KDM aluminum extrusion enclosure is designed to achieve the different hardware housing needs. KDM aluminum extrusion enclosures are suitable to be used in industrial and commercial instruments and equipment

KDM offer a comprehensive range of high-quality enclosure design and looks. They are built to associate a wide variety of components and materials enclosure. For any order needed, we can provide expert and economical cabinet products and services. We are engaged to design fully finished quality looks enclosures.

However, we are able to completely customize the aluminum extrusion enclosures with custom cut-outs, mounting options, and other objects for stronger uses. The extruded aluminum enclosure is consist of sheet and boards which make the cabinet more reliable.

- 10 years experience in manufacturing extruded enclosure

- High-quality aluminum extrusion enclosures freely customized

- All cabinets made from high-grade aluminum alloy

- Competitive pricing aluminum extrusion enclosures will meet your needs absolutely

KDM Aluminum Extrusion Enclosure Series

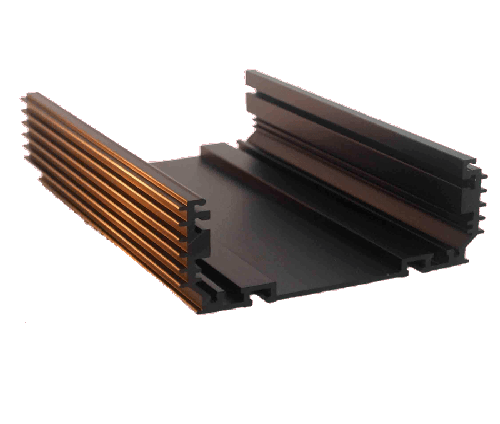

The aluminum extrusion heatsink enclosure is designed to provide specific cooling solutions to the components. These are manufactured in advanced and modern technology.

The aluminum extrusion enclosure can be custom-built according to every project’s requirements. In order to achieve site needs, we offer bespoke services to meet application demand.

The large box aluminum extruded enclosure creates an extremely robust yet lightweight solution. We offer a wide variety of components materials and sizes at affordable rates.

Split-body extruded aluminum enclosure provides protection with superior fit and finishes on the system. All the enclosure is can be customized according to their own design and specifications.

RoHS & CE Certified anodized aluminum extruded enclosure can be avail at a very competitive cost. Expect a high-quality enclosure that will meet the standards need of your unit.

The industrial aluminum extruded enclosure combines with advanced technology and high-grade materials. They are made with beautiful designs and enhance the life of the enclosure.

Send your Inquiry on KDM Aluminum Extrusion Enclosure

In KDM, you can find the right product for you. Our range of products will help you find what you’re looking for. You can choose a product according to the price range, or specifications you need for your requirements. Our selection of aluminum extrusion enclosures is actively growing, in order to meet the developing industry standards. In KDM, you will find the highest quality standard aluminum extrusion enclosure for your project.

- Robust and rugged structural construction

- Professional engineers to manage designing and engineering

- Custom structure length, width, height, and other features

- ISO9001:2015 certified aluminum extrusion enclosure supplier

Related Product with Aluminum Extrusion Enclosure

KDM Aluminum Extrusion Enclosure

They effectively protect the enclosed valuable units.

Our enclosure is well-made using the finest quality material.

The inner and outer dimensions approximately meet the specific standard for the material being housed.

Over the years, our enclosure had been popular aluminum extruded enclosure by its great quality.

Thus, its affordability makes it ideal for any customer to need a product at an economical cost.

The extruded aluminum enclosures manufactured by KDM allow you to meet your standards.

This enclosure can be used as free-standing, wall mounting, surface mounting, and more.

All enclosure provides the perfect packaging solution for every kind of valuable electrical and electronics.

These are extremely robust but lightweight enclosures.

For any industrial and commercial boxes projects and applications, this offered good workability and appearances.

It also provides great corrosion resistance and good work for thermal and cooling solutions.

All extruded aluminum enclosures provide a higher degree of stability and good heat dissipation.

It has also an attractive design and functional features.

Our range of aluminum enclosures can be used in radiators, large buildings, instruments, medical, machinery, and other applications.

KDM is one of China’s leading manufacturers and suppliers with over 10 years of experience.

Our main focused is to develop the highest quality extruded aluminum enclosures products.

From the start our every single element is individually processed into the precise dimensions, space, functional features, and all other factors.

In our state-of-the-art control room and facility, we are able to design intelligent technology.

We want to meet the elegant demands of our customers and hereby we want to satisfy yours too.

With your own special requirements, we can provide particular solutions upon request.

Our vast experience and resources in manufacturing enclosures enable us to offer the most comprehensive product line.

Our facilities are certified to ISO 9001:2015.

We offer full capabilities to fabricate components.

If you are interested in our extruded aluminum enclosures, KDM is your answer.

Contact us now.

What is Aluminum Extrusion Enclosure?

An aluminum extrusion enclosure has internal slots.

It is suitable for standard PCBs to slide into place without screws required.

The aluminum extrusion enclosure can be available with diecast end caps.

This can produce an extremely durable and lightweight solution.

It also has a Grooved exterior for faster heat removal.

What is the Purpose of Aluminum Extrusion Enclosure?

The aluminum extrusion enclosure offers great protection for various electronics, such as PCBs.

Moreover, it provides EMI/RFI protection for your device or electronic applications.

What is the Application of Aluminum Extrusion Enclosure?

An aluminum extrusion enclosure is widely used for the following:

- audio amplifier

- measuring instruments

- network devices

- FA control boxes.

Diecast Aluminum Enclosure vs. Aluminum Extrusion Enclosure, Which Type is Right for Me?

Extrusion and diecasting are the most common metal shaping methods.

Before choosing aluminum enclosures, you need to take them into considerations.

Below are the pros and cons of every technique to ensure the right aluminum enclosures you need.

Diecast Aluminum Enclosure

It is a popular metal fabricating method that involves pressing molten metal to a closed mold.

As a result, it can create the desired shape.

The diecast aluminum enclosure is suitable for both outdoor and indoor applications.

For example, this type of enclosure is widely used to protect the meter and switchboard cases in different industrial areas.

It also is found in healthcare instruments because of its natural level of RFI/EMI protection.

Pros

Diecasting methods are suitable for complex parts.

Another advantage of diecasting methods is that it evolves in lighter, thinner walls with attractive surface finishes.

Cons

The diecast aluminum enclosure has EMI shielding and corrosion resistance properties.

That’s why most design engineers choose this kind of technique.

However, the diecast aluminum enclosure has a high upfront cost, which is ideal for high-volume production.

One of the common problems of this method is porosity.

It leads to an air entrapment inside the metal dies.

Aluminum Extrusion Enclosure

This method includes taking aluminum into extrusion presses.

An aluminum extrusion enclosure can resist a degree of water and dust.

You can use it for both outdoor and indoor applications.

It can be found in the internet of things, medical, sensors, and data system applications.

Pros

An aluminum extrusion enclosure provides numerous advantages for engineers.

Most of this enclosure provides unique features that protect different environmental factors.

This enclosure also makes the installation faster since the PCBs can be slid into place easily.

The aluminum extrusion enclosure has outstanding heat dissipating properties.

As a result, it ensures high temperature without damaging sensitive PCB components.

Cons

The aluminum extrusion enclosure processes create limited counts of shapes.

In this method, there are several constraints on assembly.

Moreover, its end caps need to be manufactured separately.

What is Aluminum Extrusion Enclosure Made of?

The enclosure is manufactured of two side rails or aluminum extrusions.

It comes with rear, top, front, and bottom panels.

This enclosure can be available in two 6063 aluminum extrusions, such as:

- 1U (Height: 43.688mm/1.72 inches)

- 2U (Height: 88.138mm/3.47 inches)

The bottom and top panels of the enclosure are made of 5052 aluminum with a size of 0.064 inches to fit its slot.

Their rear and front panels are also 5052 aluminum.

What Are the Available Finishes for Aluminum Extrusion Enclosure?

There are various finishes of aluminum extrusion enclosure applied for part-by-part or all four panels, such as:

- Masking

- Vibratory finish

- Grained finish

- Anodisasi

- Chem-film coating

- Powder-coat