Stainless is magnetic and non-magnetic depending on the type. You will realize that this depends on the type of stainless steel.

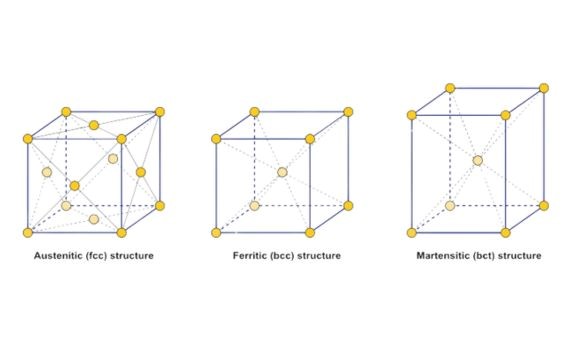

Examples of magnetic stainless steel are Ferritic and Martensitic. Austenitic is an example of a non-magnetic stainless steel.

Is Stainless Steel Magnetic

Whether or not stainless steel is magnetic is a question many ask.

A simple answer is yes and no. Despite being described as one material, stainless steel has many components with different qualities. It has other elements and metals for example iron and chromium.

The existence of factors like iron presence and crystalline structure influence stainless steel’s magnetism.

The presence of a martensitic and Ferritic structure brings magnetism while an austenitic structure brings about non-magnetism.

Factors Contributing to Stainless Steel Magnetism

· Iron Presence

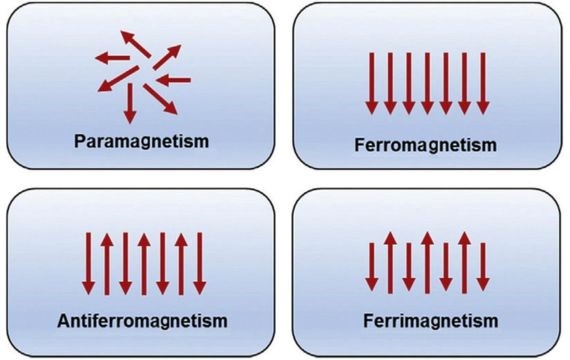

Stainless steel contains iron in its composition. Iron consists of small magnets called spins. When randomly arranged, Spins cancels each other’s magnetic effect which can lead to a lack of magnetic properties.

At times, spin arrangement aligns them forming a net magnetic moment and this creates a magnetic material. This unique structure makes it to attract magnets. Iron is a ferromagnetic element and thus exhibits magnetic properties.

· Crystalline Structure

This is the arrangement of atoms that determines its alignment and magnetic properties. A smooth alignment favors magnetism while difficulty in alignment causes non-magnetism in stainless steel.

Ferritic and martensitic structures are magnetic. The austenitic structure is nonmagnetic. The austenitic structure contains a face-centered cubic arrangement. The constant thermal motion disrupts the arrangement of iron atoms which results in non-magnetism.

Ferritic structure has a body-centered cubic arrangement. Their arrangement is not perfect which makes their magnetism weaker than that of martensitic structures. Here, tiny iron magnets are put together.

Martensitic steel has a tetragonal structure that aligns atoms neatly. The neat arrangement leads to a strong magnetic attraction.

·Processing impacts

Processes can include cold working and heat treatments. Cold working alters the crystal structure in stainless steels making them nonmagnetic. Heat treatments tamper with the internal structure of stainless steel. It alters the way atoms align, influencing their magnetic behavior.

An example is annealing an austenitic stainless steel at high temperature. This causes atoms to move randomly disrupting the alignment of magnetic moments, resulting in the non-magnetism of austenitic stainless steel.

· Other elements

Different elements act together. Each element added to stainless steel brings its unique atomic characteristics, impacting its magnetic properties. Manganese, for example strengthens the ferritic chorus, amplifying their harmonious pull.

Molybdenum boosts ferritic grades, it adds its own pull, magnetism in ferritic grades by contributing its own pull in some types of steel

Comparing Magnetism in Different Types of Stainless Steel

Now, let’s compare magnetic properties among various types of stainless steel:

· Martensitic Stainless Steel

Most of the martensitic steels are magnetic. A martensitic stainless steel may contain some fragments of iron which sometimes are magnetic. Martensitic stainless steel exists in various grades which include 410, 420, and 440. You can use this stainless steel for applications like cutlery and actuators.

· Ferritic Stainless Steel

It is a type of stainless steel that is magnetic. This is because of the presence of ferrites that are in large quantities. The crystalline structure of ferrite, combined with the presence of iron, allows for the alignment of iron atoms, creating a magnetic field.

However, when you compare ferritic stainless steel to martensitic stainless steel, they have a weak magnetic pull. They include Stainless steel grades 439, 430, and 409. They apply to budget-friendly applications like appliances and building materials.

· Austenitic Stainless Steel

Most of the stainless steels under the austenitic category are non-magnetic because of high austenite levels. Despite having iron, alloys like grades 306 and 304 are nonmagnetic because they hold an internal structure that is known as face-centered cubic. This structure disrupts the arrangement of irons resulting in non-magnetism.

However, you can make them partially magnetic by using a thermal process or work hardening like bending. This can form ferrite in some locations. Because of that, austenitic grades exhibit a slight magnetism at mechanically operated edges. They are useful in applications like medical implants and food processing equipment, where non-magnetic behavior is crucial.

· Duplex Stainless Steel

It is magnetic and also has greater corrosion resistance than ferritic grades. It is more expensive than austenitic 304 and 316 steels. It mixes austenitic and ferritic crystals offering a combination of both. You can use it in applications such as pressure vessels and offshore structures.

Factors Affecting Stainless Steel Magnetic Properties

· Heat Treatment

Heat treatments can dramatically tamper with the internal structure of stainless steel. This then alters how atoms align affecting their magnetic behavior. Promptly cooling austenitic steel from high temperatures, like quenching, traps iron atoms in their magnetic alignment, making the steel magnetic.

Aging austenitic steel at certain temperatures prompts the creation of martensite, a magnetic phase, hence causing the steel to become magnetic. Annealing an austenitic steel at high temperatures disrupts the alignment of magnetic moments, making the steel non-magnetic.

· Allowing Elements

Different elements act together. Each element added to stainless steel brings its unique atomic characteristics, impacting its magnetic properties. Manganese, for example, strengthens the ferritic chorus, amplifying their harmonious pull.

Chromium for sabotages iron’s magnetic influence. The more the percentage of chromium in steel the less magnetic it becomes. As its influence grows, the magnetism weakens. Nickel suppresses the austenitic grades, silencing their magnetic hum.

Molybdenum boosts ferritic grades, it adds its pull, magnetism in ferritic grades by adding its pull in some types of steel

· Temperature

Rising temperatures: As a magnet heats up, the electrons responsible for its magnetism begin to move around randomly. As the temperature rises, these atomic magnets become more energetic and vibrate more, disrupting their aligned formations. This messy arrangement weakens the overall magnetic field of the magnet.

Cool down, power up: On the other hand, cooling a magnet has the opposite effect. The electrons calm down and settle into a more organized formation. This uniform alignment strengthens the magnetic field, giving the magnet a magnetic boost.

Uses of Stainless Steel Based on Magnetic Properties

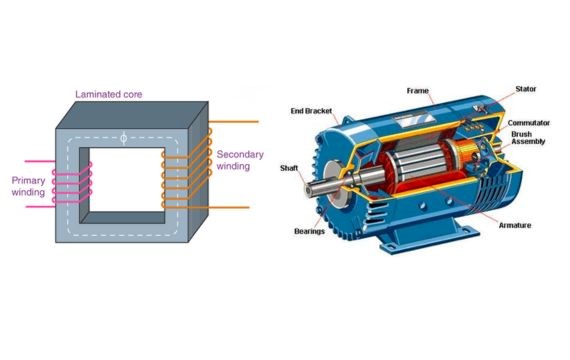

· Transformers

The high magnetic permeability grades of certain stainless steels, like 17-4PH, allow for efficient conduction and concentration of magnetic flux.

This leads to less energy being lost as heat due to reduced eddy currents and hysteresis losses. It also leads to a smaller core size saving weight and space.

· Motors

Using magnetic stainless steel strengthens the magnetic field in motors, resulting in higher torque. This increased torque allows motors to produce more force for a given size, making them suitable for demanding applications.

Additionally, stronger fields enable miniaturization, allowing for smaller motors with equivalent power output.

· Actuators

These grades excel in actuators demanding precise control, thanks to their ability to manipulate magnetic forces. This translates to highly accurate and consistent movement.

· Sensors

By tailoring these grades, we create sensors with enhanced sensitivity, allowing them to detect weaker magnetic fields with improved precision and range. Furthermore, specific properties enable faster changes in magnetic flux, resulting in quicker sensor response times.

· Medical Applications

It uses electromagnets in medical imaging to make diagnostics. It is used in magnetic shielding such as shielding Magnetic resonance imaging machines from external magnetic for accurate imaging. Biocompatibility: Certain grades are MRI-compatible and safe for medical use.

More resources:

Stainless Steel Magnetism – Source: KDM

Magnetic Properties of Stainless Steel – Source: BEMAGNET

Stainless Steel Sheet Metal Fabrication – Source: KDM