact us and we will design it for you!