Choosing the right 電気筐体 to protect your machinery ensures its longevity. NEMA 1 and NEMA 12 enclosures are two widely used ones; however, their features are very contrasting in nature between different kinds of surroundings. This guideline will help you break down all the differences, thus enabling you to make an informed decision.

Overview of NEMA 1 Enclosure

- Basic features

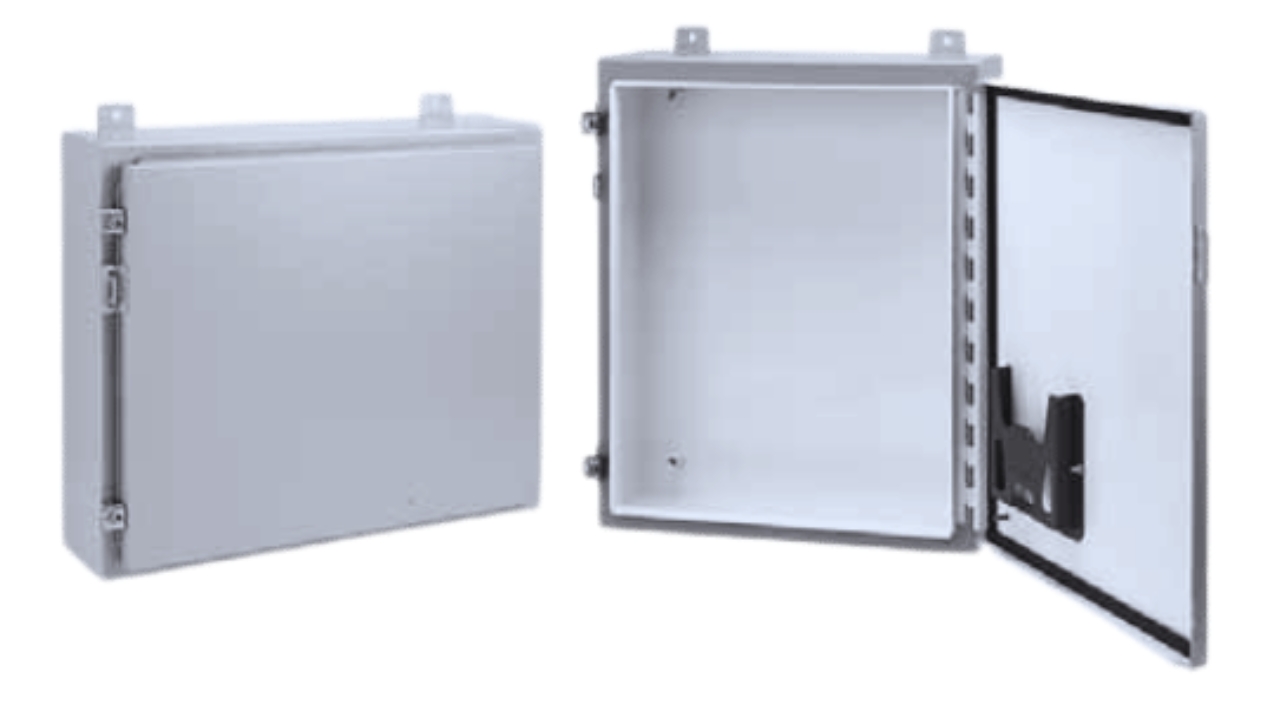

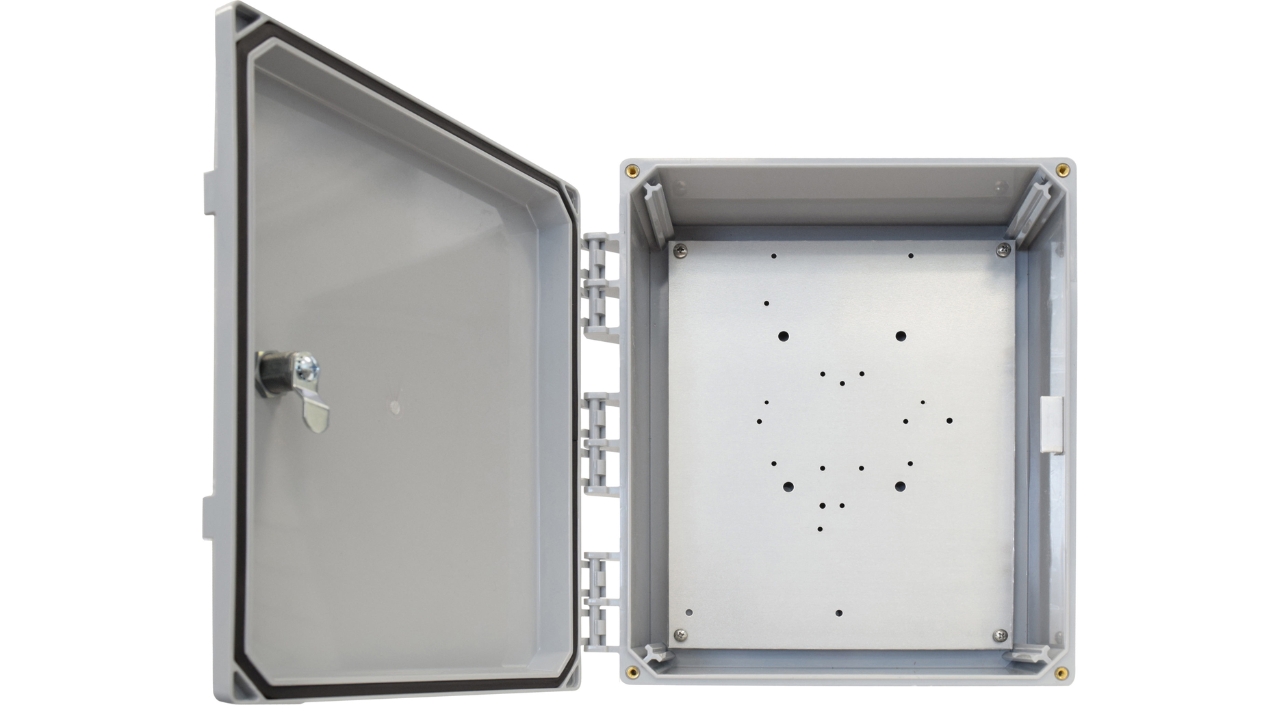

NEMA 1 enclosures are the simplest indoor enclosures that provide basic protection to the electrical components against ingress of solid foreign objects and are often made of materials like mild steel making lightweight and easy to install.

- Common applications

They suit applications with conditions that are on the cleaner and drier side, like in offices, data centers, or factories, with minimal to nil exposure to moisture and harsh chemicals. Common applications for NEMA 1 enclosures include electrical panel, control, and termination housed within an environmentally controlled environment.

- 制限事項

However, NEMA 1 might not be enough in a dusty, moist, and chemically laden environment. The protection scope of these limits makes their use restricted to general indoor conditions with very mild exposure to airborne particulates; another type of enclosure might be more appropriate for more rugged service.

Overview of NEMA 12 Enclosure

- Basic features

あ NEMA 12 enclosure will offer you a high level of protection. It is specifically designed to prevent the entry of solid foreign objects and is valued with ingress protection against dripping and light splashing water, oil, and coolant. It is fabricated from hard-wearing materials, such as stainless or galvanized steel, giving it good service in tougher industrial environments.

- Common applications

The NEMA 12 enclosure is found mainly in manufacturing, automotive, and food processing industries, as well as in warehouses where the equipment is likely to be exposed to harsh substances such as oil, coolant, or even dust. Perfect protection is attained with NEMA 12 enclosures, where electrical equipment will be safely operated in any harsh environment.

- Durability and additional protection

Although expensive more than NEMA 1, the protective gain of NEMA 12 should adequately pay back the investment in cases where you are working under severer conditions.

NEMA 1 vs NEMA 12: Key Differences

Like any equipment, NEMA 1 and NEMA 12 both have their pros and cons. However, if you’re in the market for one, here’s what you should consider:

● Environmental Protection:

While both offer environmental protection, NEMA 1 has low protection against dust and debris, while NEMA 12 can withstand vastly greater amounts of dust, dirt, moisture, and oils. If the environment is relatively clean, NEMA 1 would be okay, but consider challenging working conditions – NEMA 12 is the better option.

● Materials Used:

Unlike NEMA 12, which is manufactured using more rugged materials such as stainless and 亜鉛メッキ鋼, NEMA 1 enclosures are made of mild steel. This does make them lightweight, but they’re not as durable as their NEMA 12 counterparts.

● Suitability for Different Environments:

In comparison to NEMA 1, which is best suited for controlled indoor environments, NEMA 12 is significantly more versatile. These enclosures excel in industrial environments with a higher presence of dirt, moisture, oil, and chemicals.

● Cost Considerations:

NEMA 12 enclosures offer better protection due to their superior material selection. Because of this, they tend to come at a higher price compared to NEMA 1. While this might sound unfavorable, consider the long term value if your equipment requires protection from harsher conditions.

When to Choose NEMA 1 vs NEMA 12

- Choosing NEMA 1: The NEMA 1 is a widely used enclosure for indoor regions where no moisture or excessive dust accumulation occurs. Its low price makes it an appealing choice. It can be used for low-end applications such as electrical panels in offices or light manufacturing, as well as in data centers.

- Choosing NEMA 12: If you are working in tougher environments such as food processing, manufacturing plants or warehouses that require the equipment to be resistant to oils, coolants, and dust, then NEMA 12 is the correct choice. The increased protection will ensure that your equipment remains in working order.

Choose KDM Steel for High Quality NEMA 1 and NEMA 12 Enclosures

When it comes to NEMA 1 and NEMA 12 enclosures, KDMスチール stands out for providing top-grade enclosures that cater to your industrial requirements. Our enclosures are constructed to guarantee that your electrical devices are safely protected and operational in all situations.

結論

When deciding on NEMA 1 and NEMA 12 enclosures, it ultimately hinges on the degree of protection you are after. NEMA 1 will be enough if you are in a controlled setting with a low number of harsh elements. On the other hand, NEMA 12 will suffice if you are in challenging industrial conditions that require higher levels of protection and durability. The accurate decision must be made to protect equipment and make certain of its lifespan.

よくある質問

What is the main difference between NEMA 1 and NEMA 12?

The scales of protection are quite different. NEMA enclosures have a basic level of dust protection and cover accidental contact, while level 12 gives superior protection against dust, oil coolants, moisture, and dirt.

Can NEMA 1 be used outdoors?

No. NEMA 1 is not suited for the outdoors since it is best used in an indoor environment where moisture exposure is little to none, and weather conditions are mild.

Is NEMA 12 suitable for outdoor use?

Yes, however, the NEMA 12 is not fully suitable for harsh weather characterized by heavy rainfall and flooding. It does provide protection from dust and moisture, but it is better to not have it outdoors under harsh weather.

What industries use NEMA 12 enclosures?

NEMA 12 is widely used in manufacturing industries for the automotive, food, and chemical processing due to the constant exposure to dust, moisture, and oils.