- Customized NEMA Enclosure Solution

- IP65/IP66認証

- Fast Enclosure Sample Production

Custom NEMA 4 Enclosure Manufacturer in China

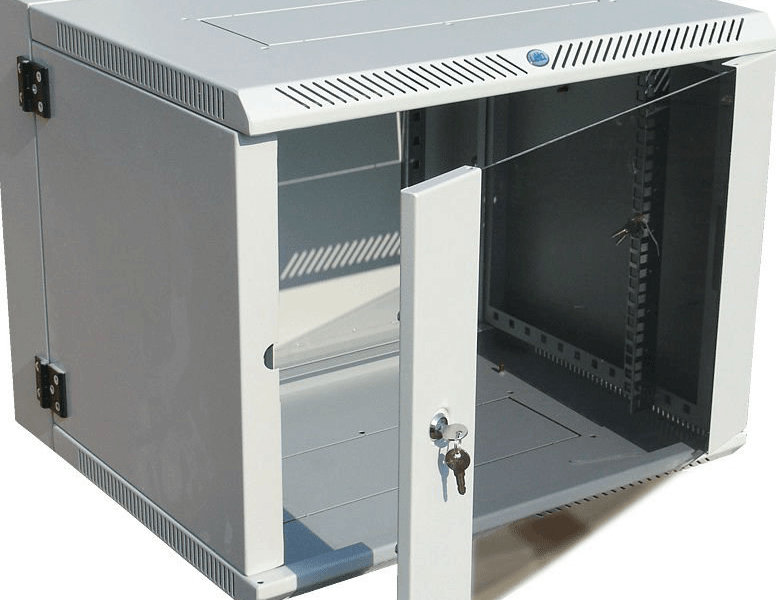

NEMA 4 enclosures are generally gaskets with doors that clamp to provide maximum sealing. Same as NEMA 3 but adds protection against hose-directed water. Designed to protect against all types of weather and direct hose blasts in factory washdown environments, these enclosures must use a closed-loop cooling system to ensure that no contaminants enter the unit. KDM NEMA 4 enclosure can be used for both breaths of air to air heat exchangers or air conditioners based on the ambient temperature surrounding them.

KDM NEMA 4 enclosure offers the best solution for both your outdoor and indoor projects. The NMEA type 4 enclosures provide extra protection against harmful effects on the electrical components due to splashing water, as well falling dirt, rain, sleet, snow, windblown dust, and hose-directed water.KDM ensures our NEMA 4 enclosures are ideal for housing sensitive electronic assemblies in your environments.

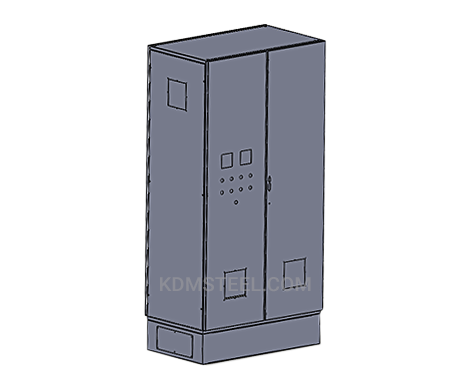

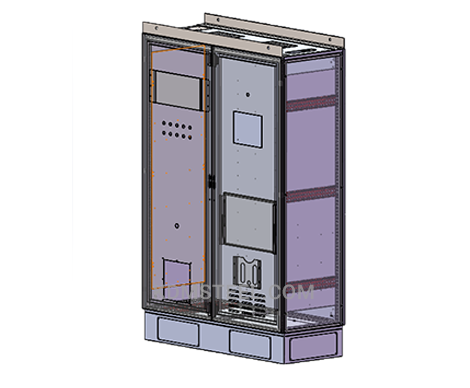

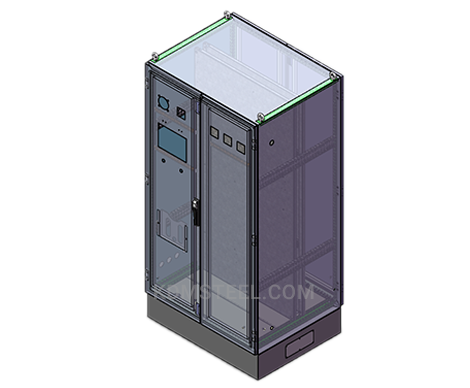

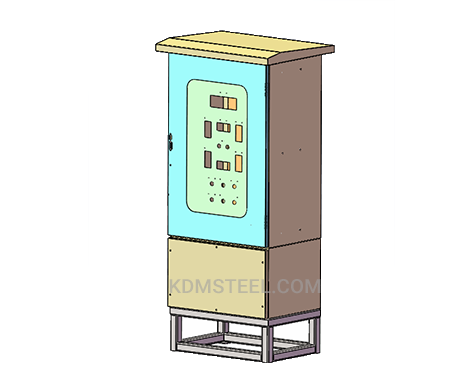

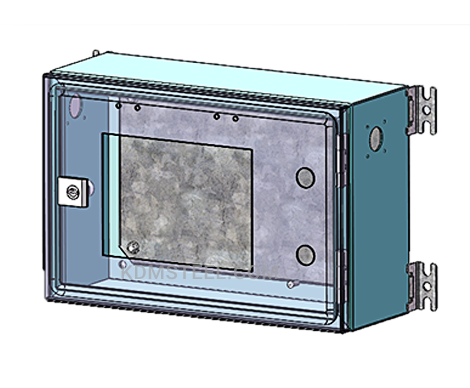

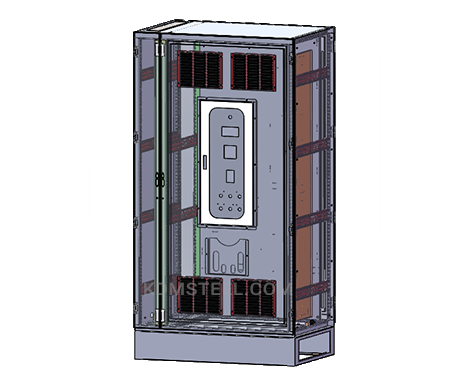

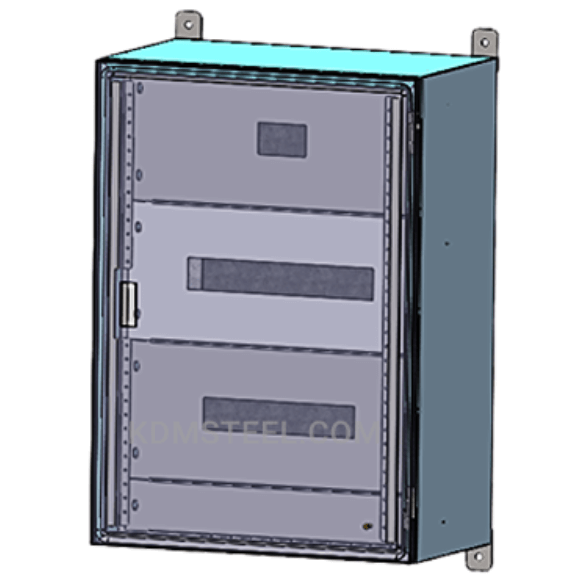

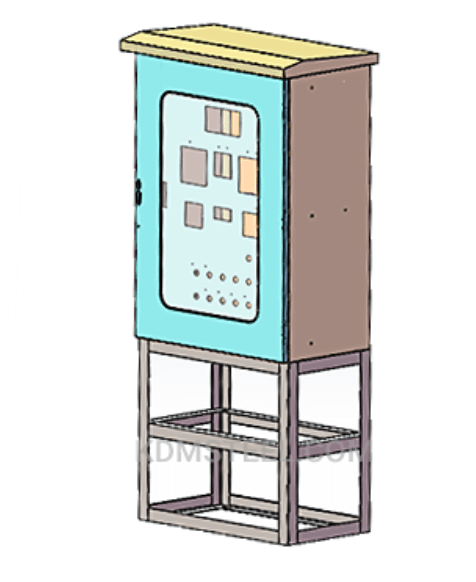

KDM NEMA 4 Enclosure Series

Send your Inquiry on KDM NEMA 4 Enclosure

KDM offers a wide selection of NEMA 4 enclosures. However, it is important that you choose a NEMA 4 enclosure according to your project requirement. Including the right dimensions, suitable sizes, and design. At KDM, we provide the specific equipment you need to ensure that your NEMA 4 enclosure meets the recommended standards and keeps your valuable equipment protected. KDM, as an industry reliable and reputable manufacturer of all kinds of enclosures, we provide each NEMA 4 enclosure, with the standards that meet your satisfaction with speed, accuracy, and reliability.

- 製造能力

- 購入ガイド

4000W 高性能レーザー切断機、+/- 0.05mm の精度。バリや傷はありません。

多機能フレキシブル溶接装置、高精度、変形なし。

+/- 0.5mmの曲げ精度、曲げ跡のない滑らかな表面。

10 名以上の溶接経験を持つ作業員がおり、全体的な外観は完璧です。

高速かつ高精度の発泡機、高速かつ高品質のガスケット

熟練した組み立てチーム、すべてのKDMエンクロージャで一貫した組み立て品質

KDM NEMA 4 Enclosure

NEMA 4 enclosure is not different from the other types as it provides a high level of protection to users against incidental contact with the enclosed equipment. Whether you are in a commercial or industrial environment, KDM NEMA 4 enclosure offers outstanding protection from the elements in your area. At KDM, we are glad to provide you a quality NEMA 4 electrical enclosure at a competitive price.

KDM NEMA 4 enclosure commonly used in industrial applications for wiring enclosures, hydraulic controls, and operator consoles as it is a watertight type of enclosure. Also, if the equipment is directly exposed to the sunlight, KDM NEMA 4 enclosure is your best choice.

NEMA 4 enclosure

https://youtu.be/sp-6BlAQkzk KDM manufacture NEMA 4 enclosure available in sizes ranging from small wall mounts to two-door floor mount models from a variety of metals depending on your specific application. They can also be equipped with continuous hinges, mounting feet, and padlock hasps.  Our NEMA 4 enclosures are available in a variety of types, such as wall-mounted, free-standing, etc. In addition to this, you can custom pre-punched holes, cutouts, lift-off hinges, insulation, latches or locks available. With KDM NEMA 4 enclosure, you can guarantee top-grade electrical enclosures, as KDM strictly adheres to the exact NEMA standards. We can expedite a custom enclosure and produce cost-effective NEMA 4 enclosure to keep safe your electrical components. From small businesses to multinational corporations, At KDM, we are committed to fulfilling each of our customer’s expectations through our top quality NEMA 4 enclosures and exceeding customer service. With over 10 year’s expertise in manufacturing enclosure, all our clients got the best NEMA 4 enclosure solutions for their various needs.

Our NEMA 4 enclosures are available in a variety of types, such as wall-mounted, free-standing, etc. In addition to this, you can custom pre-punched holes, cutouts, lift-off hinges, insulation, latches or locks available. With KDM NEMA 4 enclosure, you can guarantee top-grade electrical enclosures, as KDM strictly adheres to the exact NEMA standards. We can expedite a custom enclosure and produce cost-effective NEMA 4 enclosure to keep safe your electrical components. From small businesses to multinational corporations, At KDM, we are committed to fulfilling each of our customer’s expectations through our top quality NEMA 4 enclosures and exceeding customer service. With over 10 year’s expertise in manufacturing enclosure, all our clients got the best NEMA 4 enclosure solutions for their various needs.

The Definitive FAQ Guide to NEMA 4 Enclosures

- What does NEMA Type 4 mean?

- How is NEMA 4 different from NEMA 4X?

- Are NEMA 4 enclosures used outdoors?

- What are common applications for NEMA 4 enclosures?

- What is the standard NEMA 4 enclosure configuration?

- How are NEMA 4 enclosures tested?

- How can I be sure of the quality of NEMA 4 enclosures?

- What is NEMA 4 in IP standards?

- What are common designs for NEMA 4 enclosures?

- どのような追加機能が含まれることが多いですか?

- ノックアウト、通気口、継手などはエンクロージャの定格に影響しますか?

- How do NEMA 4 enclosures maintain the thermal environment?

- What materials are used for NEMA 4 enclosures?

- What paints and coatings can be used for NEMA 4 enclosures?

- What are some ways to put symbols on a NEMA Type 4 enclosure?

- What common mistakes should I be aware of when ordering a NEMA 4 enclosure?

What does NEMA Type 4 mean?

NEMAとは 全米電気工業会.

Type 4 enclosures protect personnel from accidental contact with live parts, as well as protect the equipment from windblown dust, rain, snow, ice, and hose-directed water.

Basically, it offers the same qualities as NEMA 3, except for improved protection against water ingress.

It is often marked as ‘watertight’.

This is due to NEMA Type 4 enclosures having more PU gaskets than Type 3, as well as having more welded parts.

NEMA 4 enclosure

This means that you can install it in places with lots of splashing water, and wash the enclosure with a hose if needed.

How is NEMA 4 different from NEMA 4X?

NEMA 4X is the same as NEMA 4, except it offers extra protection against corrosive agents, such as alkaloids, acids, and solvents.

Usually, this is due to materials used.

Are NEMA 4 enclosures used outdoors?

Yes, they are.

NEMA 4 enclosures are very often used outdoors, as well as indoors in industrial places.

Because of the type’s protection against water ingress, it is perfectly suitable for the outside.

What are common applications for NEMA 4 enclosures?

NEMA 4 enclosures are used mainly for commercial and industrial applications.

These include electrical hydraulic or pneumatic control box, terminal or junction wiring enclosures, operator interfaces.

NEMA 4 enclosures also house IT equipment, telecom wiring, security, and communications signal equipment.

Because of this type’s resistance to water these enclosures are often found in marine or naval applications.

Some industrial applications may include transportation industries, paper mill industry, and various municipalities like water treatment plants.

Commercial applications may be diaries, breweries, and such.

詳細については、 NEMA エンクロージャに関する FAQ!

What is the standard NEMA 4 enclosure configuration?

The standard configuration we provide is a gland plate with modules for cable entry, ground connections, fluorescent lamp with a switch, a radiating fan, PU gaskets.

NEMA 4 enclosures should also be marked that they require waterproof fittings, conduit connections, and mounting hubs.

You can also request any other feature you need.

How are NEMA 4 enclosures tested?

NEMA エンクロージャは NEMA ではなく、サードパーティの研究所によってテストされます。

However, you can refer to the latest NEMA 250 document for requirements of self-declaration of NEMAラベル.

NEMA 4 is tested using the external icing test, the hosedown test, the outdoor corrosion test, and the gasket test.

External icing test involves spraying the enclosure with water and then cooling down the room until 20mm of ice has formed over the enclosure.

External icing test

The enclosure should be undamaged and operable at the end of the test.

Outdoor corrosion test involves making a 5% sodium chloride solution and spraying it onto the enclosure continuously for 600 hours (25 days).

The hosedown test sprays water at a rate of 240 liters per minute from 10 feet, for 5 minutes straight.

Hosedown test

Passing this test gives automatic pass on the rod entry test and the rain test.

NEMA 4 enclosures also undergo various gasket tests to evaluate how they age while stretched at high temperatures.

As long as there are no cracks, deformations, and the tensile strength remains the same, the enclosure passes this test.

It is needed because good gaskets are key to good protection against water ingress.

Gasket

How can I be sure of the quality of NEMA 4 enclosures?

KDMでは、 ISO9001認証 見ることができるもの。

また、品質と適合性評価の確認が必要な場合は、エンクロージャの独立したサードパーティテストを実施することもできます。

What is NEMA 4 in IP standards?

Although it is difficult to translate one set of standards into another, NEMA Type 4 is roughly comparable to IP55 and IP66.

Both provide very good protection against dust and water, which is why this NEMA type is among the types used most often.

NEMAとIP

What are common designs for NEMA 4 enclosures?

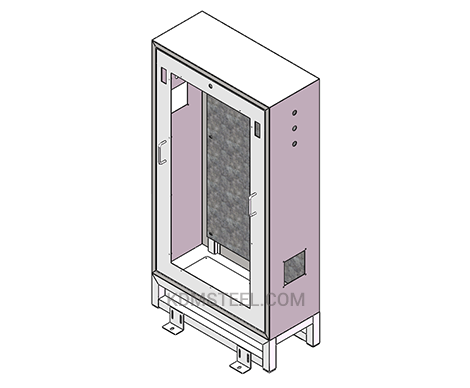

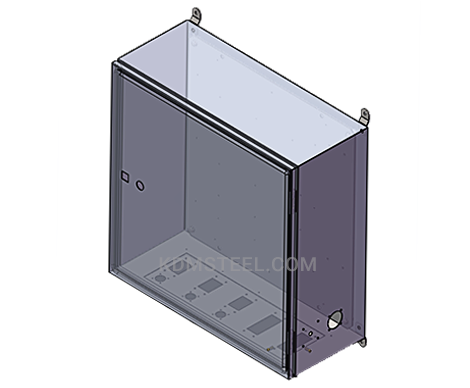

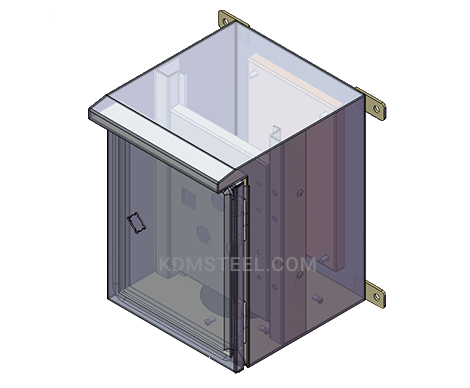

Some common designs for NEMA 4 enclosures include free-standing, floor-mounted, wall-mounted, modular, and custom.

自立型, 床置き型, and walk-in enclosures are used for bigger equipment.

要件に応じて、ドアを 1 つまたは複数にすることができます。

このようなエンクロージャには、設置や移動を容易にするための台座、キャスター、水平調整脚、吊り上げアイが付いている場合もあります。

自立型エンクロージャ

壁掛け そして ポールマウント NEMA 4 enclosures are typically small and house fuses and switches.

これらは移動性は劣りますが、占有するスペースも少なくなります。

これらは、外部のみ、または内部要素も備えた特殊なブラケットを使用して取り付けられます。

壁掛け式エンクロージャ

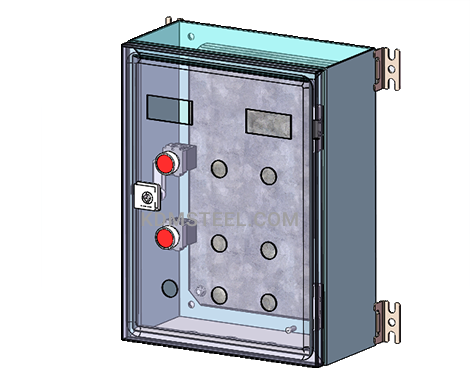

Modular enclosures are those that you can change the shape of, making them flexible in construction and modification.

These are great for NEMA 4 enclosures because that broadens their application.

Modular enclosure

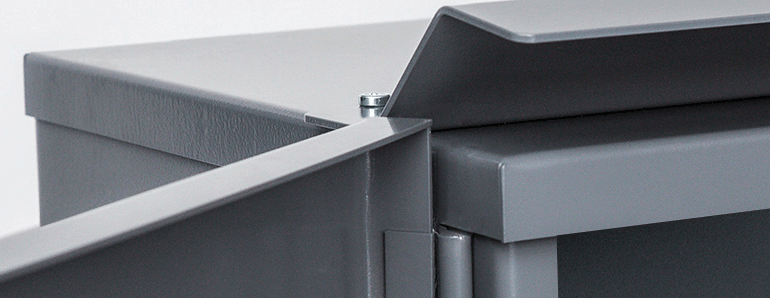

Overall, higher NEMA ratings benefit from U-shaped designs since those require less seam welding, which works well with ice and corrosion protection.

U-shaped enclosure

Of course, we also offer custom enclosures.

どのような追加機能が含まれることが多いですか?

通気口、窓、蝶番付きドア、錠、ケーブル管理システムなどをリクエストできます。

通気口、および放射ファンは、熱を逃がす経路を提供し、筐体内の電気部品を冷却します。

通気口はより受動的な空気の流れを提供しますが、ファンは積極的に空気を動かし、急速に熱くなる機器を冷却するために使用されます。

筐体内の放熱ファン

これらは筐体内の空気圧を安定させ、筐体の電気部品を損傷する可能性のある結露を防ぎます。

さらに、通気口とファンをエアコンと熱交換器にアップグレードすることもできます。

ウィンドウズ 担当者が迅速かつ非侵襲的な方法で電気部品を検査するのに役立ちます。

何か問題が発生した場合、ウィンドウによって何が起こっているかをすぐに確認できます。

Enclosure with a window and a lock

NEMA 4 enclosures benefit from continuous hinges since they minimize gaps that water can enter from.

ロック, latches, and clamps add a layer of security to your NEMA 4 enclosure, making sure no one tampers with it or accidentally accesses its electrical components.

Clamps go well with NEMA 4 enclosures since they pull the door closer to the body of the enclosure, ensuring minimal water ingress.

We also offer secondary features like casters, lifting eyes, file pockets, rain caps, cable management systems, switches, lights, and anything else you request.

レインキャップ

Casters help move the enclosure around; lifting eyes are for heavy enclosures that need to be lifted to be carried around; file pockets store operating manuals; drip caps protect the enclosure from splashing water; solar shields protect against UV rays; switches and lights help personnel do maintenance work on the equipment.

Solar shield

ノックアウト、通気口、継手などはエンクロージャの定格に影響しますか?

All these weak spots are taken into account, and all of them individually should have the same rating as the entire enclosure.

If one fitting has a lesser rating, the rating of the enclosure goes down as well.

How do NEMA 4 enclosures maintain the thermal environment?

Generally, enclosures can have air conditioners, coolers, heat exchangers, and heater strips to control the temperature inside the enclosure.

This is done to prevent overheating, but also freezing of equipment.

If cold environments are your concern, then heat exchangers and heater strips may be of interest to you.

Heat exchangers are closed loop systems that are easy to maintain.

They push hot air in colder compartments, which results in an equalized temperature and pressure.

Heat exchanger

Heater strips use electricity to heat up the air inside the enclosure to protect its contents from low temperatures, condensation, and subsequent corrosion on the inside.

Enclosure heaters range in performance from 50 to 1200 Watts, depending on the size of your enclosure.

To cool an enclosure down, there are vents and fans that circulate air.

Also, there are air conditioners that cool the incoming air.

Plus, some enclosures have moisture control that dehumidifies air to 30-50% in order to protect the electrical components.

This is especially useful for NEMA 4 enclosures since they are common in humid environments with lots of splashing and hose-directed water.

Enclosure with moisture control

What materials are used for NEMA 4 enclosures?

The materials used for NEMA 4 enclosures aren’t different from materials used for other types of enclosures.

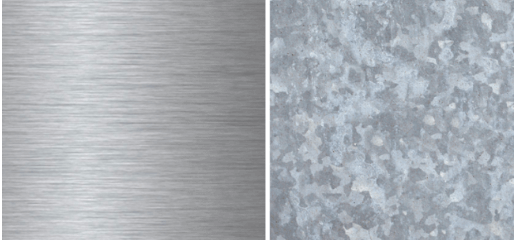

これらは 炭素鋼, 亜鉛メッキ鋼、 そして ステンレス鋼 – usually of the grades 304 or 316.

炭素鋼は通常、ステンレス鋼よりも鈍いです。

鉄と炭素のみで構成されているため、磁性があり、より展性があります。

This steel is also prone to corrosion, so it is not recommended for NEMA Type 4.

ステンレス鋼は、鉄と炭素の合金にクロム、ニッケル、モリブデンを加えて作られます。

ステンレス鋼と亜鉛メッキ鋼

鋼種 304 と 316 では、すべての添加剤の含有量が異なります。

亜鉛メッキ鋼 腐食を防ぐ亜鉛の保護層でコーティングされています。

このタイプの鋼はステンレス鋼よりも高価で重いです。

Another type of steel that can be used is cold-rolled steel, which is thinner and denser than normal steel – and thus, it is stronger.

鋼を使用する場合、製造業者は、NEMA 規格に準拠するために必要な鋼板の特定のゲージまたは厚さを念頭に置く必要があります。

NEMA 4 enclosures use 14 gauge steel, which is about 2 mm.

エンクロージャはアルミニウム合金で作ることもできます。

これらは必ずしも鋼合金より優れているわけではありませんが、目的やニーズによっては優れている場合もあります。

鋼のグレードと同様に、アルミニウム合金は 5052 シリーズまたは 6061 シリーズのいずれかになります。

アルミニウムとステンレス鋼

どちらも軽量ですが、5052 は溶接性に優れ、6061 は耐腐食性に優れています。

また、6061 の方が高価です。

アルミニウムの表面には腐食を防ぐ酸化物の層があります。

この素材は、溶剤、石油化学製品、一部の酸、ほとんどの硫酸塩および硝酸塩にさらされる筐体に特に適しています。

For NEMA Type 4 enclosures, stainless steel grade 304 and aluminum are most recommended.

また、当社の窓はポリカーボネートと ABS で作られています。

ポリカーボネートは腐食に強いですが、ABS は安価です。

さらに詳しく知りたい方は、 お問い合わせを送信 今すぐご相談ください!

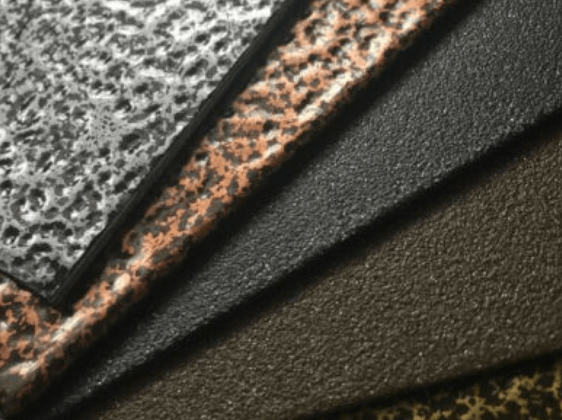

What paints and coatings can be used for NEMA 4 enclosures?

当社の筐体は十分に保護されていますが、適切なコーティングを施すことでさらに保護を強化できます。

任意の色のエナメル塗装または粉体塗装を選択できます。

エナメル塗料 has a glossy finish and is weather-resistant.

粉体塗料 静電気力で沈着するので、エナメルよりも早く簡単に沈着します。

外観もより柔軟で、光沢仕上げとマット仕上げのオプションが用意されています。

粉体塗装仕上げ

There can also be anti-graffiti and anti-poster coatings to protect your enclosure from vandalism if you plan to install it outdoors.

NEMA 4 enclosures most often use powder coating, but epoxy enamel and PU enamel are also great for industrial enclosures.

あらゆる色と仕上げのコーティングをご提供できますので、 お問い合わせ 今日!

What are some ways to put symbols on a NEMA Type 4 enclosure?

当社のカスタマイズサービスには、彫刻やシルクスクリーン印刷が含まれます。

If the equipment has to be installed in a particular orientation, this has to be marked on the enclosure.

Also, areas where live parts will be also has to have a mark.

Any warning or danger signs should also be engraved or silk-screened onto the enclosure as well.

シルクスクリーンは、最も簡単で手頃なカスタマイズ方法です。

筐体の平らな面には、ラベル、警告、シリアル番号、会社名、ロゴなどをシルクスクリーン印刷できます。

However, silk-screening on stainless steel or aluminum can be worn off or scratched off, but a clear powder coating helps to prevent that.

Thus, silk-screening may not be the best for NEMA 4 enclosures.

S

ilk-screening

エンクロージャに彫刻を施すことは、エンクロージャをカスタマイズするもう 1 つの方法です。

ロゴやシンボルのデザインでは、筐体の表面から少しの金属が取り除かれます。

通常、表面から約 0.005 インチまたは 0.010 インチの金属が除去されます。

金属が取り除かれたら、ご要望に応じて任意の色のエポキシ塗料で塗りつぶします。

This option may be better for NEMA 4 enclosures because it is more long-lasting.

彫刻

What common mistakes should I be aware of when ordering a NEMA 4 enclosure?

Some common mistakes that people make include choosing the wrong NEMA type, wrong material, wrong size, wrong design, and disregarding features.

NEMA タイプには、適した特定の環境があります。

NEMA 4 is built for non-hazardous, indoor and outdoor locations with dust, rain, snow, ice, and hose-directed water.

NEMA 4 usually uses stainless steel 304 or aluminum to increase resistance to outdoor corrosion.

筐体のサイズとデザインは、そこに収容する予定の特定の電気機器によって異なります。

Industrial enclosures tend to be big, but they don’t have to.

As for the design and features, these are case-specific, so consult your manufacturer for advice.

Recent NEMA 4 Enclosure Order

What is A NEMA 4 Enclosure?

NEMA 4 enclosure is a weatherproof or water-tight enclosure built for outdoor and indoor use.

It provides a high level of protection against falling dirt, windblown dust, airborne dust, circulating dust, falling dust, and other solid objects.

Relatively, NEMA 4 enclosure provides protection from water ingress, light splashing, dripping, hose-down, and splashing water.

NEMA 4 enclosures are available in a variety of types.

It includes JIC, freestanding, and wall-mounted.

Additionally, most NEMA 4 enclosure is gasketed with clamped doors for a maximum seal.

NEMA 4 enclosures are equipped with the following:

- Mounting feet

- Continuous hinges

- Padlock hasps

What is the Characteristic of NEMA 4 Enclosure?

Below are the characteristics of the NEMA 4 enclosure:

- Outdoor or indoor applications

- Protects equipment from rain and windblown dust inside the enclosure

- Protects electrical components from hose-directed water and splashing water

- Protection of ice forming damage

- Custom cutouts, pre-punched holes, locks, latches, insulation, lift-off hinges

- Provides a high level of protection to workers against hazardous parts accessed

What is the Difference Between NEMA 4 Enclosure and NEMA 4X Enclosure?

NEMA 4 enclosure is often utilized for its element protection.

It includes ice formation and cold weather outside the enclosure.

This enclosure is the lowest-rated dustproof among NEMA enclosures.

But it provides extra protection.

NEMA 4X enclosure is often waterproof but can’t be submerged in water.

Nevertheless, the NEMA 4X enclosure should be intense water spray resistance without any water ingress allowed.

What is the Disadvantage of NEMA 4 Enclosure?

NEMA 4 enclosure is not explosion-proof.

Therefore, it is not applicable for hazardous applications.

What Are the Accessory Options for NEMA 4 Enclosure?

Below are the accessory options for NEMA 4 enclosure:

- Switches

- Lights

- Power panels

- Fuse blocks

- Leveling feet

- Casters

- Viewing windows

- NEMA 4 rated A/C units

- Heaters

- Thermostats

- NEMA 4 rated wash-down for fan assembly

What is the Application of NEMA 4 Enclosure?

NEMA 4 enclosure is the solution for different applications, such as:

- Industrial application

- Commercial application

- Military application

What is the Size of NEMA 4 Enclosure?

The NEMA 4 enclosure is available in different sizes.

You can avail yourself of small boxes and large free-standing enclosures, suitable for different applications.

What is NEMA 4 Enclosure Made of?

NEMA 4 enclosure can be available in stainless steel, steel, aluminum, and plastic.

However, most manufacturers use excellent grade carbon steel to construct NEMA 4 enclosures.

It comes with various finishes, such as durable powder coated and oven-baked.

The standard door turn knobs and door handles of this enclosure is powder-coated.

However, you can request your manufacturer to upgrade it to your specific materials with interesting features.

Is NEMA 4 Enclosure Similar with IP65 Enclosure?

IP ratings and NEMA aren’t identical.

They are similar and sometimes be interchangeably used for rating enclosure’s purposes in industrial environments.

IP ratings are primarily determined for liquid or solid foreign objects protection.

NEMA ratings also determine corrosive agents and other conditions protection.

| NEMA RATING (US) | = | IP RATING (International) |

| 1 | = | IP20 |

| 2 | = | IP22 |

| 12 | = | IP54 |

| 4 | = | IP65/IP66 |

| 4X | = | IP65/IP66 |