KDM Machine Enclosure is built to protect the expensive machinery from conditioning, noise, and other factors. These enclosures maintain and enhance the proper working temperature of the specific machines.

They are ideal to support different industrial, commercial, and any special needs of facility equipment. For all necessary applications, the KDM enclosure can accommodate a variety of equipment dimensions and design configurations. Hence, they can be pre-engineered to specifically meet the requirements of your request.

In KDM, we have stock a wide range of heavy-duty machine enclosure options that keep your valuable equipment working well.KDM designed, engineered, and manufactures machine enclosures exclusively suit, cover your machine. The panels may come in interior and exterior forms which increase the level of protection in your facility.

- KDM specialized machine enclosure production for over 10 years

- A wide range of machine enclosures meet every project requirements

- Professional engineers to design, engineer, and construct machine enclosure

- Full certification is provided for all machine enclosure

KDM Machine Enclosure Series

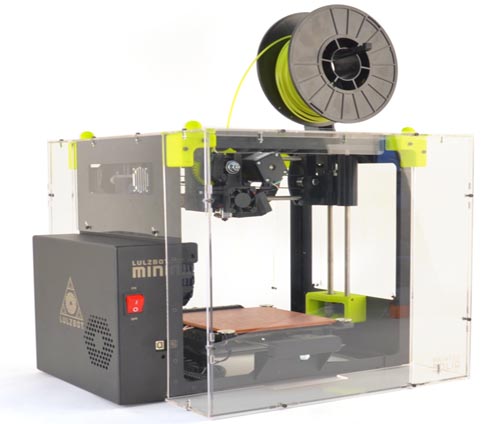

KDM printing machine enclosure help maintain the condition, cleanliness of facility. Thus, provide protection to the printing machines and equipment effectively.

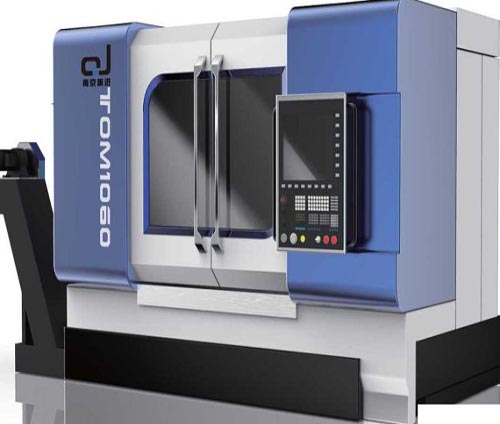

The CNC machine enclosure is solidly-built to control noise, dust, dirt and any elements. Great and durable design which keep the machines reasonable attractive.

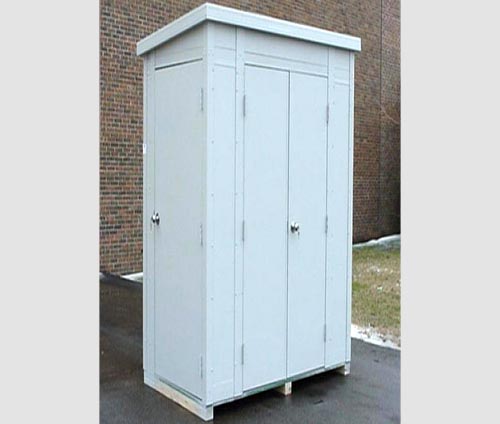

Our machine enclosure can be custom-made according to the specific application of equipment. Whether they need for indoor or outdoor application, KDM has the capability to design equipment to your request.

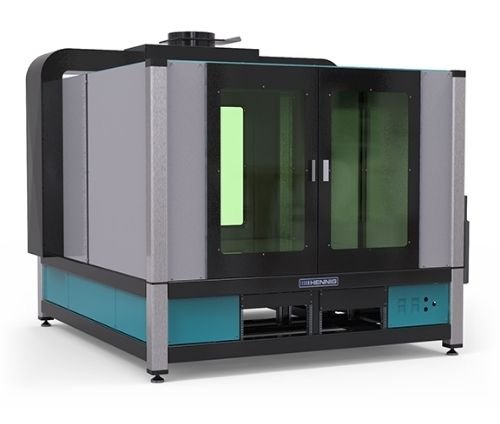

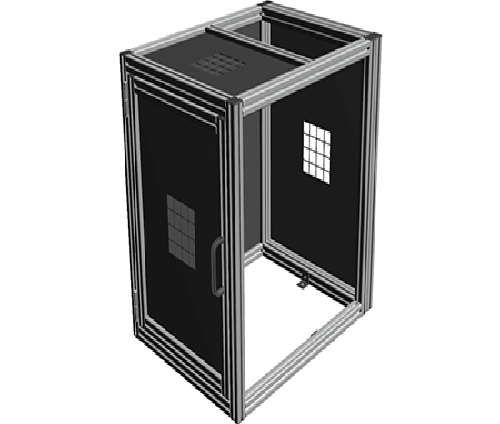

The aluminum profile machine enclosure is made out of heavy-duty, reliable material. This is the perfect solution for covering and protecting equipment even the most demanding application.

The modular machine enclosure is designed and engineered by our well-trained, professional engineers. Effectively protect and sensitive and expensive equipment from any environmental impact.

Our Quad door Machine Enclosure can be configured to meet the specific requirements of the application. These are type-tested, time-tested and fully meet the international quality standards.

Send your Inquiry on KDM Machine Enclosure

Enclosures can be reused, re-locatable and expandable. A great solution to save installation cost and time as our machine panels require minimal installation time. Ultimately, save total charges for the installation and all other charges.

In KDM, our machine enclosure is available in a variety of colors, finishes, and dimensions. With that, you can find the best panel for your valuable and vulnerable machines. These machines are solidly constructed to withstand the heavy and toughest environmental conditions.

- Competitive cost machine enclosures

- Pre-engineered design specifically meet your request

- Fastest production capability

- On-time orders delivered

Related Product with Machine Enclosure

KDM Machine Enclosure

Our lightweight, highly compact and reliable structural panels can surely meet all the industry’s specifications.

These panels exceed highest national structural requirements.

Our panel products are 100% made onsite ready.

Enclosed machinery and keep your equipment and employee safe with KDM machine enclosures.

This enclosure can be custom-design according to meet the needs of your facility.

Even the loudest machinery of your facility, these structures can control sounds and serves as a reliable barrier to protect sensitive equipment from environmental elements.

These machine enclosures are engineered closely to fit all the requirements of your application.

Our dedicated sales team design every unit to provide quick and easy access to the project.

They ensure every panel is designed with safety features for optimum functionality, protection and aesthetically.

Our team expertise can specify construction to meet the exact needs of your building.

Over our decade of experienced in designing, constructing, installing and delivering enclosure, we can produce world-class machine packaging tools.

All the machine enclosures from KDM will deliver effective control of all the hazardous effect of the conditions.

Enhance working area safety, employee health and business productivity.

KDM is your one-stop-shop solution for all kinds of machine enclosure requirements.

We have rich industrial expertise designing the entire product line with a variety of panel materials available.

We had the resources and capabilities to deliver a precise solution for sensitive equipment packaging.

Even if you can find what you’re looking for in our selection, we are open to design your unique and innovative product.

Our team is willing to help you with your project.

Please contact us with your inquiry. Our design will answer any questions about a quotation thus will help you design what you need.

Machine Enclosure- Your Ultimate FAQs Guide

Machine Enclosure

KDM is an experienced machine enclosure manufacturer and producer in China. KDM ensures to provide a complete guide to help you consider different factors and determine various options.

This guide will help you know more about machine enclosures. Let’s check it now!

What Is Machine Enclosure?

This is an equipment enclosure that provides consistent machinery.

Machine enclosure provides own room to your machines, accommodate dimensions, and layout.

It is environmental noise control, humidity, and temperature.

What Are Common Machine Enclosure Applications?

The enclosure is perfect housing and machine protection. There are common applications that include:

- Printing equipment

- Coordinate measuring machines

- Process control

- Pharmaceutical manufacturing

- Injection molding machines

What Are The Common Machines Enclosure Should I Consider?

There are many machines enclosure used in various productions and processing. It helps Here are some processing machines you should consider to choose the right enclosure:

CNC Enclosures

The enclosure can reduce rejection rates. It is a crucial process that occupies CNC machines.

Laser Rooms

This is a crucial process. Laser machine enclosure can lesser messy processes and prevent disruption.

CMM Enclosure

CMM enclosure has great features ensuring a secured process. Prevent disturbance created from different production lines.

EDM Enclosures

EDM machines required controlled environments. The enclosure is the perfect solution to provide constant temperature

Printing Enclosure

Printing machines and process needs housing for great results. It controls temperature prevents humidity.

Automated Machinery

It provides excellent controls and solutions storing machines. The enclosure is designed to improve the process.

What Does The Machine Enclosure Benefits Produce To My Factory?

Machine Enclosure Factory Benefits

Machine enclosure has great benefits for various plant spaces. Most of the factories produce each machine’s enclosure to prevent dirty. It can reduce your maintenance cost and save space.

Isolating machines’ effective enclosures can lesser rejection rates.

What Are The Machine Enclosure Advantage?

There are various advantages when using machine enclosures. It has excellent durability and effectiveness.

- Durable Panels: The panels are made of various materials. The panel’s finishes are also based on your request.

- Temperature and Noise Control: It has an acoustical barrier that provides additional insulation. The roof is panelized that control temperature and is also designed soundproof.

- Oversized doors: Oversized doors to facilitate large equipment. Easily store and accommodate large materials.

- Extra Tall Walls: It has extra walls for incorporated designs.

- Free Maintenance: It is based on the materials used that guard against rust. Easier to maintain and clean.

- Ease installations: Easier to fabricate and design

- Improve safety:

What Are The Importance Of Machine Enclosure?

Machine enclosure is common for industrial and work sites. Providing housing is the best way to protect machines.

This is an environmental control that protects machines from damage. The damage is caused by high temperatures, humidity, noise, and particles.

Machine enclosure is a versatile and long-life service.

What To Consider When Choosing The Right Machine Enclosure?

You can consider different options to get the right machine enclosure. Here are some important options you need to determine:

Types of machines

Consider different types of machines you need to find for the enclosure. You need to consider the number of components and other parts.

Sizes and Shapes

Enclosure sizes and shapes are based on machine types and dimensions. They are customizable according to the buyer’s request.

Designs

Ensure to determine your enclosure designs can fit to your machines. You can choose the right doors, roofing, panels, and more.

Materials

Machine enclosures are made of plastic, aluminum, metal steel, stainless steel, and more. The materials are based on their applications and types of machines’ requirements.

Weight

The machine enclosures are based on types of materials and structures. Metal steels are heavy and durable for long-term use.

Finishes

It has different finishes according to its panel materials. Attractive appearance and effective finishes that protect panels with anti-aging.

Features

Machine enclosure featuring various finishes that protect enclosures from scratches when it moving. The panel finishes are the following:

- Vinyl

- Painted steel

- Aluminum

- PVC

- Special FRP finish

What Are Different Materials Used For Machine Enclosures?

Machine Enclosure is made of different materials. Created with verified materials and parts according to applications and types of machines.

Plastic Machine Enclosure

Machine enclosures are also made of rigid plastic. It is designed with durable clear acrylic for fixed windows and other machine enclosure styles.

Metal as Steel

Metal as steel machine enclosure has amazing structures durable and long life span. Heavy-duty machine enclosure widely used in large and field machinery.

Stainless Steel

Stainless steel machine enclosure is lightweight and easier to fabricate. It is widely used for indoor machine housing such as factories.

Aluminum

Aluminum is one of the materials used for machine enclosures. It has a lightweight and durable ability. Perfect for indoor and field applications.

What Custom Machine Enclosure Are There?

There is plenty of custom machine enclosure you should consider and request. It has various designs, materials, finishes, and more.

1) Custom Open Top Machine Enclosure

Minimize and Maximize machine enclosures on top for different purposes. Durable structures and parts like hinges, bolts, and nuts.

2) Sliding Doors

There are different dividing door options of machine enclosures. It is designed with clear glass or acrylic fixed windows.

3) Mobile Enclosure

It provides excellent machine transport to different locations. Durable structures and wheels which able to carry heavy machines.

Custom machine enclosures are perfectly designed suitable for your applications according to the working site environment.

How Much Does Machine Enclosure Cost?

Machine enclosure prices are based on its sizes, dimension, and material used. It is offered a friendly price which helps your business special needs.

Machine enclosure surely money-back guarantee. Highest quality at acceptable prices.

Conclusion

KDM is a popular producer providing complete information and guide. We are helping customers get their ideal machine enclosures perfect fit for final applications.

Whether you need them for personal and other business purposes, KDM can fully support your process. Hope this guide helps you a lot.