KDM Electrical Enclosure Cooling System is built for different industrial use.We are a professional electrical enclosure cooling system supplier in China for over 10 years.

KDM Electrical Enclosure Cooling System has strength and durability. These effectively dissipate heat from sealed electrical and electronic enclosures operating in indoor, outdoor, and other types of environments.KDM is skilled in the greatest electrical enclosure cooling system manufacturing.

There are various types of electrical enclosure cooling systems, mainly are Heat Sink Electrical Enclosure Cooling System, Heat Pipe Electrical Enclosure Cooling System, Air Conditioners Electrical Enclosure Cooling System, Water Electrical Enclosure Cooling System, Outdoor Electrical Enclosure Cooling System and more. We also provide KDM electrical enclosure cooling systems in different types like fan and filter systems, heat sink and heat pipe coolers, thermoelectric coolers, air conditioners, vortex coolers.

- The manufacturer’s production line offers you a competitive price.

- We have a long-time cooling system manufacturing experience.

- Both customized and standard cooling systems are available.

- Offers sample presentation and sampling workshop.

KDM Electrical Enclosure Cooling System Series

Heat Sink Electrical Enclosure Cooling System is designed consisting of two high performance. It also has aluminum finned heat sinks bonded to the opposite sides of a common mounting plate.

Heat Pipe Electrical Enclosure Cooling System consists of a heat pipe heat exchanger core with excellent fin features for improved heat transfer performance. It is also optimized for high achievement and volume ratios.

Air Conditioners Electrical Enclosure Cooling System has a solid-state Peltier cooling and has no compressors or refrigerants. It is also made of powder-coated aluminum construction.

Water Electrical Enclosure Cooling System can allow you to host up equipment without warming the air on output. And also without obstructing the ventilation of the servers.

Outdoor Electrical Enclosure Cooling System leaders make them excellent for installation in outdoor cabinets. It also guarantees top performance with minimum maintenance.

IP55 Electrical Enclosure Cooling System is designed specifically for use in electronics boxes and housings also small switch cabinets. It also provides all the advantages of Peltier technology.

Send your Inquiry on KDM Electrical Enclosure Cooling System Now

KDM Electrical Enclosure Cooling System is a durable and reliable enclosure cooling system that features make them ideal for installation in outdoor cabinets, ensuring top performance with minimal maintenance. It is exposed in inside applications also recessed indoor or outdoor.KDM Electrical Enclosure Cooling System is widely used in various industries.

You can use our electrical enclosure cooling system in various industries including Industrial Automation, Food Processing, Chemical, Petrochemical, Wastewater Treatment, and Telecommunications.

- Electrical Enclosure Cooling System is manufactured by highly experienced staff

- Providing extremely good and reliable electrical enclosure cooling system

- 10 years of experience in the manufacturing field

- Customized but Cost-effective electrical enclosure cooling system

Related Products with Electrical Enclosure Cooling System

KDM Electrical Enclosure Cooling System

KDM has a great electrical enclosure cooling system manufacturing capacity, we can produce hundreds of electrical enclosure cooling systems every day with our automated production line, so you will always have enough electrical enclosure cooling systems even on peak days.

We have some sets of different electrical enclosure cooling system manufacturing lines and in a house electrical fabrication facilities.

Whether you are in need of an electrical enclosure cooling system distributor, retailer, or a custom enclosure cooling system factory, KDM is always your most reliable choice because we can always provide for your demands.

We are committed to excellence and our innovations in the electrical enclosure cooling system are an example of our commitment.

Our unparalleled electrical enclosure cooling system is specialized for various tasks and our facility is ISO9001 certified.

Our superior units come with full customer support.

For value-added experiences, you can rely on us to give you a fair price.

We are excited to hear from you.

We offer our valued customers the very best products at the most affordable pricing.

We will render you the one-stop solution for all your electrical enclosure cooling system requirements.

For any type of electrical enclosure cooling system, contact KDM Steel, we will provide you with the best enclosure cooling system solution, order or no order, we’re always happy to help your business.

KDM ensures maximum control over quality and the ability to design and produce custom to customers’ specifications.

We can help you design your product and have the capability of fastly producing for your evaluation.

Our products undergo extremely accurate quality control for the quality you request.

KDM can also manufacture other that are related to electrical enclosure cooling systems such as Quiet Cooling Fan System with Speed Control, Cooling Dual-Fan System with Thermostat Control, USB Powered Cooling Fan Kits, USB Blower Fan with Speed Control, and more.

Get a quick quote for your electrical enclosure cooling system order now!

Electrical Enclosure Cooling System: The Ultimate FAQ Guide

- Why Do You Need an Electrical Enclosure Cooling System?

- How do You Fully Integrate Electrical Enclosure with Cooling Systems?

- How Does Heat Damage Electrical Components?

- What is Enclosure Cooling?

- Open-loop or Closed-loop Enclosure Cooling System; How Do They Compare?

- Where Can You Mount Electrical Enclosure Cooling Systems?

- Do Enclosure Cooling Systems have Remote Monitoring Capability?

- What is a Side Mount Enclosure Filter Fan?

- What is a Directional Cooling Fan for Electrical Enclosures?

- Can Vent and Louvers Cool Electrical Enclosure?

- What is NEMA Requirement for Enclosure with Cooling System?

- For Hazardous Locations, What is the Best Enclosure Cooling System?

- How Efficient is the Electrical Enclosure Cooling System?

- What Causes Electrical Enclosure to Heat Up?

- How Do You Determine Enclosure Heat Load?

- What is Air Conditioner Enclosure Cooling System?

- How Do Vortex A/C Enclosure Coolers Work?

- Electrical Enclosure Air Conditioner vs. Enclosure Vortex Cooler; How do they Compare?

- Where Can You use Thermostat Controlled Electrical Cabinet Cooling System?

- What is a Sealed Enclosure Cooling System?

- Our Ventilation Systems Part of Enclosure Cooling System?

- How Fast will Electrical Enclosure Eliminate Unwanted Heat?

- How Frequently Should You Maintain Enclosure Cooling System?

- How do Above Ambient and Sub-ambient Enclosures Cooling System Compare?

- When Do You Need a Sealed Enclosure Cooling System?

- What is a Thermoelectric Cabinet Cooler?

- How do Enclosure Heat Sinks Work?

- What is Hot Spot in Electrical Enclosure?

- How Do You Reduce Enclosure Cooling Fan Failure?

- What Are the Common Mistakes when Sizing Electrical Enclosure Cooling System?

- What Air to Air Heat Exchanger?

- What are the Benefits of Fan and Filter System?

- Can You Recommend Best Temperature Control Solutions for Electrical Enclosure?

- What is Heat Pipe Electric Cabinet Coolers?

- How Do You Choose Cooling Systems for IP Enclosures?

- What is Electrical Enclosure Thermal Management?

- How Do You Determine Suitable Thermal Management Solution for Enclosures?

- How Does Electrical Enclosure Cooling System Work?

- When Should You Upgrade Enclosure Cooling System?

- What Type of Enclosure Cooling Systems does KDM Provide?

- Why Choose KDM for Your Enclosure Cooling Solutions?

- Does KDM Provide Enclosure Cooling System Maintenance and Replacement?

- Will KDM Provide Custom Enclosure Cooling Solution?

- How Does KDM Test Electrical Enclosure Cooling System?

- Can You Add Cooling Systems Once You Purchase KDM Electrical Enclosure?

- Does KDM Assemble Large Electrical Enclosure On-Site or in the Factory?

- What is KDM MOQ for Electrical Enclosure with Cooling System?

- Does KDM Manufacture Enclosure Cooling Systems In-house?

- Can KDM Help in CAD Drawing of Electrical Enclosure?

- How Much Does KDM Sell Electrical Enclosure Cooling Systems?

Why Do You Need an Electrical Enclosure Cooling System?

You need electrical enclosure cooling systems to:

i. Control the maximum internal temperature of the enclosure to the recommended threshold

II. Remove access heat from the electrical enclosure. The excess heat may be from the surrounding environment or dissipated by the electronic components.

iii. Reduce components failure due to excess heat

iv. Lower cost of operating electrical enclosures and systems

a. Prevent malfunctioning caused by overheating

vi. Extend electronic component service lifespan

viii. Eliminate the possibility of a fire outbreak due to overheating

Additionally, during the electrical enclosure cooling process, you will protect it from dirt, corrosive vapor, debris, etc.

Electrical enclosure cooling system – Photo courtesy

In the long run, you will save money and time, hence optimizing operations.

How do You Fully Integrate Electrical Enclosure with Cooling Systems?

There are many electrical enclosure cooling systems and accessories such as air conditioners, fans, ventilation systems, vortex coolers, etc.

Therefore, by integrating an electrical enclosure with a cooling system, you debe choose a set of accessories that optimally remove excess heat from the enclosure.

To achieve this, you must consider the following:

- UL certified enclosure cooling system

- A cooling system that guarantees optimal productivity

- Thermal load of the electrical enclosure

- Fully automated (where necessary), with the ability to control all/some operations remotely or automatically

- Cools and protects the enclosure from dirt or water ingress

- By understanding the surrounding environment, you can choose an open-loop or closed-loop enclosure cooling system

- The cooling system must maintain CE requirements, NEMA rating, and IP rating

- Exact location to install an electrical enclosure cooling system

With all these, you can choose and install the enclosure cooling system for optimal temperature control.

How Does Heat Damage Electrical Components?

Excess heat due to overheating will cause partial or total electronic components breakdown.

The damage can be in the form of:

- Burnt electrical component

- Material degradation of electronic components can manifest itself as deformation, cracks, expansion, change in color, etc.

- Electronic component failure

- Inaccurate transmission of signal or compromise signal integrity

- Increased stress that hinders normal performance

Overheating can cause an explosion or fire outbreak that eventually causes injuries and component damage.

Some of the main causes of heating are insulation breakdown, inadequate cooling system, poor connections, and excess currents.

Here is a research paper on the Effects of Heat on Electronic Components.

What is Enclosure Cooling?

Enclosure cooling is the process of maintaining a normal operating temperature within the electrical cabinet.

It aims to protect enclosure and electrical components from high internal heat loads that can cause component breakdown/failure, overheating, or fire.

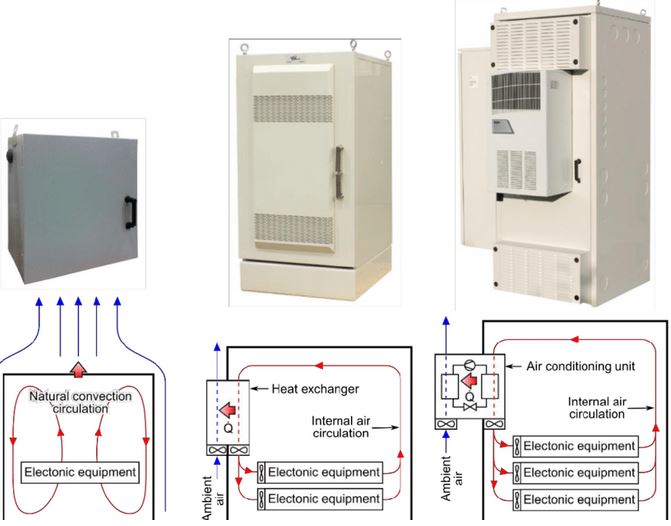

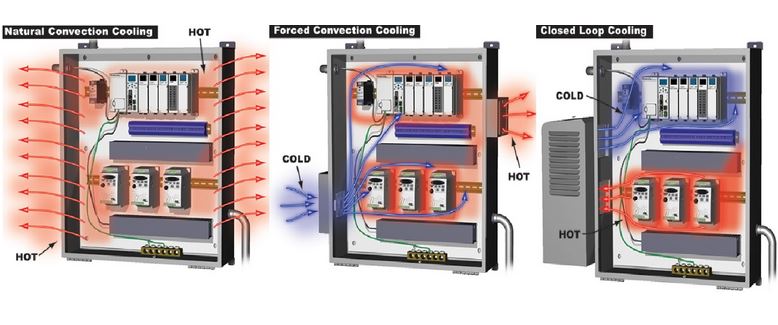

There exist many enclosure cooling mechanisms such as closed-loop cooling, natural convection cooling, and forced convection cooling.

Ways of cooling enclosure – Photo courtesy: Automation Notebook

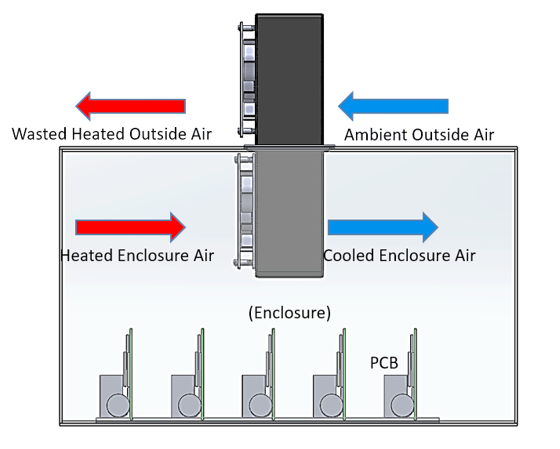

Open-loop or Closed-loop Enclosure Cooling System; How Do They Compare?

|

Closed-loop Electrical Enclosure Cooling System |

Open-loop Electrical Enclosure Cooling System |

| Suitable for harsh and hostile environments where NEMA 4x enclosures are a perfect choice |

Recommended for normal outdoor and indoor conditions where the environment is favorable (clean and cool surrounding areas) such as where you can use NEMA 1 enclosure |

|

High initial installation cost |

Initial installation cost is low |

| Completely isolates the surrounding environment from the internal section of the enclosure, i.e. air within the enclosure does not mix with the surrounding |

Ambient air and that of the enclosure mix hence it does not isolate the two environments |

|

Can attain very low working temperature below the surrounding ambient air |

Cannot lower the internal temperature of the enclosure below the ambient temperature of the surrounding air |

| Best for high heat loads |

Suitable for low heat loads |

|

By completely isolating the enclosure, there will be no dirt, corrosive vapor, dirt, gases, or water vapor ingress |

Dirt, corrosive vapor, humidity, or dirt can infiltrate the electrical enclosure |

| Examples include heat exchangers and air conditioners |

Examples include filter fans and ventilation systems such as louvers |

Where Can You Mount Electrical Enclosure Cooling Systems?

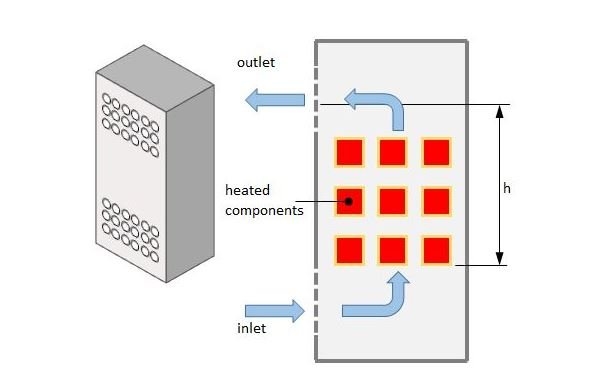

The best location will depend on the design of the caja eléctrica and the type of cooling system.

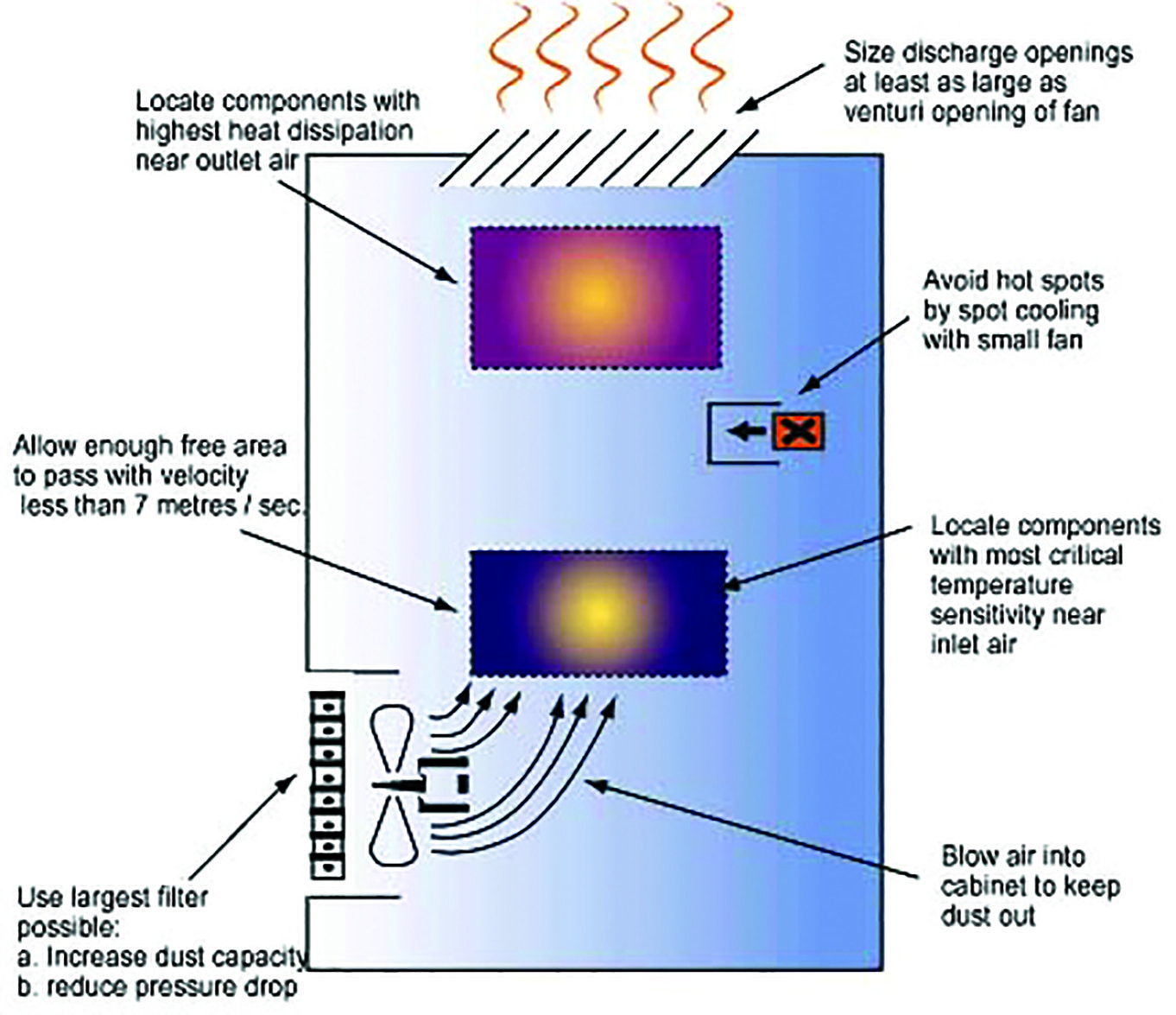

For instance, most enclosure cooling fans are on the lower corner of the electrical enclosures while the outlet grills are on the upper section.

On the other hand, enclosure air conditioners are always at a central location.

Still, as a rule of thumb, the enclosure cooling system should allow for optimal flow of air and cooling.

Do Enclosure Cooling Systems have Remote Monitoring Capability?

Some enclosure cooling systems such as the closed-loop designs have remote monitoring capability.

However, most open-loop cooling systems do not have this feature.

When importing an electrical enclosure with the cooling system, specify if you need a remote monitoring capability.

What is a Side Mount Enclosure Filter Fan?

These are cooling systems you can mount on the wall of an electrical enclosure panel.

As the name suggests, they have both a fan and filter system.

They come when fully assembled, so you will fix them on the enclosure, and connect the power source.

Side-mount enclosure filter fan

What is a Directional Cooling Fan for Electrical Enclosures?

Directional cooling fans blow air in a specific direction with the electrical enclosure.

They are a perfect choice for dealing with hot spots in electrical enclosures.

Depending on the design and size, you can install it on the DIN rail or the wall of an electrical enclosure.

Directional fan – Photo courtesy: Electronics cooling

Can Vent and Louvers Cool Electrical Enclosure?

Yes, vents and louvers are important parts of Ventilación del armario eléctrico and cooling systems.

Vents in an electrical enclosure

In electrical enclosures that depend on natural convection cooling systems, the vents and louvers allow for a free flow of air.

The cool ambient air flows into the enclosure thereby providing the necessary cooling.

What is NEMA Requirement for Enclosure with Cooling System?

The requirements vary depending on the type of NEMA enclosure rating.

Therefore, whether you choose electrical cabinet cooling fans, heat exchangers, or enclosure air conditioners, they must conform to specific Caja NEMA specifications.

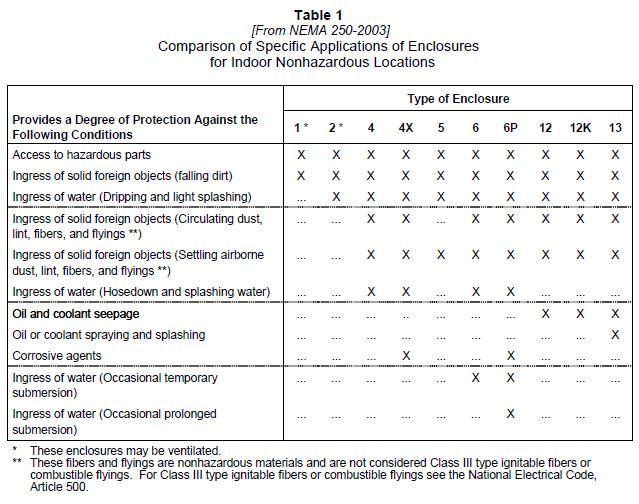

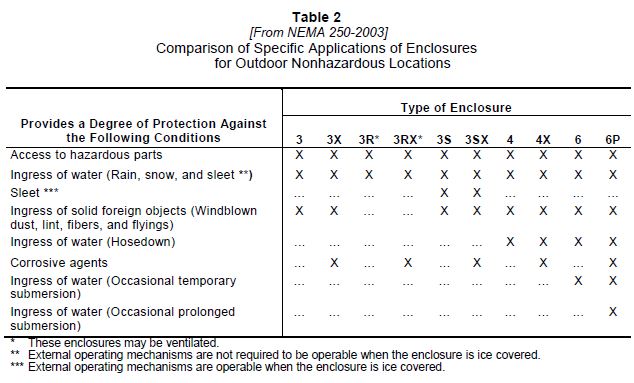

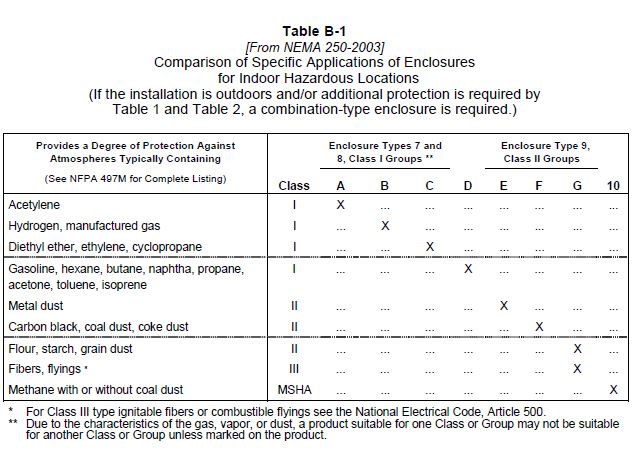

Use the following NEMA enclosure table requirement when choosing cooling systems.

All tables courtesy of NEMA.ORG.

NEMA Enclosure table 1

NEMA Enclosure table 2

NEMA enclosure tablet B1

Note: Anytime you choose an electrical enclosure cooling system, it debe conform to the NEMA enclosure standards and requirements.

For Hazardous Locations, What is the Best Enclosure Cooling System?

You should choose an electrical enclosure for air conditioners.

Closed-loop cooling system – Photo courtesy: Automation Notebook

They will completely isolate the surrounding environment from the internal section of the electrical enclosure.

Consequently, there will be no dust, dirt, moisture, corrosive gases, or excess heat ingress from the external environment into the enclosure.

It is for this reason that air conditioners are common cooling systems in NEMA 4x enclosures.

How Efficient is the Electrical Enclosure Cooling System?

The degree of efficiency will depend on:

- Type of electrical enclosure cooling systems – whether you are using fans, air conditioners, or other ventilation systems

- Size of an electrical enclosure

- Components in the electrical enclosure

- The environment around the electrical enclosure

Generally, the modern electrical enclosure cooling systems are fully integrated to provide an efficient and eco-friendly cooling mechanism.

For your unique electrical enclosure cooling requirements, talk to the manufacturer who will tailor a sustainable solution for you.

What Causes Electrical Enclosure to Heat Up?

i. The heat from the surrounding environment is transmitted into the enclosure

II. Inappropriate insulation that may prevent the enclosure from radiating heat to the surrounding environment

iii. Electrical components dissipate heat during their normal operation such as drives, PLC systems, transistors, servers, transformers, etc.

iv. Lack of proper ventilation and cooling system for the enclosure

a. Failure to comply with the set enclosure standards and regulations

How Do You Determine Enclosure Heat Load?

Electrical enclosure heat load is the total amount of heat from the external environment into the electrical cabinet plus, heat dissipated by the enclosure components.

Heat load forms the basis of choosing an electrical enclosure cooling system.

For example, where there is a high enclosure heat load, a closed-loop cooling system will be a perfect choice.

On the other hand, for low internal heat load, go for an open-loop cooling system.

Electrical enclosure

This is how to estimate the total enclosure heat load.

Technique 1 Determine the Theoretical Heat Loss

By estimating the theoretical heat loss within the electrical enclosure, you can easily estimate the total internal heat load.

In this technique, you will:

i. Identify the electrical enclosure input and output conductors. Then, go ahead to determine the operating voltage and current for each.

II. Calculate the power for each conductor using the formula – Power = Voltage x Current

iii. Add power from the input and output conductors separately

iv. To get theoretical heat load use the formula – Power Input – Power Output

Technique 2: Estimate Heat Dissipated by Each Component

In this technique, you will examine the efficiency of the individual electrical components in the enclosure.

Normally, every electrical component has a part number, datasheet, or details about power consumption, heat dissipation/loss, efficiency, etc.

In case you can’t find such information, you should use similar components for the estimation.

You can use the efficiency of the components to estimate the heat dissipated or wasted by each device.

Then go ahead to add the values to determine the total heat load for the enclosure.

For instance, let’s look at a VFD with an efficiency of 97%, which is rated 1200W.

Assuming it is operating to full capacity.

Then, it’s likely to dissipate the amount of heat equivalent to 1200 × (1-0.97) = 36W.

Implying, if the enclosure has one VFD, then the heat load will be 36W.

However, if they are two, then it will be 36+36=72W.

Remember, electronic components manufacturers’ will indicate the efficiency and the power rating of their devices.

Technique 3: Considering Variables that Affect Enclosure Heat Load

Unlike techniques 1 and 2, here, you will consider all the variables that are likely to affect the total heat load of the electrical enclosure.

Here is how to go about it:

- Calculate the total surface area of the electrical enclosure that is exposed to air

- Determine the heat transfer coefficient (it varies from one enclosure material to another)

- Calculate electrical enclosure conductance – Enclosure surface area × heat transfer coefficient

- Calculate the change in temperature – Enclosure temperature – ambient temperature

- Total heat load for the enclosure = Change in temperature × Electrical enclosure conductance

With the information about the internal heat load of electrical enclosures, you can determine a suitable thermal management system for your enclosure.

That is, you will choose an appropriate electrical enclosure cooling system.

What is Air Conditioner Enclosure Cooling System?

It is a closed-loop cooling system, which uses refrigeration cycles to remove excess heat during electrical enclosure thermal management.

That is, it “sucks” hot air in the electrical enclosure, directs it into the evaporator coil that cools it.

Once it cools the hot air, the air conditioner recirculates it in the electrical enclosure.

Consequently, it cools an electrical enclosure and its components.

During the process, the air conditioner completely isolates the internal and external environments of the electrical enclosure.

How Do Vortex A/C Enclosure Coolers Work?

Vortex enclosure cooler – Photo courtesy:EVENT

Vortex enclosure cooler uses a slightly unique principle.

It uses a pressurized system to ensure the electrical enclosure cabinet remains dry and clean.

Besides, most of the vortex enclosure coolers control the working temperature range using a thermostat.

For consistent airflow, vortex enclosure coolers depend on compressors.

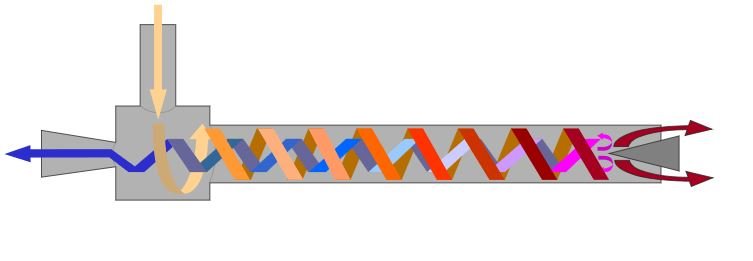

They use a Ranque-Hilsch vortex tube (vortex tube) that creates a swirling effect.

The swirling effects separate compressed air into two streams – hot and cold.

Hot and cold air stream – Photo courtesy: Wikimedia

As a result, the vortex A/C enclosure cooling system causes a high-speed rotating air stream, flowing down to the vortex tube and into an electrical enclosure.

At this stage, a series of events take place:

i. A portion of exhaust air, with a slightly elevated temperature, leaves through the needle valve of the hot tube.

II. Remaining air will flow back through the vortex tube, at the center of the incoming rotating air stream at a low speed

iii. Heat transfer takes place, from slow-moving air to high-speed rotating air

At this stage, cool air flows to the generator and leaves via exhaust the port for cold air.

The vortex A/C enclosure cooling design is such that, the cooler has an inbuilt exhaust.

Therefore, you don’t need vents for such electrical enclosures.

At the same time, a positive purging effect removes dirt and debris from the enclosure.

By the end of the process, it keeps the enclosure component cool and clean.

Electrical Enclosure Air Conditioner vs. Enclosure Vortex Cooler; How do they Compare?

|

Electrical Enclosure Air Conditioners |

Electrical Enclosure Vortex Coolers |

|

Large size for same cooling capacity |

Small size for same cooling capacity hence suitable where space is limited |

| May have a heating option |

No heating option |

|

Depends on refrigerant and coils for enclosure cooling |

Depends on compressed air and vortex tubes to cool the enclosure |

| Requires direct electrical connections |

May not require a direct electrical connection |

|

Has moving parts such as fan system |

Has almost no moving part |

| Can work anywhere |

Works where there is a source of compressed air |

|

Thermoelectric air conditioners are environmentally friendly and compressor-based use refrigerant chemicals |

Requires high energy for enclosure cooling |

| Portable |

Only portable when you have a mobile air compressor system |

|

Operates quietly |

Produces a lot of noise |

| Can either be electro-mechanical or solid-state |

Are mainly pneumatic systems |

|

Operating and initial installation cost is moderate |

Operating cost is very high however if there is an existing air compressor system, the initial installation cost is very low |

| Can cool enclosure below ambient temperature |

Cools electrical enclosure below ambient temperature |

Where Can You use Thermostat Controlled Electrical Cabinet Cooling System?

Thermostatically controlled cooling systems are suitable where you want to maintain the temperature within a specific range.

The thermostat will switch ON/OFF the enclosure cooling system depending on the calibration requirements.

Besides, they are suitable for electrical enclosures in hostile environments, closed-loop, and open-loop cooling systems.

What is a Sealed Enclosure Cooling System?

It is an above ambient enclosure cooling system with limited capacity that completely isolates the internal and external enclosure environment, while efficiently removing excess heat from enclosure cabinets.

Sealed enclosure cooling systems are cost-effective and suitable where the internal temperature of the enclosure is higher than the external environment.

Our Ventilation Systems Part of Enclosure Cooling System?

Yes; ventilation systems form an integral part of electrical enclosure cooling systems more so in:

i. Natural convection cooling – here cold air around the enclosure flow in freely and leaves through the louvers or enclosure ventilation systems.

II. Forced convection cooling – electrical enclosure cooling fans and blowers, suck surrounding air (cold) and forces it into and out of the enclosure through the louvers and vents.

Cooling enclosure through ventilation system – Photo courtesy: Automation Notebook

So, ventilation systems provide a path through which airflow in and out of the electrical enclosure.

How Fast will Electrical Enclosure Eliminate Unwanted Heat?

It will depend on the electrical enclosure thermal management strategy.

That is, with an efficient electrical enclosure cooling system, and a proper understanding of thermal load; it will take a few minutes.

To eliminate unwanted heat faster, choose a cooling system that matches the exact specifications of the electrical enclosure.

How Frequently Should You Maintain Enclosure Cooling System?

The time interval will depend on:

- Where you have installed the electrical enclosure – outdoor, indoor, or hazardous environment

- Type of enclosure cooling system – they could be air conditioners, fan filters, louvers, etc.

- Nature of the maintenance process – it can be general cleaning, condensate management, or part replacement

Generally, you can have a regular maintenance and cleaning schedule that ranges from after 7 days to 1 or 2 months.

You should inquire from the manufacturer about the recommended schedule for cleaning and maintaining enclosure cooling systems.

How do Above Ambient and Sub-ambient Enclosures Cooling System Compare?

You can classify electrical enclosure cooling systems as:

- Above ambient enclosure cooling systems – here, the temperature inside the electrical enclosure is higher than the external temperature (ambient temperature). Among the cooling systems in this category include filter fans, heat pipe coolers, and heat sinks.

- Sub-ambient enclosure cooling systems – here, the temperature inside the electrical enclosure is lower than the surrounding environment (ambient temperature). It implies that, in sub-ambient cooling, both natural convection y forced convection cannot provide efficient cooling. Some of the main enclosure cooling systems in this category include liquid to air heat exchangers, vortex coolers, thermoelectric coolers, and air conditioners.

When Do You Need a Sealed Enclosure Cooling System?

You need sealed enclosure cooling systems in sub-ambient cooling.

It is where you install the electrical enclosure in hostile or hazardous environments.

It is a situation where the enclosure must provide sufficient cooling, while completely isolating the two environments (inside and outside the electrical enclosure).

It implies a sealed enclosure cooling system will maintain a suitable temperature within the enclosure, without the possibility of dirt, dust, moisture, water or corrosive vapor ingress.

What is a Thermoelectric Cabinet Cooler?

Also called Peltier coolers, from Peltier Effect; are special types of cooling systems designed for harsh and hazardous environments.

The working principle of thermoelectric cabinet coolers depends on Peltier Effect.

Peltier effect states that; when you apply a voltage across a junction between two materials, heat is either absorbed or given out.

Implying, when transferring heat from one electrical junction to another, there will be a temperature difference.

As current flows, and heat is transferred from one junction to another, there will be a cooling effect.

Peltier effect forms the basis for designing thermoelectric air conditioners. Still, you can use the Peltier effect for temperature control and heating.

How do Enclosure Heat Sinks Work?

Heat sinks are flat or protruded (with fins) metal structures that “trap” heat from the surrounding air and conduct it away, creating a cooling effect.

With the help of a fan mechanism, enclosure heat sinks will conduct heat from the enclosure to the surrounding environment.

This effect will cool the electrical enclosure.

Heat sink

What is Hot Spot in Electrical Enclosure?

At times, you may have areas within the electrical enclosure that you cannot cool through natural convection resulting in the accumulation of heat.

Such sections are called hot spots.

They are mainly due to the restricted flow of air within the electrical enclosure or undercuts.

In case you want to know whether there are hot spots in an electrical enclosure, use any of the following techniques:

- Heat transfer simulations

- Infrared testing

- Thermal imaging

How Do You Reduce Enclosure Cooling Fan Failure?

i. Service and maintain enclosure cooling fan regularly

II. Consider the electrical enclosure fan rating before installation

iii. Troubleshoot cooling fan according to manufacturer’s guidelines

iv. Buy high-quality enclosure cooling fans that conform to the market standards and regulations

a. Don’t overuse the fan or operate it unnecessarily to reduce the rate of wear and tear

vi. Enclosure cooling fan must work in only those conditions recommended by the manufacturer

viii. Only trained technicians should maintain, replace or adjust the enclosure cooling fan

What Are the Common Mistakes when Sizing Electrical Enclosure Cooling System?

- Choosing an oversized electrical enclosure cooling system

- Buying enclosure cooling system before calculating the internal heat load of an electrical cabinet

- Using air conditioners in ventilated electrical enclosure systems

- Failure to consider IP and NEMA enclosure rating

- Assuming any electrical cooling system can work on any enclosure

- Failure to maintain and service the enclosure cooling system

- Hiring untrained technicians to install or upgrade the enclosure cooling system

- Choosing a cheaper and low-quality enclosure cooling system

- Ignoring the environmental effects on electrical enclosure cooling and heating

- Failure to consider allowable thermal limits

What Air to Air Heat Exchanger?

Air to air heat exchanger – Photo courtesy: Cooling Source

Air to air heat exchangers is closed-loop cooling systems for enclosures that effectively remove excess heat while isolating internal and external environments of the electrical cabinet.

Most electrical enclosure air to air heat exchanges use copper pipes with small fins that facilitate faster heat dissipation and absorption.

The copper tubes are filled with a liquid that easily into different phases (from liquid to vapor and vice versa).

Now, to cool the electrical enclosure, this is what happens:

- Installation of air to the air heat exchanger is such that one end is the enclosure while the other section is in direct contact with ambient air.

- As the electrical enclosure gets heated, the copper tubes and fins absorb heat, thereby heating the liquid in copper tubes.

- The liquid in copper tubes readily vaporizes into vapor and moves to the end of the air to the air heat exchanger.

- Once the vapor reaches the opposite side, copper tubes and fines expel heat (dissipate heat to the external environment), and it changes into liquid again.

- It again flows back into the enclosure. After this, the cycle repeats, as it cools the electrical enclosure.

Unlike other enclosure cooling systems, air to air heat exchangers don’t have any moving parts.

It makes them efficient and cost-effective due to low maintenance costs.

Besides, the working principle depends on the ability to transfer heat from a hot to a cold region or medium.

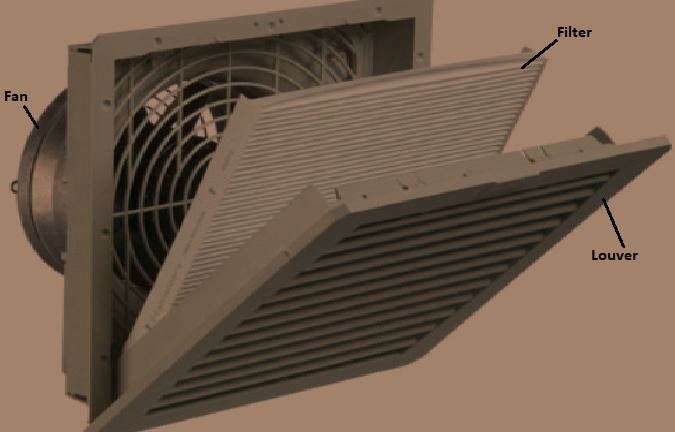

What are the Benefits of Fan and Filter System?

Electrical enclosure filter fan

Fan and filter systems provide and efficient forced convection cooling in electrical enclosures.

The enclosure fan and filter systems are made up of:

- Louver system that allows air to flow into the electrical enclosure

- The filter system, which removes possible contaminants such as dirt, dust, and moisture

- Fan system which circulates air into the electrical enclosure

Can You Recommend Best Temperature Control Solutions for Electrical Enclosure?

When it comes to temperature control in electrical enclosures, you can choose any of the following:

- Compressor based air conditioners

- Fans and filter system

- Air to air heat exchangers

- Enclosure ventilation system (louver and vents)

- Thermostatic air conditioners

- Vortex coolers

- A heat sink cooler heat exchanger

Choosing a specific technology will depend on the environment, efficiency, and enclosure cooling requirements.

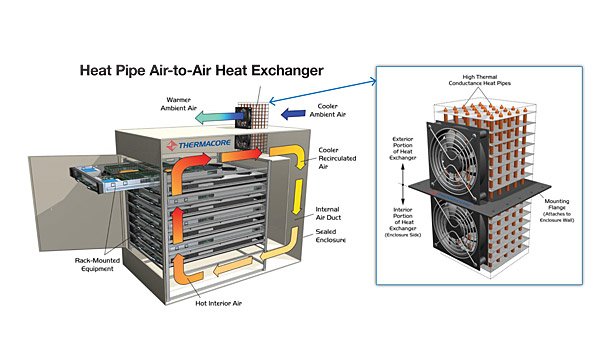

What is Heat Pipe Electric Cabinet Coolers?

Heat pipe technology plays a fundamental role in the air to air heat exchangers.

It makes them a popular closed-loop enclosure cooling system.

The heat pipe enclosure cooling technology depends on two main principles:

- Conduction – pipes conduct heat energy from the enclosure and to the outside environment

- Phase transition – vaporization and condensation of the coolant fluid in the pipe

Mostly, the pipe features copper material due to its excellent conduction properties.

At times, the copper pipes may have small fins to increase the surface area for heat absorption and dissipation.

Inside the copper pipes, there is a coolant fluid that easily changes phases from liquid to gas.

Here is what happens:

Heat pipe air to air heat exchanger – Photo courtesy: Process Cooling

The pipes absorb heat from the air in the electrical enclosure and conduct it to the coolant fluid.

Coolant fluid heats up, evaporates to the opposite side.

When on the opposite section, it gives up this heat energy to the external environment.

At the same time, the coolant fluid then transitions from vapor to liquid and flows back to the initial location.

It is a continuous process that efficiently cools electrical enclosures.

How Do You Choose Cooling Systems for IP Enclosures?

- You need to understand the unique specifications of the Cajas IP you want to cool.

- Calculate the total heat load for the IP enclosure.

- Understand the surrounding environment where you intend to install the IP enclosure with a cooling system.

- Choose a suitable enclosure cooling technology.

- Remember to consult the IP enclosure manufacturer or an expert.

What is Electrical Enclosure Thermal Management?

It is the process of monitoring, evaluating, and controlling the internal temperature of an electrical enclosure.

The process involves a proper analysis of the temperature outside and inside the electrical enclosure.

It aims at striking a balance that will ensure optimal temperature that will prevent overheating and maximize the working of enclosure components.

How Do You Determine Suitable Thermal Management Solution for Enclosures?

- Know the electrical enclosure specifications such as size, ventilation systems, insulation, etc.

- Calculate the total amount of heat dissipated by enclosure components

- Determine the temperature of the surrounding environment

- Know the desired operating temperature of enclosure components

- Understand the property of the surrounding environment – Is it hostile and hazardous or normal conditions?

- Choose a suitable electrical enclosure cooling system?

How Does Electrical Enclosure Cooling System Work?

They create a suitable environment within an electrical enclosure for components to function optimally.

How the electrical enclosure cooling system works will depend on the technology.

Some use a closed-loop cooling technology, whereas others depend on forced convection.

Besides, they also depend on the various ways of heat energy transmission – convection, conduction, and radiation.

When Should You Upgrade Enclosure Cooling System?

It is important to upgrade the enclosure cooling system when the heat load increases.

Also, you may upgrade the enclosure system when:

- Environmental conditions change – say from indoor to outdoor or normal to hostile conditions

- You need to adapt to changes in enclosure cooling technology

What Type of Enclosure Cooling Systems does KDM Provide?

We provide a range of enclosure cooling solutions such as fans, filter systems, heat exchangers, ventilation systems, air conditioners, heat sinks, heat pipes, and vortex coolers amongst others.

Our technicians will help you to determine a suitable electrical enclosure cooling system depending on your environment and heat load.

Why Choose KDM for Your Enclosure Cooling Solutions?

KDM provides eco-friendly, efficient, cost-effective, and reliable enclosure cooling solutions.

We have an enclosure cooling system for both above ambient and sub-ambient cooling solutions.

They come in different sizes and enclosure cooling capacities depending on your unique requirements and specifications.

Does KDM Provide Enclosure Cooling System Maintenance and Replacement?

KDM can send technicians or recommend maintenance experts in your area.

It will depend on the nature and complexity of the problem.

Also, we provide enclosure cooling system replacement.

Even if you did not buy it from us, KDM would give you an exact replacement for your enclosure cooling needs.

Will KDM Provide Custom Enclosure Cooling Solution?

Yes, simple, send us the following information:

- Enclosure dimensions

- Where do you want to install the enclosure

- Intended enclosure components

Our team will estimate the enclosure heat load and recommend a custom enclosure cooling solution.

How Does KDM Test Electrical Enclosure Cooling System?

KDM adheres to strict quality testing of the electrical enclosure cooling performance.

All our enclosure cooling systems are:

- UL listed

- CE compliant

- IP rating compliant

- NEMA rating compliant

- NFPA compliant

- CSA compliant

KDM tests all enclosures and cooling systems according to international standards, and we provide test reports.

Can You Add Cooling Systems Once You Purchase KDM Electrical Enclosure?

Yes, you can.

However, you should discuss this with our technicians so that we advise you accordingly.

KDM team offers free consultation on electrical enclosure cooling systems.

Does KDM Assemble Large Electrical Enclosure On-Site or in the Factory?

We prefer to assemble the large electrical enclosures on-site. Our electrical enclosures are easy to assemble.

The reason we insist on this is to save on shipping space and cost.

What is KDM MOQ for Electrical Enclosure with Cooling System?

KDM offers flexible MOQ for electrical enclosures with cooling systems starting from 1 piece.

Just Habla con nuestro equipo hoy, so that we can give you a way forward.

Does KDM Manufacture Enclosure Cooling Systems In-house?

KDM manufactures some cooling systems in-house but others we source from top brands in the global market.

We have good working relationships with our partners, and KDM will certainly provide you with the best enclosure cooling system.

Can KDM Help in CAD Drawing of Electrical Enclosure?

Yes, our technicians will help you with concept development, CAD drawing, manufacturing/fabrication, quality testing, shipping to installation.

How Much Does KDM Sell Electrical Enclosure Cooling Systems?

It will depend on the size, design, and enclosure cooling capacity.

One thing you can count on is that KDM offers competitive prices on electrical enclosure cooling systems.

Simply tell our technicians what you want, and you will get a quotation within 24 hours.