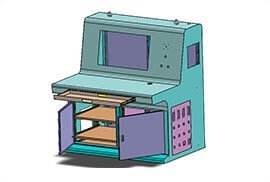

- Custom Nema electrical enclosure based on your picture or drawing

- 2D or 3D drawing in 1 day, sample in 3 days

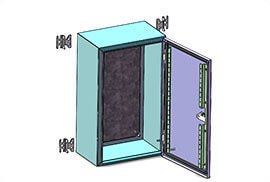

- IP65/IP66 Report for All Customized Electrical Enclosures

Tailor-Made Unique Electrical Enclosure for Your Project

The precision of KDM Electrical Enclosure:

+/- 1mm tolerance for overall cabinet size

Standard Configuration:

Gland plate, radiating fan, fluorescent lamp, lamp switch, ground connections, PU foaming seals.

Warranty:

1-year warranty for KDM electrical enclosure, you will get free accessories within our warranty

Envíe su consulta sobre los gabinetes eléctricos lavables KDM

Como fabricante líder de todo tipo de gabinetes, incluidos los gabinetes para control de tráfico, KDM tiene las soluciones que necesita. Nos especializamos en el ensamblaje de paneles de control repetibles y de alta calidad. En KDM, controlamos cada paso para garantizar que su proyecto cumpla con los estándares más altos posibles.

La caja de control de tráfico KDM ha sido fabricada por nuestros ingenieros experimentados con tecnologías avanzadas. Nuestro equipo de profesionales trabajará con usted en cada paso del proceso, asegurándose de que obtenga productos de caja de control de tráfico de la más alta calidad. Nuestro objetivo siempre ha sido construir relaciones a largo plazo con usted.

- Capacidad de fabricación

Máquina de corte láser de alto rendimiento de 4000 W, precisión de +/- 0,05 mm. Sin rebabas ni rayones.

Equipo de soldadura flexible multifunción, alta precisión, sin deformación.

Precisión de doblado de +/- 0,5 mm, superficie lisa sin marcas de doblado.

Más de 10 trabajadores con experiencia en soldadura, apariencia general perfecta.

Máquinas de espumado de alta velocidad y precisión, empaquetadoras rápidas y calificadas.

Equipo de ensamblaje experto, calidad de ensamblaje constante en cada gabinete KDM

KDM Electrical Enclosure Manufacturing Capacity

What Types of Custom Electrical Enclosures Can KDM Make?

Custom Electrical Enclosures

KDM is a professional custom electrical enclosure manufacturer in China. They designed electrical enclosures suitable for indoor and outdoor applications. Custom enclosures can be built to virtually any size and dimension. It has a precision-cut opening for the perfect fit. All custom electrical enclosures they produced meet any industry standards including UL Certifications & IEC Ingress Protection.

What are the Elements Must Consider for Custom Design Electrical Enclosures?

Custom electrical enclosures will add value to your product. It is a more application-specific and functional enclosure with a unique appearance.

Some are the elements your manufacturer must consider in custom electrical enclosures productions:

- Enclosure sizes

- Gland Plates

- Standing Types

- Box Colors

- Specific Cutouts

- Ventanas

- Door Types

- Mounting Plates

- Thickness of sheets

- Door Locks

- Protective Covers/ Shielding

- Special Packaging

- Other accessories insulation, lights, fans, and more

How to Manufacture Custom Electrical Enclosures?

- The manufacturer should verify your project type

Your manufacturer will consult you to understand the nature of your applications. The team will recommend and advise the best custom electrical enclosures.

- Choosing the Right IP Rating

Electrical enclosures for indoor and outdoor installations have their own specific IP ratings. The manufacturer should ensure the right IP rating for your custom enclosures.

- Verify the Enclosure Configuration

Confirmation of the interior design details of an enclosure. It includes racks and paneling of your electrical enclosures.

- Custom Enclosures Design

Once it’s done confirming the interior designs and features, your manufacturer will create a custom enclosure design. You can review the design for changes and approval before the enclosure is built.

- Choosing the Right Enclosure Materials

You can choose the best material based on your applications. Electrical enclosures are available in various materials such as weatherproof custom stainless steel enclosures, corrosion-resistant aluminum, galvanized steel, etc.

- Confirming the Enclosure Size ( height, width, or depth )

It is important to know the exact dimensions and sizes of your custom electrical enclosures. Custom-fit electrical enclosures are space-saving, easy to install, and cost-effective.

- Special Power Coat Paint and Finishes

Clients will be satisfied with these modifications for branding purposes. If you want your custom electrical enclosure to stand out and represent your brand, it is perfect for you.

What are the Available Materials in Producing Custom Electrical Enclosures?

You can choose the material on the electrical enclosure based on your project or business. Electrical enclosures are available in various materials such as stainless steel, aluminum, galvanized steel, etc. It has different advantages and features. Enclosures must be made using high-quality materials and in strict adherence to NEMA standards.

Stainless Steel Carbon Steel

It is the strongest among the rest materials. These materials are both durable and corrosion-resistant. It is suitable for manufacturing electrical enclosures. Stainless steels are also moisture resistant and chemical resistant. Stainless steel is available in different grades such as 316, 304, etc.

Carbon Steel

Carbon steel is available in hot or cold rolled. Hot rolled carbon steel is utilized for moderate forming applications. While cold-rolled sheets formed from low-carbon steel. It is cold reduced to a certain thickness.

Aluminio

This material is lightweight and low cost compare to stainless steel. It offers relative strength to any application. Aluminum is a corrosion-resistant material. Due to its sturdy features, it can perform well in harsh environments, withstanding high impact conditions. It is used as a barrier against electromagnetic interference.

All of the mentioned metal cabinets can exceed the conductivity essential for electrical safety bonding and shielding. It protects enclosed equipment from electromagnetic interference.