- Affordable NEMA Enclosure Solution

- Certificación IP65/IP66

- Fast Enclosure Sample Production

Custom NEMA 3R Enclosure Manufacturer in China

At KDM, we produce and designed high-quality NEMA 3 enclosures to withstand tough environments. We have a variety of styles, sizes, types, and materials NEMA 3 enclosures for you to choose from, all at affordable costs. For even more options, such as alternate locking, latching mechanisms, and more, you can select from our wide selection of enclosures that exceeds NEMA 3R rating.KDM is a professional NEMA enclosure manufacturer, an expert in manufacturing enclosures depending on the client’s requirements and applications. For the past 10 years, we have worked with thousands of clients. We have the expertise to help you with each stage of the process.

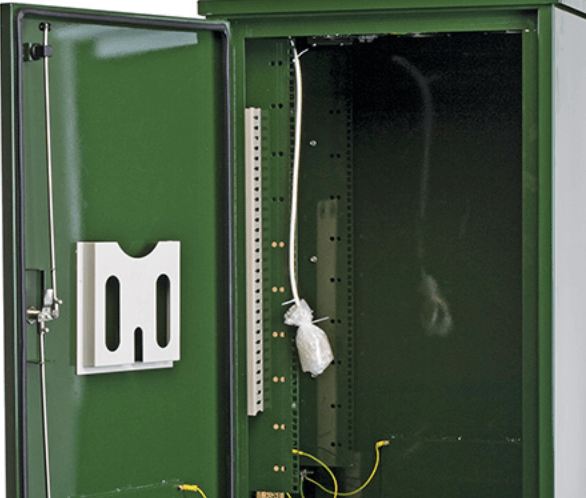

KDM NEMA 3R enclosure is intended for outdoor use primarily to provide additional protection to the components against rain, sleet, snow, water, dust, and damage from external ice formation. KDM NEMA 3 enclosure is commonly used in switch gears, lighting contractors, power distribution, housing, and other electrical appliances that require protection in an outdoor environment that were mentioned above.

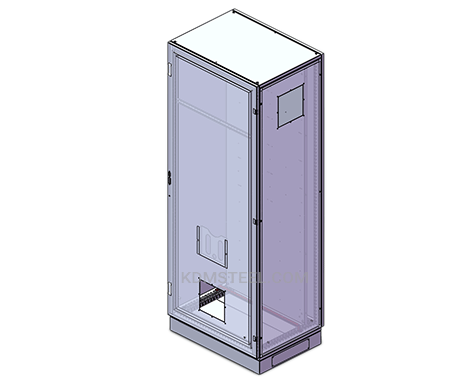

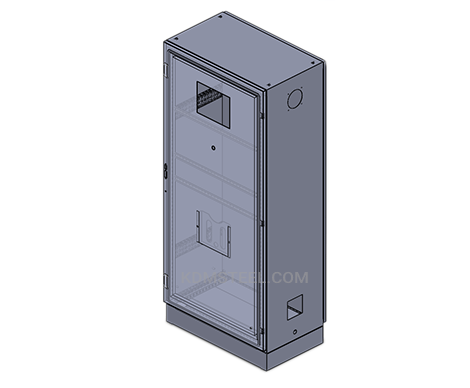

KDM NEMA 3R Enclosure Series

Send your Inquiry on KDM NEMA 3R Enclosure

At KDM, we produce and designed high-quality NEMA 3 enclosures to withstand tough environments. We have a variety of styles, sizes, types, and materials NEMA 3 enclosures for you to choose from, all at affordable costs. For even more options, such as alternate locking, latching mechanisms, and more, you can select from our wide selection of enclosures that exceeds NEMA 3R rating. We use the 316 stainless steel, 304 stainless steel, carbon steel as the enclosure panel. We provide a 1-year warranty for KDM NEMA enclosure, you will get free enclosure accessories within our warranty.

- Capacidad de fabricación

- Guía de compra

Máquina de corte láser de alto rendimiento de 4000 W, precisión de +/- 0,05 mm. Sin rebabas ni rayones.

Equipo de soldadura flexible multifunción, alta precisión, sin deformación.

Precisión de doblado de +/- 0,5 mm, superficie lisa sin marcas de doblado.

Más de 10 trabajadores con experiencia en soldadura, apariencia general perfecta.

Máquinas de espumado de alta velocidad y precisión, empaquetadoras rápidas y calificadas.

El equipo de montaje experto, calidad de montaje constante en cada carcasa KDM

KDM NEMA 3R Enclosure

Apart from the protection, KMD NEMA 3R enclosure offers from the environmental factors, NEMA type 3R enclosures from KDM is able to protect the live appliances from high water levels in case of floods. It has a provision for drainage, alternate latching and locking mechanisms.

Somehow, KDM NEMA 3R enclosure can be used in indoor environments, it protects against dripping water and provides much more protection to personnel against incidental contact with enclosed equipment. Besides, the protection against any form of contact with the material that has been enclosed.

KDM NEMA 3R enclosure does not have a gasket sealing surface. Some models have hasps for padlocking, new models include galvanized steel units and larger sizes with hinge covers.

NEMA 3R enclosures are designed very similar to NEMA 3 enclosures, however, 3R enclosures can be ventilated. Enclosure ventilation is typically accomplished through the use of louvered openings to filter the air within the enclosure, and necessary for a vented battery enclosure. When ventilated, the additional protection provided by NEMA 3R enclosures against windblown dust lessen.

KDM NEMA 3 enclosure offers unbeatable value in the market. Our NEMA 3R enclosure conforms to the NEMA 250-2014, RoHS, CE, ATEX, IECEx, EN / IEC 60529 and CSA for electrical enclosures.

KDM NEMA 3R enclosure manufactured using advanced technology and automated tools. Set standards materials for electrical and telecommunications equipment. This improves safety, economics, and communication for us as a manufacturer as well as the user. For custom NEMA 3 enclosure, you can send us specific sizes, lay outs, and designs. Furthermore, KDM offers custom powder coating and silk-screening.

At KDM, you can easily find the right NEMA 3R enclosure solutions for your needs. We also provide custom NEMA 3R enclosure to provide what exactly you need. No matter what your design requirements are, we can help you develop the perfect NEMA 3 enclosure that fits your needs and work well for your business. Take the frustration out of the side of your business and rely it on us, contact us today!

The Definitive FAQ Guide to NEMA 3R Enclosures

- What does NEMA Type 3R mean?

- How is NEMA 3R different from NEMA 3, 3S, 3X, etc?

- How are NEMA 3R enclosures structurally different from NEMA 3?

- Are NEMA 3R enclosures used outdoors?

- Do NEMA 3R enclosures protect from corrosion?

- What are common applications for NEMA 3R enclosures?

- How are NEMA 3R enclosures tested?

- How can I be sure of the quality of NEMA 3R enclosures?

- What is NEMA 3R in IP standards?

- What are common designs for NEMA 3R enclosures?

- ¿Qué características adicionales suelen incluirse?

- ¿Los orificios, las rejillas de ventilación, los accesorios, etc. afectan la clasificación del gabinete?

- Can NEMA 3R enclosures protect from cold?

- What materials are used for NEMA 3R enclosures?

- What paints and coatings can be used for NEMA 3R enclosures?

- What are some ways to put symbols on a NEMA Type 3R enclosure?

- ¿Qué más debo tener en cuenta al pedir un gabinete?

What does NEMA Type 3R mean?

NEMA significa Asociación Nacional de Fabricantes Eléctricos.

NEMA Type 3R is meant for use both indoors and outdoors.

The enclosure protects inside equipment from snow and sleet, and guarantees that everything will work even if the enclosure is covered with ice.

Also, 3R enclosures guarantee that any external mechanisms covered in ice will still work well.

How is NEMA 3R different from NEMA 3, 3S, 3X, etc?

NEMA 3R is the same as NEMA 3, except it does not offer as much protection against windblown dust, so it is better for cold inside applications like freezer rooms.

This is because 3R usually lack a few gaskets that other NEMA 3 enclosures have.

NEMA 3S is the same as NEMA 3R, but also ensures that any external mechanism is still operable when covered with ice.

NEMA 3RX includes added protection against corrosion.

There could also be enclosures with a subtype rating NEMA 3SX.

Subtypes of NEMA 3

How are NEMA 3R enclosures structurally different from NEMA 3?

NEMA 3R enclosures have drainage openings that prevent accumulation of liquid at the bottom of the enclosure.

This, along with a lack of some sealing gaskets, leads 3R to be vulnerable towards windblown dust.

Are NEMA 3R enclosures used outdoors?

Yes and no.

NEMA 3R enclosures do protect against water ingress, as well as snow and sleet, but not from windblown dust.

Thus, it is more suitable for cold indoor applications.

Do NEMA 3R enclosures protect from corrosion?

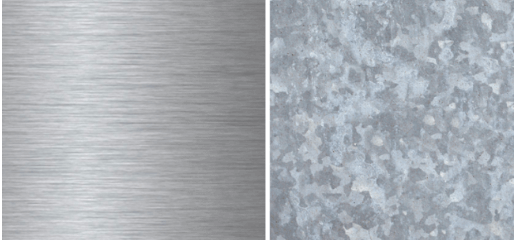

NEMA Type 3R enclosures do not protect against corrosion well, as they are.

However, you can increase the enclosure’s resistance to corrosion with the material you request.

Galvanized steel and stainless steel are the best options.

Also, powder and enamel coatings can help deter corrosion.

Also, you can order NEMA 3RX enclosures, which include protection against corrosion.

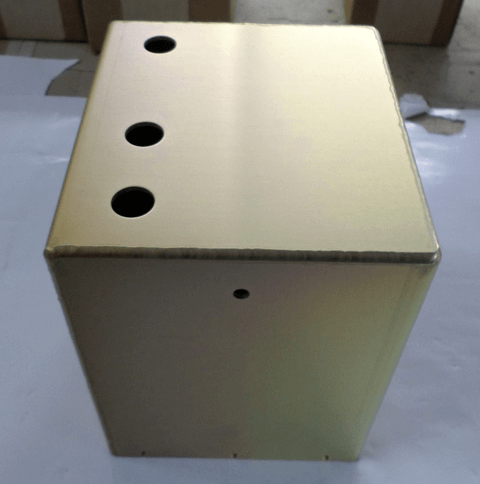

What are common applications for NEMA 3R enclosures?

NEMA 3R enclosures are great for indoor and outdoor commercial uses.

These may be junction boxes, utility boxes, outdoor meter cabinets, transformers, generator skids, frequency converters, power conditioners, switch gears, lighting contractors, power distribution, and rotating equipment.

Typical NEMA 3R box

Because of this type’s resistance to water and ice, such enclosures are great for commercial freezer rooms, ship docks, subway systems, outdoor construction sites, and anywhere else where it gets cold.

However, because 3R is not well protected against dust, indoor applications are more recommended.

Para obtener más información, consulte nuestra Preguntas frecuentes sobre gabinetes NEMA!

How are NEMA 3R enclosures tested?

Los gabinetes NEMA no son probados por NEMA, sino por laboratorios de terceros.

Etiquetas NEMA se puede utilizar para autodeclarar las clasificaciones del gabinete.

NEMA 250 describe todas las pruebas exhaustivas a las que se someten los gabinetes para lograr una etiqueta NEMA.

For NEMA 3R, one of the tests is the rod entry test, which involves inserting a rod of different diameters into openings and vents of the enclosure in an attempt to reach live parts of the circuit.

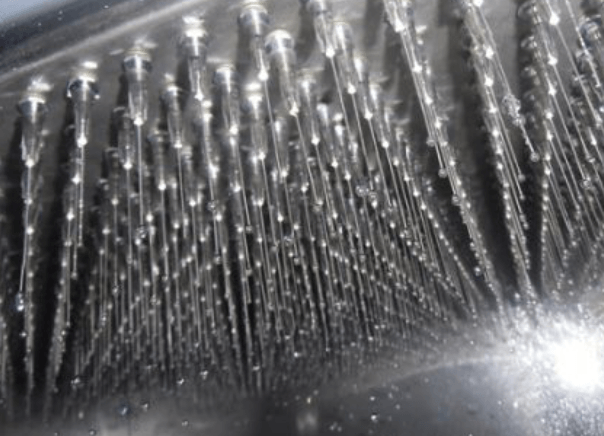

NEMA 3R enclosures also undergo a rain test for 1 hour.

Rain test chamber

The test is considered passed if there is no significant water accumulation inside the enclosure.

NEMA 3R enclosures are further tested with an external icing test and outdoor corrosion test.

External icing test involves spraying the enclosure with water and then cooling down the room until 20mm of ice has formed over the enclosure.

Outdoor icing test

The enclosure should be undamaged and operable at the end of the test.

Outdoor corrosion test is included for NEMA Types 3X, 3RX, and 3SX.

It involves making a 5% saline solution (using sodium chloride) and spraying it continuously for 600 hours (25 days).

How can I be sure of the quality of NEMA 3R enclosures?

En KDM, tenemos la Certificación ISO9001 que puedes mirar a través de él.

Además, puede realizar pruebas independientes de los gabinetes por parte de terceros si desea confirmar la calidad y la evaluación de la conformidad.

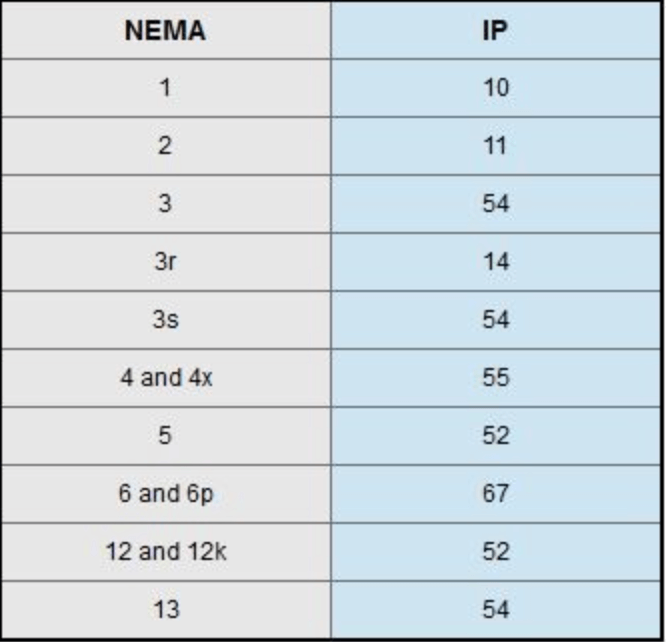

What is NEMA 3R in IP standards?

Although it is difficult to translate one set of standards into another, NEMA Type 3R is roughly comparable to IP14 and IP24.

Both provide good protection against dust and water.

NEMA y IP

What are common designs for NEMA 3R enclosures?

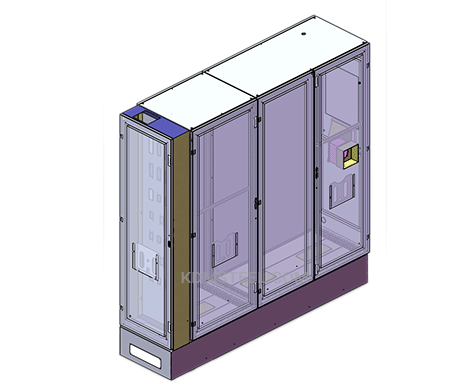

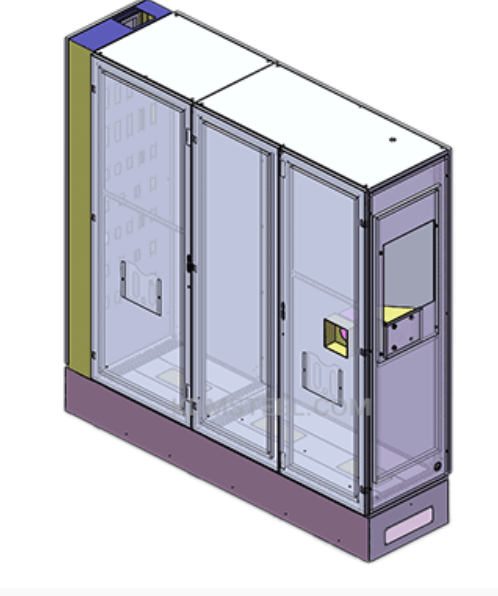

Some common designs for NEMA 3R enclosures include free-standing, floor-mounted, wall-mounted, and pole-mounted.

Independiente, montado en el suelo, and walk-in enclosures are used for bigger equipment.

Pueden tener una o varias puertas, dependiendo de sus necesidades.

Estos gabinetes también pueden tener pedestales, ruedas, pies niveladores y argollas de elevación para facilitar su instalación y movimiento.

Multi-door free-standing enclosure

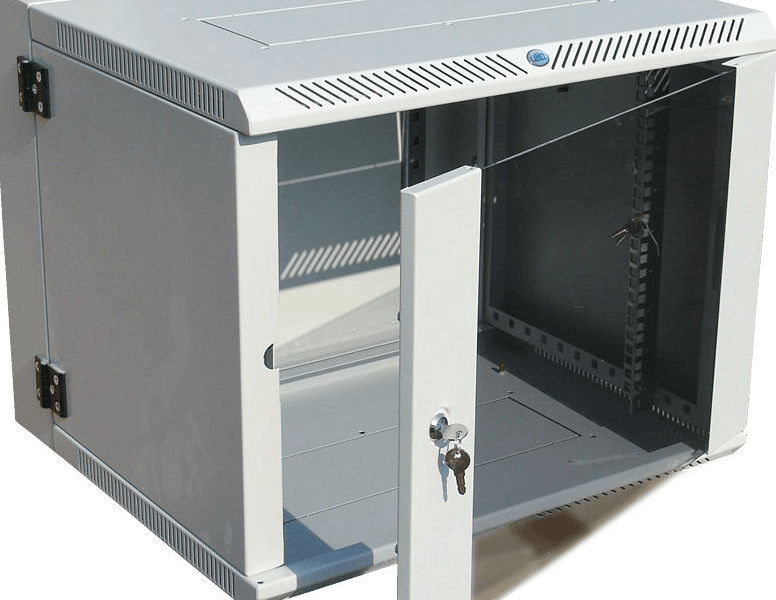

Montado en la pared y montado en poste NEMA 3R enclosures are typically small and house fuses and switches.

Son menos móviles, pero también ocupan menos espacio.

Se instalan mediante soportes especiales que pueden ser simplemente externos o tener también elementos internos.

Wall-mounted fuse box

Overall, higher NEMA ratings benefit from U-shaped designs since those require less seam welding, which works well with ice and corrosion protection

U-shaped enclosure (top part)

Of course, we also offer custom enclosures.

¿Qué características adicionales suelen incluirse?

Puede solicitar ventilaciones, ventanas, puertas batientes, cerraduras, sistemas de gestión de cables y mucho más.

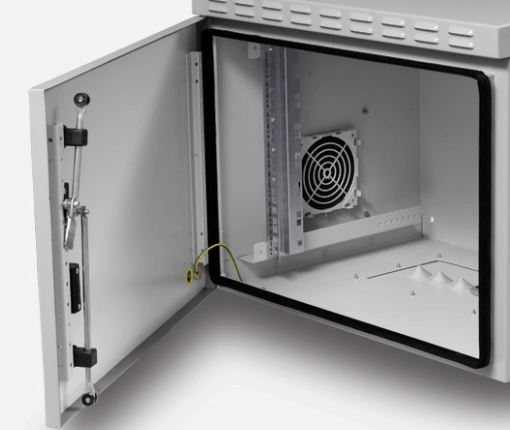

RespiraderosAdemás de los ventiladores radiantes, proporcionan una vía para que escape el calor, enfriando los componentes eléctricos del gabinete.

Las rejillas de ventilación proporcionan un flujo de aire más pasivo, mientras que los ventiladores mueven el aire activamente y se utilizan para enfriar equipos que se calientan rápidamente.

You can request a heating fan that will not only move air in and out of the enclosure, but also heat it up in very cold environments.

Esto prolonga su vida útil y disminuye la posibilidad de fallos de funcionamiento.

Ventilador radiante en un recinto

Éstos también estabilizan la presión del aire dentro del gabinete, evitando la condensación que puede dañar los componentes eléctricos del gabinete.

Ventanas Ayudar al personal a examinar los componentes eléctricos de forma rápida y no invasiva.

Y si algo sale mal, una ventana ayuda a ver lo que está sucediendo de inmediato.

Además, las ventanas infrarrojas ayudan a proteger a los trabajadores de arco eléctrico accidentes al dejarles ver la acumulación de calor.

Enclosure with a window and a lock

Puertas batientes controlar cómo y cuánto se abre la puerta o cubierta del recinto.

Esto también incluye una variedad de manijas que puedes solicitar.

Puede elegir entre bisagras continuas, desplazadas y de otros tipos.

Cabellos, latches, and clamps add a layer of security to your NEMA 3R enclosure, making sure no one tampers with it or accidentally accesses its electrical components.

Los sistemas de gestión de cables pueden incluir ganchos, estantes y otros elementos de organización.

We also offer secondary features like casters, lifting eyes, file pockets, drip caps, switches, lights, and anything else you request.

File pocket

Casters help move the enclosure around; lifting eyes are for heavy enclosures that need to be lifted to be carried around; file pockets store operating manuals; drip caps protect the enclosure from splashing water; solar shields protect against UV rays; switches and lights help operate the equipment inside the enclosure.

¿Los orificios, las rejillas de ventilación, los accesorios, etc. afectan la clasificación del gabinete?

Lo ideal es que los accesorios individuales, las rejillas de ventilación, los orificios ciegos, etc. tengan una clasificación NEMA mejor que la del gabinete.

Pero generalmente esto no es posible, por lo que estas características deberían tener la misma calificación que la estructura general.

This means that if you request a NEMA 3R enclosure with such features, the resulting enclosure will still be rated 3R.

Can NEMA 3R enclosures protect from cold?

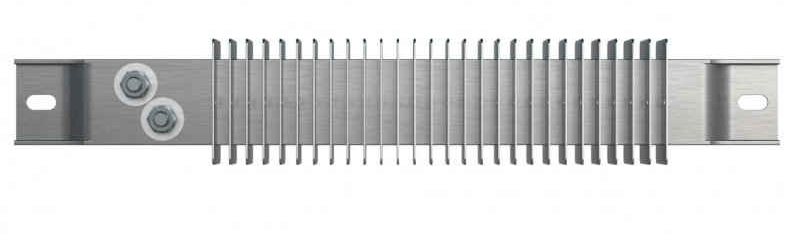

Generally, enclosures can have air conditioners, coolers, heat exchangers, and heater strips to control the temperature inside the enclosure.

This is done to prevent the equipment from freezing over, getting slower or fragile, but also to prevent condensation.

Heat exchangers are closed loop systems that are easy to maintain.

They push hot air in colder compartments, which results in an equalized temperature and pressure.

Heat exchanger

Heater strips use electricity to heat up the air inside the enclosure.

Heater strip

There can also be fan filters and small positive temperature coefficient heaters.

Enclosure heaters range in performance from 50 to 1200 Watts, depending on the size of your enclosure.

What materials are used for NEMA 3R enclosures?

The materials used for NEMA 3R enclosures aren’t different from materials used for other types of enclosures.

Se pueden hacer a partir de acero carbono, acero galvanizado, y acero inoxidable – usually of the grades 304 or 316.

El acero al carbono suele ser más opaco que el acero inoxidable.

También es magnético y más maleable ya que solo tiene hierro y carbono.

This type of steel is vulnerable to corrosion, so it is not recommended for NEMA 3R.

El acero inoxidable se crea añadiendo cromo, níquel y molibdeno a la aleación de hierro y carbono.

Acero inoxidable vs acero galvanizado

Los grados de acero 304 y 316 difieren en el contenido de todos los aditivos.

For NEMA 3R enclosures, stainless steel grade 304 is most recommended.

Acero galvanizado Está recubierto con una capa protectora de zinc que evita la corrosión.

Este tipo de acero es más caro y más pesado que el acero inoxidable.

Otro tipo de acero que se puede utilizar es el acero laminado en frío, que es más fino y denso que el acero normal y, por tanto, es más resistente.

Al utilizar acero, el fabricante debe tener en cuenta un cierto calibre o espesor de la chapa metálica que es necesario para cumplir con las normas NEMA.

NEMA 3R enclosures use 12-14 gauge steel, which is about 1.9-2.6 mm.

Fibra de vidrio is another possible material you can request.

It is very strong, can dissipate heat and insulate electricity, lowering the effect of interference and the possibility of shocking personnel.

Caja de fibra de vidrio

Las carcasas también pueden fabricarse con aleaciones de aluminio.

Al igual que los grados de acero, las aleaciones de aluminio pueden ser de la serie 5052 o 6061.

Aluminio vs acero inoxidable

Ambos son livianos, pero el 5052 es más soldable, mientras que el 6061 tiene una mayor resistencia a la corrosión.

Además, el 6061 es más caro.

Este material es especialmente bueno para recintos expuestos a solventes, petroquímicos, algunos ácidos, la mayoría de los sulfatos y nitratos.

If you need such protection, then NEMA 3RX with aluminum would be great.

Además, nuestras ventanas están fabricadas en policarbonato y ABS.

El policarbonato es más resistente a la corrosión, mientras que el ABS es más barato.

Si desea obtener más información, Envía tu consulta ¡Ahora para una consulta!

What paints and coatings can be used for NEMA 3R enclosures?

Nuestros recintos están bien protegidos, pero el revestimiento adecuado también puede aumentar su protección.

Puedes elegir capas de pintura esmaltada o en polvo en cualquier color.

Pintura de esmalte has a glossy finish and adds weather resistance.

Pintura en polvo Se deposita con la fuerza electrostática y es más rápido y fácil que el esmalte.

También tiene una apariencia más flexible, lo que le brinda la opción de acabados brillantes y mate.

Acabados con recubrimiento en polvo

También ofrecemos recubrimientos anodizados y alodizados.

Anodizado El recubrimiento utiliza ánodos para oxidar un metal, generalmente aluminio, para aumentar su espesor y lograr una mejor resistencia a la corrosión.

El acero normalmente no se anodiza porque esto puede acelerar la corrosión del metal.

Recubrimiento de alodina, también conocido como recubrimiento de conversión de cromato, se utiliza para imprimar acero y aluminio para pintar, así como para prevenir la corrosión.

Recubrimiento de alodine

This is a cheaper process than anodizing, and can be recognized by its characteristic greenish-yellow hue.

También puede haber recubrimientos antigraffiti y anticarteles para proteger su recinto del vandalismo.

NEMA 3R enclosures most often use powder coating.

Podemos proporcionar cualquier recubrimiento en cualquier color y acabado, por lo que Contáctenos ¡hoy!

What are some ways to put symbols on a NEMA Type 3R enclosure?

Nuestros servicios de personalización incluyen grabado y serigrafía.

La serigrafía es el método de personalización más sencillo y asequible.

Cualquier lado plano del gabinete puede ser serigrafiado con etiquetas, advertencias, número de serie, el nombre de su empresa y su logotipo.

However, silk-screening on metal like stainless steel or aluminum can be worn off or scratched off, but a clear powder coat prevents that.

Serigrafía

Engraving is more expensive and takes more time, but it is also more long-term than silk-screening.

Usually, about 0.005 inches or 0.010 inches of metal is removed from the surface to trace the design.

Una vez retirado el metal, se rellena con pintura epoxi del color que se desee según sus necesidades.

Grabado

¿Qué más debo tener en cuenta al pedir un gabinete?

Hay algunos errores comunes que la gente comete.

Estos incluyen elegir el tipo NEMA incorrecto, el material incorrecto, el tamaño incorrecto, el diseño incorrecto y no tener en cuenta las características.

Los tipos NEMA tienen ciertos entornos para los cuales son adecuados.

NEMA 3R is built for non-hazardous, indoor and outdoor locations with normal air pressure, rain or dripping water, some dust, snow, sleet, and ice.

NEMA 3R usually use stainless steel 304 or galvanized steel to increase resistance to corrosion.

El tamaño y el diseño del gabinete dependen del equipo eléctrico específico que planeas alojar allí.

However, NEMA 3R enclosures are usually medium-sized or big.

As for the design and features, these are case-specific, so consult your manufacturer for advice.

Recent MCC Enclosure Order

Caja NEMA 3R – Your Ultimate FAQs Guide

What is a NEMA 3R Enclosure?

It is made by NEMA Enclosures for housing power transmission. It is suitable for housing power distribution, switch gear, and more types of electrical components.

NEMA 3R enclosures can be used indoors or outdoors and have the least demanding rating for outdoor use.

NEMA 3R enclosure complies with the National Electrical Manufacturers Association’s standard rating system (NEMA).

Because of this stability, the NEMA 3R electrical enclosure is commonly used for junction and wiring boxes for utilities and communications.

What does NEMA 3R Enclosure Protect For?

NEMA 3R enclosures, in fact, are used in a wide array of uses.

This type of enclosure has been used to safeguard safety switches in apartments and houses, as well as electrical parts.

NEMA 3R enclosures,are intended for both indoor and outdoor use and provide some protection against the following:

- Hazardous Components

- Foreign Objects that are Solid (falling dirt)

- Moisture Absorption (rain, snow, sleet, etc.)

- Forming of External Ice

NEMA 3R enclosures are still commonly used to house switchgear, lighting, electrical junctions, and other components in a variety of outdoor applications.

What is the Cost of a NEMA 3R Enclosure?

NEMA 3R Enclosure is a high-quality metal covering that comes in a variety of styles and materials at reasonable prices.

The true cost of the enclosure, of course, is determined by factors such as content and appearance.

However, for outdoor applications, a NEMA 3R is the most cost-effective option.

What are The Capabilities and Benefits of a NEMA 3R Enclosure?

This kind of enclosure offers a lot of capabilities and benefits such as the following:

- Security from unintentional interacting with insulated devices.

- Dropping dust particles, downpours, sleet, and/or snow protection.

- Provision for drainage.

- Storm safety at a greater level than the lowest live part.

- There are various access control and latching technologies available.

- Intended for use as a control box or a pull box.

- It is weatherproof, non-corrosive, and completely customizable to your needs.

- It can last a long time and very appropriate for your implementation.

- When compared to lower-tier NEMA ratings, the NEMA 3R rating can withstand more extreme weather conditions.

- It is offering all-around protection from the elements.

- Prevents liquid, dirt, and dust from entering.

- Precludes workers from gaining access to potentially dangerous components.

Why Does NEMA 3R Enclosure are Made?

It is made to withstand normal weather patterns and are used in residences, business, and commercial processes.

NEMA 3R enclosures are intended for interior or exterior usages and provide some moisture control for internal equipment.

NEMA 3R enclosures are also developed to be unaffected by the forming of ice on the enclosure’s exterior.

It is manufactured to provide you with a high-quality extremely durable enclosure that is impervious to rain, ice, and snow.

What Materials Does NEMA 3R Enclosure Made?

NEMA 3R enclosures are highly made of strong and durable materials.

Each type of NEMA 3R enclosure material has different capabilities and functions.

It is ranging from lightweight polycarbonate and aluminum boxes to tough stainless-steel enclosures.

- Aluminio

This type of metal is both attractive and tough.

- Polycarbonate

It is a heavy-duty plastic polymer that have a light and tough functioning and a vigorous resistance in UV.

- ABS Plastic

It offers great robustness and it is not costly as it is meant to be indoors and not outdoors.

- Acero inoxidable

It is an ultimate corrosion-resistant protection. It is a standardized enclosure and stronger for construction.

- Plástico

It is use ABS which applied indoor installations. Polycarbonate for a stronger cabinet and long-life service.

What are The NEMA 3R Enclosure Key Features and Size Specification?

Here are the features that every NEMA 3R Enclosure has:

- The enclosure and cover are made of gauge and steel sections.

- A plated metal bolt holds the protective cover beneath the liquid armored top.

- Accessible with or without base interlocking knockouts.

- Evey enclosure comes with intensifying embosses on the back.

- Protections for securing on the front cover.

- The enclosure and cover are made of gauge galvanized steel.

- Pad lockable flip hook on a constructed metal hinge.

- Available with or without bottom concentric knockouts.

- On the back of the box, four mounting holes are provided.

- The top has a drip shield and the sides, front and back are seam-free.

- Intended to keep connection configurations.

- The cover is made to fit beneath the drip shield top and is secured with machined metal wrenches.

- Junction boxes with premised covers.

Size Specifications

These NEMA 3R Enclosures are available in a variety of materials, sizes, and styles.

The NEMA 3R Enclosurestandard gives rating, testing and marketing requirements.

Most of the companies build their own enclosures of any size. There are no regular sizes for NEMA 3R Enclosure.

Which Industries Does NEMA 3R Enclosure Commonly Operate?

NEMA 3R Enclosure is designed for different industries that help avoid electrical shock and explosion.

Here are different industries that usually NEMA 3R Enclosureoperates:

- Telecomunicaciones

- Substitute Energy

- Marina

- Grease and Smoke Industry

What are The Common Applications of NEMA 3R Enclosure?

NEMA 3R Enclosuresare widely known among manufacturers all over the world for their extreme performance.

Here are some of its applications:

- Junction boxes in indoor

- Indoor electronic applications

- Industrial environments and non-corrosive coolants- greases and oil.

- Electronic mechanism panels for the purpose of the application in the manufacturing of light.

- Utility control equipment