- Custom Ip66 or Any IP rating Enclosure

- Certificación IP65/IP66

- Producción rápida de muestras en 3 días

Custom IP66 Enclosure Manufacturer in China

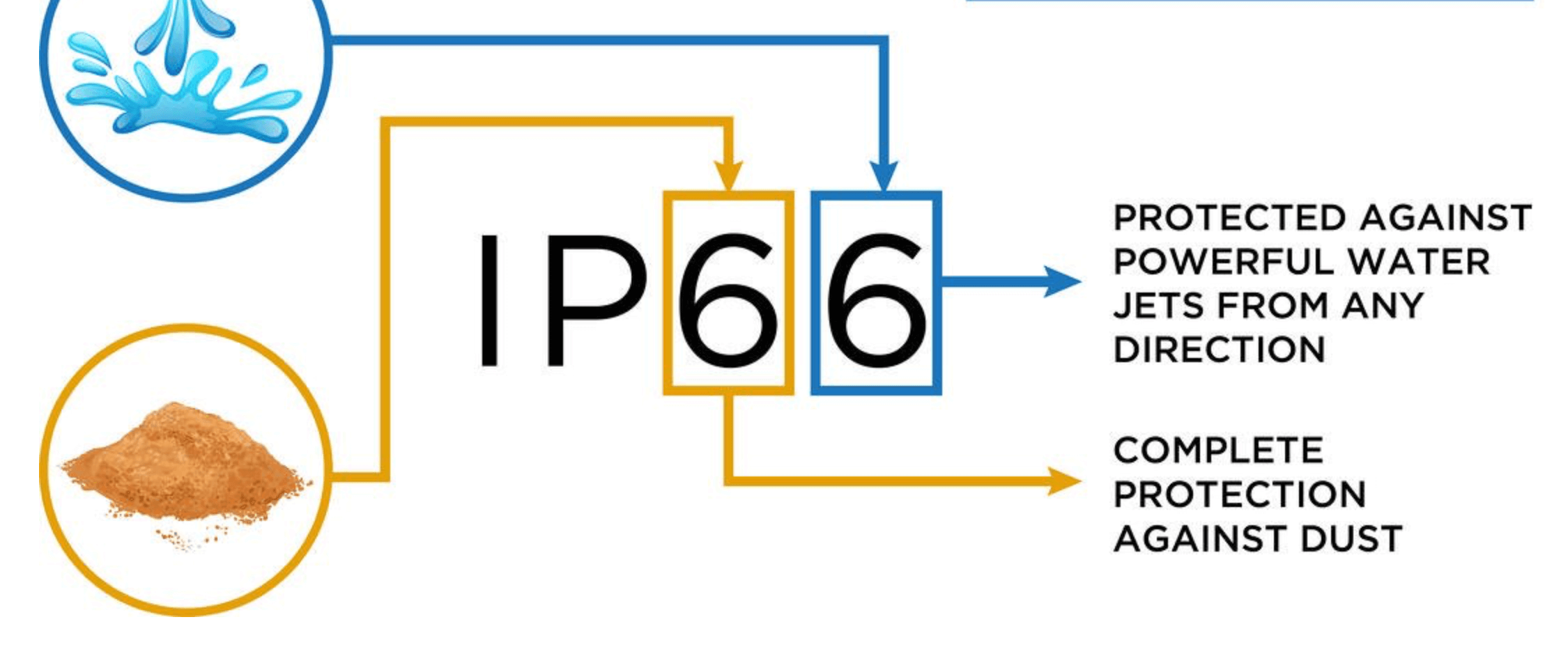

- KDM IP66 enclosure offers the highest protection against particles and is able to protect high levels from water, including powerful jet sprays and temporary flood conditions.

- IP 66 electrical enclosures can withstand 30 KPA water jets from 3 meters in any direction. Furthermore, it prevents contact with live or moving parts with the equipment, and against the ingress of dust. KDM enclosures stringently adhere to these standards, and you can expect superior quality and craftsmanship.

KDM IP66 enclosure Series

Send your Inquiry on KDM IP66 enclosure

KDM IP66 enclosure is specified for harsher indoor industrial or outdoor applications. These IP66 rated enclosures are ideal for your watertight projects.

IP66 electrical enclosure ensures your components are prevented in wet environments. The KDM IP66 enclosures have a locking catch that engages to positively hold the lid closed until disengaged.

- Capacidad de fabricación

- Guía de compra

Máquina de corte láser de alto rendimiento de 4000 W, precisión de +/- 0,05 mm. Sin rebabas ni rayones.

Equipo de soldadura flexible multifunción, alta precisión, sin deformación.

Precisión de doblado de +/- 0,5 mm, superficie lisa sin marcas de doblado.

Más de 10 trabajadores con experiencia en soldadura, apariencia general perfecta.

Máquinas de espumado de alta velocidad y precisión, empaquetadoras rápidas y calificadas.

El equipo de montaje experto, calidad de montaje constante en cada carcasa KDM

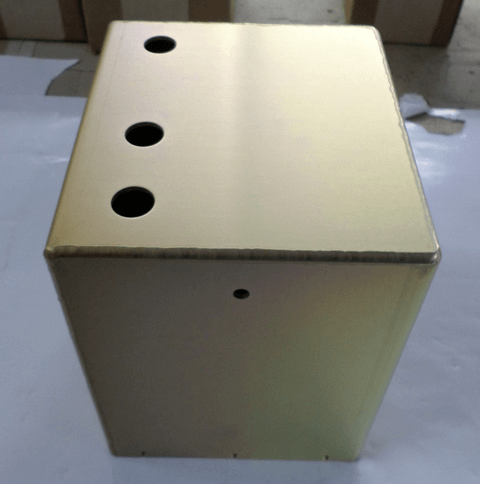

KDM IP66 Enclosure

KDM has a range of high-performance IP66 enclosure are available in different sizes and types, so you could easily find the right enclosure solutions for your needs. Our enclosures are manufactured to the highest quality standards which ensure consistent fit and finish on all batches. So you can be sure that every enclosure will conform to its IP rating. KDM designed electrical enclosure meeting IP66 standards to satisfy customer specific requirements.

Galvanized IP66 Enclosure

Stainless Steel IP66 Enclosure

IP rated 66 enclosures are offered in a wide array, including free-standing, modular, wall mounted, an enclosure with window, acero inoxidable, a prueba de la intemperie, control panel, acero galvanizado and more other types of enclosure.

For custom enclosure meeting IP66 standards, we can customize any of our enclosures with cutouts and printing. Any size or shape cutout can be added to all surfaces of our enclosures. Furthermore, insulation, hinges, latches or locks can be add-on according to your requirements.

At KDM, we are choosing an electrical enclosure based on your application and what qualities it requires to succeed. Examples of such qualities include corrosion resistance, thermal insulation, spark resistance, explosion resistance, low-temperature resistance, durability, security, etc. Our flexible engineering and manufacturing systems enable us to customize enclosures to save your valuable time and cost in your process, to populate the enclosure and install it.

At KDM, we cater to your needs and offer modified standard and custom IP66 enclosure products through step-by-step design support. Over the last 10 years, we are a trusted manufacturer for any types of electrical enclosures. Our professional engineering and designing team has developed enclosures to the standard required for IP66 enclosure. KDM is a 9001:2015 certified manufacturer of electrical enclosure based in China.

Our expertise in fabricating high-quality enclosure, leaned us to provide the best to our customers and grow as a company to a higher level. Our state-of-the-art manufacturing process ensures a quick turnaround without sacrificing the quality you expect from KDM IP66 enclosures.

By selecting KDM IP66 enclosure, you can benefit from outstanding quality products, fully finished enclosures that are ready for installation, individually modified based on your request and a high level of functionality and innovative strength. Our excellent knowledge and experience will let you receive the appropriate enclosure for your needs. Let us know your specifications and we will provide a competitive quote.

The Ultimate FAQ Guide to IP66 Enclosures

- What does IP66 mean?

- Why are there additional letters after the main IP code?

- What testing do IP66 enclosures undergo?

- What NEMA type is IP66 comparable to?

- Do IP66 enclosures protect against corrosion?

- Do IP66 enclosures protect against explosions?

- How and why do IP66 enclosures maintain inside temperature?

- How can I be sure of the quality of IP66 enclosures?

- Where can IP66 enclosures be used and for what applications?

- What designs of IP66 enclosures can I choose from?

- What features can I request for IP66 enclosures?

- What accessories can I request for IP66 enclosures?

- ¿Las cerraduras, ventanas, rejillas de ventilación y bisagras reducen la clasificación IP?

- How are enclosures made to have a high IP rating, such as IP66?

- What materials can be used for IP66 enclosures?

- What paints and coatings can be used for IP66 enclosures?

- How do you customize the symbols or writing on an IP66 enclosure?

What does IP66 mean?

Enclosures rated with IP66 are fully dust-tight, and protect from low-pressure water jets from any direction.

High-pressure water jets can be measured at 100 liters per minute.

In the workplace, these could manifest as rainstorms, temporary floods, or water spray from nearby machinery.

This also means that IP66 enclosures are well protected against fog, humid air, oil and coolant leaks, and corrosion induced by moisture.

IP66 rating

Why are there additional letters after the main IP code?

Como ya mencionamos la “X” significa que no hay información disponible, o que es irrelevante o sustituible.

Hay 2 juegos de letras opcionales Puedes agregar después de los dígitos.

El conjunto adicional – A, B, C, D – describe la protección de la carcasa contra manipulaciones.

A stands for protection against the back of a hand; B stands for protection against a finger; C stands for protection against access with a tool, while D indicates for protection against access with a wire.

El conjunto complementario de letras (H, M, S, W) le indica al usuario para qué sirve el estuche.

H indica que el recinto puede servir para un dispositivo de alto voltaje; M indica que el dispositivo dentro del recinto se estaba moviendo durante una prueba de agua, mientras que S significa lo contrario: que estaba parado.

Finalmente, W significa que el recinto es resistente a la intemperie.

El código IP completo

You can use these to indicate what features you want your IP66 enclosures to have.

Estos se utilizan principalmente para una mejor comunicación entre el cliente y el fabricante.

What testing do IP66 enclosures undergo?

La prueba IP6X se realiza utilizando un espacio cerrado donde un vacío atrae una gran cantidad de polvo y diferentes polvos que se esparcen por todo el recinto durante al menos 15 minutos y luego se verifica el recinto para detectar la entrada de polvo.

Prueba de cámara de polvo

IPX6 is tested using spray nozzles, measured at 12.5mm, with oscillating tubes that pressurize and spray water at 100 liters per minute for at least 3 minutes in any imaginable angle from a distance of 3 meters.

Some submersion is also possible since these enclosures need to withstand temporary flooding up to 1 meter for about 30 minutes.

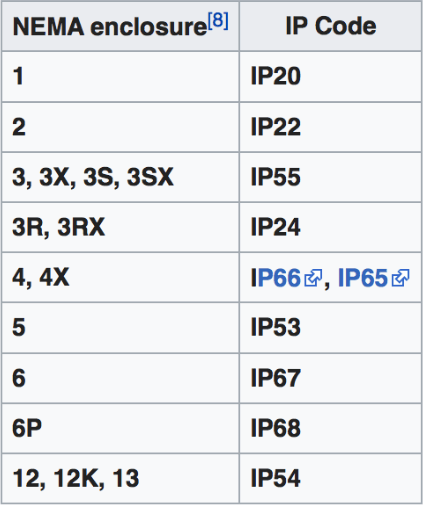

What NEMA type is IP66 comparable to?

Para Normativa nacionalOfrecemos cualquier tipo, empezando por el 1 y hasta el 13, incluyendo subtipos como el 3X.

Nuestro Cajas NEMA Están protegidos contra el clima, la corrosión, las filtraciones de refrigerante, los productos químicos y mucho más.

Las clasificaciones IP y los tipos NEMA no se pueden convertir directamente entre sí, pero se pueden convertir de forma flexible. comparado como se muestra a continuación.

Comparación de clasificaciones NEMA e IP

As the table shows, IP66 can be compared to NEMA 4 and 4X.

These types provide high degrees of protection from weather, including ice and sleet.

El tipo 4X tiene cualidades adicionales de resistencia a la corrosión.

Do IP66 enclosures protect against corrosion?

IP66 is not fully waterproof, so it may not protect against corrosive agents if they are strongly sprayed on it or submerged in.

Si simplemente se salpican o incluso se rocían, no hay problema, pero aún así pueden entrar vapores corrosivos.

El material también juega su papel: el aluminio y el acero inoxidable son los materiales más resistentes a la corrosión.

Feel free to scroll down to learn more about different materials!

Do IP66 enclosures protect against explosions?

IP66 enclosures are not designed to contain an explosion or an arc flash.

No son comparables con los tipos NEMA 7, 8, 9 o 10.

Estos recintos deben soportar fuertes impactos y altas temperaturas.

En cuanto al arco eléctrico, los gabinetes generalmente no pueden proteger contra eso, por lo que el personal debe tenerlo en cuenta.

Sin embargo, si necesita un recinto a prueba de explosiones, Contáctenos ¡Y lo diseñaremos para usted!

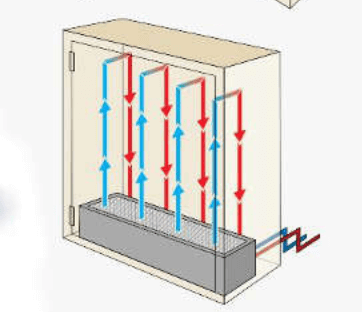

How and why do IP66 enclosures maintain inside temperature?

KDM IP66 enclosures can be equipped with double-wall technology, a thermal chamber, insulation, heat strips, heat exchangers, and vents with air conditioning.

Todo esto proporciona protección contra el calor eléctrico y la radiación solar para prolongar la vida útil de los componentes eléctricos dentro del gabinete.

Intercambiador de calor

If you plan to install IP66 enclosures in a cold environment, then we can also include small heaters, so the electrical components don’t freeze or slow down in work.

Tira calefactora

Además, la gestión térmica reduce los puntos calientes, iguala la presión y minimiza la condensación, que puede dañar los dispositivos electrónicos y diversos.

How can I be sure of the quality of IP66 enclosures?

Tenemos una proceso de dar un título Puede consultarlos, lo que le brindará más detalles y confianza en nuestros gabinetes.

Where can IP66 enclosures be used and for what applications?

IP66 enclosures can be used both indoors and outdoors.

IP66 enclosures are commonly used in industry and factory

machinery and equipment, heavy-duty construction, swimming and spa pools, bathrooms, transformers, and medical equipment.

Otras aplicaciones pueden ser armarios de telecomunicaciones o tableros de control, entre otras.

Caja IP66

IP66 enclosures are especially great for control boards since they provide superb security both from the environment and from tampering.

And such security is perfect for important electrical components.

Industrial PCs are often housed in IP65 and IP66 enclosures.

Then, other devices may be included as well, such as bar code scanners, USB hubs, and RFID receivers.

Esta clasificación IP es perfecta para entornos exteriores porque es resistente al polvo y a la lluvia.

The dust-proof and water-resistant qualities make it possible to be put underground, fully or partially, if you are catering to gardening applications.

What designs of IP66 enclosures can I choose from?

We are delighted to offer you a range of designs of free-standing enclosures, wall-mounted enclosures, junction boxes, modular enclosures and custom enclosures.

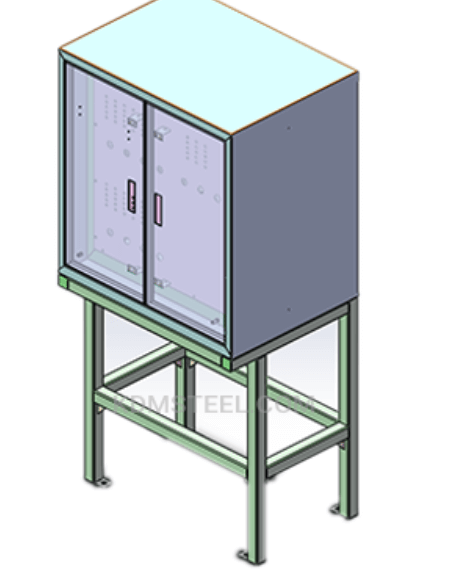

Cerramientos autoportantes Son perfectos para unidades eléctricas grandes que son demasiado pesadas para montarlas en la pared o en un poste.

They could be of any height and width. They are also portable, and can be big enough to be categorized as walk-in enclosures.

Recinto independiente

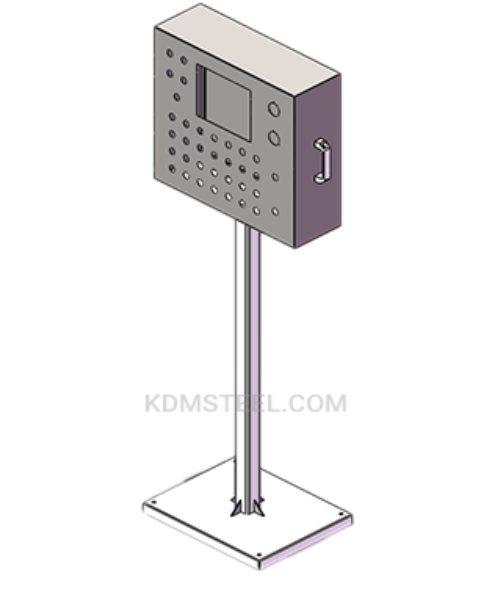

Cajas de pared Utilice soportes de montaje, tornillos y almohadillas para la instalación.

Son perfectos para dispositivos pequeños en lugares públicos, así como en cualquier lugar donde el espacio sea una preocupación.

These can also be montado en poste with special circular brackets.

Caja de montaje en pared

Cajas de conexiones are enclosures with a lot of wires that all interconnect.

Such boxes are usually used for control boards, so they need to be protected with IP65 and up.

They also often have pedestals, which help in case of flooding, so this is another thing to consider.

Junction box

Modular enclosures are similar to custom since they allow for flexible configurations.

You can add or remove walls and doors as you need, varying the size and shape of the enclosure.

Having these in IP66 provides a great deal of flexibility and security, so you have less things to worry about.

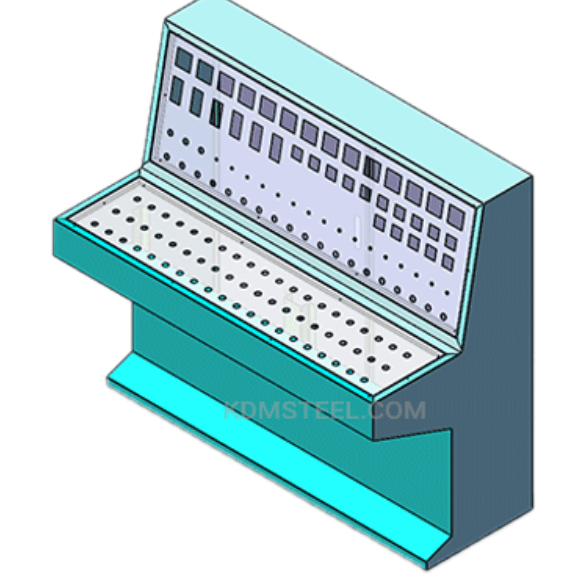

Por supuesto, también tenemos nuestro recintos personalizados, que puede ser de cualquier diseño, forma y requerimiento, además de tener múltiples puertas.

Custom IP66 enclosure

This includes piano-type control boards, various electrical boxes, cabinets, and enclosures on pedestals.

Just reach out, and we will be happy to create your perfect custom enclosure!

What features can I request for IP66 enclosures?

Puede solicitar ventilaciones, ventanas, puertas batientes, cerraduras, sistemas de gestión de cables y mucho más.

RespiraderosAdemás de los ventiladores radiantes, proporcionan una vía para que escape el calor, enfriando los componentes eléctricos del gabinete.

Esto prolonga su vida útil y disminuye la posibilidad de fallos de funcionamiento.

Ventilador radiante en un recinto

Éstos también estabilizan la presión del aire dentro del gabinete, evitando la condensación que puede dañar los componentes eléctricos del gabinete.

Además, las rejillas de ventilación se pueden actualizar aún más para convertirlas en acondicionadores de aire e intercambiadores de calor.

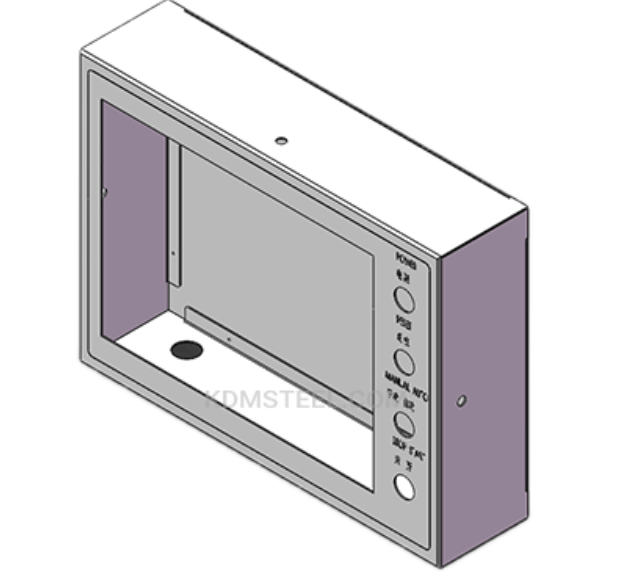

Ventanas Ayudar al personal a examinar los componentes eléctricos de forma rápida y no invasiva.

Y si algo sale mal, una ventana ayuda a ver lo que está sucediendo de inmediato.

Además, las ventanas infrarrojas ayudan a proteger a los trabajadores de arco eléctrico accidentes.

Recinto con ventana

Puertas batientes controlar cómo y cuánto se abre la puerta o cubierta del recinto.

Esto también incluye una variedad de manijas que puedes solicitar.

Cabellos add a layer of security to your IP66 enclosure, making sure no one tampers with it or accidentally accesses its electrical components.

Cerrar

What accessories can I request for IP66 enclosures?

Los sistemas de gestión de cables, como marcos de entrada de cables y abrazaderas, sirven para mantener los cables organizados y facilitar su instalación y mantenimiento.

Los protectores solares son básicamente otra capa en la parte superior de un gabinete que refleja la radiación solar, controlando la temperatura interna del gabinete para prolongar la vida de sus componentes eléctricos.

Escudo solar (la placa superior)

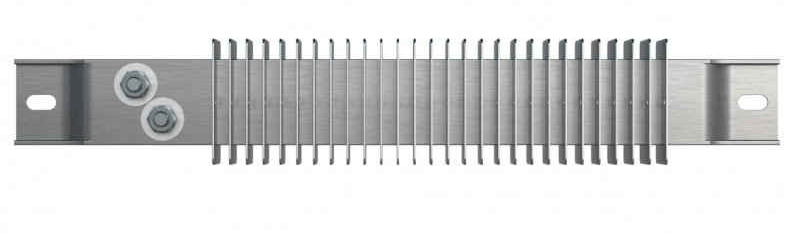

Rieles DIN Se utilizan para montar disyuntores en carcasas de equipos utilizados en aplicaciones industriales.

Las tapas de lluvia son piezas superiores inclinadas similares a un techo que hacen que el agua se deslice por el costado del recinto, protegiéndolo así de la entrada de agua.

IP66 enclosures benefit especially much from this feature, prolonging its life outdoors.

IP66 rain cap with lifting eyes

También fabricamos ruedas, termómetros, interruptores de luz, argollas de elevación, dispositivos de operador y características específicas como teclados e intercambiadores de calor.

To learn more, feel free to Contáctenos for more information about all the different features and accessories we offer! We will also provide any custom feature you request.

¿Las cerraduras, ventanas, rejillas de ventilación y bisagras reducen la clasificación IP?

Sí, características como ventilaciones, ventanas y cerraduras comprometen un poco la clasificación IP, pero hay formas de evitarlo.

Pero KDM supera esta dificultad ofreciéndote algunos de los mejores gabinetes para tu negocio.

Incorporamos varias juntas, sellos de PU, pestillos y filtros para equilibrar la clasificación IP.

How are enclosures made to have a high IP rating, such as IP66?

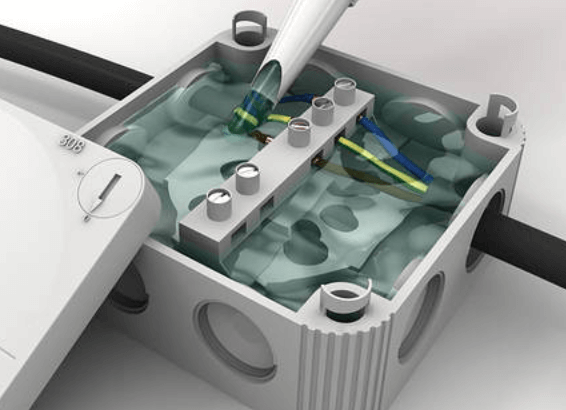

The most vulnerable place in an enclosure is between its body and its lid – here is where dust and moisture can creep in.

However, KDM designs sealing gaskets that are either moulded or screwed in place flush against the surface.

PU sealing gaskets

Medium IP ratings are often equipped with a ‘push-click’ mechanism in the lid.

This makes it quicker to use, but allows for a small degree of gasket movement once closed.

To achieve a high IP rating, some enclosures are filled with a silicone gel that sets and prevents any moisture or dust from coming into contact with the electrical components.

Gel-filled IP66 Enclosure

This allows for the enclosure itself to be cheaper, but it also means that the components will not be easily accessible.

So, if you need an accessible and secure enclosure, IP66 is the way to go.

What materials can be used for IP66 enclosures?

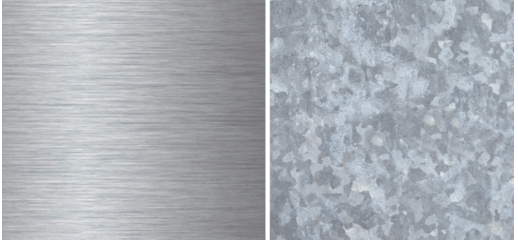

The materials used for IP66 enclosures aren’t different from materials used for other types of enclosures.

Se pueden hacer a partir de acero carbono, acero galvanizado, y acero inoxidable – generalmente de los grados 304, 316 o 316L.

El acero al carbono suele ser más opaco que el acero inoxidable.

También es magnético y más maleable ya que solo tiene hierro y carbono.

Este acero también es propenso a la corrosión.

El acero inoxidable se crea añadiendo cromo, níquel y molibdeno a la aleación de hierro y carbono.

Acero inoxidable vs acero galvanizado

Los grados de acero 304 y 316 difieren en el contenido de todos los aditivos.

El grado 316 es ligeramente más fuerte y resistente al agua salina y ácida debido al molibdeno.

Pero el grado 304 es más barato y más común.

El grado 316L tiene un menor contenido de carbono, lo que lo hace un poco más fuerte.

Acero galvanizado Está recubierto con una capa protectora de zinc que evita la corrosión.

We have galvanized steel enclosures, and this metal is vulnerable to salt water.

Tenga en cuenta que el acero galvanizado es más caro y más pesado que el acero inoxidable.

Otro tipo de acero que se puede utilizar es el acero laminado en frío, que es más fino y denso que el acero normal y, por tanto, es más resistente.

Fibra de vidrio Es muy fuerte, puede disipar el calor y aísla la electricidad, reduciendo el efecto de interferencia y la posibilidad de descarga.

Está hecho de fibras de vidrio colocadas en plástico.

Caja de fibra de vidrio

Además, nuestras ventanas están fabricadas en policarbonato y ABS.

El policarbonato es más resistente a la corrosión, mientras que el ABS es más barato.

IP66 enclosures can also be made from aluminum alloys.

No son necesariamente mejores que las aleaciones de acero, pero pueden serlo dependiendo de lo que busques y de cuáles sean tus necesidades.

Al igual que los grados de acero, las aleaciones de aluminio pueden ser de la serie 5052 o 6061.

Aluminio vs acero inoxidable

Ambos son livianos, pero el 5052 es más soldable, mientras que el 6061 tiene una mayor resistencia a la corrosión.

Además, el 6061 es más caro.

El aluminio tiene una capa de óxido en la parte superior que evita cualquier corrosión.

Este material es especialmente bueno para recintos expuestos a solventes, petroquímicos, algunos ácidos, la mayoría de los sulfatos y nitratos.

So, if you are looking to put IP66 enclosures in such mildly hazardous environments, aluminum is good for that.

Si desea obtener más información, Envía tu consulta ¡Ahora para una consulta!

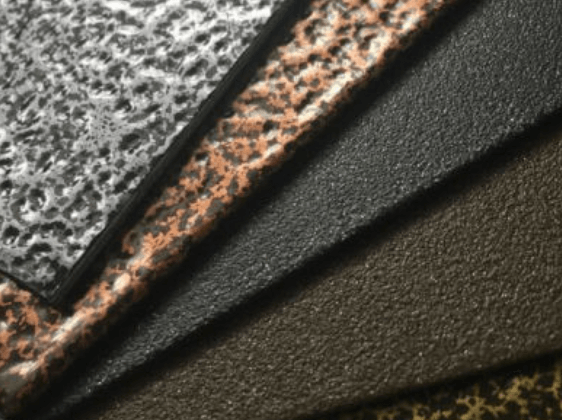

What paints and coatings can be used for IP66 enclosures?

Nuestros recintos están bien protegidos, pero el revestimiento adecuado también puede aumentar su protección.

Puedes elegir capas de pintura esmaltada o en polvo en cualquier color.

Pintura de esmalte Tiene un acabado brillante y es resistente a diferentes condiciones climáticas.

Las pinturas de esmalte específicas, como el esmalte epoxi y el esmalte PU, se utilizan comúnmente para carcasas industriales, ya que son resistentes a la corrosión.

Pintura en polvo Se deposita con la fuerza electrostática y es más rápido y fácil que el esmalte.

También tiene una apariencia más flexible, lo que le brinda la opción de acabados brillantes y mate.

Acabados con recubrimiento en polvo

También ofrecemos recubrimientos anodizados y alodizados.

Anodizado El recubrimiento utiliza ánodos para oxidar un metal, generalmente aluminio, para aumentar su espesor y lograr una mejor resistencia a la corrosión.

El acero normalmente no se anodiza porque esto puede acelerar la corrosión del metal.

Recubrimiento de alodina, también conocido como recubrimiento de conversión de cromato, se utiliza para imprimar acero y aluminio para pintar, así como para prevenir la corrosión.

Recubrimiento de alodine

Este es un proceso más económico que el anodizado y se puede reconocer por su característico tono amarillo verdoso, a menos que esté pintado encima.

There can also be anti-graffiti and anti-poster coatings to protect your IP66 enclosure from vandalism.

Podemos proporcionar cualquier recubrimiento en cualquier color y acabado, por lo que Contáctenos ¡hoy!

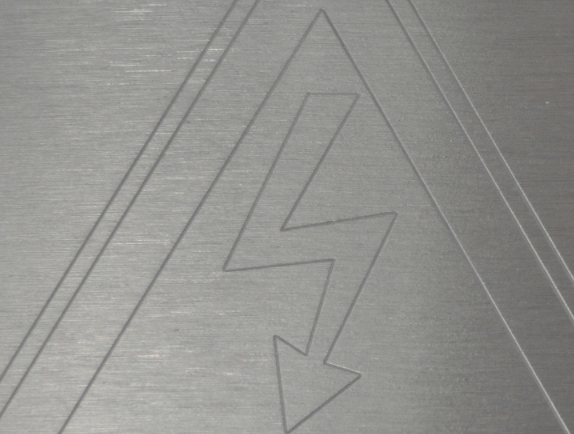

How do you customize the symbols or writing on an IP66 enclosure?

Nuestros servicios de personalización incluyen grabado y serigrafía.

La serigrafía es el método de personalización más sencillo y asequible.

Cualquier lado plano del gabinete puede ser serigrafiado con etiquetas, advertencias, número de serie, el nombre de su empresa y su logotipo.

Sin embargo, la serigrafía sobre metales como el acero inoxidable o el aluminio puede desgastarse o rayarse, pero una capa de polvo transparente ayuda a evitarlo.

Serigrafía

El grabado de la caja es otro método para personalizar sus cajas.

Esta opción es más costosa y requiere más tiempo, pero también es más a largo plazo que la serigrafía.

Se elimina un poco de metal de la superficie de la carcasa en el diseño del logotipo o símbolo.

Generalmente, se eliminan alrededor de 0,005 o 0,010 pulgadas de metal de la superficie.

Una vez retirado el metal, se rellena con pintura epoxi del color que se desee según sus necesidades.

Grabado

Recent IP66 enclosure Order

Marine Electrical Enclosure – Your Ultimate FAQs Guide

What is a Marine Electrical Enclosure?

Marine Electrical Enclosure is designed to withstand the harshest maritime constraints. It is built to last for a long time.

It provides security from elements such as dust, wind, water, and chemicals. It is engineered to survive in high temperatures.

Marine Electrical Enclosure provides comprehensive barrier protection and leak prevention for the equipment inside.

It is primarily utilized in a waterproof marine environment and it is also be tough on its own.

What are the Functions of a Marine Electrical Enclosure?

Marine electronic enclosure can be used in a series of things, in fact, in almost all day-to-day operations these days.

The marine electronic enclosure can be used for a range of functions ranging from storage to packaging and much more.

Marine electronic enclosure protects internal electrical & mechanical elements in any setting especially in marine aspects.

It is built to last and are particularly created to surpass numerous prerequisites, makes them perfect in any application.

It is used in application domains in which delicate machinery or connection points require extra security.

It is commonly used in marinas to:

- Store power cables and infrastructural facilities

- House wireless connections or base stations

- Secure gate operating systems or other connection control devices

- House a security system completes with cameras

What Security Features does this Marine Electrical Enclosure Provide?

Because of their environmentally sealed nature, this enclosure aids in the prevention of fire if one occurs within the compartment.

It serves an important special purpose by lowering the risk of fire propagation, which can ultimately save lives.

Marine Electrical Enclosureis long-lasting, high-quality and is built to withstand the marine environment.

Other Features:

Apart from security features, Marine Electrical Enclosurealso have a wide range of characteristics such as the following:

- Fuse holders that are water resistant for safety precautions.

- Fully water resistant and high-quality steel materials are used in the construction process.

- Kits include everything you need, including a water resistant cord glands, and an adapters block with mounts.

- Simple to use, simple to set up and a wide range of compositional accessories are available.

- It has intrinsic connectivity wiring blocks, busbars and includes air circulation screensand shade structure.

- Port selection is flexible and fit the provided glands to ensure water resistant authenticity.

- Designs are made to orderand is ideal for marine applications.

- It has universal mounting brackets for walls and poles and the back plate configurable and detachable.

- It has surveillance camera lock, foam stripping for weatherproofingand insulation.

- These multifunctional storage boxes are heatproof and can be customized.

- These have tight-fitting lids and distinct molded handles for a strong grip.

- It has personalized screen printing and cutouts to windows and a variety of sizes.

- Variant with a glass roof for outdoor use, preserving the seal’s quality.

- There are a lot of installation options and numerous coupling options.

- Combination of the four versions, each with three different types of doors and a rear door instead of a panel.

What Materials Does a Marine Electrical Enclosure is Made of?

Marine Electrical Enclosure is made of durable polymeric materials that are good enough to defend the objects kept within them.

It is made of aluminum and captive stainless-steel fixings and offers excellent resistance to corrosion and ingress protection.

Marine Electrical Enclosure can also be available in plastic, aluminum, and steel.

It can be machined and squeezed with a variety of thread forms and is excellent for extensive machining on all sides.

What are the Benefits and Advantages of a Marine Electrical Enclosure?

It comes in a variety of forms, dimensions, colors, and designs that can perfectly fit your needs while also saving money.

These marine electronic enclosures are inspected and tested to guarantee best performances and itis extremely useful.

Here are its additional benefits and advantages:

- It is extremely dependable and durable.

- It is suitable for professional advanced manufacturing use with excellent corrosion resistance.

- It safeguards the silicon seal and keeps contaminants out of the main enclosure.

- It keeps electrical & electronic devices secure in damp environments.

- It is perfect for marketing or recreational marine applications and in the hottest engine rooms.

- It is ideal for new installations as well as substituting devices on your boat.

- It has long-lasting polycarbonate composition and deteriorates rusts over time.

- It is eco-friendly and fashionable.

- It is built with highly specialized technologies that enable them to last a long time.

- It is particularly developed and produced for clean and easy integration.

- It stands out because they are extremely durable and built to last.

- It is light weight that allows for simple installation and has a strong resistance to shocks.

- Longevity without the need for maintenance.

- There are no electrical contact hazards and it is really resistant to harsh environments.

- It is suitable for both indoor and outdoor use and can be used across a wide temperature range.

- It is UV resistant and immensely powerful, with abrasion resistance.

- It has polyester enclosure on the floor.

- Machining is simple, and there is no corrosion as a result of the process.

In What Industries Does Marine Electrical Enclosure Widely Serve?

Marine Electrical Enclosure is used by professionals all over the industry and are a very worthwhile investment.

It is used in a wide range of industries including the following:

- Solar and Wind Power

- Agricultural Production

- Oil and Gas

- Food and Beverage

- Marina

- Pumping Water

- Aquarium Filtering

- Car Industry

- Energy Industry

- Medical Industry

What Ratings Does Marine Electrical EnclosurePassed?

Marine Electrical Enclosure has been rigorously tested and have managed to pass all of the following benchmark tests:

- International IP and NEMA performance standards

- UL/CUL Requirements

- Rohs Regulations

- Chemical Resistance is Excellent.

- Atex Requirements

- Exceptional Impact Ratings

- UV Characteristics

What are the Essential Components Inside a Marine Electrical Enclosure?

Marine Electrical Enclosure is capable of housing intrinsic devices that contains the following components:

- Wiring Harness for Heavy Duty

- It is responsible for convenient and simple service delivery.

- It guarantees the consistency of all electrical power and signal circuitry.

- Capacitors with Soft Start

- These devices safeguard the compressor and fan motors against opening cycle surge voltages.

- Itconstrains energy spikes in the air conditioning unit circuitry.

- Thermal Overload Protection for Motors

- It is used to meet potentially dangerous location requirements.

- It is properly sealed and act to cut power when excessive winding temperature is detected.

- Thermal Overload Protection for Compressors

- This device safeguards the cooling system by evaluating head temperature and flow of current.

- It avoids compressor temperature fluctuations and premature failure.

How to Choose the Proper Size of a Marine Electrical Enclosure?

The size of your application is the most essential factor to consider when choosing a Marine Electrical Enclosure.

It’s a simple technique to choose the correct one once you know the size of your area and the parts that will go in the enclosure.

It will give you lots sufficient space both inside and outside to allow for some wiggle room.

The last thing you want is for everything to be stuffed in so tightly that it puts strain on connectors or terminals.

When choosing your enclosure, another thing to be certain of is the safety features it includes.