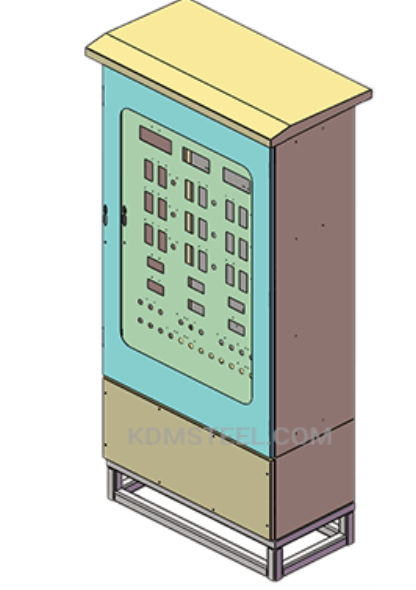

With years of experience in the enclosure industry, consider our NEMA 13 enclosure for the best equipment protection.

NEMA 13 Enclosure and Box

At KDMFAB we offer NEMA 13 enclosure with the ideal balance of security, power, and practicality. Which is made of premium stainless steel, or steel that provide outstanding durability, resistance to non-corrosive oil, water, coolants and dust.

The manufacturing plant, pharmaceutical facilities, automotive industry, food and beverage industry can all benefit greatly from our NEMA 13 enclosure.

KDM NEMA 13 Enclosure Series

Send your Inquiry on KDM NEMA 13 Enclosure

Customized Detail for NEMA 13 Enclosure

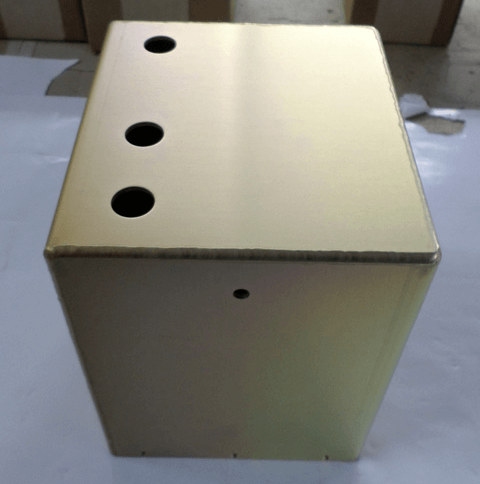

KDMFAB offer customization options for NEMA 13 enclosures.

We can include custom sizes, additional mounting options, cutouts for switches and displays, and specific finishes or coatings to meet the needs of your application.

For additional mounting options our NEMA 13 enclosures can be installed on a wall, a floor, or a pole, depending on the purpose.

And for our common finishes for NEMA 13 include powder coating, enamel paint, and galvanized coating.

- 제조 능력

4000W high-performance laser cutting machine, +/- 0.05mm accuracy. No burr, no scratching.

다기능 유연 용접 장비, 정확도가 높고 변형이 없습니다.

+/- 0.5mm 굽힘 정밀도, 굽힘 자국 없는 매끄러운 표면.

10+ welding experienced workers, perfect overall appearance.

고속 및 정확도가 높은 발포기, 빠르고 품질이 좋은 가스켓

The expert assembling team, consistent assembly quality on every KDM enclosure

We manufacture NEMA 13 enclosure that should be able to function in a specific temperature range, usually between -40°C and +60°C (40°F and +140°F).

Our enclosure is approved by the appropriate authorities and satisfies NEMA 13 criteria. Sush as CSA (Canadian Standards Association) or UL (Underwriters Laboratories) signify that our enclosure has undergone testing and satisfies performance and safety requirements.

We designed our NEMA 13 enclosure with completely customized accessories, including:

- Panel mounting hardware, including screws and brackets.

- Panels might be internal, metal or non-metallic.

- Mounting kits and feet

- Seals and gaskets

- Swing-out shelves

- Drip shields

- Vents for breathers

- Window inspections

- Brackets to mount external devices

- Variations in door hinge types

- Filters, fans, vents, and accessories for cooling

- Interior lighting, either fluorescent or LED

- Straps and bars for grounding

- Wire troughs, strain reliefs, and cable glands

- Heating units and thermostats

- Personalized labels and nameplates for identification

- Other locking systems, such as quarter-turn latches and padlockable handles

Recent IP67 Enclosure Order

The Definitive FAQ Guide to NEMA 13 Enclosures

- What does NEMA type 13 mean?

- How is NEMA 13 different from NEMA 12?

- Are NEMA 13 enclosures used outdoors?

- Are NEMA 13 explosion-proof?

- What are common applications for NEMA 13 enclosures?

- How are NEMA 13 enclosures tested?

- How can I be sure of the quality of NEMA 13 enclosures?

- What is NEMA 13 in IP standards?

- What are common designs for NEMA 13 enclosures?

- What additional features are often included?

- How do NEMA 13 enclosures maintain temperature?

- What materials are used for NEMA 13 enclosures?

- What paints and coatings can be used for NEMA 13 enclosures?

- How can symbols be put on a NEMA Type 13 enclosure?

- What else should I be aware of when ordering an enclosure?

What does NEMA type 13 mean?

NEMA type 13 enclosures protect personnel from accidental contact with live parts, as well as protect the equipment from dirt, dust, lint, various flyings, splashing water, oil, and non-corrosive coolants.

NEMA Type 13 enclosures are rated for indoor environments only.

These enclosures are fairly rare; much rarer than type 4 or type 12 enclosures.

NEMA 13 box

How is NEMA 13 different from NEMA 12?

NEMA 13 is the same as NEMA 12, except that it protects equipment from splashing oil and coolants better than NEMA 12 boxes do.

So, only pick type 13 if splashing oil and coolants are major concerns to your application.

Coolants include cutting and polishing fluids that cool down machinery.

As a material is getting polished or cut, it and the machinery will heat up due to friction; cutting fluids do just that.

Other such liquids include liquid nitrogen, rubbing alcohol, and kerosene.

Cutting fluid

So, any metalwork industry may need some NEMA 13 enclosures.

Oils that NEMA 13 protects from may include mineral oils, which are sometimes used in cosmetics and biomedicine, and motor/engine oils.

Are NEMA 13 enclosures used outdoors?

NEMA 13 enclosures cannot be used outdoors since they are rated for indoor use only.

You could install NEMA 13 enclosures outside, but only if the climate is dry and not windy.

Even then, it is not recommended.

If you need enclosures for the outdoors, NEMA types 3, 3R, 4, and 4X are better.

In the same way, NEMA 13 enclosures are not fully weatherproof.

They do protect from some dust and liquid ingress, but not enough to withstand outdoor weather conditions.

Are NEMA 13 explosion-proof?

No, you need NEMA types 7 or 8 for that.

If you plan to install your enclosures in chemical or petroleum refineries, then your enclosures need to be rated with NEMA 7 or 8.

Also, no NEMA rating can protect from an arc flash.

What are common applications for NEMA 13 enclosures?

NEMA 13 enclosures are used mainly for industrial applications.

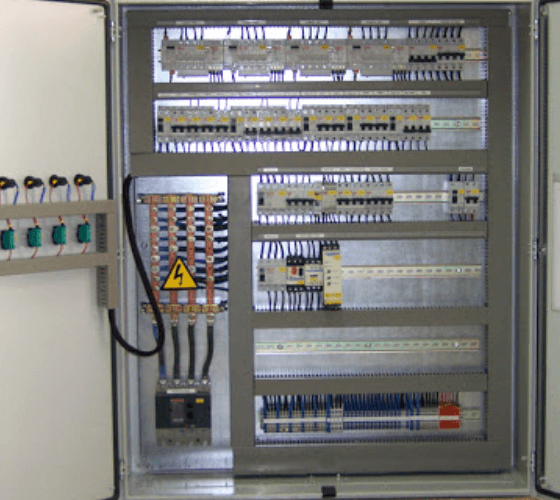

These include indoor electrical hydraulic or pneumatic controls, terminal or junction wiring enclosures, operator interfaces, and consoles.

NEMA 13 enclosures can house electrical equipment rated at 1000 Volts or lower.

NEMA 13

These enclosures are often found in transportational industries, and various municipalities like water treatment plants, and general indoor control applications.

Because NEMA 13 enclosures are resistant against oil and coolants, they can be used in non-hazardous petroleum-processing rooms, boiler rooms, car assemblies or service garages, and general-purpose applications.

For more information, check out our general NEMA enclosure FAQ!

How are NEMA 13 enclosures tested?

You can refer to the latest NEMA 250 document for requirements of self-declaration of NEMA labels.

NEMA 13 is tested using the indoor corrosion protection test, oil exclusion test, and gasket test.

Oil exclusion test involves making a solution with water and a wetting agent, also called a surfactant, that act as detergents.

This solution is then sprayed on the enclosure at a rate of 7 liters per minute for at least 30 minutes.

Spray test

Passing this test guarantees a pass for the dust test, the rod entry test, and the rain test.

Indoor corrosion test involves making a 5% sodium chloride solution and spraying it onto the enclosure continuously for 24 hours.

NEMA 13 enclosures also undergo various gasket tests to evaluate how they age while stretched at high temperatures.

Gasket

This is the aging gasket test.

If there are no cracks, deformations, and the tensile strength remains the same, the enclosure passes this test.

For NEMA 13 enclosures, there also are oil immersion gasket tests.

To pass the test, the PU gaskets may not expand more than 25% or shrink more than 1%.

Gaskets are tested in oil for 70 hours.

It is needed because good gaskets are key to good protection against water ingress.

How can I be sure of the quality of NEMA 13 enclosures?

At KDM, we have the ISO9001 certification that you can look through.

Also, you can do independent third-party testing of the enclosures if you want confirmation of quality and conformity assessment.

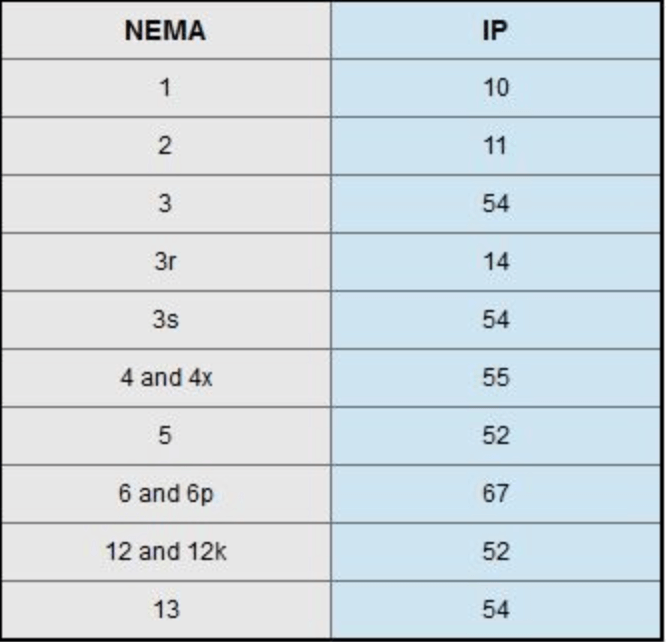

What is NEMA 13 in IP standards?

Although it is difficult to translate one set of standards into another, NEMA Type 13 is similar to IP54.

NEMA standards are slightly more strict than the IP standards.

Thus, if an enclosure passes a given NEMA standard, it will meet the requirements for its equivalent IP rating, but the reverse is not guaranteed.

What this means is that NEMA 13 will always pass IP54, but IP54 may not pass for NEMA 13.

NEMA and IP

What are common designs for NEMA 13 enclosures?

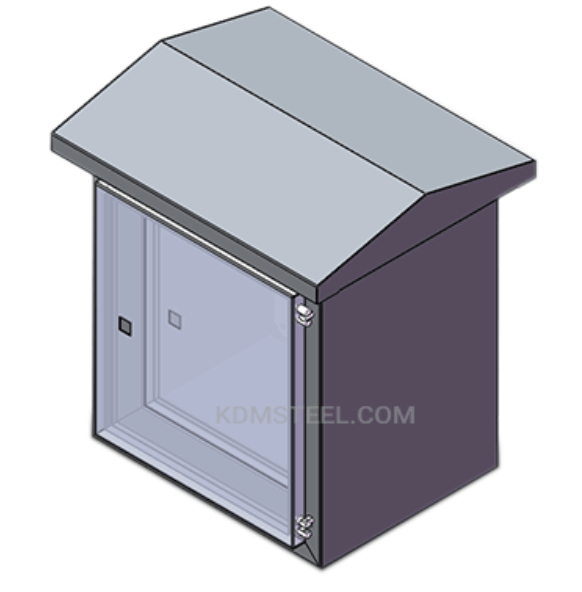

Some common designs for NEMA 13 enclosures include free-standing, floor-mounted, wall-mounted, modular, and custom.

Free-standing, floor-mounted, and walk-in enclosures are all made for bigger equipment.

These enclosures can have one or multiple doors, depending on your requirements and the size of the enclosure—bigger ones may need multiple doors.

Such enclosures can also have pedestals, casters, leveling feet on the bottom, and lifting eyes on the top to help install and move them around.

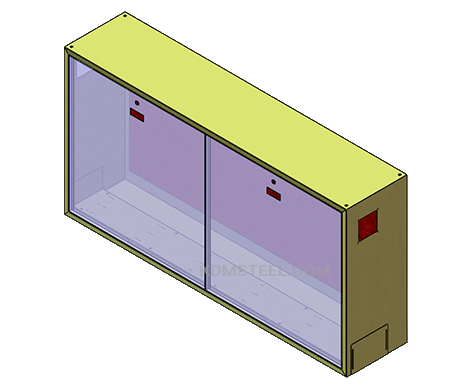

Free-standing enclosure with casters

Wall-mounted 그리고 pole-mounted NEMA 13 enclosures are typically small and are used to house fuses, switches, and buttoned panels.

These are less mobile, but take up less space as well.

They can even be recessed into a wall to save more space.

They are installed using special brackets that can be just external or have internal elements too.

Wall-mounted enclosure

We also offer modular enclosures, which can be changed and reassembled into a differently shaped enclosure.

Modular enclosures are great if you are not sure of where the enclosure will go, or if it will be moved from location to location.

Modular enclosure

Custom enclosures can be of any size, dimension; they can have any combination of features, such as doors, hinges, ventes, windows, and much more.

Custom enclosure

What additional features are often included?

You can request vents, windows, hinged doors, locks, cable management systems, and much more.

Vents, as well as radiating fans, let heat escape.

They cool down the electrical components of the enclosure.

Vents provide a more passive flow of air, whereas fans actively move air and are used to cool down equipment that heats up quickly.

This prolongs the life of equipment and decreases the possibility of malfunctions and electrical fires like arc flash.

Fan in an enclosure

These also stabilize air pressure inside the enclosure, preventing condensation which can damage the electrical components of the enclosure.

윈도우 help personnel examine the electrical components in a quick and non-invasive way.

And if something does go wrong, a window helps to see what is happening right away.

If your enclosure is supposed to have buttons, gauges, or signal lights, then a window is necessary.

It will allow personnel to inspect said gauges and lights without messing with the cover or door.

Usually, windows are made from polycarbonate or ABS.

Enclosure with a window

Hinged doors control how and how much the door or cover of the enclosure opens.

You can also choose from a variety of handles for your hinged doors.

Hinge

Some of the hinges we offer include continuous, offset, flag, spring-loaded, and more.

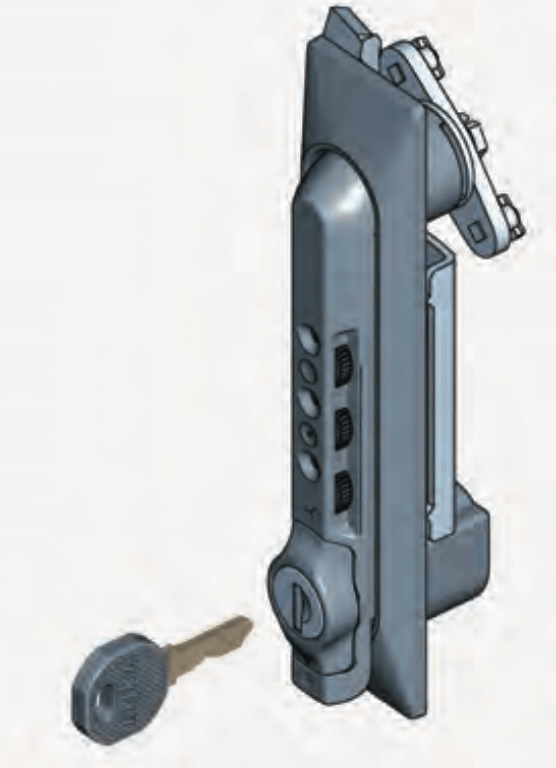

Enclosures also need security from tampering and accidental access.

Locks, latches, and clamps do just that.

Lock

Hooks, racks, and other organizing features comprise a cable management system.

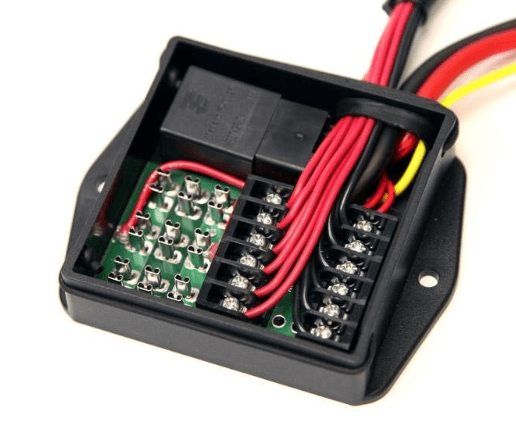

Some popular secondary features for NEMA 13 enclosures include file pockets, thermostats, heaters, casters, fuse blocks, power panels, lights, and switches.

File pocket

File pockets store operating manuals; casters are wheels on the bottom of an enclosure

Thermostats and heaters help maintain internal temperature

Fuse blocks house different circuits, while power panels may have circuit breakers, and generally control the circuits.

Fuse block

Switches and lights help operate the equipment inside the enclosure.

We offer outdoor features like rain caps and solar shields; however, these are not necessary for NEMA 13 enclosures, since they will be indoors.

How do NEMA 13 enclosures maintain temperature?

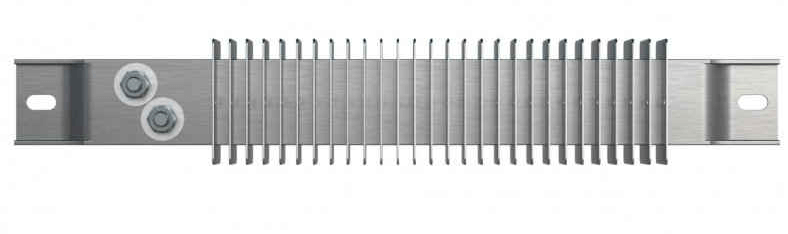

Generally, enclosures can have air conditioners, coolers, heat exchangers, and heater strips to control the temperature inside the enclosure.

This prevents the equipment from overheating or freezing.

If your enclosures are for cold locations, like freezers or cellars, then heat exchangers and heater strips may be necessary.

As equipment does its work, it may produce heat, which transfers to the air around it.

Heat exchangers push hot air into colder compartments.

This movement of air also results in an equalized temperature and pressure, which prolongs the life of electrical equipment.

Heat exchanger

Heater strips use electricity to heat up the air inside the enclosure.

Heater strip

Enclosure heaters range in performance from 50 to 1200 Watts, depending on the size of your enclosure.

Air conditioners and various air coolers are vital for enclosures situated in warm locations, like industrial boiler rooms and such.

Equipment needs to be cooled down to prolong its life.

What materials are used for NEMA 13 enclosures?

They can be made from galvanized steel, and stainless steel – usually of the grades 304, 316, or 316L.

Carbon steel, also called mild steel, is usually duller than stainless steel.

It is magnetic and more malleable since it only has iron and carbon.

This steel is also prone to corrosion, but it works well for indoor enclosures, such as NEMA type 13.

Carbon steel vs. stainless steel

Stainless steel is created by adding chromium, nickel, and molybdenum in different proportions to the iron-carbon alloy.

Steel grades 304 and 316 differ in the content of all additives.

316 stainless steel provides the best protection against salt spray, certain acids, and high temperatures.

This is why 316 is used more for marine applications.

Meanwhile, 304 resists sulfates and chlorine more.

Steel grades 304L and 316L differ from other grades by their lower proportion of carbon, making them stronger.

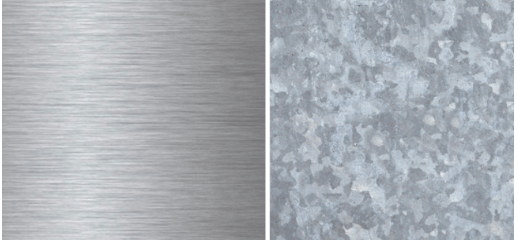

Galvanized steel is coated with a protective layer of zinc that prevents corrosion.

Stainless steel vs. galvanized steel

This type of steel is more expensive and heavier than stainless steel.

When using steel, there may be a certain gauge, or thickness, of the sheet metal that is necessary to comply with NEMA standards or with requirements of the environment.

NEMA 13 enclosures use 14 or 12 gauge steel, which is about 2-2.8 mm.

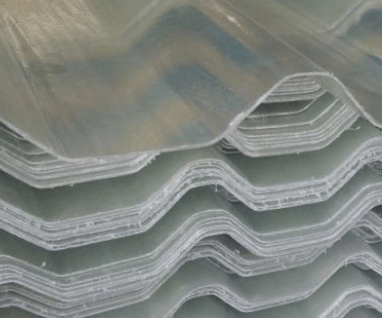

Enclosures can also be manufactured from various polymers.

One such material is fiberglass.

It is very strong, can dissipate heat, and insulates electricity, lowering the effect of interference and the possibility of shock.

As such, fiberglass enclosures are good as transformers, junction boxes, and compartments for telecom equipment.

It is made from glass fibers placed in plastic.

유리섬유

Enclosures can also be made from aluminum alloys.

They are not necessarily better than steel alloys, but can be depending on what you are going for and what are your needs.

Just like steel grades, aluminum alloys can be either of the 5052 or the 6061 series.

Aluminum vs. stainless steel

Both are lightweight, but 5052 is more weldable, whereas 6061 has a higher resistance to corrosion.

Also, 6061 is more expensive.

Aluminum has a layer of oxide on top that prevents any corrosion.

For NEMA Type 13 enclosures, carbon steel, galvanized steel, stainless steel, and polymers like fiberglass are the best.

However, other materials will work just as well.

If you would like to learn more, send in your inquiry now for a consultation!

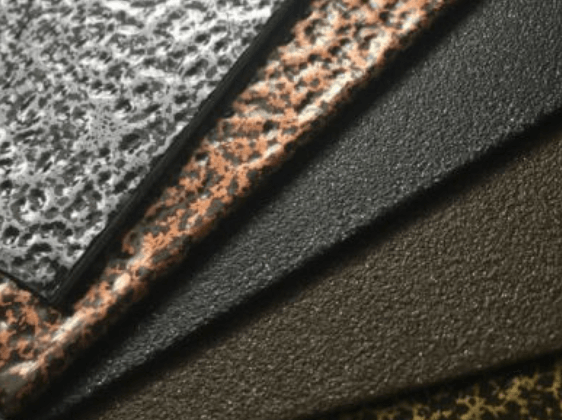

What paints and coatings can be used for NEMA 13 enclosures?

Our enclosures are well-protected, but the right coating can add a layer of corrosion protection.

Alodine coating, also known as the chromate conversion coating, is used to prime steel and aluminum for paint, as well as to prevent corrosion.

Alodine coating

This coating is fairly cheap and can be recognized by its characteristic greenish-yellow hue.

On top of this, you can choose enamel or powder paint coats in any color.

Powder paint is deposited with the electrostatic force, and is quicker and easier than enamel.

It is also more flexible in appearance, giving you the option of glossy and matte finishes.

Powder coating finishes

Enamel paint has a glossy finish and is weather-resistant.

Anodizing coating uses anodes to oxidize a metal, usually aluminum, to increase its thickness for better corrosion resistance.

Steel is not typically anodized because it can actually speed up its corrosion.

There can also be anti-graffiti and anti-poster coatings to protect your enclosure from vandalism if you plan to install it outdoors.

NEMA 13 enclosures most often use powder coating.

Powder coating

We can provide any coating in any color and finish, so contact us today!

How can symbols be put on a NEMA Type 13 enclosure?

You can customize your enclosure with our engraving and silk-screening services.

Engraving is more expensive and difficult, but it is also more long-term than silk-screening.

Usually, about 0.005-0.010 inches of metal is removed from the surface.

Once the metal has been removed, it is filled in with epoxy paint of any color to match your requirements.

Engraving

Silk Screening, on another hand, is the easiest and most affordable method.

Any flat side of the enclosure can be silk-screened with labels, warnings, serial number, your company name, logo, and anything else.

Although, beware!— silk-screening on stainless steel or aluminum can be worn or scratched off.

However, a clear powder coat can help prevent that.

Silk-screening

Besides symbols, there should be other markings.

If the equipment has to be installed in a particular orientation, this has to be marked on the enclosure.

Also, areas where live parts will be also has to have a mark.

Any warning or danger signs should also be engraved or silk-screened onto the enclosure as well.

What else should I be aware of when ordering an enclosure?

There are some common mistakes that people make.

These include choosing the wrong NEMA type, wrong material, wrong size, wrong design, and disregarding features.

NEMA 13 is built for non-hazardous, indoor locations with normal air pressure, rain or dripping water and some dust.

Enclosures

NEMA 13 enclosures are usually medium-sized or small.

Another note is that if you are choosing stainless steel, be prepared that it is not stain-free.

Sometimes, corrosion does show in the form of mild staining, but it is easy to get rid of with just water.

As for the design and features, these are case-specific, so consult your manufacturer for advice.

What is a NEMA 13 Enclosure?

NEMA 13 enclosures are designed to protect against dirt, fiber, splattering oil, and non-corrosive liquids in interior industrial uses.

Operators are protected from dangerous parts by NEMA 13 electrical enclosures.

It also protects electronic systems from extraneous debris and water filtration.

Figure-1 NEMA 13 Enclosure

What is the Advantage of NEMA 13 Enclosure?

- Access to dangerous areas.

NEMA 13 enclosure offers a level of protection against accessibility to dangerous parts.

Most other sections, including NEMA type 12, do as well.

Personnel who often operate within the enclosure and the material it protects should have been shielded from harm.

- Solid foreign objects ingress.

The NEMA 13 enclosure delivers some security from solid foreign substance intrusion.

In addition to preventing dirt from dropping NEMA 13 enclosure protect against the spread of dust, lint, fibers, and non-harmful flying.

- Ingress of water.

NEMA 13 offers additional protection from water contamination.

- Coolants and oil ingress

The NEMA 13 enclosure protects oil and coolant spray and splash.

What Does the NEMA 13 Enclosure Rating Mean?

The NEMA 13 enclosure rated system is an effective tool for electrical and electronic device designers.

To choose enclosures that provide the protection that equipment requires.

Defining the NEMA 13 rating.

The NEMA 13 rating is very similar to the more often used NEMA 12 rating.

Enclosures rated NEMA 13 offer protection against the following:

- Contact with dangerous or sensitive areas by accident

- Infiltration of flowing and drifting foreign material such as dust, filth, lint, and other contaminants.

- Splashing or dripping water intrusion

- Coolant seepage and non-corrosive oil ingress

Enclosures with a NEMA 13 rating are additionally protected against non-corrosive chemical agents such as fuel, coolant splashing, and spraying.

Figure-2 NEMA 13 Enclosure

What Isn’t Protected By a NEMA 13 Enclosure?

Snow, rain, sleet, submersion in water, or windblown dust are all things NEMA 13 enclosures aren’t designed to defend against.

NEMA 13 enclosures are also not qualified to guard against corrosive liquid splashing or leaking.

What are the Design Features of NEMA 13 Enclosure?

- Compartment for batteries.

It is suited for indoor electrical applications.

- Covered in the clear.

For uses that need visible access to internal components, polycarbonate is built with a clear translucent cover.

- Enclosure for din rails.

DIN rail enclosures come in various sizes to suit your electrical or electronic needs.

- Surface/flagged mount.

For applications requiring rapid surface attachment, wall mount enclosures are built with flanges that are molded on or fitted with screws.

- Cover with hinges.

Hinged electrical enclosures and junction boxes are NEMA rated for weatherproof and watertight protection.

- Knockout boxes.

Knockout boxes for electrical applications allow for onsite cable, wire, or conduit installation.

- Lockable.

NEMA and IP certified waterproof outdoors protection is given by lockable electrical enclosures and locked electrical connections.

- Low Visibility.

Outdoor enclosures with a low profile are waterproof and fulfill a variety of NEMA and IP classifications.

- Together in a flash.

Snap-together cases are a quick and easy way to store gadgets in a plastic utility box.

Figure-3 NEMA 13 Enclosure

What are the NEMA 13 Enclosure Types?

At below are some of the most common types of NEMA 13 enclosures:

- Enclosures for indoors

- Enclosures for the outdoors

- Enclosures with hinges

- Dust-proof enclosures

- Waterproof enclosures

- Boxes of interconnection

- Squares with a transparent cover