電気筐体溶接

When you’re building enclosures, it is vital to get reliable welding to keep the computers and cabinets.

Electrical enclosure welding is a type of fabrication technique that involves fusing two or more parts together by means of heat or pressure or both.

It is the art of heating the metals to melting point and allowing the parts and filler metal to flow together.

Ideally, welding is generally a diverse technology encompassing different processes.

Welding

- Main Types Of Electrical Enclosure Welding Services At KDM Steel

- Factors That Make KDM Steel Electrical Enclosure Welding Unique

- How KDM Steel Finishes The Welds

- Types Of Material KDM Steel Weld For Electrical Enclosures

- Common Gases Mixes For Electrical Enclosure Welding Services

- Why You Should Consider KDM Steel For Electrical Enclosure Welding Services

Main Types Of Electrical Enclosure Welding Services At KDM Steel

KDM steel has decades of experience in welding different complex and straightforward electrical enclosures.

We have a skilled workforce providing a full range of welding services for these parts. Specifically, we offer the following types of electrical enclosure welding services;

MIG (Metal Inert Gas)

This process uses a continuously fed, solid wire electrode through a welding gun.

The welding gun is triggered to feed the consumable electrode. It leads to formation of electric arc between electrode and base material heating and causing it to melt and join.

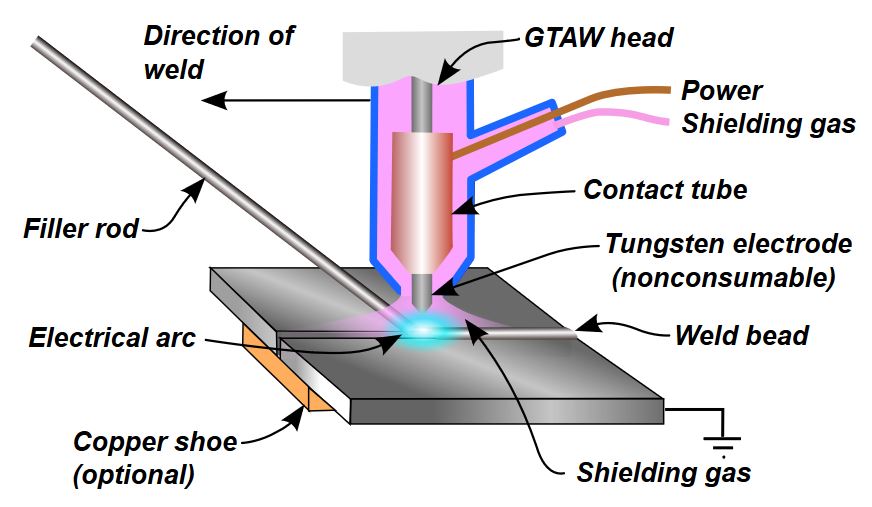

TIG (Tungsten Inert Gas)

It is a welding process, which uses a non-consumable tungsten electrode to heat the base material to form a molten weld puddle.

A no-filler metal weld can be created by melting two pieces of metal together.

You can add an external filler rod in molten puddle to form a weld bead and increase the mechanical properties.

Stick

It is a welding technique, which uses an electrode (welding rod) to carry the electric current and carry electric current and provide majority of weld metal.

The welding rod consists of core wire coated in flux. An electric arc forms across the gap when energized circuit and electrode tip touches workpiece and is withdrawn

Fluxcore

This welding process uses a continuously fed electrode and a tubular wire filled with flux rather than solid wire.

The flux-cored wire welding process is available in two types; self-shielded and dual-shield.

Self-shielded option hardly requires aid of an external shielding gas shield. Instead, it uses flux to shield molten weld puddles.

Dual shield option uses flux and external shielding gas for protecting the molten weld puddle.

Laser

It is the process for joining electrical enclosure using a laser to provide a concentrated heat suitable for barrow, deep welds, and high joining rates.

Laser welding is easily automated, making it perfect for high-volume applications.

Factors That Make KDM Steel Electrical Enclosure Welding Unique

Welded electrical enclosure

Simply put, KDM steel offers incredibly fast welding services for all your electrical enclosure welding solutions.

We offer a wide range of welding options, including the ones mentioned above.

Thus, it is easy to pick the right technique based on the specific desired results and other factors such as the primary material.

We have exceptional experience in this industry, providing different electrical enclosure welding services.

For many years, KDM Steel has been integrating various techniques to ensure it meets the industrial demands.

In essence, it has enabled the company to grow and become among the most sought-after in the market for welding solutions.

The overall workmanship quality we offer at KDM Steel for your electrical enclosures is beyond reproach.

In simple words, we weld electrical enclosures with fine and spotless surfaces giving a clean a polished look from outside.

All the hardware and weld marks on our electrical enclosures are secured inside.

Our enclosures welding services ensure the entire face of a fastener is held accordingly. Of course, this is essential since it creates secure and even seismic electrical enclosures.

Most importantly, KDM Steel offers affordable welding solutions for a variety of electrical enclosures.

How KDM Steel Finishes The Welds

Ideally, different electrical enclosure welding tasks have varied requirements.

However, KDM Steel welders often grind, polish, and descale the welds.

We prepare the welded surface for painting then prime the prepared electrical enclosure services once the welding process is complete.

Nevertheless, the final design requirement is based on individual customer’s preferences.

Types Of Material KDM Steel Weld For Electrical Enclosures

At KDM Steel, you can find electrical enclosures made of different base materials.

Of course, the choice is often based on specific customer’s needs and preferences.

However, we ensure that we provide electrical enclosure welding services for both common and more exotic metals.

Here are some of the varieties our welders have experience in fabricating for these components;

- アルミニウム

- Low carbon steel

- ステンレス鋼

- High-speed steel

- Air hardening alloys

- Oil hardening alloys

- Titanium

- Chrome-moly

- Inconnel

- Powdered metals

- Shock resisting metals

Common Gases Mixes For Electrical Enclosure Welding Services

KDM Steel provides a wide range of options as far as choice for ideal gas mixture for welding electrical enclosures is concerned. Some of these options include the following;

100% CO2 – Offers greatest penetration and higher levels of spatter. Additionally, this gas is somewhat the lowest price.

75% Argon, 25% CO2 – Relatively expensive and often used for small-scale electrical enclosure welding and related services.

It exhibits lower spatter and flatter weld bead levels than 100% CO2.

85% Argon, 15% CO2 – It is also comparatively costly but offers an excellent combination of lower spatter levels and excellent penetration.

This gas mixture is suitable for fabricating electrical enclosures made using heavier plates. It can be used in short circuits, spray, pulse, and globular transfer.

90% Argon, 10% CO2 – Relatively expensive and exhibits a good combination of good penetration and spatter levels for various steel electrical enclosures.

Why You Should Consider KDM Steel For Electrical Enclosure Welding Services

KDM Steel has provided expert electrical enclosure welding solutions for over 10 years.

We strive to constantly stay steps ahead of our competitors. Additionally, we have top-of-the-line equipment and professional expertise, guaranteeing you the best results possible.

We can provide welding services for any type of electrical enclosure.

Moreover, if you are in a hurry and need relatively bulk order, we provide a “rush order” option to guarantee a faster production turnaround.

KDM Steel produces prototypes and samples depending on customer’s preference and situation.

However, we have adequate capacity to conduct R&D and developing the specific prototype you may need as your electrical enclosure.

Contact us now for all your electrical enclosure welding.