- Custom Any Size for MCC Enclosure

- MOQ 1pc

- Fast Sample Production within 3 days

Custom MCC Enclosure Manufacturer in China

KDM MCC Enclosure designed to be placed over MCC. This enclosure protects MCC from environmental hazards such as dust, dirt, moisture, and more. Aside from MCC, this is also suitable use for protecting components, power distribution, instruments, and so on.

Whether you are looking forward to expanding your current facilities or planning on building up enough room, MCC Enclosure from KDM is your best solution. These are cost-effective and easy to install, at a short period of time, they can be installed effectively.

KDM MCC Enclosure Series

Send your Inquiry on KDM MCC Enclosure

KDM MCC Enclosure can be built up using stainless steel, aluminum, and mild steel materials. With these versatile, rigid materials, structure durability and robustness is extreme.

They are constructed to last therefore you can assure enclosure can securely protect content for a long time. In KDM, we are always excited to solve any space limitations problems and/or make facility expansion more economical.

- Manufacturing Capacity

- Buying Guide

4000W high-performance laser cutting machine, +/- 0.05mm accuracy. No burr, no scratching.

Multi-Functioning flexible welding equipment, high accuracy, no deformation.

+/- 0.5mm bending precision, smooth surface without bending marks.

10+ welding experienced workers, perfect overall appearance.

High speed and accuracy foaming machines, fast and qualified Gasket

The expert assembling team, consistent assembly quality on every KDM enclosure

KDM MCC Enclosure

KDM MCC Enclosures are available in various selections, different size, dimensions, environmental factors, NEMA ratings, and features. With these options, you can select the appropriate equipment for your requirements. Moreover, we can manufacture a custom enclosure to the exact specifications you need for your MCC. The entire structure can be custom-made according to your requirements. The enclosure height, width, depth, door configuration as well. The enclosure can also be developed with tapped holes and cut-outs, fasteners, doors, and sub-panel.

You can send us the general information, every detail with your specifications. In KDM, we will work with to deliver precisely what you need on your project.

Our MCC Enclosures are fabricated through our skilled professionals. They are able to design and manufacture offered enclosures in the highest standard quality form. These enclosures have been tested on comprehensive quality parameters. Through the latest testing technology and machines, products are rigorously checked. Imperfections and the quality issue will no longer be a concern. Moreover, you can acquire our MCC enclosures at a very minimal rate. With KDM, you can eventually save time and cost. Anyway, you will have stress-free purchasing experience here in KDM.

With the comprehensive industry expertise and understandings of the allied domain, we are engaged in manufacturing and supplying superior quality of MCC Enclosures. All our MCC Enclosures are appreciated by different customers because of its extraordinary features. In the easiest way, the equipment can hassle-free extend life, increased cost and extensive downtime of MCC. All our MCC Enclosure passed and certified by UL, NEMA, CE, and more. Our expertise in manufacturing and supplying MCC Enclosure allow us to offer wider range of products in you.

KDM as one of the Leading and Prominent Manufacturer of MCC Enclosure in China, we are engaged to offer MCC Enclosures exactly what you need. With the best range of products, we can effectively offer you the attractive, reliable yet compactable MCC enclosures. KDM can timely deliver your orders.

With KDM MCC Enclosure, we ensure you can easily maintain the types of equipment, requires less power. With a decade in the industry, KDM knows the best way to solve your specific enclosure challenges. Our MCC Enclosure and all other types of enclosure have been trusted by our clients throughout the nation. Let us also help with yours. Contact us today!

MCC Enclosure

Leading MCC Enclosure Supplier to Boost Your Business

KDM- Your Reliable MCC Enclosure Manufacturer in China

- KDM design MCC enclosure using versatile, rigid materials

- High-quality yet cost-effective MCC enclosure

- Best range of reliable, compact and attractive MCC enclosure products

- Custom-built MCC enclosure to own requirements

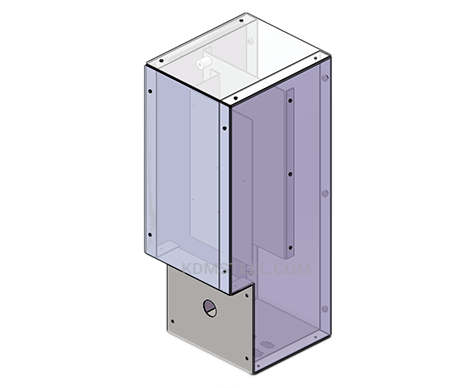

Single-door MCC Enclosure

KDM design single-door MCC enclosure consistently offers a great way to display your brand. We could custom products for you.

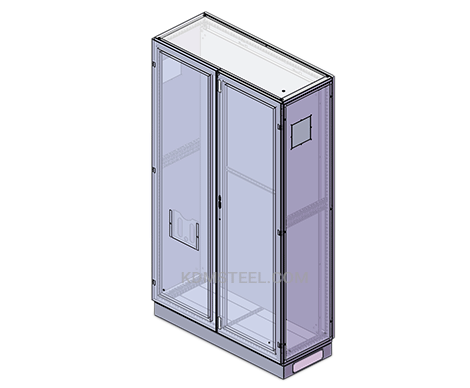

Stainless steel Double door MCC Enclosure

KDM offers you a complete choice of premium quality stainless steel double-door MCC enclosure products. Customize the whole design.

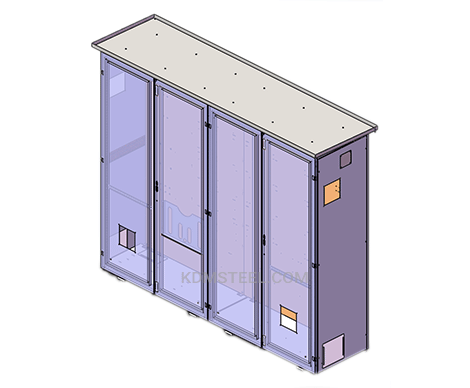

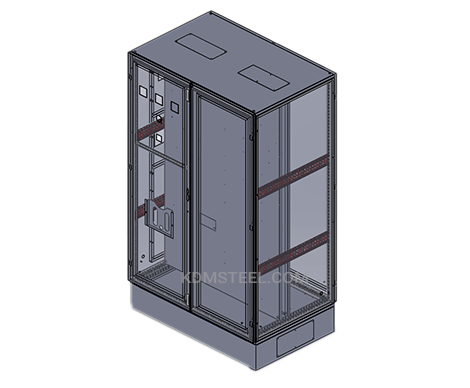

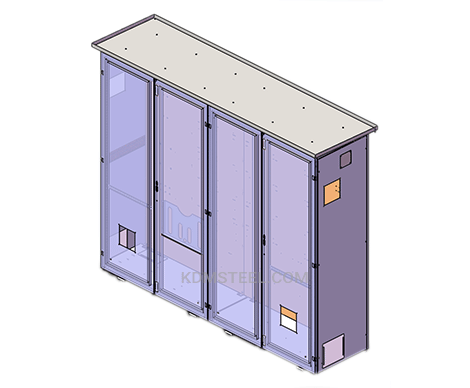

Multi door Stainless steel MCC Enclosure

Custom multi-door stainless steel MCC enclosure to fit the needs of your specific project with KDM. We have full fabrication capabilities.

Stainless steel MCC Enclosure

The stainless steel MCC enclosure manufactured by KDM has high protection against all environmental factors. Our state of the art technology offers you consistent quality products.

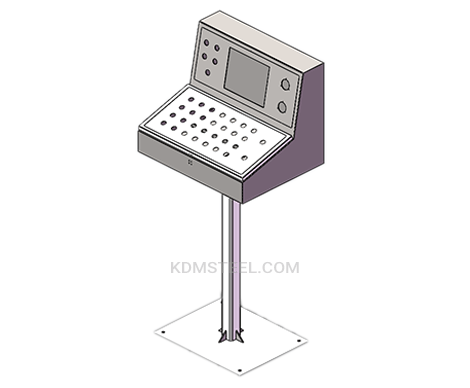

MCC panel Enclosure

KDM MCC panel enclosure provides reliable and effective features surely skyrocket your business. KDM can provide bespoke solutions.

NEMA 3R MCC Enclosure

KDM NEMA 3R MCC enclosure has a high protective structure to withstand in tough and most demanding applications. Also include electric shock and damages

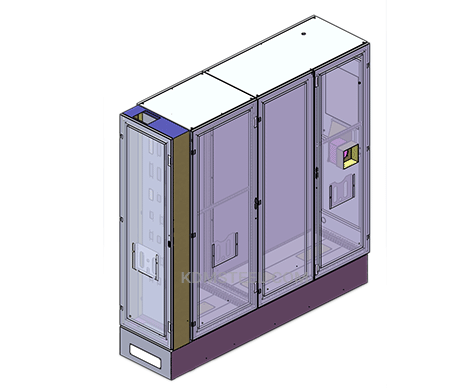

Free-standing Stainless steel MCC Enclosure

KDM free-standing stainless steel MCC enclosures are built to provide massive protection from environmental elements.

Stainless steel single door MCC Enclosure

KDM stainless steel single door MCC enclosures are available in different sizes. You can choose the right one for your application.

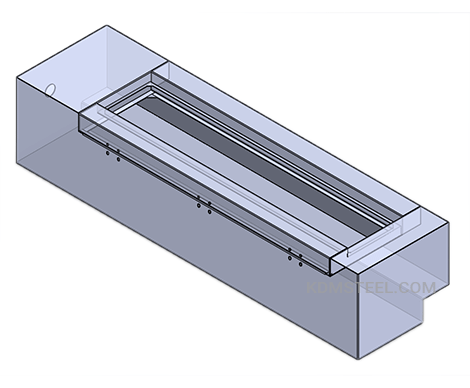

Drawout MCC Enclosure

KDM draw out MCC enclosure comes in multiple selections of shapes, sizes, and features. KDM offered products at minimal rates.

LV MCC Enclosure

LV MCC enclosure is made up of rigid and versatile material which provides a tough and stronger structure wherever they may installed. In KDM, you can customize the enclosure to own layout.

Related Product with MCC Enclosure

CNC Machine Enclosure

KDM CNC machine enclosure offers an undeniably tough and reliable structure to be store and protect machines.

Milling Machine Enclosure

KDM manufactures a large variety of milling machine enclosure in different materials, dimensions, types, etc.

Thermostat Enclosure

We are pleased to offer high-quality range of thermostat enclosure in any amount of orders.

Roadside Electrical Cabinet

KDM can fabricate new and unique roadside electrical cabinets ideally suited to housed and protect panels.

Send your Inquiry on KDM MCC Enclosure Now

- Durable and robust MCC enclosure to protect machines in a longer time

- Easily maintain equipment with KDM best types of enclosure

- Assembled to latest manufacturing technology and machines

- Compact cabinets able to solve space limitations challenges

KDM MCC Enclosure

KDM is one of the leading professional MCC enclosure manufacturer based in China.

We are engaged in offering a wide range of stated products such as industrial MCC enclosure, stainless steel MCC enclosure, single-door MCC enclosure, double-door and more.

We have more than 10 years of experience in manufacturing and supplying different kinds of MCC enclosures.

Our expertise allows us to design and develop innovative cabinets perfectly housed and protect valuable equipment.

There is a huge selection of enclosures, in different shapes, sizes, styles, and features. With that, you can certainly find the best and appropriate case suits your specifications and requirements.

During the production, each and every enclosure is checked and tested through different quality standards in order to meet every classification required.

Utilizing advanced testing machines and technology, you can be so sure with its reliability and effectiveness. Eliminate all your concerns with high-quality tested and approved boxes. You can avail our range of outputs at competitive rates.

With the professional insight and expertness of our technical team, we are always proud to present a superior quality range of MCC enclosure.

They are in charge of the designing, manufacturing and engineering cabinet in our modern production unit. These professionals keep everything managed, cleaned and precise.

Our MCC enclosure outstands with its finest-quality structure. It features optimum durability, robustness, and superior performances to withstand harsh environmental conditions.

The enclosure material can be made from stainless steel, plastic, aluminum, and mild steel raw materials. The structure has high resistant to corrosive environments and wet areas.

Furthermore, the enclosure can be designed with functional and practical accessories such as tapped holes, cut-outs, ventilation, doors and more.

In order to enhance efficiency and structure excellent, we develop enclosure with those objects.

Moreover, with our main focus to fulfill every requirement hand over with us, we are dedicated to offering bespoke solutions. You can choose within our selection and customize it to own specifications and final application.

Whether you need it for business or any specific projects, you can guarantee quality service with KDM. We aim to fulfill every project requirement therefore we make use of different ultra-modern techniques with the fabrication.

Our experience, engineering, and planning capability make us exceptional with others. With KDM, you can find dimensionally stable, sturdy and attractive output design.

Gathered 50 professionals who’d been expert with the production, KDM was able to give you a one-stop solution for all your MCC enclosure requirements.

The whole production procedure including laser cutting, casting, forging, bending. . . spraying will be managed.

KDM possesses sophisticated infrastructural equipment without compromising all the requirements of the industry. Our range of MCC enclosure will help in performing better operations with every system.

Your customers would surely love these cabinets. At KDM, we aim to achieve growing market needs. Through improving services and systems, we, therefore, satisfy existing and upcoming needs.

Tell us what you’re looking for! Contact us today via email or call.

MCC Enclosure: The Ultimate FAQ Guide

Today, I have compiled answers to questions clients ask every day about MCC enclosure.

This is basically everything you would like to know about the motor center control enclosure.

It starts from the basic definition, specification, application, standard rating to heat control, and many more.

Let’s dive right in:

- What is Motor Center Control Enclosure?

- Is there a difference between MCC Enclosure and Standard Electrical Cabinets?

- Which Types of MCC Enclosures are there?

- Why do you need MCC Enclosure?

- Are there Limitations of using MCC Enclosure?

- Which Materials are used in making MCC Enclosures?

- Why Ventilate MCC Enclosure?

- What is Modular Motor Control Center Enclosures?

- Is NEMA Rating Important for Motor Center Control Enclosures?

- Can you Get Weatherproof NEMA Motor Center Control Enclosures?

- Where can you use MCC Enclosures?

- How does NEMA 4 and NEMA 4X MCC Electrical Enclosures compare?

- How do Environmental Conditions determine the choice of MCC Electrical Enclosure?

- Are there Custom MCC Panel Electrical Enclosures?

- Which Accessories does MCC Enclosure come with?

- What is Electronic MCC Enclosure?

- What is IP Rating for Motor Control Center Enclosure?

- How does Wall Mount and Floor Mount MCC Enclosures Compare?

- When should you use Freestanding MCC Panel Electrical Enclosure?

- Which Locks and Latches do you need for MCC Enclosure?

- How does Junction Box compare to MCC Enclosure?

- Which Types of Hinges are suitable for MCC Enclosure?

- Are there Recessed Motor Control Center Electrical Enclosure?

- How does Indoor MCC Enclosure compare to Outdoor MCC Enclosure?

- How can you choose the best Cooling for Motor Control Center Enclosure?

- Should you Insulate MCC Panel Electrical Enclosure?

- Which Heater is suitable for MCC Electrical Enclosure?

- How much does the Motor Control Center Panel Cost?

- Which Safety Features does MCC Enclosure come with?

- Is there Size Limitations for MCC Electrical Enclosure?

- How do you Manage Cables in MCC Electrical Enclosure?

- How do you Choose MCC Electrical Enclosure Back-plate?

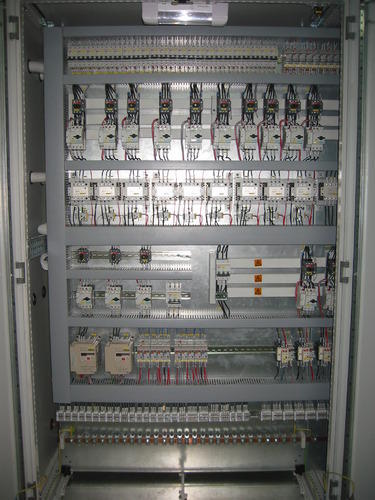

- Which Components can you install in MCC Enclosure?

- What is the Motor Control Center Enclosure Standard Design?

What is Motor Center Control Enclosure?

This is an assembly with single or multiple enclosed sections that are used to control electric motors.

It contains a common power bus with each section made up of a combination of starters.

These form the motor starters, fuses, and disconnect.

Apart from these, the assembly contains push-button, indicator lights, variable frequency drivers, programmable logic controllers, and a metering machine.

This motor control enclosure helps in centralizing the control of electric motors.

They are normally useful in large commercial or industrial buildings with several motors that need to be centrally controlled.

For instance, in mechanical or electrical rooms.

Motor center control enclosure

Is there a difference between MCC Enclosure and Standard Electrical Cabinets?

No, there is no difference.

MCC enclosure is the same as the standard electrical cabinets.

They are used for protecting electrical machines that have switches, knobs, and displays.

They both help in preventing electrical shock to machine users.

Both of them are made from stainless steel, copper, aluminum, fiberglass, or polycarbonate.

Which Types of MCC Enclosures are there?

There are many types of motor control center cabinet enclosures.

The classification depends on a range of factors.

They may include:

i. Type of material – where we have stainless steel MCC enclosure, aluminum MCC electrical enclosure, etc.

ii. Mounting position – free standing MCC enclosure, wall mounted MCC enclosure or floor mount MCC electrical enclosure, etc.

iii. Voltage rating – we have high voltage MCC enclosure, medium MCC enclosure, and low voltage MCC enclosure

iv. Quality standard – these many include NEMA rated MCC enclosure, IP rated MCC enclosure or UL listed MCC enclosure

v. Size – It may include small MCC enclosure, large MCC enclosure, etc.

power distribution enclosure

Why do you need MCC Enclosure?

The MCC enclosure is important for various reasons.

For example, it helps in protecting the motor center’s control from dust, dirt, and moisture, among other environmental hazards.

In addition to these components, power distribution and instruments are also protected by this MCC enclosure.

In addition to these, it provides a central location where all electrical motors within the same enclosure are controlled.

Are there Limitations of using MCC Enclosure?

MCC enclosure exhibits some shortcomings. For example, the horizontal one requires a spacious building for installation.

When you have less space, this may pose a challenge to you.

Many devices installed and centrally controlled within an enclosure pose difficulty in identifying the specific device with a default.

Which Materials are used in making MCC Enclosures?

The MCC enclosure can be made from materials like 304band 316 stainless steel, aluminum, mild steel, and neoprene gaskets.

Others are manufactured from powder-coated copper, fiber-glass, polycarbonate among other materials.

Why Ventilate MCC Enclosure?

It is very important to ventilate an MCC enclosure because it provides airflow.

It also protects the MCC from small solid materials that may enter inside.

Apart from this, it also helps in protecting it from the egress of gasses that may come from arc flash.

The ventilation opens for air to flow in and out of the MCC enclosure.

This occurs due to the response from air pressure waves.

It bends at perforation lines, thereby shifting the flap closer to the mesh.

An electrical one can have a closed, exhausted system configured to respond by opening when subjected to air pressure waves.

This helps in allowing the gasses to escape from the MCC.

MCC enclosure ventilation

What is Modular Motor Control Center Enclosures?

This is an enclosure that has a motor control point, power control center, capacitors, and metering panels.

This enclosure has a bolted design, superior surface finish, easy to work with, and easy to transport.

It can easily and quickly be assembled using standard tools, and it is highly flexible.

Is NEMA Rating Important for Motor Center Control Enclosures?

NEMA means National Electrical Manufacturers Association.

It’s a rating system for devices that might be exposed to liquids, ice, and corrosion and contaminants like dust.

This is a rating system that ensures proper construction of MCC indoor or outdoor.

It guarantees safety from any form of environmental materials.

NEMA rating is important because it can withstand short circuits.

Secondly, they are versatile and can be used in many applications.

Thirdly, they can be used even in large size machines.

What are NEMA 12 MCC Electrical Enclosures?

NEMA MCC Enclosure

This is the NEMA type that protects against any objects that might enter into the MCC enclosure.

For example, fingers that might be poked into MCC, dirt, liquid that are not corrosive, oil, lubricants, and drips.

They are mainly used for indoor enclosures to prevent airborne dust from settling on the surface.

It also protects the MCC from lint, fibers, and objects that fly.

In most cases, they are used in industrial, manufacturing, and machining applications that have installed indoors.

Can you Get Weatherproof NEMA Motor Center Control Enclosures?

Yes, you can because they are ideal for the expansion of a facility.

For instance, NEMA 3 is normally used outdoor to protect the MCC enclosure against dust blown by the wind.

It also gives protection away from rain, sleet, and ice that may form outside the enclosure.

Type 4 also adhere to NEMA standards that provide good quality enclosures use for basic applications.

The type 4 waterproof is ideal for making both indoor and outdoor since it offers protection against dirt and rain.

Sleet, snow, dust that is window-blown, splashing water, and horse-directed water can also not reach the MCC enclosure.

NEMA rating 3R is equivalent to IP14, and they both give protection against solid materials of 50 mm and above.

Apart from these, NEMA rating 3S, which is the same as IP54, protects the MCC against dust, rain, and dirt.

These elements may be harmful to the equipment users and the machine.

Also, NEMA rating 4 and 4X are equivalent to IP 66.

They both provide protection against dust, rain, sleet

Where can you use MCC Enclosures?

The MCC enclosures protect the environment in many different buildings, industries, and utility devices.

It also helps in protecting machines from electromagnetic and radio frequency interference.

For example, circuit breakers, contactors, control panels, switches, distribution boards, and panel boards.

Other devices protected are pressurization and purging machines and systems, and telephone cabinets.

The MCC enclosures can be used to construct electrical, chemical plants, and telecommunication rooms and equipment for charging electric vehicles.

In addition to these, manufacturing plants, mining, oil, and gas facilities also use MCC enclosures.

How does NEMA 4 and NEMA 4X MCC Electrical Enclosures compare?

The NEMA 4x is a rating category found in NEMA 4 rating.

They offer an equivalent outdoor weather protection level.

However, NEMA 4x gives extra and better protection as compared to NEMA 4.

Both NEMA 4 and 4X rating can be used to protect either indoor or outdoor of the MCC.

The NEMA 4 gives protection against solid materials like dust blown by wind and dirt.

On the contrary, NEMA 4x protects the MCC against corrosion, dust, dirt, splashing, and hose directed water, rain, and ice.

NEMA 4X ratings are ideal for the manufacturing of wide MCC that have overlapping doors and center posts.

These help in maintaining a sound enclosure structure that can be accessed from many points.

On the other hand, NEMA 4 ratings are not good for such wide MCCs.

When MCC is to be protected against some worst environmental materials, NEMA 4X is the ideal rating.

The NEMA 4 is made from carbon steel that has been coated with powder.

They are available in many types, including wall-mounted, free-standing, and JIC coated carbon steel.

Contrary to these, NEMA 4X is made from stainless steel since it has to protect against corrosion.

How do Environmental Conditions determine the choice of MCC Electrical Enclosure?

Figure 5 Inside NEMA MCC Electrical Enclosure

The MCC enclosure helps to protect the MCC from damage by environmental factors like dirt.

It is also ideal for component protection, distribution of power, and instruments, among others.

The choice of an MCC electrical enclosure is influenced by environmental factors. For instance, NEMA type 1 and type 12 are relevant for indoor MCC electrical enclosure use.

The NEMA type 1does not have harsh or differing conditions, and its enclosure is gasketed.

NEMA type 12 guarantees protection against dust, airborne materials, and dripping liquids.

All the doors, door cutouts, cover plates, side and top, and back sheets of NEMA type 12 must be gasketed.

NEMA type 3R, type 4, and 4x are used outdoor.

The NEMA type 3R offers protection against rain and sleet. In addition to these, it is gasketed with overlapping doors.

NEMA type 4 and 4x give MCC protection against falling dirt, sleet, snow, splashing water, and hose-directed water.

But 4X provides additional protection to MCC against corrosion and external ice formation.

Therefore, depending on where you want to install your device, you can choose either indoor or outdoor.

Are there Custom MCC Panel Electrical Enclosures?

Yes, there are. For instance, there are different selections, sizes, dimensions, environmental factors, NEMA ratings, and features. These options can allow you to choose an appropriate machine that may have been manufactured with the specifications you desire.

To get the custom MCC panel, you have to determine the enclosure height, width, depth, and door configuration. Determining the height involves considering the height of the MCC. You must also consider the horizontal wire-way that can either be put at the bottom or top of the MCC.

Width determination requires consideration of the MCC width and the wire-way of both sides of the MCC. To determine the depth, add 8 to the existing MCC depth.

Door configurations are determined by considering the number of buckets, enclosure width, and MCC position. This could be an open area indoor or outdoor, or it may be at a production facility with space limitations. MCCs that are smaller and use NEMA 3R/12 rating can have overlapping doors that have no center post.

On the contrary, large custom MCCs use NEMA 4x rating and have overlapping doors. These doors have center posts that aid in facilitating the soundness of the MCC structure. This helps in allowing access to too many structure points.

Which Accessories does MCC Enclosure come with?

MCC enclosure comes with accessories for installation like plain, silkscreen, micro-perforated, polyester, and Bakelite mounting plate.

DIN rain, modular chassis, and vertical upright and support are also other MCC enclosure accessories.

Fixed and pivoted 19 inches rack that are used for wall-mounting and floor-standing enclosures is also another accessory.

Others include hardware and support accessories for equipment such as trays and heavy-duty supports.

What is Electronic MCC Enclosure?

This is an electrical switchboard enclosure.

It has either a single or many motor starter sections.

It’s an automatic power system that promotes efficiency in production through the centralization of all components control in one place.

What is IP Rating for Motor Control Center Enclosure?

This is a type of rating that prevents the dust and water from entering the MCC enclosure.

The entry of non-detrimental materials into the MCC enclosure can be indicated by IP and two numbers.

For instance, IP67 signifies dust-tight with full protection against contact.

This IP67 can also be immersed in 1mm of water for at most 30 minutes without causing any damage.

IP65 is also dust-tight but is additionally protected against water that is projected from a nozzle.

IP 66 is also dust-tight but specifically protected from heavy seas or powerful water jets.

Finally, IP 68 is uniquely protected against continuous and completer submission in water.

The waterproof IP ratings include IP67, IP66, and IP65.

IP reference chart

How does Wall Mount and Floor Mount MCC Enclosures Compare?

- Floor mount MCC enclosures look like free-standing enclosures and are ideal for spacious rooms.

They are normally made as monolithic enclosures in a definite size that can be used as a stand-alone enclosure.

- Wall mount, on the other hand, is ideal for limited space applications. The enclosure is lifted, and this helps in leaving some space on the floor for other activities.

The floor-mount, on the contrary, is installed slightly above the floor, and this facilitates easy cleaning of under the enclosure.

- Floor mount MCC enclosures are raised slightly above the floor, and this facilitates easy accessibility to the cables.

On the other hand, the wall-mount is on the wall, and it’s coated with a white carbon steel back panel.

- The floor mount MCC enclosure has one or two wider doors, whereas the wall mount one has overlapping doors.

- The floor mount has no center posts, and for this reason, it can easily be installed.

Contrary to this, a floor mount counterpart has center posts that help to reduce MCC exposure to high voltage.

- These MCC enclosures have large panels that help in automating electronics, controls, and instruments.

- These MCC enclosures have a durable hinge that aids in easy pivoting and rotation as desired by the users. The hinge is hidden, though easy to install.

- The two types of MCC enclosures have a three-point latch system, and this promotes easy accessibility to the MCC components.

- The customized ones are available, and therefore, you can get an enclosure with specifications like cutouts, insulation, hinges, latches /locks.

- They both have back panels that make mounting of electrical and electronic controls content easy.

- Both of these MCC enclosures are made from powder-coated carbon steel, 304 stainless steel or 316 stainless steel.

- They are all NEMA rated and listed by UL or IP.

- They are made to protect MCC from too many wet environmental conditions.

When should you use Freestanding MCC Panel Electrical Enclosure?

A freestanding MCC electrical enclosure should be used when you want to make an enclosure that is simple in design.

It should also be used when you intend to produce a stand-alone enclosure.

Which Locks and Latches do you need for MCC Enclosure?

Locks and latches are mounted on the cabinet doors to lock them.

The latches hold the door in place when it is pushed while the locks close the door.

Spring-loaded, single piece and complex options are some of the latches that can be used in MCC enclosures.

MCC locking mechanism

MCC enclosures may use either keyed alike or master keyed electric panel locks.

Keyed alike is where a single key is used to open an electric panel.

This is ideal for one section to minimize the use of many keys and relevant during security concerns.

When the security of the MCC is not a concern, a master key can be used to unlock the doors.

This is a single key that opens all the electrical enclosures.

How does Junction Box compare to MCC Enclosure?

A junction box is an enclosure that houses and protects electrical connections or branch circuits.

MCC enclosure protects against dust, dirt, moisture, and corrosion.

Junction box

The junction box acts as a safety barrier that could be made from metal or plastic.

The MCC enclosure is also a barrier that is made from powdered carbon steel, 304, and 416 stainless steel.

Junction boxes are representations for conduit end runs whereas, an MCC enclosure is a covering for MCC.

The junction box is normally positioned near compressors, pumps, or large machines pieces.

On the other and, the MCC enclosure is positioned in a building.

The junction box can be used on commercial building roofs to connect the circuit to air-conditioning systems and ventilation fans.

On the contrary, the MCC enclosure is used in large industrials and commercial buildings.

Both Junction box is an approved enclosure for wiring splices.

It is an alternative to socket outlets.

When a junction box is used instead of the socket, it’s connected to a ring and a spur cable.

MCC enclosure is also an approved enclosure, but it’s for MCC.

Which Types of Hinges are suitable for MCC Enclosure?

Many types of hinges can be used on the MCC enclosure doors.

For example, butt hinges include barrel, piano, butterfly, pivot, spring, and flush hinges.

Are there Recessed Motor Control Center Electrical Enclosure?

Yes, there are.

For instance, a recessed horizontal bus can be used to protect MCC components.

NEMA type 1 can also be recessed.

They have a slotted flush and knockout that is installed to secure the MCC electrical enclosure.

How does Indoor MCC Enclosure compare to Outdoor MCC Enclosure?

The indoor MCC electrical enclosure includes type 1 that offers protection against falling dirt.

Type 2, drip-proof, is also an indoor enclosure, and this protects the dripping of non-corrosive liquids.

On the other hand, outdoor include 3R MCC enclosures which protect it against rain sleet and contact with the MCC.

The NEMA type 1 and 12 are indoor MCC enclosures represented by IP ratings of IP10 and IP52, respectively.

Contrary to these, The NEMA type 3R is an outdoor MCC enclosure with an IP rating of IP14.

How can you choose the best Cooling for Motor Control Center Enclosure?

A good cooling system for the MCC enclosure is very important because a device gets hot, leading to failure.

The MCC temperature should, therefore, be monitored and, if possible, install a cooling system.

This plays a role in reducing the life span of the machine.

One of the best cooling for the MCC enclosure is 4x 60,000 BTU/h spilled air conditioner.

HVAC machines can also be used to cool and ventilate it.

Other cooling systems that might also help are heat exchangers, fans and blowers, and other electrical cabinet accessories.

Should you Insulate MCC Panel Electrical Enclosure?

Yes, it can be insulated.

An insulated MCC electrical enclosure has IP65 protection that prevents it from damage by dust, moisture, and other environmental factors.

Insulation also protects you from the electric shock that might occur when you come into contact with the MCC enclosure.

Which Heater is suitable for MCC Electrical Enclosure?

MCC enclosure heater

The heaters are used to freeze and control heat.

It uses an electrical anti-condensation process to heat its content.

Many heaters can be used for MCC electric enclosures.

For example, fan heaters that run electrical current throughout the heating device.

The heated air leaves the heater and is propelled into the MCC enclosure, thereby heating it.

Another heater that can be used is the positive temperature coefficient heater.

This type of heater works through conductive materials means.

An increase in temperature prompts an increase in material resistance, and this leads to a current flow limit.

The MCC panel electrical enclosure is made from materials that allow current flow.

When it’s cold, it allows the free-flow of current, but it begins to limit current as it continues to become hot.

Furthermore, the explosion heater is another one, and it’s used to heat the enclosure through a conventional means.

The convention current passes through the heater leading to heating up of the air therein.

When this is continuously done, all the MCC electrical enclosure air becomes hot, resulting in attaining the right temperature.

This type of heater is preferred for MCC electrical enclosures installed in hazardous environments.

Therefore, the application you intend to work with will greatly influence the type of heater you can go for.

How much does the Motor Control Center Panel Cost?

MCC panels vary in their cost.

Some may cost between 100 to 1000 US Dollars. Others can be sourced at a price that may vary be6tween 2000 to 50,000 US dollars.

The cost of the MCC panel is influenced by the amount of wire that you will use in installing it.

If the wire required is much, the cost of purchasing a complete MCC panel will be high.

Or, if less wire is used, it can be sourced at a cost-effective price.

The cost of labor also plays a role in determining the price of the MCC panel.

When the workforce is paid much for manufacturing the MCC panel, the price will be high.

This is because the labor cost is calculated per hour.

Another determining factor for the cost of the MCC panel is the materials used.

If expensive materials are used, the price becomes high and vise vasa.

Which Safety Features does MCC Enclosure come with?

Safety, when dealing with MCC enclosed devices, is very important.

There has to be a way of troubleshooting, opening doors, entering data, or making any changes in programming.

Without safety measures, the technicians will be exposed to electrical hazards from the enclosure.

The MCC enclosure is arc-resistant or positioned in a controlled-access area where they cannot cause harm to the users.

Besides, the ventilation systems, door locking mechanism and alarms are all part of the safety system.

Is there Size Limitations for MCC Electrical Enclosure?

No, there are no size limitations.

This is because the MCC electrical enclosures are available in a variety of sizes.

You can also order for a custom specific size if you so desire.

MCC electrical enclosure

How do you Manage Cables in MCC Electrical Enclosure?

Cables in the MCC enclosures are managed by feeding them through the ground or overhead.

This helps in reducing bending wire difficulties that you may experience.

How do you Choose MCC Electrical Enclosure Back-plate?

MCC enclosure backplate

Choosing the MCC electrical enclosure back-plate is influenced by the type of enclosure materials.

It will also be determined by the components you intend to mount on the MCC enclosure.

You should also choose MCC electric enclosure back-plate that is simple in design and cost-effective.

In addition to these, choose the MCC enclosure back-plate that has been built accurately to offer maximum protection.

The back-plate should be strong, durable, and reliable to facilitate the use of the device for a long time.

Which Components can you install in MCC Enclosure?

Inside MCC enclosure

Many components can be installed in the MCC enclosure.

For example, the vertical metal cabinet section has a power bus.

It has large controllers that are bolted while the small ones are plugged-in.

Other components installed include overload relays that protect the motor and circuit breakers that protect for short-circuits.

Apart from these, the disconnecting switch must also be installed because it helps in isolating the motor circuit.

There are also terminals through which the motor is wired.

Lastly, in-built lighting, cooling, and heating systems must also be installed in the MCC enclosure.

What is the Motor Control Center Enclosure Standard Design?

Motor control center enclosures also have some quality standards that they have to meet.

These will help in making the MCC enclosed device durable and reliable. Below are some of them.

a) Listing by Organizations

The motor control center must be listed by the underwriter’s laboratory (UL), National Electrical Manufacturers Association (NEMA) and Intertek.

Internationally, most MCC enclosure manufacturers use a listing from the international electro-technical Commission (IEC).

Another important listing for MCC enclosures is the Institute of Electrical and Electronic Engineering (IEEE).

b) Materials used for making MCC enclosure

All MCC enclosures must be made from metal (stainless steel), plastic, fiber-glass, die-cast, or copper.

The choice of a good one must consider weight, appearance stability, cost, options for mounting, and durability.

c) The MCC has to be protected from the Environmental Factors

This can be reviewed in NEMA and IP ratings.

This gives a description of the level of protection the enclosure can offer from the environment.

It’s from a review of NEMA ratings that you can determine whether the enclosure can be indoor or outdoor.

d) The MCC Enclosure must have a Mounting and Specific Orientation.

MCC enclosure must either be vertically or horizontally oriented. It can also be mounted or free-standing.

e) MCC Enclosure should have a Climate Control Mechanism

The heat from within or outside the enclosure can damage a device.

High heat output and the surrounding external environment that is relatively hot require a heat transfer mechanism.

In this case, a good cooling system for the MCC enclosure is crucial.

f) The Size of the MCC Enclosure

This is also a standard quality issue because there are different sizes.

Care should be taken not to purchase many enclosures of different sizes because this increases the cost of production.

If you are working with a small enclosure, think about upgrading it.

g) The Modularity and Versatility of the MCC Enclosure

The MCC enclosure should give room for customizing so that it can suit the user’s needs.

It should be flexible enough to accommodate any adjustments that may be needed, even in the future.

h) Ampacity

This is the maximum current the main horizontal bus tolerates without having to overheat.

The MCC enclosure minimum capacity is 600A, and their nameplate is revised.

These can be obtained through special orders since they are small and are not easy to come by.

The vertical bus has a minimum ampacity of 300A.

The MCC enclosure with 2,000A as its minimum horizontal ampacity and has a maximum of 1,600A.

However, some manufacturers may order for MCC enclosure that has a maximum of 5,000A.

i) Fault Current Level on the Power Distribution System

This is the electric current amount that flows when a direct short takes place between the phase and the ground.

It interrupts rating via circuit breakers and fuses, resulting in short circuits.

The current opens and breaks to machines it protects without causing damages or injuries to personnel.

Therefore, a good motor control center must have a fault current level on its system of power distribution.

This will help in ensuring the safety of all the electric components of the circuit within the MCC.

The determining factor for fault current level withstanding rate is the lowest rated machine within the motor control center.

MCC assembly is rated according to the withstanding rate and not according to the MCC bus structure rating.

For instance, the MCC bus structure rated 42,000A with a withstanding rating of 18,000A has MCC assembly rated 18,000A.

j) A good MCC Enclosure should have Correct Bussing Materials

The bussing materials for MCC are very critical when it comes to quality standards consideration.

Copper is the most common material used.

Sometimes, aluminum can be used, although it has some setbacks.

For instance, it over expands and contracts, unlike copper, even though it is cost-effective.

To resolve this aluminum problem of over-expansion and contraction, an aluminum bus can be connected to insulated bus support.

In addition to this, the aluminum bus must be bigger to handle a current that copper can handle.

Copper also may corrode over time due to constant exposure to ammonia gas leading to MCC failure.

This can be prevented by using tin to coat the copper bus, and therefore tin may corrode, leaving copper safe.

Corrosion is likely to occur in wastewater treatment plants, fossil fuel-based power penetrating machines, and marine surroundings.

Silver can be used to coat copper, although it ends up forming a very thick insulating layer of silver sulfide.

When it is attacked by chloride sources, copper may erode, leaving silver behind.

Therefore, depending on the environment of the MCC enclosure, materials for manufacturing MCC enclosures should be selected appropriately.

k) The MCC Enclosure should have Feeder Cables

This is very important because the cables determine how the current enters the MCC.

These can either be overhead or underground cables.

MCC has many connections, and therefore, planning how to feed it helps in minimizing bending wire problems.

Apart from this, it also eliminates the extra cost of removing incorrect wire feed.

Other quality standards that must also be adhered to are metering, wire marking, and indicator lights.

In addition to these, a good MCC should specify the enclosure type, which could be indoor or outdoor.

Lastly, it must have an automatic switch.

In short, choosing the right MCC enclosure requires you to understand every concept, from design to accessories.

The good news – this guide has explored everything you need to know.

But, still, in case you have any questions, KDMSteel team is here to help.

Recent MCC Enclosure Order

FAQS

What are MCC Enclosures?

MCC Enclosure is cabinet inhouse MCC (Motor Control Center), power distribution, instruments, etc. It protects sensitive parts against hazardous elements such as moisture, dust, dirt, etc. This is typically NEMA or IP rated for protection against various hazardous elements.

What is MCC and How Does it Work?

Motor Control Center is a type of electrical switchboard. It distributes electric power. It consists of one or more vertical metal cabinet sections. It combined all electrical starters in one assembly. Motor Control Center controls all electric motors in a centralized location. This equipment contains:

- pushbuttons,

- programmable logic controllers,

- programmable automation controllers

- variable frequency drives

- metering equipment,

- indicator lights,

- motor starter,

- fuses or circuit breaker,

- power disconnect.

Where Can MCC Enclosures Be Used?

MCC enclosures are suitable for indoor and outdoor uses. It is used in many industrial and commercial applications. It includes the following:

- Automotive applications

- Chemical plants

- Food and beverage

- Manufacturing factory floors

- Mining, metals, and minerals area

- Water-treatment and wastewater plants

- Commercial construction

- Industrial construction

- Oil and gas

- Pulp and paper

- Utility, etc.

What are the MCC Enclosures Advantages?

- Offer good safety measures

- Highly customizable

- Superior construction quality

- High-security locks

- High protection door hardware

- Alluring look and eye-catchy design

- Deliver with best IP protection

- The best strength to weight ratio

- Dimensioned and constructed to real conditions

- Provides high personnel safety.

- Easy to modify and extend.

- IEC/EN 61439 verified

- Cost-effective with the very low installation time

Is Custom MCC Enclosure Available?

Several manufactures offer custom MCC enclosures to meet your diverse requirements. Manufacturers will gather information about your MCC enclosures specifications such as:

- MCC General Information – it includes enclosure height, width, depth, enclosure door configuration

- Environmental factors & NEMA Rating

- Structure requirements

- Custom features

What are the Types of MCC Enclosures?

Rectangular MCC Enclosures

It has rectangular shape MCC enclosures. It is specifically designed for power station, factories applications. This enclosure has a 1000 mm – 2200 mm height, 450 mm – 1000 mm depth, and 300 mm – 800 mm width. Rectangular MCC enclosures are manufactured using excellent quality raw materials and ultra-modern techniques.

Industrial MCC Enclosures

MCC enclosures can be specifically designed to suit various industrial applications where a highly corrosive environment is active.

Stainless Steel MCC Enclosures

Stainless steel is an excellent material in producing MCC enclosures. It is popular for its corrosion-resistant characteristics and resilient in high saline environments. It also offers high impact resistance. Stainless steel enclosure is an extremely tough and highly durable enclosure.

Mild Steel MCC Enclosures

Mild Steel MCC Enclosures is used for the distribution of electrical energy. It provides the highest safety operation to users. It is designed safe from the risk of leakage current. It features efficiency, reliability, and rugged constructions.

Cast Iron MCC Enclosures

Cast iron provides several advantages compared to steel. It offers more improved corrosion resistance and castability. It has homogenous durability and structure. This material has a low density of 7,3 kg/dm3 thus offering a significant weight reduction.

IP Rated MCC Enclosures

IP Rated MCC Enclosures are suitable for outdoor applications. It is protected from liquid ingress, low-pressure water jets, condensation, water spray, and extreme weather. It offers the great assurance of longevity and sustainability.