Looking for the Reliable Low Voltage Switchgear Manufacturer?

KDM is one of China leading LV Switchgear Manufacturer and Supplier

Over 10 years of experience in the switchgear system field, KDM gained a solid background in designing and engineering products in accordance with international testing. Professional technical assistance is provided for your orders.ISO9001 Certified low voltage switchgear Supplier.

KDM low voltage switchgear can also be custom-engineer according to your specifications. With our in-house fabrication and advanced manufacturing equipment, we are able to produce competitive output. We can customize your preferred LV switchgear in order to meet your specific needs.

KDM Low Voltage Switchgear Series

Our arc-resistant low voltage switchgear offers a degree of protection to the person against dangerous circumstances. Rigid construction with a flexible design to fit a variety of toughest industrial applications.

Indoor Low Voltage Switchgears are available in an extensive range of durable color finishes. KDM offered an existing product that meets the requirement of any installation environment.

The GCS low voltage switchgear has high technical performance that can adopt the improvement needs of power distribution systems. As a whole, these products are engineered based on the requirement of industry requirements.

Our comprehensive range of withdrawable low voltage switchgear can be widely used for various industry electric systems. The different sectors like power plants, chemical engineering, textile, etc., can cover up this product.

KDM MNS low voltage switchgear is suitable for most industrial applications such as chemical, food and beverage, power plants, and so on. The product is verified for maximum safety standards. Outstanding safety for personnel and plant protection.

In KDM, we have a wide variety of 380V low voltage switchgear options available for you. Flexible, maintenance-free, and safe product you are assured of. With ISO9001 certification as a reliable supplier, you can guarantee product functionality.

Send your Inquiry on KDM Low Voltage Switchgear

For over 10 years, we had evolved and continuously improve the range of low voltage switchgear to meet market and industry standards. As the need for power distribution and motor controls keeps growing, we are able to cope with those improvements with our finest innovative production.

- Higher functionality performances, a strong commitment to safety for personnel, and a power system.

- Quality tested and certified into IEC, UL, ANSI, and more standards.

- Competitive range of units, custom-made to suit your project requirements.

- Guarantee high-quality low voltage switchgear as ISO9001 certified Manufacturer

Related Products of Low Voltage Switchgear

KDM Low Voltage Switchgear

KDM low voltage switchgear completely designed and engineered through our latest in-house machinery.

With that, we are able to upgrade offered products into different designs, dimensions with various safety features.

As a result, our LV switchgear extends and meets the most demanding industrial applications.

Mainly, it serves the following sector including healthcare, oil and gas, data center, industrial applications and more of.

Our low voltage switchgear provides safety, intelligent and versatile solutions for all electric systems.

It has high operational performances in terms of power distribution and motor controls.

Also, they have a strong commitment to safety, as they serve as a reliable room for all electronic and electrical system installations.

Aside from the safety of the equipment, it protects people, particularly personnel who are in charge of the operation.

A highest level of safety, reliability, and stability our low voltage switchgear offered.

In KDM, we design LV switchgear with a variety of accessories for more workable and flexible solutions to the required applications.

Our low voltage switchgear compactness makes it the ideal space-saving power solutions.

This solution is tested and certified with the main international standards.

They meet IEC, UL, ANSI and other standards.

In our production, our main focuses are to provide an optimum solution with your difficulties.

Supplying quality tested and certified high-quality low voltage switchgear products is what we are engaged of.

With a competitive range of functional units, you can find suitable low-voltage switchgear well-positioned to suit your project requirements.

Our long-run in the business enables us to deliver high quality and efficient solutions for any customer specifications.

We aim to fully satisfy every power distribution equipment challenges sent upon us.

From the designing, engineering to production up to delivery, we will support you.

Throughout the process, we offer professional services for your orders.

As a premier low voltage switchgear manufacturer and supplier, KDM is truly your reliable partner.

With unmatched domain expertise and knowledge, we are able to design a product to the highest quality standard.

At the core of our business, we only offer the greatest value for our customers.

KDM low voltage switchgears are unquestionably safe, flexible, and reliable for all switchgear system challenges.

With our skilled workers project designing expertise and deep understanding, we had fully accomplished various projects demand.

We had been recognized as one of the professional low voltage switchgear manufacturers in China.

Now if you have any questions or inquiries, we highly appreciate that.

Please feel free to contact us today!

Within a working hour you can get a reply or speak with our experts.

Low Voltage Switchgear: The Complete FAQ Guide

- What is Low Voltage Switchgear?

- How does Low Voltage Switchgear compare to High Voltage Switchgear?

- What is the Function of Low Voltage Switchgear?

- Which Industries use Low Voltage Switchgear?

- Are there Drawbacks of Low Voltage Switchgear?

- What are the Benefits of Low Voltage Switchgear?

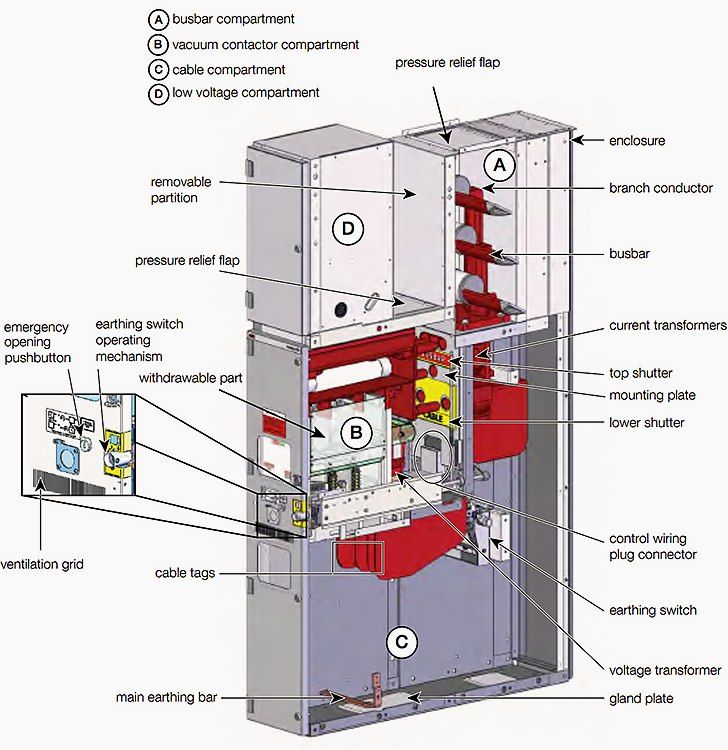

- What are the Components of Low Voltage Switchgear?

- What is the Voltage Range for Low Voltage Switchgear?

- How does Low Voltage Switchgear Work?

- How does Low Voltage Switchgear compare to Medium Voltage Switchgear?

- What is the difference between Low Voltage Switchgear and Control Gear?

- How does Low Voltage Switchgear compare to Switchboard?

- Is there a difference between Circuit Breaker and Low Voltage Switchgear?

- How do you Test Low Voltage Switchgear?

- How do you Maintain Low Voltage Switchgear?

- What are the Quality Standards Certifications for Low Voltage Switchgear?

- What is Low Voltage Switchgear Specification?

- What is an Incomer, Feeder, and Sub-incomers in Low Voltage Switchgear?

- What are the Types of Low Voltage Switchgear available?

- Why Trust Low Voltage Switchgear Manufacturer in China?

- Are there Low Voltage Switchgear Design Rules?

- What should you consider when Commissioning LV Switchgear?

1. What is Low Voltage Switchgear?

Low Voltage switchgear is a type of switchgear that handles applications with an AC voltage range of between 50 and 100V.

It can also handle applications with a DC rating of between 120 and 1500V.

Low voltage switch gear

2. How does Low Voltage Switchgear compare to High Voltage Switchgear?

Low voltage switchgear handles the power system with a voltage rating of below 1kV.

High Voltage Switchgear handles a power system that has a voltage rating of above 36kV.

3. What is the Function of Low Voltage Switchgear?

The functions of low voltage switchgear are:

- Isolation of electrical circuits from the main power source, which helps in safe clearance of electrical faults and general maintenance.

- It has devices that help in the distribution and control of electric currents.

- Connection and disconnection of electric induction motors

- Performing quantitative and qualitative power supply measurements.

- It has devices that offer protection against overloading and short circuits. This helps in ensuring the safety and functionality of the electrical equipment.

4. Which Industries use Low Voltage Switchgear?

The main industries that use low voltage switchgear include:

- Transport industry including the railway and subway transport

- Energy generating firms such as wind and solar energy generating industries

- Residential power distribution

- Marine industries such as ships and shipping ports

- Manufacturing industries like steel, mining, and paper industries.

- Underground stations

- Power supply system

- Environmental sensitive installations such as electrical fences

5. Are there Drawbacks of Low Voltage Switchgear?

Yes.

There are several drawbacks to the use of low voltage switchgear, including:

LV Switchgear

· Installation Space

You will need a large installation space if you are going to use an LV switchgear.

This can be a challenge if you lack space.

Installation space should allow for easy operation and maintenance of your LV switchgear.

· Initial Cost

The cost of purchasing an LV switchgear is relatively expensive, including the installation cost.

This requires proper planning and budgeting.

6. What are the Benefits of Low Voltage Switchgear?

The benefits of low voltage switchgear include:

· Reliability

An LV switchgear ensures power reliability for your power needs.

This ensures your industrial machinery run without any power interruptions.

· Protection

An LV switchgear offers protection for your machinery and those operating them.

The use of LV switchgear prevents arcing, which has negative effects on your industrial equipment.

· Easy Maintenance

The use of LV switchgear facilitates the maintenance procedures for your industrial equipment.

This is because of reduced power interruption.

· Reduced Cost

LV switchgear reduces the overall cost of purchasing and maintenance of your industrial equipment.

Without LV switchgear, power interruptions may result in electrical damages on your appliances.

7. What are the Components of Low Voltage Switchgear?

The components of low voltage switchgear include:

Parts of LV Switch gear

- A surge arrestor. The function of these components is to disperse excess voltage within the Low Voltage switchgear to the ground. This helps the system to function appropriately.

- Step-down transformer helps in the conversion of voltage from high to low, which the low Voltage switchgear can use.

- Instrument transformers. Their function is to measure the electrical parameters necessary to protect the low voltage switchgear.

- Earthing Switch. Earthing switch helps in directing excess electrical current in the switchgear to the ground. This helps in reducing electrical overload and the occurrence of electrical faults.

- Busbar. A busbar acts as a connector for various lines distributing power to different sections of the low voltage switchgear.

- Air break switches. They help in the sustenance of two lines or equipment of the Low Voltage Switchgear, thus minimizing electrocution. This is through isolation of circuit and equipment within the switchgear.

- Circuit breaker protects the electrical circuit whose source has an overload. They also help in fault interference during a repair.

- The voltage regulator helps in ensuring the low Voltage switchgear uses the right voltage during operation.

- Metal clad. This is the nerve center for distribution lines leaving the low Voltage switchgear. It helps in the isolation of lines during maintenance.

- A Disconnecting Switch/ Isolator. The function of a disconnecting switch in a Low Voltage Switchgear is to interrupt small currents which are capacitively coupled or induced.

- Protective relays. This component helps in detecting any fault within the Low Voltage switchgear and relays it to the circuit breaker.

8. What is the Voltage Range for Low Voltage Switchgear?

The voltage range for an LV switchgear is 50-100V for an AC and 120-1500V for a DC.

9. How does Low Voltage Switchgear Work?

Overloading of the line inhibits the current from making an electromagnetic release action.

However, it initiates the production of heat by the thermal element.

The heater heats the bi-metal sheet causing it to bend upwards.

This pushes the lever upwards, making the hook to lock off.

This breaks off the primary contact, cutting power supply off.

By doing this, when there is an overload, it exceeds the set current causing the electromagnetic tripper to produce suction.

A combination of the suction and the impact lever results in the lap hook to rotate upwards around the

Shaft seat, thereby releasing the lock.

10. How does Low Voltage Switchgear compare to Medium Voltage Switchgear?

Low voltage switchgear handles the power system with a voltage rating of below 1kV.

Medium voltage switchgear handles the power system with a voltage rating of between 2kV and 35kV.

11. What is the difference between Low Voltage Switchgear and Control Gear?

LV Switchgears

The function of switchgear is to isolate electrical current and to disconnect, connect and distribute power.

The function of a control gear is to control and protect a piece of electrical equipment.

12. How does Low Voltage Switchgear compare to Switchboard?

A Low Voltage Switchgear is bigger than a Switchboard.

This is because of the front and rear access that it has, which is important during maintenance.

A low Voltage Switchboard has a 20% testing power factor for a 3-cycle duration.

A Switchgear has a 15% testing power factor for 30 cycles.

Low Voltage Switchgear has switching devices and components like lightning arrestors, circuit breakers, isolators, and relays.

These components regulate current flow in an electrical circuit.

Switchboard refers to a panel consisting of switches, electrical and protective control devices and buses.

The function of a Low Voltage Switchgear is to switch on and power motors, generators, transformers, and transmission lines for industrial and commercial use.

They help in supplying, protecting, and controlling power loads.

A switchboard is used in the distribution of power to different sources and to transmit it to specific, transformers, control equipment, and transformers.

Low Voltage Switchgear is expensive when you compare to a Switchboard.

13. Is there a difference between Circuit Breaker and Low Voltage Switchgear?

The function of a circuit breaker is to break off an electric current in case there is an overload.

An LV switchgear helps in the isolation, connection, disconnection and distribution of an electric current in a piece of electrical equipment.

A circuit breaker is a component within an LV switchgear.

14. How do you Test Low Voltage Switchgear?

The following are the main tests that you need to carry on your Low Voltage Switchgear:

· Creepage and Clearance Distance

You need to carry out this test between the live parts of the low voltage switchgear and also its exposed conductive parts.

You measure the distance between the live parts using the different polarities.

Bolted connections, joints, unsuitable connectors minimize the initial insulation values.

· Protective Circuit Effectiveness

This helps in determining the safety of the low voltage switchgear.

This test also determines the occurrence of high fault current in case the conductor detaches accidentally.

Effective protective circuits need to withstand optimum short-circuit thermal stress, which happens as per the supply current.

· Short-circuit Resistance

This test determines the resistance of the busbars and their breaking, supports, and protective devices to the electrodynamic and thermal stress.

· Temperature Rise Limits

Temperature rise limits help in determining the appropriate operating temperature for the low voltage switchgear.

High temperature has the effect of components aging prematurely, leading to the failure of the low voltage switchgear.

· Checking Operational Degree

This test determines the operational safety of the low voltage switchgear.

It also helps in preventing solid and liquid contaminants from getting in contact with the switchgear.

· Current Transformer Core Test

You need to test the ration and polarity of the current transformer core and compare the results to the primary current injection.

You need to perform this test phase by phase.

· Dielectric Test

The dielectric test is on the auxiliary circuits. For this test, apply 500 voltage DC between the terminal blocks and the earth point.

· Low Voltage Tests on the Main Circuit

You need to check on the dielectric strength to remove causes like damage during handling, wrong fastening, and presence of foreign bodies.

Such issues may result in an internal malfunction of the switchgear of not addressed.

15. How do you Maintain Low Voltage Switchgear?

There are two maintenance procedures for an LV switchgear. This includes:

· Regular Maintenance

This is a type of maintenance that involves checking on the operational level of your LV switchgear.

Proper adjustment of the operating conditions, as well as having a fault history, is necessary for regular maintenance.

Regular maintenance also involves checking on the meter readings and correcting any abnormality.

You need to check on the metal parts for any rusting and peeling of the metal paint.

The peeling of the paint can be an indicator of the overheating of the LV switchgear.

Use a temperature sensor to note such variation.

Rusting affects the quality of the LV switchgear and its overall performance in the long run.

If you notice such, you need to replace the section for the effective working of your LV switchgear.

· Yearly Maintenance.

Involves checking on the performance of the LV switchgear every year.

This is to compare the variation in terms of its working and also to rectify electrical faults of the LV switchgear.

Yearly maintenance also involves applying a fresh coat of paint to the metallic parts of the switchgear.

Paint helps in minimizing rusting and corrosion of the metal parts.

16. What are the Quality Standards Certifications for Low Voltage Switchgear?

The main quality standards certifications for low voltage switchgear are:

LV Switching

- American National Standards for Insulators (ANI) standards.

- International Electrotechnical Committee (IEC) standards.

- National Electrical Manufacturer Association (NEMA) standards.

- Institute of Electrical and Electronics Engineers Standards Association (IEEE-SA)

- ISO standards which check on the quality and safety of the LV switchgear.

17. What is Low Voltage Switchgear Specification?

Low Voltage specification refers to the requirements necessary for the proper functioning of the LV switchgear.

These specifications include the type of LV switchgear, the voltage requirements, and the type of insulation on your LV switchgear.

18. What is an Incomer, Feeder, and Sub-incomers in Low Voltage Switchgear?

- An incomer supplies incoming electrical current to an incomer bus. The low voltage switchgear, in this case, needs to contain a central switching device.

- A feeder is a connection to the feeder bus whose function is to feed the different loads. These loads include lighting loads, motor loads, and industrial machinery loads.

A switch fuse protects the various feeders. The various types of feeders include motor feeder, lighting load feeder, and industrial machinery load feeder.

- Sub-incomer helps in drawing power from the main incomer bus and feeding it to the feeder bus. Parts of the sub-incomer should have special features.

These features include protective economic and minimal interlocking numbers.

19. What are the Types of Low Voltage Switchgear available?

The following are the main types of low voltage switchgear available:

· Arc resistant LV switchgear

Arc resistant LV switchgear offers a high protective level for the people operating the switchgear.

It has a rigid design that can adapt to various industrial applications.

· Indoor LV switchgear

This type comes in different designs and color finishes for various installation environments.

· GCS LV switchgear

GCS LV switchgear offers a high technical performance maximizing the power performance needs of your applications.

· Withdrawable LV switchgear

It is an ideal LV switchgear for use in different industries such as chemical, textile, and engineering industries.

· MNS LV switchgear

MNS LV switchgear has unique plant and personnel operational safety for its effective working.

· 380V LV switchgear

This is a flexible LV switchgear that guarantees you of its functionality.

It is ISO9001 certified and has a high level of flexibility.

· UL LV switchgear

UL LV switchgear offers a high degree of safety, accuracy, and flexibility.

Its fabrication uses quality raw material for optimal performance.

- Custom LV switchgear

Custom LV switchgear allows for the designing and manufacturing of an LV switchgear as per your specifications.

We offer professional advice that ensures your design fits the set standards.

· GGD LV switchgear

This type of LV switchgear is suitable for applications such as the power and mining industries.

It offers an easy to assemble options and a high degree of protection.

· LV Fixed switchgear

LV fixed switchgear guarantees you quality, availability and safe option for switchgear.

It utilizes less space while meeting environmental demands.

· Marine LV switchgear

The design for marine LV switchgear allows for use in marine applications.

The design meets all the engineering and manufacturing specifications necessary for its use.

20. Why Trust Low Voltage Switchgear Manufacturer in China?

A trusted LV switchgear manufacturer in China is important because of:

· Reliability

A reliable LV switchgear manufacturer will meet your requirements within a given time frame.

Through reliability, you don’t worry about the quality of your LV switchgear.

· Informative

A trusted LV switchgear is important in giving you the correct information.

You are sure that you will purchase an LV switchgear with the correct functioning information.

· Customization

With a trusted LV switchgear, it is easy to get a customized LV switchgear with your specifications.

All you have to do is to give your specifications and wait for the manufacturing of your LV switchgear.

· Price

A reliable LV switchgear manufacturer will offer you competitive prices for their LV switchgear.

This offers you a wide range of prices and different types of LV switchgear to select.

· Warranty

A trusted LV switchgear manufacturer offers a warranty that guarantees you a refund in case of faults with your LV switchgear.

This allows you to use your LV switchgear without worrying about the performance.

21. Are there Low Voltage Switchgear Design Rules?

Yes. There are design rules for an LV Switchgear.

They include; the size, the insulation method for the switchgear, the voltage requirements, and the applicational area for the LV switchgear.

22. What should you consider when Commissioning LV Switchgear?

You need to consider the following when you are commissioning your LV switchgear:

· Inspection

The inspection process ensures you have the correct components for the proper functioning of the LV switchgear.

It involves visual inspection and verification against specifications.

The visual inspection aims at ensuring you have the correct and proper functioning of the switchgear components.

It also includes checking on damages on the components.

Verifications against specifications aim to ensure that the LV switchgear meets the industrial specifications.

· Testing

Testing helps in detecting any faults within the LV switchgear. Such faults include damages as a result of shipping or installation.

Testing involves carrying out mechanical tests on the LV switchgear.

It also involves carrying out tests such as dielectric tests and continuity tests.

Proper testing helps in maximizing the operational time for your LV switchgear.

It also helps in predicting any future failures of the LV switchgear and formulating proper mitigation ways.