- Custom Ip56 or Any IP rating Enclosure

- IP65/IP66認証

- Fast Sample Production within 3 days

Custom IP56 Enclosure Manufacturer in China

KDM IP56 enclosure is specially designed for industry and factory automation, heavy-duty vehicles, outdoor kiosk, swimming and spa pool kiosk, toilet AD display, and medical equipment. This enclosure undergoes rigorous testing against harsh environments such as water jets, rain, flood, salt fog, moisture, severe dust, and dirt exposure.

Small quantities of dust can enter the enclosure, but the quantity of dust cannot impact the operation of the equipment.

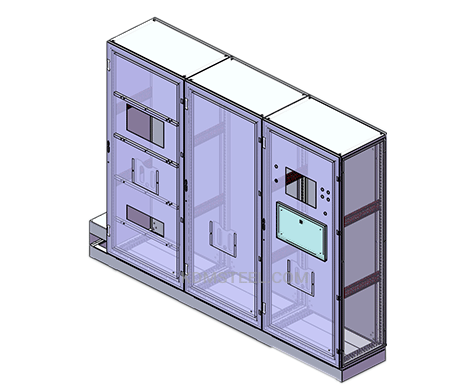

KDM IP56 Enclosure Series

Send your Inquiry on KDM IP56 Enclosure

KDM IP56 enclosure is manufactured using the highest quality materials, which ensures excellent insulating properties and a high level of resistance to chemical and mechanical influences.

KDM IP56 enclosure is resistant to heat, shocks, atmospheric agents, and UV rays. The right choice of materials is a core competence of KDM engineering and design capabilities.

- 製造能力

- 購入ガイド

4000W 高性能レーザー切断機、+/- 0.05mm の精度。バリや傷はありません。

多機能フレキシブル溶接装置、高精度、変形なし。

+/- 0.5mmの曲げ精度、曲げ跡のない滑らかな表面。

10 名以上の溶接経験のある作業員が、完璧な全体的な外観を実現します。

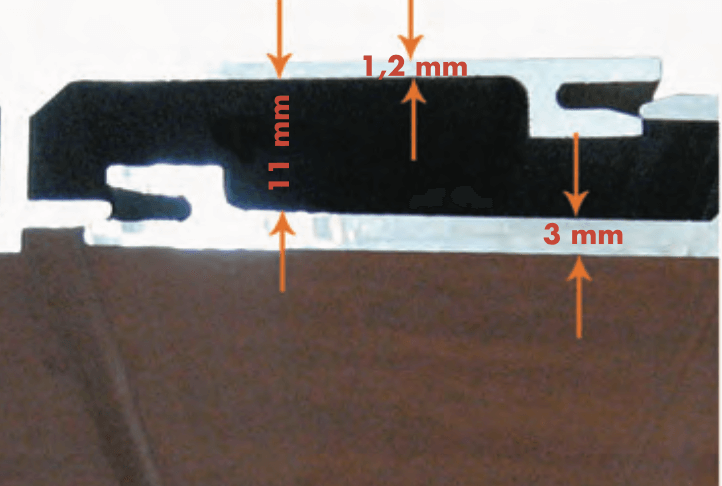

高速かつ高精度の発泡機、高速かつ高品質のガスケット

熟練した組み立てチーム、すべてのKDMエンクロージャで一貫した組み立て品質

KDM IP56 Enclosure

Stainless Steel IP56 Enclosure

We, at KDM, provide enclosures range of electrical enclosure including pole mounts, wall mounts, floor mounts, free-standing, lockable, modular and more. These enclosures can vary in size, from relatively small street-side cabinets to large walk-in cabins located trackside greenfield sites, street-sides, etc.

KDM IP56 Enclosure Factory

IP56 Enclosure Welding

IP56 enclosure designed to satisfy customer needs, precisely engineered & carefully manufactured by KDM. KDM features a reliable and long lifetime and versatile IP56 enclosure mechanical design. KDM IP56 enclosure protects people who come in contact with the component. Besides the protection mention above, the IP56 enclosure also adds protection from splashing water, horse-driven water, snow, and corrosion. IP56 from KDM offered in high standards and at the same time can be customized to meet your specific application requirements.

KDM electrical enclosure that meets IP56 standards can be customized. Custom IP56 products can be painted in any number of colors or color combinations. Also, you can choose the materials, finishes, shapes, sizes, holes, and cutouts, in each of these, we can handle with expertise. We design and manufactures custom IP56 enclosure according to customer’s requirements to meet their exact job needs.

At KDM, we present your wide variety of electrical enclosure meeting IP56 standards. Our large range of innovative enclosure solutions supplemented by a vast selection of accessories. With the immediate availability of products, your product can be individually adapted to fit any of your applications. The KDM range of IP 56enclosure has been on the market for over 10 years.

KDM as a premier manufacturer with a strong customer service approach, our extensive experience, in designing, engineering, and manufacturing capability enables us to meet the advancing needs of our clients. IP56 enclosure quality is essential to ensuring longevity and value for your money, which is why we strive to supply customers with high-quality, durable products that will stand the test of time.

With 10 years of manufacturing experienced, KDM has a team of the most creative & highly skilled professionals who use optimum quality raw materials and innovative technology in manufacturing. Our IP56 enclosure is crafted as per the standard guidelines and stringently tested on various quality parameters by our expert quality controllers. So you can guarantee that our IP56 enclosure is convenient, user-friendly and quality assured.

For further details in our IP enclosure, contact us today!

The Definitive FAQ Guide to IP56 Enclosures

- What does the IP code mean?

- What does IP56 mean?

- What is the difference between IP55 and IP56?

- What is associated with the letters after the main IP code?

- What testing do IP56 enclosures undergo?

- Can IP56 standards be converted into any NEMA type?

- Are IP56 enclosures explosion-proof?

- Do IP56 enclosures protect against corrosive agents?

- How do IP56 enclosures deal with thermal hazards?

- Where can IP56 enclosures be used and for what applications?

- What designs of IP56 enclosures can I choose from?

- How many doors can an IP56 enclosure have?

- What features can I request for IP56 enclosures?

- What accessories can I request for IP56 enclosures?

- Do locks, windows, vents, and hinges lower the IP rating?

- What different types of steel can be used for IP56 enclosures?

- Is fiberglass a good material for IP56 enclosures?

- Why use aluminum for IP56 enclosures?

- What paints and coatings can be used for IP56 enclosures?

- How do you customize the symbols or writing on an IP56 enclosure?

What does the IP code mean?

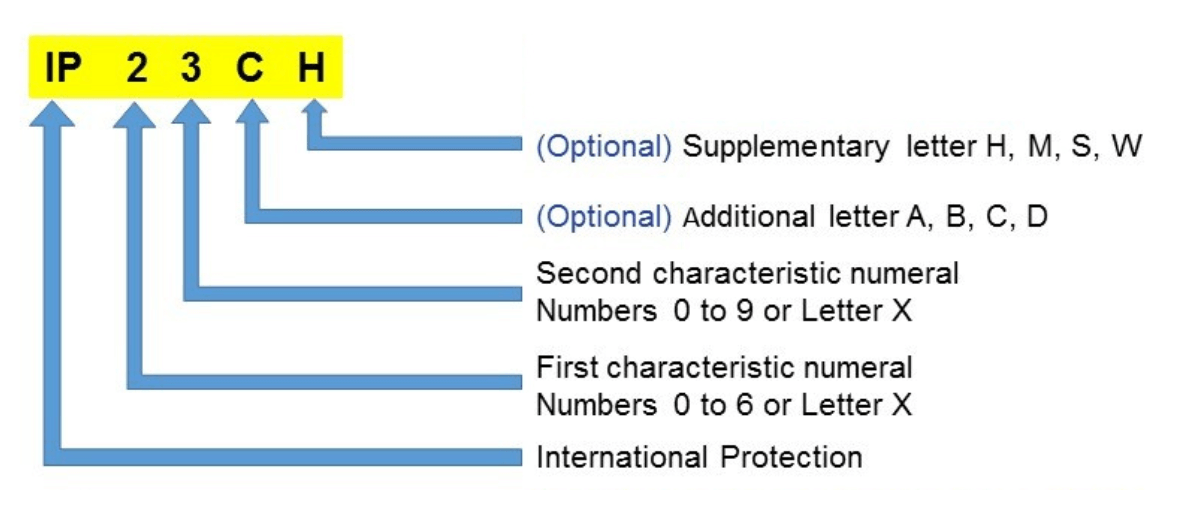

The IP code stands for Ingress Protection. It is also known as IEC standard 60529.

It is called EN 60529 in Europe.

It consists of 2 numbers after the IP.

The first number corresponds to the level of protection against the ingress of solids, whereas the second digit corresponds to the ingress of liquids.

For dust, the numbers go from 1 to 6, and for liquids, they go from 1 to 9K.

Enclosures with a dust rating of 1 would protect against anything that is bigger than 50 mm, or 1.9 in.

On the other hand, enclosures that are fully dust-tight protect against any solid particles.

IP chart

Enclosures with a liquid rating of 1 are effective against dripping water in an upright position, thus, they are protected against rain.

Meanwhile, 9K enclosures are able to withstand pressurized jets of hot water.

There can be a zero marked, which means no protection.

There can also be an “X” mark, which usually means that any number can be put there.

There can be other lettered markings as well.

What does IP56 mean?

Enclosures rated with IP56 are protected against limited dust ingress, and from high-pressure water jets from any direction.

Limited dust ingress refers to the fact that most dust cannot enter the enclosure, but a small quantity of it can.

However, the dust that does manage to get through is not enough to damage the electrical components of the enclosure or disrupt its work.

High-pressure water jets can be measured at 100 liters per minute and could be heavy rain, water spray from nearby machinery or marine environments.

IP56 enclosures are also stronger in environments with chemicals and corrosion since it has a good weather-proof rating.

Especially, IP56 enclosures are able to withstand the heavy seas, so they can be put in beachy locations, on ships, or near pools.

Also, places with fog and humidity will be okay as well.

IP56 enclosure

What is the difference between IP55 and IP56?

These two IP ratings are exactly the same in terms of dust protection, but IP56 can take on pressurized water jets, whereas IP55 is good only for splashes and low-pressure spray.

Both are very similar, but if your business involves a lot of water, then IP56 is better than IP55.

What is associated with the letters after the main IP code?

As we already mentioned the “X” means that there is no available information, or that it is irrelevant or replaceable.

There are 2 sets of optional letters you can add after the digits.

The additional set – A, B, C, D – describes the protection of the enclosure against tampering.

A stands for protection against the back of a hand; B stands for protection against a finger; C stands for protection against access with a tool, while D indicates for protection against access with a wire.

The supplementary set of letters – H, M, S, W – tell the user what the enclosure is for.

H tells that the enclosure can serve for a high-voltage device; M indicates that the device inside the enclosure was moving during a water test, whereas S means the opposite – that it was standing still.

Finally, W means that the enclosure is weather-proof.

The full IP code

You can use these to indicate what features you want your IP56 enclosures to have.

These are mainly used for better communication between the client and the manufacturer.

What testing do IP56 enclosures undergo?

IP5X is tested using a closed space where a vacuum attracts a lot of dust and different powder that is blown all around to the enclosure for 8 minutes, and then the enclosure is checked for dust ingress.

Dust chamber testing

IPX6 is tested using spray nozzles, measured at 12.5mm, with oscillating tubes that pressurize and spray water at 100 liters per minute for 5-10 minutes in any imaginable angle.

IP56 enclosures can also be submerged underwater for 2 minutes.

Can IP56 standards be converted into any NEMA type?

As for ネマ, we offer any type, starting with 1 and up to 13, including subtypes, such as 3X.

Our NEMAエンクロージャ are protected against weather, corrosion, coolant seepage, chemicals, and much more.

IP ratings and NEMA types cannot be directly converted into one another, but they can be loosely compared as shown below. ZZZZ

NEMA and IP rating comparison

As the table shows, there is no direct comparison, but there can be a close resemblance between IP56 and NEMA types 3, 3X, 3S, and 3SX.

Types 12, 13, and 5 are also fairly close.

These types are often used outdoors, protecting against rain, dust, snow, and sleet.

It is often used with junction boxes.

The type 3X is extra corrosion-resistant. Type 3S is aimed to protect from ice.

And, type 3SX has both properties.

Thus, you can get all these properties with IP56 as well.

Are IP56 enclosures explosion-proof?

Unfortunately, IP56 enclosures are not strong enough to contain an explosion or an arc flash.

They are not comparable to NEMA types 7, 8, 9, or 10.

These enclosures need to withstand high impacts and high temperatures.

As for arc flash, enclosures typically can’t protect from that, so personnel needs to keep that in mind.

However, if you need an explosion-proof enclosure, お問い合わせ and we will engineer it for you!

Do IP56 enclosures protect against corrosive agents?

IP56 is not fully waterproof, so it may not protect against corrosive agents if they are strongly sprayed on it or submerged in.

If they are just splashed, or even sprayed, then there is no problem, but corrosive fumes may still get in.

The material plays its role as well – aluminum and stainless steel are the most corrosion-resistant materials.

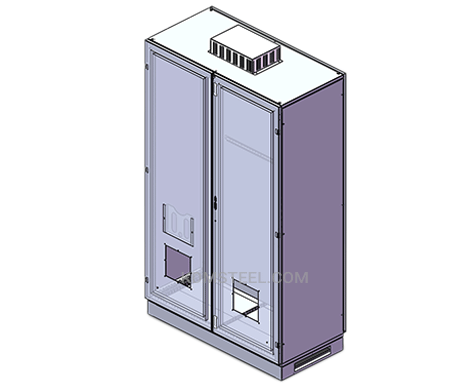

How do IP56 enclosures deal with thermal hazards?

KDM IP56 enclosures are equipped with double-wall technology, a thermal chamber, insulation, heat strips, heat exchangers, and vents with air conditioning.

All this provides protection from the electrical heat and solar radiation to prolong the life of electrical components within the enclosure.

Double-wall technology

Plus, thermal management reduces hot spots, equalizes pressure, and minimizes condensation, which can damage electronics and various devices.

Where can IP56 enclosures be used and for what applications?

IP56 enclosures can be used both indoors and outdoors in non-hazardous environments.

IP56 enclosures are commonly used in industry and factory

machinery/equipment, heavy-duty construction, swimming and spa pools, bathrooms, transformers, and medical equipment.

Some other applications include medical equipment, like a CPR machine, and even medications.

Other applications may be telecom cabinets or control boards, among other things.

This IP rating is perfect for outdoor environments because it is rain-proof and sufficiently protected against dust ingress.

IP56 enclosures are also well protected against tampering, just as any IP5X enclosure is.

IP56 outdoor enclosure

What designs of IP56 enclosures can I choose from?

We are pleased to offer you countless designs of free-standing enclosures, floor-mounted, wall-mounted enclosures, modular enclosures, junction boxes, and custom enclosures.

自立型エンクロージャ are perfect for large electrical units that are too heavy to be wall-mounted or pole-mounted.

They could be of any height and width.

They are also portable and can be walk-in enclosures.

自立型エンクロージャ

床置き型エンクロージャ are very similar to free-standing enclosures, only floor-mounted ones are secured to the floor – thus, they are not portable.

If you are mounting them into concrete, a guide plate or pedestal is needed.

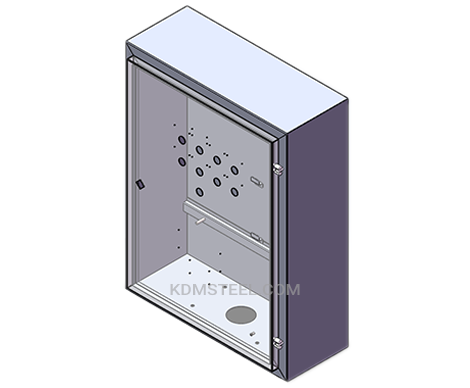

壁掛け式エンクロージャ use mounting brackets, screws, and pads.

They are perfect for small devices, and thus are cost-effective.

壁掛け式エンクロージャ

Modular enclosures are highly versatile and can be switched around, which is great for any application.

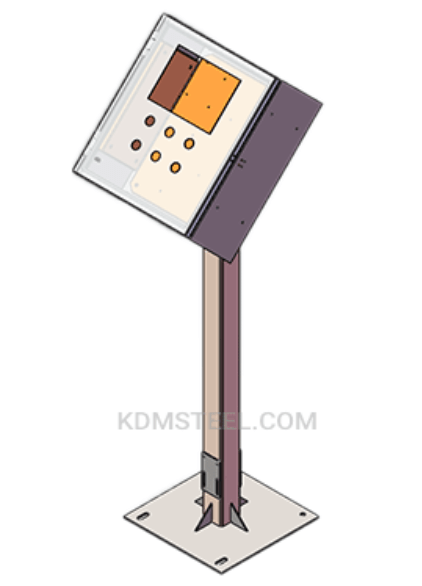

Junction boxes and operator interfaces are usually enclosures on a stand.

They have user-friendly layouts, are great for small electrical units, and can be portable.

These are the most common with IP56 enclosures that are used for control panels.

Junction box enclosure

Of course, we also have our custom enclosures, which can be of any design, shape, and requirements.

How many doors can an IP56 enclosure have?

Single doors are perfect for smaller and less complex electrical units, whereas double doors are used for large and complex units.

複数のドアは、大規模な産業用途やセキュリティ強化のために使用されます。

If you would like a consultation on our designs, you are welcome to reach out to us!

What features can I request for IP56 enclosures?

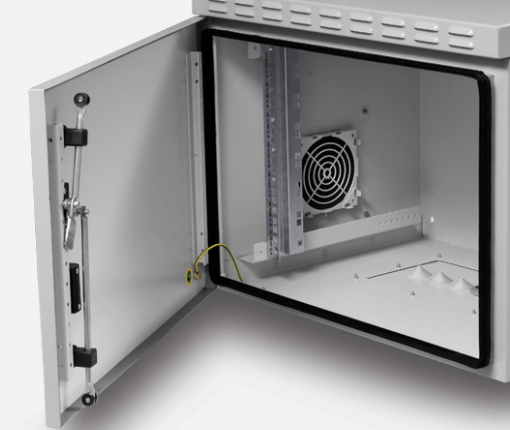

通気口、窓、蝶番付きドア、錠、ケーブル管理システムなどをリクエストできます。

通気口、および放射ファンは、熱を逃がす経路を提供し、筐体内の電気部品を冷却します。

これにより寿命が延び、故障の可能性も減ります。

筐体内の放熱ファン

これらは筐体内の空気圧を安定させ、筐体の電気部品を損傷する可能性のある結露を防ぎます。

Plus, the vents can be further upgraded to air conditioners and heat exchangers.

ウィンドウズ 担当者が迅速かつ非侵襲的な方法で電気部品を検査するのに役立ちます。

何か問題が発生した場合、ウィンドウによって何が起こっているかをすぐに確認できます。

さらに、赤外線窓は作業員を アークフラッシュ accidents.

Enclosure with window and casters

蝶番ドア 筐体のドアまたはカバーがどのように、どの程度開くかを制御します。

これには、リクエストできるさまざまなハンドルも含まれます。

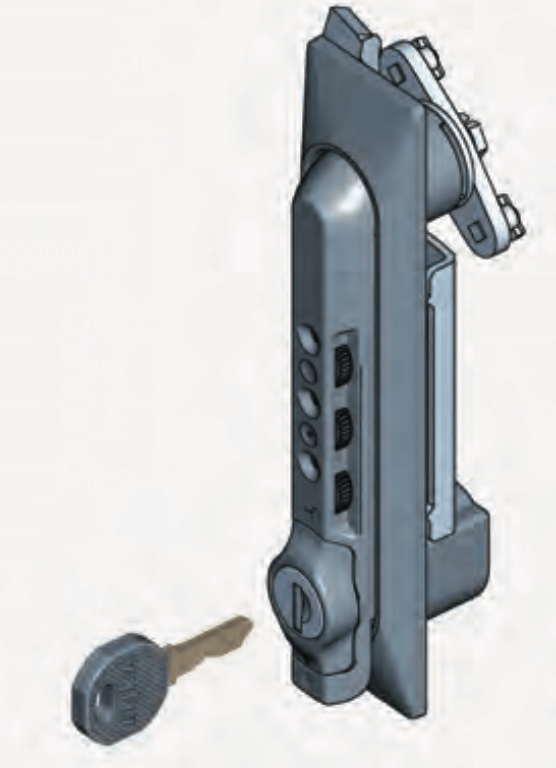

ロック add a layer of security to your IP56 enclosure, making sure no one tampers with it or accidentally accesses its electrical components.

Lock

What accessories can I request for IP56 enclosures?

File pockets are used to store files like operating manuals, shift logs, information booklets, and anything else important that pertains to electrical components within the enclosure.

File pocket

Cable management systems such as cable entry frames and clamps serve to keep wires organized and make them easier to install and maintain.

Solar shields are basically another layer on top of an enclosure that reflects solar radiation, controlling the inner temperature of the enclosure to prolong the life of its electrical components.

Solar shield (the top plate)

DIN rails are used to mount circuit breakers in equipment enclosures used in industrial applications.

We also make casters, thermometers, light switches, lifting eyes, operator devices, and purpose-specific features like keypads and heat exchangers.

To learn more, feel free to お問い合わせ for more information about all the different features and accessories we offer! We will also provide any custom feature you request.

Do locks, windows, vents, and hinges lower the IP rating?

Yes, features like vents, windows, and locks do somewhat compromise the IP rating, but there are ways around it.

But KDM overcomes this difficulty, offering you some of the best enclosures for your business.

We incorporate various gaskets, PU seals, latches, and filters to balance out the IP rating.

What different types of steel can be used for IP56 enclosures?

The materials used for IP56 enclosures aren’t different from materials used for other types of enclosures.

これらは 炭素鋼, 亜鉛メッキ鋼、 そして ステンレス鋼 – 通常はグレード 304、316、または 316L です。

炭素鋼は通常、ステンレス鋼よりも鈍いです。

鉄と炭素のみで構成されているため、磁性があり、より展性があります。

This steel is also prone to corrosion.

ステンレス鋼は、鉄と炭素の合金にクロム、ニッケル、モリブデンを加えて作られます。

ステンレス鋼と亜鉛メッキ鋼

鋼種 304 と 316 では、すべての添加剤の含有量が異なります。

Grade 316 is slightly stronger and resistant to saline and acidic water because of molybdenum.

But grade 304 is cheaper and more common.

Grade 316L has a lower carbon content, making it a little bit stronger.

亜鉛メッキ鋼 腐食を防ぐ亜鉛の保護層でコーティングされています。

We have galvanized steel enclosures, and this metal is vulnerable to salt water.

Please note that galvanized steel is more expensive and heavier than stainless steel.

Another type of steel that can be used is cold-rolled steel, which is thinner and denser than normal steel – and thus, it is stronger.

さらに詳しく知りたい方は、 お問い合わせを送信 今すぐご相談ください!

Is fiberglass a good material for IP56 enclosures?

グラスファイバー 非常に強力で、熱を放散し、電気を絶縁し、干渉の影響とショックの可能性を低減します。

プラスチックの中にガラス繊維を入れて作られています。

Fiberglass enclosures can be up to IP65, so IP56 is possible.

Fiberglass is also effective against corrosion.

ファイバーグラス製筐体

Speaking of plastics, we can include windows made from polycarbonate and ABS.

ポリカーボネートは腐食に強いですが、ABS は安価です。

Why use aluminum for IP56 enclosures?

IP56 enclosures can also be made from aluminum alloys.

They are not necessarily better than steel alloys but can be depending on what you are going for and what are your needs.

鋼のグレードと同様に、アルミニウム合金は 5052 シリーズまたは 6061 シリーズのいずれかになります。

アルミニウムとステンレス鋼

どちらも軽量ですが、5052 は溶接性に優れ、6061 は耐腐食性に優れています。

また、6061 の方が高価です。

アルミニウムの表面には腐食を防ぐ酸化物の層があります。

This material is especially good for enclosures exposed to solvents, petrochemicals, some acids, most sulfates, and nitrates.

So, if you are looking to put IP56 enclosures in such mildly hazardous environments, aluminum is good for that.

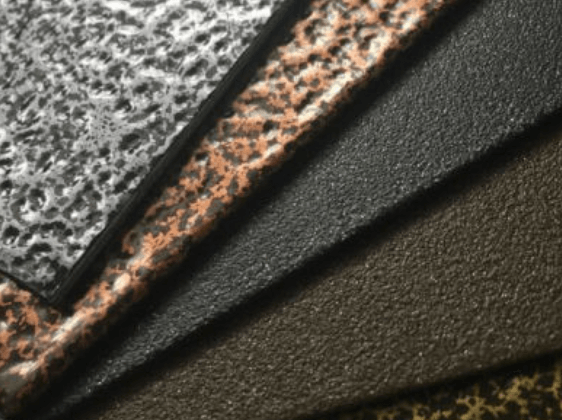

What paints and coatings can be used for IP56 enclosures?

当社の筐体は十分に保護されていますが、適切なコーティングを施すことでさらに保護を強化できます。

任意の色のエナメル塗装または粉体塗装を選択できます。

エナメル塗料 光沢のある仕上がりで、さまざまな気象条件に耐性があります。

エポキシエナメルや PU エナメルなどの特殊なエナメル塗料は、耐腐食性があるため、工業用筐体によく使用されます。

粉体塗料 is deposited with the electrostatic force and is quicker and easier than enamel.

粉体塗装仕上げ

陽極酸化処理やアルダイニングコーティングも承ります。

陽極酸化処理 コーティングでは、陽極を使用して金属(通常はアルミニウム)を酸化し、厚さを増やして耐腐食性を高めます。

鋼鉄は、金属の腐食を早める可能性があるため、通常は陽極酸化処理されません。

アロジンコーティングとも呼ばれる クロメート化成コーティングは、塗装の下地として鋼鉄やアルミニウムに使用され、腐食を防止します。

外観もより柔軟で、光沢仕上げとマット仕上げのオプションが用意されています。

アロジンコーティング

これは陽極酸化処理よりも安価なプロセスであり、塗装されていない限り、特徴的な緑がかった黄色の色合いで認識できます。

あらゆる色と仕上げのコーティングをご提供できますので、 お問い合わせ 今日!

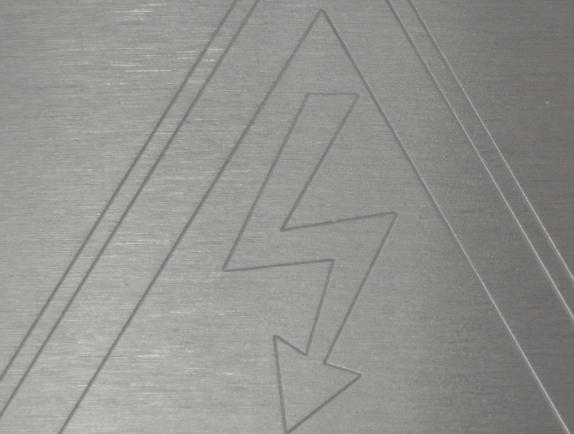

How do you customize the symbols or writing on an IP56 enclosure?

当社のカスタマイズサービスには、彫刻やシルクスクリーン印刷が含まれます。

Silk Screening is the easiest and most affordable method to customize an enclosure.

Any flat side of the enclosure can be silk-screened with labeling operators, serial number, your company name, and logo.

Examples of operators include emergency stop and gas detection among others.

ただし、ステンレス鋼やアルミニウムなどの金属にシルクスクリーン印刷すると、摩耗したり傷が付いたりすることがありますが、透明な粉体塗装を施すとそれを防ぐことができます。

シルクスクリーン

エンクロージャに彫刻を施すことは、エンクロージャをカスタマイズするもう 1 つの方法です。

このオプションはシルクスクリーン印刷よりもコストがかかり、時間もかかりますが、より長期にわたります。

ロゴやシンボルのデザインでは、筐体の表面から少しの金属が取り除かれます。

Usually, about 0.005 inches or 0.010 inches of metal is removed.

金属が取り除かれたら、ご要望に応じて任意の色のエポキシ塗料で塗りつぶします。

彫刻

There can also be anti-graffiti and anti-poster coatings to protect your IP56 enclosure from vandalism.