With years of experience in the enclosure industry, consider our NEMA 13 enclosure for the best equipment protection.

NEMA 13 Enclosure and Box

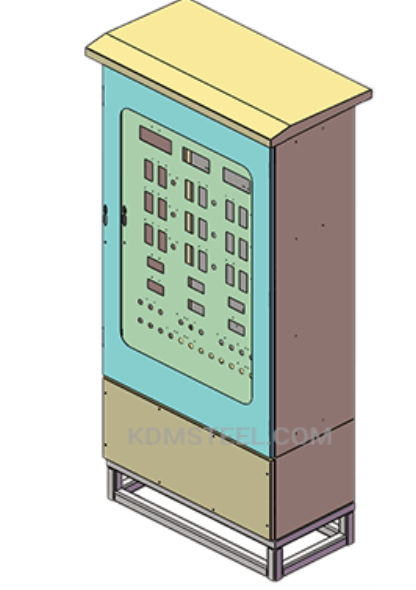

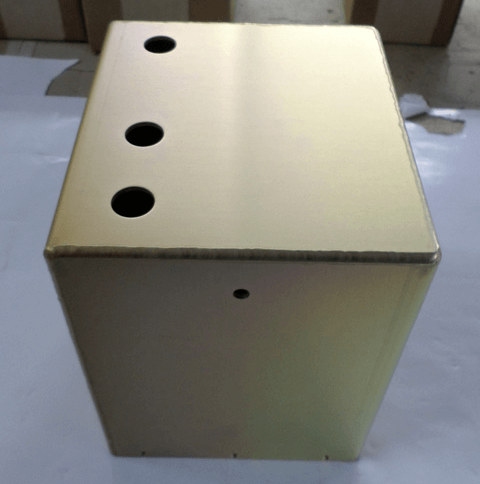

At KDMFAB we offer NEMA 13 enclosure with the ideal balance of security, power, and practicality. Which is made of premium stainless steel, or steel that provide outstanding durability, resistance to non-corrosive oil, water, coolants and dust.

The manufacturing plant, pharmaceutical facilities, automotive industry, food and beverage industry can all benefit greatly from our NEMA 13 enclosure.

KDM NEMA 13 Enclosure Series

Send your Inquiry on KDM NEMA 13 Enclosure

Customized Detail for NEMA 13 Enclosure

KDMFAB offer customization options for NEMA 13 enclosures.

We can include custom sizes, additional mounting options, cutouts for switches and displays, and specific finishes or coatings to meet the needs of your application.

For additional mounting options our NEMA 13 enclosures can be installed on a wall, a floor, or a pole, depending on the purpose.

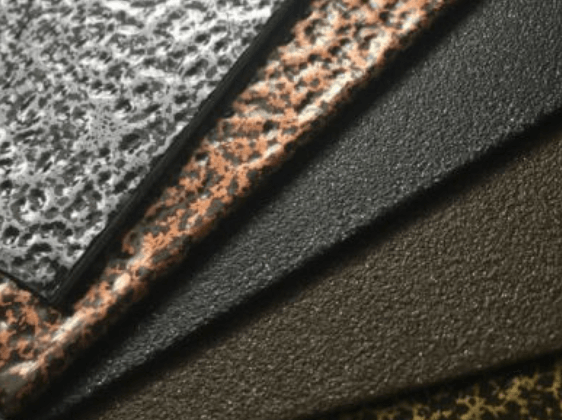

And for our common finishes for NEMA 13 include powder coating, enamel paint, and galvanized coating.

- 製造能力

4000W 高性能レーザー切断機、+/- 0.05mm の精度。バリや傷はありません。

多機能フレキシブル溶接装置、高精度、変形なし。

+/- 0.5mmの曲げ精度、曲げ跡のない滑らかな表面。

10 名以上の溶接経験のある作業員が、完璧な全体的な外観を実現します。

高速かつ高精度の発泡機、高速かつ高品質のガスケット

熟練した組み立てチーム、すべてのKDMエンクロージャで一貫した組み立て品質

We manufacture NEMA 13 enclosure that should be able to function in a specific temperature range, usually between -40°C and +60°C (40°F and +140°F).

Our enclosure is approved by the appropriate authorities and satisfies NEMA 13 criteria. Sush as CSA (Canadian Standards Association) or UL (Underwriters Laboratories) signify that our enclosure has undergone testing and satisfies performance and safety requirements.

We designed our NEMA 13 enclosure with completely customized accessories, including:

- Panel mounting hardware, including screws and brackets.

- Panels might be internal, metal or non-metallic.

- Mounting kits and feet

- Seals and gaskets

- Swing-out shelves

- Drip shields

- Vents for breathers

- Window inspections

- Brackets to mount external devices

- Variations in door hinge types

- Filters, fans, vents, and accessories for cooling

- Interior lighting, either fluorescent or LED

- Straps and bars for grounding

- Wire troughs, strain reliefs, and cable glands

- Heating units and thermostats

- Personalized labels and nameplates for identification

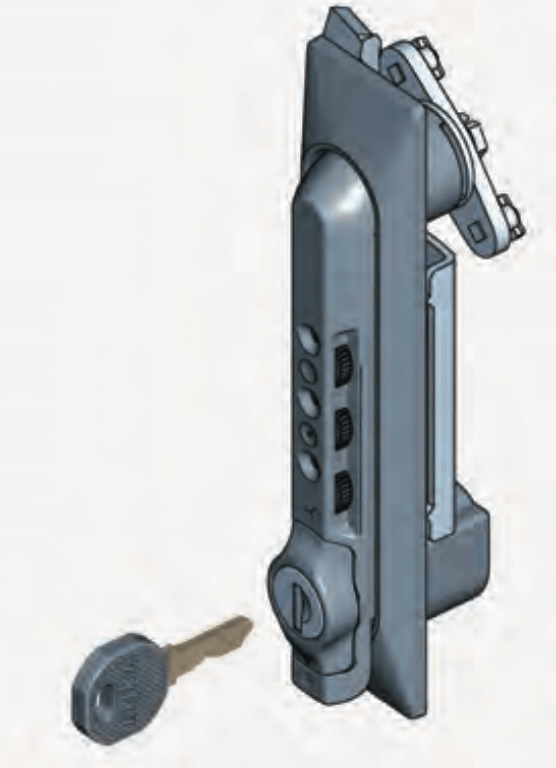

- Other locking systems, such as quarter-turn latches and padlockable handles

最近の IP67 エンクロージャの注文

The Definitive FAQ Guide to NEMA 13 Enclosures

- What does NEMA type 13 mean?

- How is NEMA 13 different from NEMA 12?

- Are NEMA 13 enclosures used outdoors?

- Are NEMA 13 explosion-proof?

- What are common applications for NEMA 13 enclosures?

- How are NEMA 13 enclosures tested?

- How can I be sure of the quality of NEMA 13 enclosures?

- What is NEMA 13 in IP standards?

- What are common designs for NEMA 13 enclosures?

- どのような追加機能が含まれることが多いですか?

- How do NEMA 13 enclosures maintain temperature?

- What materials are used for NEMA 13 enclosures?

- What paints and coatings can be used for NEMA 13 enclosures?

- How can symbols be put on a NEMA Type 13 enclosure?

- エンクロージャを注文する際に他に注意すべきことはありますか?

What does NEMA type 13 mean?

NEMA type 13 enclosures protect personnel from accidental contact with live parts, as well as protect the equipment from dirt, dust, lint, various flyings, splashing water, oil, and non-corrosive coolants.

NEMA Type 13 enclosures are rated for indoor environments only.

These enclosures are fairly rare; much rarer than type 4 or type 12 enclosures.

NEMA 13 box

How is NEMA 13 different from NEMA 12?

NEMA 13 is the same as NEMA 12, except that it protects equipment from splashing oil and coolants better than NEMA 12 boxes do.

So, only pick type 13 if splashing oil and coolants are major concerns to your application.

Coolants include cutting and polishing fluids that cool down machinery.

As a material is getting polished or cut, it and the machinery will heat up due to friction; cutting fluids do just that.

Other such liquids include liquid nitrogen, rubbing alcohol, and kerosene.

Cutting fluid

So, any metalwork industry may need some NEMA 13 enclosures.

Oils that NEMA 13 protects from may include mineral oils, which are sometimes used in cosmetics and biomedicine, and motor/engine oils.

Are NEMA 13 enclosures used outdoors?

NEMA 13 enclosures cannot be used outdoors since they are rated for indoor use only.

You could install NEMA 13 enclosures outside, but only if the climate is dry and not windy.

Even then, it is not recommended.

If you need enclosures for the outdoors, NEMA types 3, 3R, 4、 そして 4X are better.

In the same way, NEMA 13 enclosures are not fully weatherproof.

They do protect from some dust and liquid ingress, but not enough to withstand outdoor weather conditions.

Are NEMA 13 explosion-proof?

No, you need NEMA types 7 or 8 for that.

If you plan to install your enclosures in chemical or petroleum refineries, then your enclosures need to be rated with NEMA 7 or 8.

Also, no NEMA rating can protect from an アークフラッシュ.

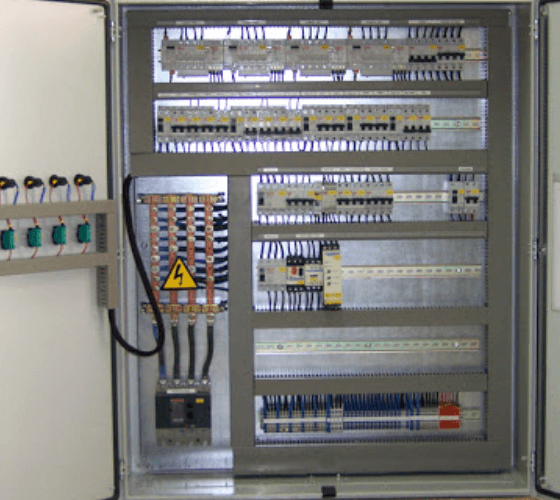

What are common applications for NEMA 13 enclosures?

NEMA 13 enclosures are used mainly for 産業用途。

These include indoor electrical hydraulic or pneumatic controls, terminal or jファンクション配線エンクロージャ, operator interfaces, and consoles.

NEMA 13 enclosures can house electrical equipment rated at 1000 Volts or lower.

NEMA 13

These enclosures are often found in transportational industries, and various municipalities like water treatment plants, and general indoor control applications.

Because NEMA 13 enclosures are resistant against oil and coolants, they can be used in non-hazardous petroleum-processing rooms, boiler rooms, car assemblies or service garages, and general-purpose applications.

詳細については、当社の一般情報をご覧ください。 NEMA エンクロージャに関する FAQ!

How are NEMA 13 enclosures tested?

自己宣言の要件については、最新のNEMA 250文書を参照してください。 NEMAラベル.

NEMA 13 is tested using the indoor corrosion protection test, oil exclusion test, and gasket test.

Oil exclusion test involves making a solution with water and a wetting agent, also called a surfactant, that act as detergents.

This solution is then sprayed on the enclosure at a rate of 7 liters per minute for at least 30 minutes.

Spray test

Passing this test guarantees a pass for the dust test, the rod entry test, and the rain test.

Indoor corrosion test involves making a 5% sodium chloride solution and spraying it onto the enclosure continuously for 24 hours.

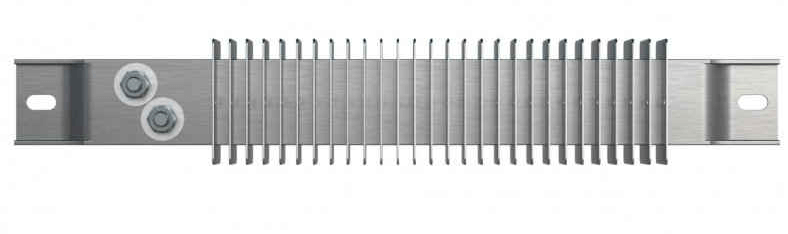

NEMA 13 enclosures also undergo various gasket tests to evaluate how they age while stretched at high temperatures.

Gasket

This is the aging gasket test.

If there are no cracks, deformations, and the tensile strength remains the same, the enclosure passes this test.

For NEMA 13 enclosures, there also are oil immersion gasket tests.

To pass the test, the PU gaskets may not expand more than 25% or shrink more than 1%.

Gaskets are tested in oil for 70 hours.

水の浸入を防ぐには、良質のガスケットが鍵となるため、これが必要です。

How can I be sure of the quality of NEMA 13 enclosures?

KDMでは、 ISO9001認証 見ることができるもの。

また、品質と適合性評価の確認が必要な場合は、エンクロージャの独立したサードパーティテストを実施することもできます。

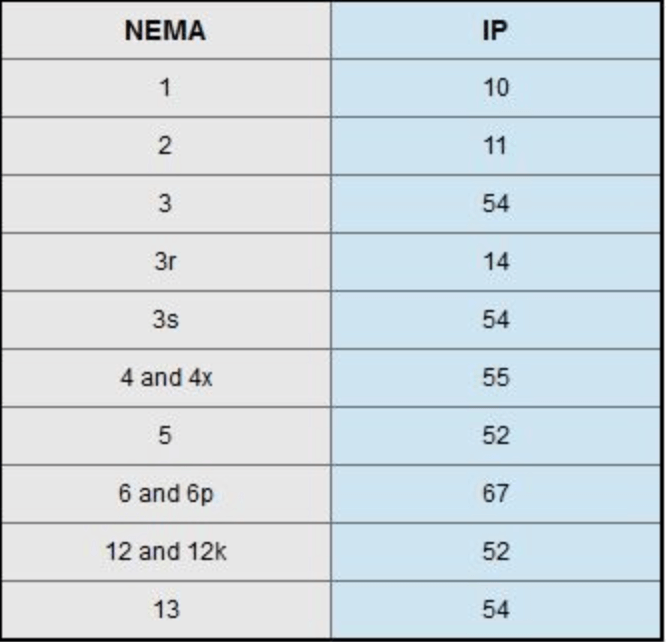

What is NEMA 13 in IP standards?

Although it is difficult to translate one set of standards into another, NEMA Type 13 is similar to IP54.

NEMA standards are slightly more strict than the IP standards.

Thus, if an enclosure passes a given NEMA standard, it will meet the requirements for its equivalent IP rating, but the reverse is not guaranteed.

What this means is that NEMA 13 will always pass IP54, but IP54 may not pass for NEMA 13.

NEMAとIP

What are common designs for NEMA 13 enclosures?

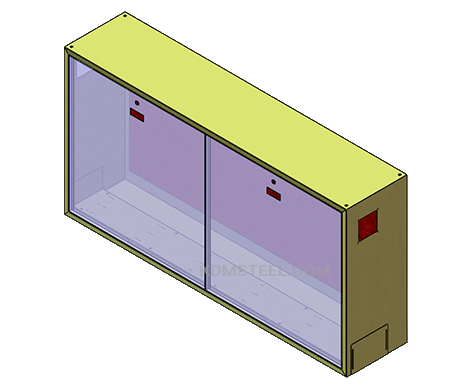

Some common designs for NEMA 13 enclosures include free-standing, floor-mounted, wall-mounted, modular, and custom.

自立型, 床置き型, and walk-in enclosures are all made for bigger equipment.

These enclosures can have one or multiple doors, depending on your requirements and the size of the enclosure—bigger ones may need multiple doors.

Such enclosures can also have pedestals, casters, leveling feet on the bottom, and lifting eyes on the top to help install and move them around.

Free-standing enclosure with casters

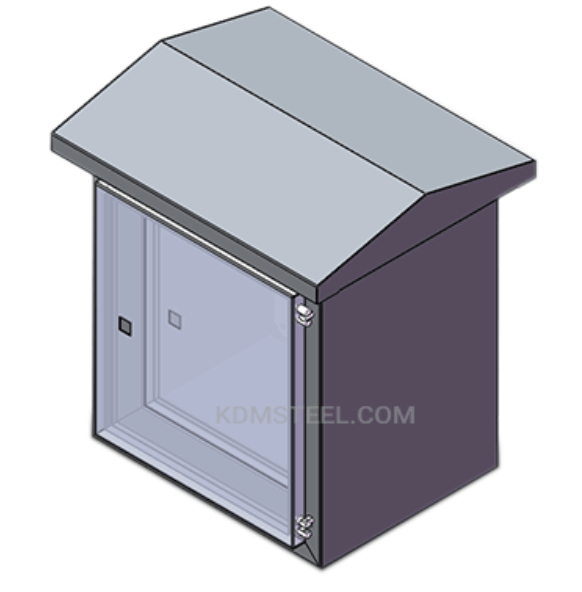

壁掛け そして ポールマウント NEMA 13 enclosures are typically small and are used to house fuses, switches, and buttoned panels.

これらは移動性は劣りますが、占有するスペースも少なくなります。

They can even be recessed into a wall to save more space.

これらは、外部のみ、または内部要素も備えた特殊なブラケットを使用して取り付けられます。

壁掛け式エンクロージャ

We also offer modular enclosures, which can be changed and reassembled into a differently shaped enclosure.

Modular enclosures are great if you are not sure of where the enclosure will go, or if it will be moved from location to location.

Modular enclosure

Cカスタムエンクロージャ あらゆるサイズ、寸法にすることができ、ドア、ヒンジ、通気口、窓などの機能をあらゆる組み合わせで持つことができます。

Custom enclosure

どのような追加機能が含まれることが多いですか?

通気口、窓、蝶番付きドア、錠、ケーブル管理システムなどをリクエストできます。

通気口, as well as radiating fans, let heat escape.

筐体内の電気部品を冷却します。

通気口はより受動的な空気の流れを提供しますが、ファンは積極的に空気を動かし、急速に熱くなる機器を冷却するために使用されます。

This prolongs the life of equipment and decreases the possibility of malfunctions and electrical fires like アークフラッシュ.

Fan in an enclosure

これらは筐体内の空気圧を安定させ、筐体の電気部品を損傷する可能性のある結露を防ぎます。

ウィンドウズ 担当者が迅速かつ非侵襲的な方法で電気部品を検査するのに役立ちます。

何か問題が発生した場合、ウィンドウによって何が起こっているかをすぐに確認できます。

If your enclosure is supposed to have buttons, gauges, or signal lights, then a window is necessary.

It will allow personnel to inspect said gauges and lights without messing with the cover or door.

Usually, windows are made from polycarbonate or ABS.

窓付きの囲い

蝶番ドア 筐体のドアまたはカバーがどのように、どの程度開くかを制御します。

蝶番ドア用のハンドルもさまざまな種類から選択できます。

Hinge

当社が提供するヒンジには、連続ヒンジ、オフセットヒンジ、フラグヒンジ、バネ式ヒンジなどがあります。

Enclosures also need security from tampering and accidental access.

ロック, latches, and clamps do just that.

Lock

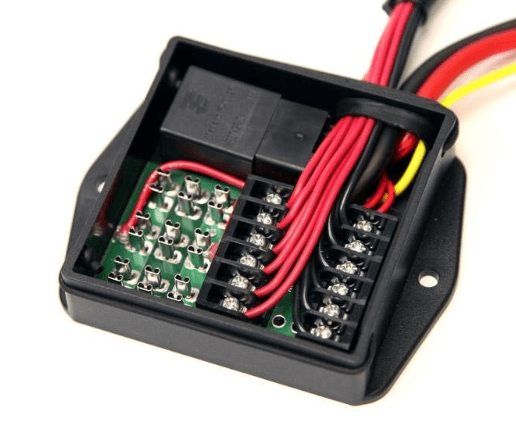

Hooks, racks, and other organizing features comprise a cable management system.

Some popular secondary features for NEMA 13 enclosures include file pockets, thermostats, heaters, casters, fuse blocks, power panels, lights, and switches.

ファイルポケット

File pockets store operating manuals; casters are wheels on the bottom of an enclosure

Thermostats and heaters help maintain internal temperature

Fuse blocks house different circuits, while power panels may have circuit breakers, and generally control the circuits.

Fuse block

Switches and lights help operate the equipment inside the enclosure.

We offer outdoor features like rain caps and solar shields; however, these are not necessary for NEMA 13 enclosures, since they will be indoors.

How do NEMA 13 enclosures maintain temperature?

一般的に、エンクロージャには、エンクロージャ内の温度を制御するためのエアコン、クーラー、熱交換器、ヒーターストリップが備わっています。

これにより、機器の過熱や凍結を防ぎます。

If your enclosures are for cold locations, like freezers or cellars, then heat exchangers and heater strips may be necessary.

As equipment does its work, it may produce heat, which transfers to the air around it.

Heat exchangers push hot air into colder compartments.

This movement of air also results in an equalized temperature and pressure, which prolongs the life of electrical equipment.

熱交換器

Heater strips use electricity to heat up the air inside the enclosure.

ヒーターストリップ

エンクロージャ ヒーターの性能は、エンクロージャのサイズに応じて 50 ~ 1200 ワットの範囲になります。

Air conditioners and various air coolers are vital for enclosures situated in warm locations, like industrial boiler rooms and such.

機器の寿命を延ばすには冷却する必要があります。

What materials are used for NEMA 13 enclosures?

これらは 亜鉛メッキ鋼、 そして ステンレス鋼 – 通常はグレード 304、316、または 316L です。

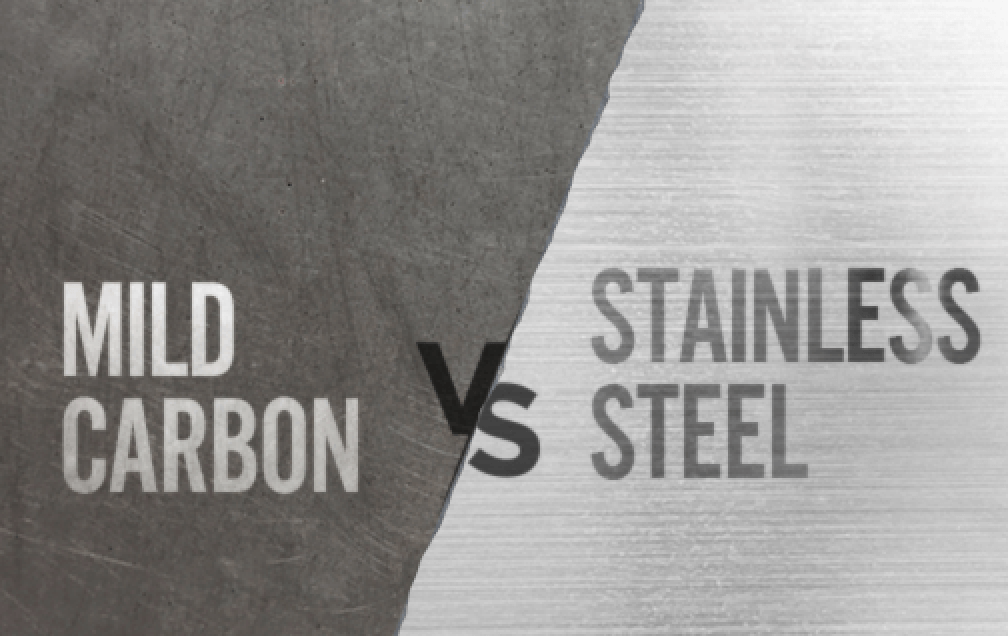

Carbon steel, also called mild steel, is usually duller than stainless steel.

It is magnetic and more malleable since it only has iron and carbon.

This steel is also prone to corrosion, but it works well for indoor enclosures, such as NEMA type 13.

Carbon steel vs. stainless steel

Stainless steel is created by adding chromium, nickel, and molybdenum in different proportions to the iron-carbon alloy.

鋼種 304 と 316 では、すべての添加剤の含有量が異なります。

316 ステンレス鋼は、塩水噴霧、特定の酸、高温に対する最高の保護を提供します。

このため、316 は海洋用途でより多く使用されます。

一方、304 は硫酸塩と塩素に対してより耐性があります。

Steel grades 304L and 316L differ from other grades by their lower proportion of carbon, making them stronger.

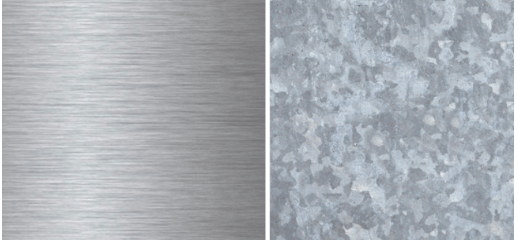

亜鉛メッキ鋼 腐食を防ぐ亜鉛の保護層でコーティングされています。

ステンレス鋼と亜鉛メッキ鋼

このタイプの鋼はステンレス鋼よりも高価で重いです。

When using steel, there may be a certain gauge, or thickness, of the sheet metal that is necessary to comply with NEMA standards or with requirements of the environment.

NEMA 13 enclosures use 14 or 12 ゲージ鋼, which is about 2-2.8 mm.

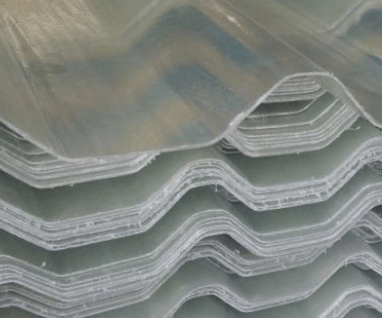

Enclosures can also be manufactured from various polymers.

One such material is fiberglass.

It is very strong, can dissipate heat, and insulates electricity, lowering the effect of interference and the possibility of shock.

As such, fiberglass enclosures are good as transformers, junction boxes, and compartments for telecom equipment.

プラスチックの中にガラス繊維を入れて作られています。

グラスファイバー

エンクロージャはアルミニウム合金で作ることもできます。

これらは必ずしも鋼合金より優れているわけではありませんが、目的やニーズによっては優れている場合もあります。

鋼のグレードと同様に、アルミニウム合金は 5052 シリーズまたは 6061 シリーズのいずれかになります。

Aluminum vs. stainless steel

どちらも軽量ですが、5052 は溶接性に優れ、6061 は耐腐食性に優れています。

また、6061 の方が高価です。

アルミニウムの表面には腐食を防ぐ酸化物の層があります。

For NEMA Type 13 enclosures, carbon steel, galvanized steel, stainless steel, and polymers like fiberglass are the best.

However, other materials will work just as well.

さらに詳しく知りたい方は、 お問い合わせを送信 今すぐご相談ください!

What paints and coatings can be used for NEMA 13 enclosures?

Our enclosures are well-protected, but the right coating can add a layer of corrosion protection.

アロジンコーティングとも呼ばれる クロメート化成コーティング, is used to prime steel and aluminum for paint, as well as to prevent corrosion.

アロジンコーティング

This coating is fairly cheap and can be recognized by its characteristic greenish-yellow hue.

On top of this, you can choose enamel or powder paint coats in any color.

粉体塗料 静電気力で沈着するので、エナメルよりも早く簡単に沈着します。

外観もより柔軟で、光沢仕上げとマット仕上げのオプションが用意されています。

粉体塗装仕上げ

エナメル塗料 光沢のある仕上がりで耐候性があります。

陽極酸化処理 コーティングでは、陽極を使用して金属(通常はアルミニウム)を酸化し、厚さを増やして耐腐食性を高めます。

鋼鉄は、腐食を早めてしまう可能性があるため、通常は陽極酸化処理されません。

屋外に設置する場合は、エンクロージャを破壊行為から保護するための落書き防止およびポスター防止コーティングを施すこともできます。

NEMA 13 enclosures most often use powder coating.

Powder coating

あらゆる色と仕上げのコーティングをご提供できますので、 お問い合わせ 今日!

How can symbols be put on a NEMA Type 13 enclosure?

当社の彫刻およびシルクスクリーン サービスを利用して、エンクロージャをカスタマイズできます。

Engraving is more expensive and difficult, but it is also more long-term than silk-screening.

Usually, about 0.005-0.010 inches of metal is removed from the surface.

金属が取り除かれたら、ご要望に応じて任意の色のエポキシ塗料で塗りつぶします。

彫刻

Silk Screening, on another hand, is the easiest and most affordable method.

筐体の平らな面には、ラベル、警告、シリアル番号、会社名、ロゴなどをシルクスクリーン印刷できます。

ただし、注意してください。ステンレス鋼やアルミニウムのシルクスクリーンは摩耗したり傷が付いたりする可能性があります。

ただし、透明なパウダーコートを塗れば、それを防ぐことができます。

シルクスクリーン

シンボル以外にも、他のマークも必要です。

機器を特定の方向に設置する必要がある場合は、筐体にその旨を記載する必要があります。

また、通電部品がある部分にもマークを付ける必要があります。

Any warning or danger signs should also be engraved or silk-screened onto the enclosure as well.

エンクロージャを注文する際に他に注意すべきことはありますか?

人々が犯す一般的な間違いがいくつかあります。

これらには、間違った NEMA タイプ、間違った材料、間違ったサイズ、間違った設計の選択、機能の無視などが含まれます。

NEMA 13 is built for non-hazardous, indoor locations with normal air pressure, rain or dripping water and some dust.

Enclosures

NEMA 13 enclosures are usually medium-sized or small.

もう 1 つ注意すべき点は、ステンレス鋼を選択する場合は、汚れが付着しないわけではないことを覚悟しておくことです。

時々、腐食が軽い汚れの形で現れることがありますが、水だけで簡単に取り除くことができます。

デザインや機能に関しては、ケースによって異なりますので、 メーカーにご相談ください アドバイスを求めます。

What is a NEMA 13 Enclosure?

NEMA 13 enclosures are designed to protect against dirt, fiber, splattering oil, and non-corrosive liquids in interior industrial uses.

Operators are protected from dangerous parts by NEMA 13 electrical enclosures.

It also protects electronic systems from extraneous debris and water filtration.

Figure-1 NEMA 13 Enclosure

What is the Advantage of NEMA 13 Enclosure?

- Access to dangerous areas.

NEMA 13 enclosure offers a level of protection against accessibility to dangerous parts.

Most other sections, including NEMA type 12, do as well.

Personnel who often operate within the enclosure and the material it protects should have been shielded from harm.

- Solid foreign objects ingress.

The NEMA 13 enclosure delivers some security from solid foreign substance intrusion.

In addition to preventing dirt from dropping NEMA 13 enclosure protect against the spread of dust, lint, fibers, and non-harmful flying.

- Ingress of water.

NEMA 13 offers additional protection from water contamination.

- Coolants and oil ingress

The NEMA 13 enclosure protects oil and coolant spray and splash.

What Does the NEMA 13 Enclosure Rating Mean?

The NEMA 13 enclosure rated system is an effective tool for electrical and electronic device designers.

To choose enclosures that provide the protection that equipment requires.

Defining the NEMA 13 rating.

The NEMA 13 rating is very similar to the more often used NEMA 12 rating.

Enclosures rated NEMA 13 offer protection against the following:

- Contact with dangerous or sensitive areas by accident

- Infiltration of flowing and drifting foreign material such as dust, filth, lint, and other contaminants.

- Splashing or dripping water intrusion

- Coolant seepage and non-corrosive oil ingress

Enclosures with a NEMA 13 rating are additionally protected against non-corrosive chemical agents such as fuel, coolant splashing, and spraying.

Figure-2 NEMA 13 Enclosure

What Isn’t Protected By a NEMA 13 Enclosure?

Snow, rain, sleet, submersion in water, or windblown dust are all things NEMA 13 enclosures aren’t designed to defend against.

NEMA 13 enclosures are also not qualified to guard against corrosive liquid splashing or leaking.

What are the Design Features of NEMA 13 Enclosure?

- Compartment for batteries.

It is suited for indoor electrical applications.

- Covered in the clear.

For uses that need visible access to internal components, polycarbonate is built with a clear translucent cover.

- Enclosure for din rails.

DIN rail enclosures come in various sizes to suit your electrical or electronic needs.

- Surface/flagged mount.

For applications requiring rapid surface attachment, wall mount enclosures are built with flanges that are molded on or fitted with screws.

- Cover with hinges.

Hinged electrical enclosures and junction boxes are NEMA rated for weatherproof and watertight protection.

- Knockout boxes.

Knockout boxes for electrical applications allow for onsite cable, wire, or conduit installation.

- Lockable.

NEMA and IP certified waterproof outdoors protection is given by lockable electrical enclosures and locked electrical connections.

- Low Visibility.

Outdoor enclosures with a low profile are waterproof and fulfill a variety of NEMA and IP classifications.

- Together in a flash.

Snap-together cases are a quick and easy way to store gadgets in a plastic utility box.

Figure-3 NEMA 13 Enclosure

What are the NEMA 13 Enclosure Types?

At below are some of the most common types of NEMA 13 enclosures:

- Enclosures for indoors

- Enclosures for the outdoors

- Enclosures with hinges

- Dust-proof enclosures

- Waterproof enclosures

- Boxes of interconnection

- Squares with a transparent cover