Your Trustworthy and Dependable EMC Box Supplier in China

KDM is the Leading and Expert Manufacturer and Factory of EMC Box in China

Premier EMC Box Supplier in China

In KDM, we have a wide variety of EMC enclosure that allows you to find the right and great option well-suited for your own application. Ensure reliable, constant operation of equipment and instruments with high-performance EMC enclosure. Our EMC enclosure gives the protection needed for electronic, mechanical, and electromagnetic fields.

This box provides an excellent and complete EMC solution. It has great endurance against high-frequency electronic fields.

- EMC box can be totally customized for own application

- Superior quality yet affordable EMC box

- All EMC boxes meet necessary standards such as CE, ISO

- Largest range of reliable and high-performance EMC box

Request A Quote.

KDM EMC Box Series

The EMC box is guaranteed for enhancing life-long for all installations. It provides perfect compatibility on all electrical, electromagnetic, and magnetic fields.

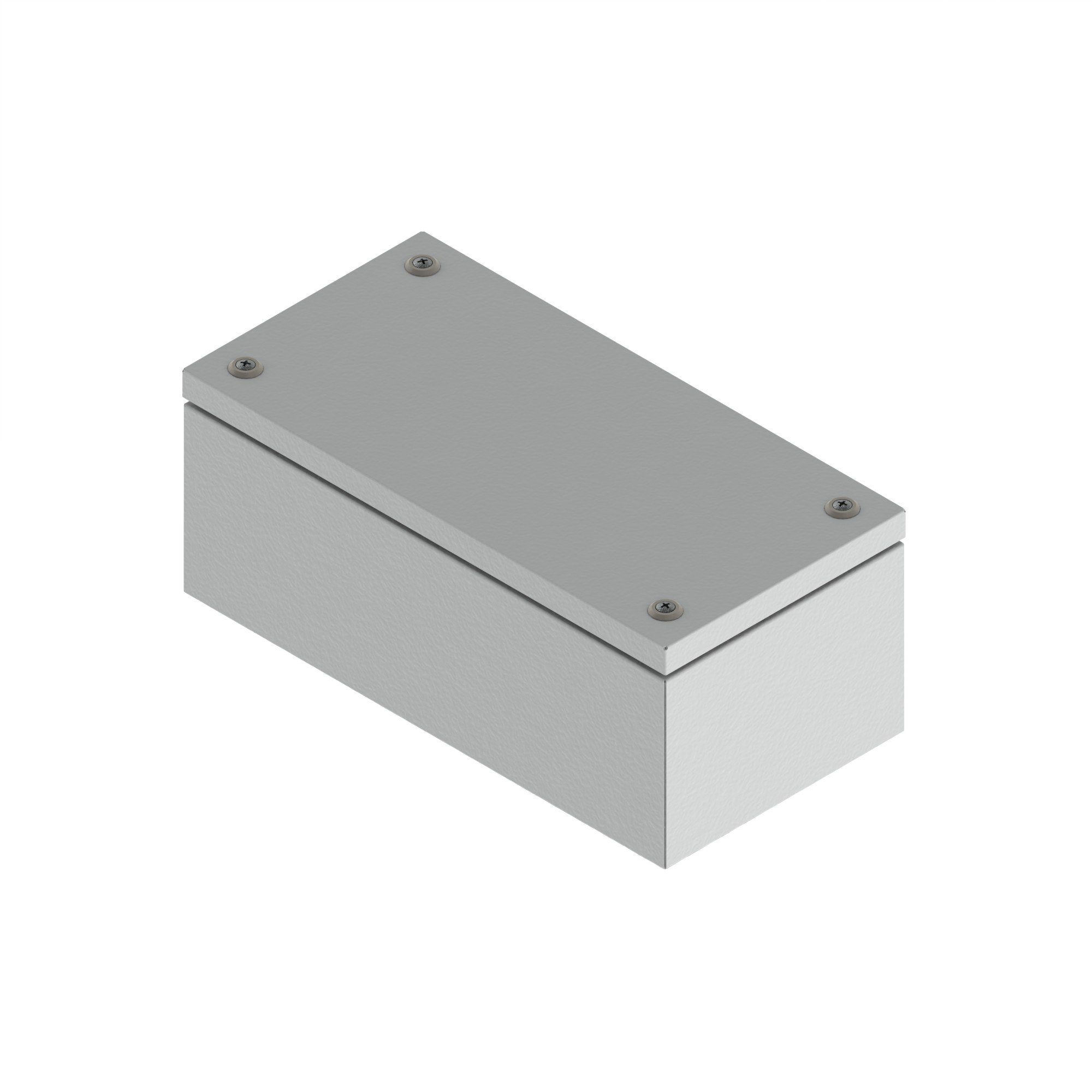

Durable, top-quality EMC junction box provides an optimum shield for prevention to all sensitive components application. The boxes come in different varieties for a wider selection.

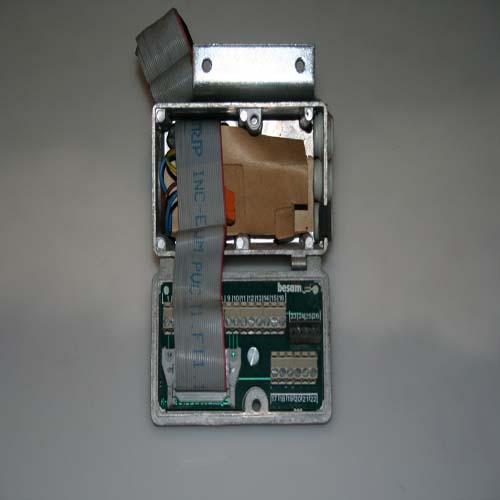

EMC electrical enclosure has the ability to provide a satisfactory solution in all electronic, instrumental fields. It is designed to meet required standards.

The weatherproof EMC Box is the perfect cabinet to be used in outdoor applications. They are tested to provide the optimal solutions for electronic and industrial uses.

The EMC wall mount enclosure is excellently designed to offer full safety solutions in electrical installations. Whether needed for business or any other specific application, you can find great goods for you.

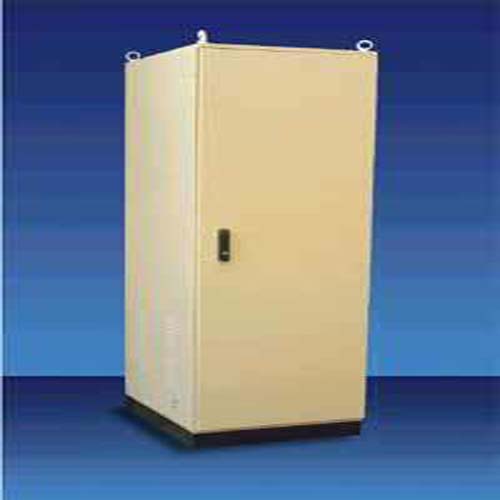

EMC free-stand enclosure offers excellent conductivity thus it meets all the required standards. Each cabinet is tested to withstand extreme environmental conditions.

Send your Inquiry on KDM EMC Box

KDM is one of the world-class EMC enclosure specialists. We design, engineer, manufacture, and develop EMC enclosures to meet the component’s requirements.KDM’s goal is to provide excellent services and complete solutions for your business or any project needs. We can give bespoke service from designing, execution, packaging, and more. We can provide a complete range of EMC enclosures suitable for any crucial application.

- Reliable box allow constant system operation

- Meet and approved regulations for a quality product

- Available in different shapes and sizes

- Better, smarter, and faster result

Related Products of EMC Box

KDM EMC Box

KDM EMC enclosure is designed to meet the harshest and most challenging application.

It is equipped with high performing functions that enhance the system continuous operations.

This enclosure offers a mixture of mechanical and electromagnetic shield property which allows each event flows smoothly.

Every environmental factor and condition concern will be eliminated with high performing EMC box.

KDM cabinets consist of highly effective features such as rigid structure, temperature control and more of.

The enclosure application not only limited to a specific fields, yet it can be applied in the most demanding, critical conditions.

Its strong solutions make it an excellent choice for any critical and risky electronic uses.

The EMC enclosure is made up from heavy-duty metal material.

They have a rigid characteristics to withstand any conditions.

Enclosure can be done with a matte finish so they can provide an optimum solution well suited for applications where EMC requirements will meet.

Each EMC enclosure is created to exceed EMC guidelines and requirements.

Any risk of component failure and malfunction can be prevented, the unnecessary delay will be eliminated.

Our EMC enclosure has great protection from elements such as water, dust, dirt, and many more from entering the cabinet.

KDM Design and engineer EMC enclosure using advanced technical equipment and techniques.

Combined with professional and high-trained engineers and technicians, we are pleased to produce the safest and most valuable solution.

Our technical team will handle the engineering method.

Hence, if you want a unique, new, and innovative product, we can execute customization for your own product application.

Moreover, every enclosure had been tested to various parameters to ensure quality regulations will be met.

CE, ROHS, UL, SGS are some of the authoritative testing authorities where these are enclosures are certified.

For more than 10 years, KDM bears in mind that customers view quality value most.

Therefore, every enclosure is crafted to meet every customer’s design detail would reach.

We will strive to offer a quality product with excellent services.

Have any questions or inquiries?

Please send us mail or call us.

We will get in touch with you shortly and provide further information regarding the EMC enclosure.

EMC Box: The Complete FAQ Guide

There are a lot of natural phenomenons affecting our everyday life.

The electromagnetic field is such a force that can cause significant damage to the electrical equipment.

To avoid these issues, EMC boxes and enclosures were invented.

Let’s see how they are operating exactly.

- What are the main sources of electromagnetic threats to the equipment?

- What is electromagnetic shielding? Why it is needed for electrical equipment?

- What is EMC? How to differ EMC and EMI?

- What materials are better for the production of EMC boxes?

- How to design an enclosure with a high EMC rating?

- How to calculate the shielding effectiveness of the EMC box?

- Can you name the main applications of EMC boxes and enclosures?

- What kind of customization options are available for your EMC boxes?

- Besides electromagnetic shielding, what kind of protection can your EMC boxes provide?

- What kind of coating is used when manufacturing KDM EMC boxes?

- Can the EMC box have holes? Does it influence its electromagnetic shielding properties?

- What is the difference between RFI and magnetic shielding?

- How to test EMC boxes for electromagnetic shielding capabilities?

- What types of EMC boxes/enclosures are available in the KDM Steel catalog?

- Are KDM Steel EMC boxes NEMA/IP rated?

What are the main sources of electromagnetic threats to the equipment?

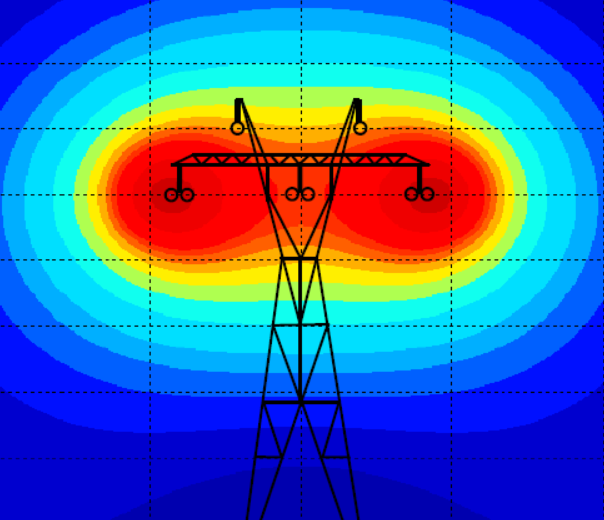

An electromagnetic field (also called EMF or EM field) is a magnetic field produced by moving electrically charged objects.

It affects the behavior of non-comoving charged objects at any distance of the field.

The electromagnetic field extends indefinitely throughout space and describes the electromagnetic interaction.

And it is one of the four fundamental forces of nature.

The electromagnetic field is typically unharmful to human health, however, it can affect the electrical equipment and disrupt its work.

There are three main sources of the electromagnetic field:

# 1. Radio and radar transmissions

Radio and radar transmission are all around us, and their influence is only growing each day.

This problem is especially significant in big cities, as well as around manufacturing facilities and sites.

It is necessary to use EMC boxes and enclosures in the place where such influence is a case.

# 2. Lightning

Lighting explained as an electrostatic discharge during which two electrically charged regions in the atmosphere or ground cause the instantaneous release of a huge amount of energy.

This discharge may produce a wide range of electromagnetic radiation, that rapidly moves throughout the atmosphere.

Thus, lighting can affect not only equipment it hits directly but also nearby devices.

# 3. Transient events

A transient is an event of a fleeting burst of energy in a system caused by a sudden change of state.

The source of the transient energy may be an internal event or a nearby event.

The energy then couples to other parts of the system, typically appearing as a short burst of oscillation.

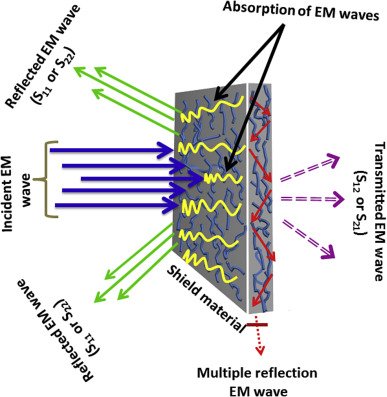

What is electromagnetic shielding? Why it is needed for electrical equipment?

Due to the above-mentioned threats, humanity has found the answer in the form of electromagnetic shielding.

Electromagnetic shielding is the practice of reducing the electromagnetic field in a space by blocking the field with barriers made of conductive or magnetic materials.

Shielding in enclosures is needed to isolate electrical devices from their surroundings, while shielding of cables helps to isolate wires from the environment through which the cable runs.

Electromagnetic shielding that blocks radio frequency (RF) electromagnetic radiation is also known as RF shielding.

The shielding can reduce the coupling of radio waves, electromagnetic fields, and electrostatic fields.

The amount of reduction depends very much upon:

- the used material and its thickness;

- the size of the shielded volume;

- the frequency of the fields of interest;

- the size, shape, and orientation of apertures in a shield to an incident electromagnetic field.

What is EMC? How to differ EMC and EMI?

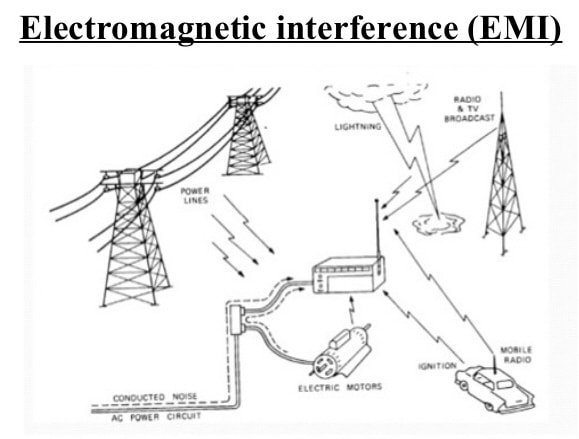

Electromagnetic compatibility (EMC) and electromagnetic interference (EMI) are often mentioned together, especially when someone discusses the regulatory testing and compliance of electronic devices.

Even though they might be closely related, it is important to understand that EMC and EMI are not the same things.

EMI is the interference caused by an electromagnetic disturbance which affects the performance of a device.

Sources of EMI can be environmental, such as electrical storms and solar radiation but more usually will be another electronic device or electrical system.

If the interference is in the radio frequency spectrum it is also known as radio frequency interference or RFI.

EMC is a measure of a device’s ability to operate as intended in its shared operating environment while, at the same time, not affecting the ability of other equipment within the same environment to operate as intended.

Electromagnetic compatibility and interference are extremely important design considerations.

Failing to consider them in the early stages of product development can result in the time consuming and costly need to redesign the product at a later stage to meet EMC/EMI specification tests and prevent product failure or safety risk.

Evaluating how a device will react when exposed to electromagnetic energy is known as susceptibility or immunity testing and involves determining the ability of a device to tolerate noise from external sources.

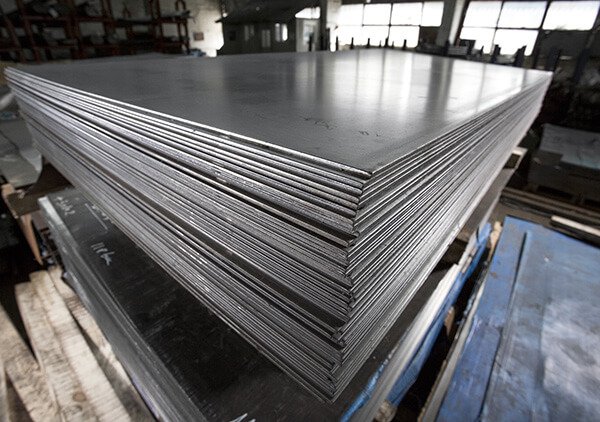

What materials are better for the production of EMC boxes?

Electromagnetic shielding is the process of lowering the electromagnetic field in an area by barricading it with conductive or magnetic material.

Electromagnetic shielding is impossible without three key components:

- Sheet metal.

- Metal screen.

- Metal foam.

Sheet metal itself has such a structure that helps to block electromagnetic waves.

The metal screen is made of metal sheet that is punched to form holes in its structure.

Finally, metal foam is a special mixture of solid metal with gas-filled pores comprising a large portion of the volume.

All the above-mentioned materials can be used singly or in combination to manufacture metal EMC enclosure.

Another commonly used shielding method, especially with electronic goods housed in plastic enclosures, is to coat the inside of the enclosure with metallic ink or similar material.

The ink consists of a carrier material loaded with a suitable metal, typically copper or nickel, in the form of very small particulates.

It is sprayed on to the enclosure and, once dry, produces a continuous conductive layer of metal, which can be electrically connected to the chassis ground of the equipment, thus providing effective shielding.

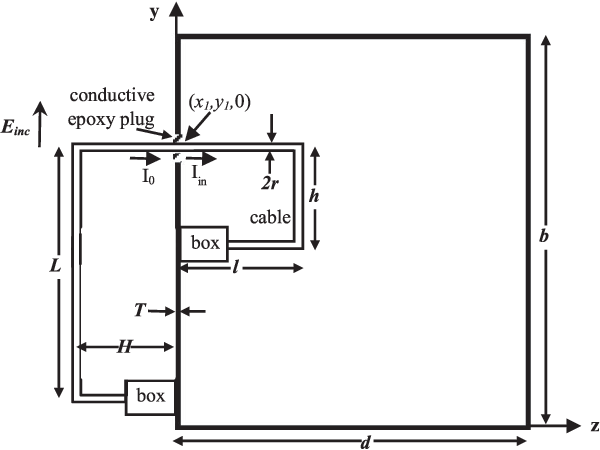

How to design an enclosure with a high EMC rating?

EMC boxes and enclosures rarely have a simple design of a closed box.

To make the inner equipment operate correctly, it may have openings for optical displays, ventilation and cable entry.

Such areas have to be additionally processed to keep the electromagnetic shielding:

- Optical displays can be made with the help of a screened optical window laminated in glass or clear plastic.

- Enclosure ventilation can be screened using simple pierced or expanded metal in low-performance applications or with the use of honeycomb ventilation panels made of aluminum or steel in higher performance applications.

- Cable entry into an EMC box or enclosure needs to have the cable screening bonded to the conductive surface of the enclosure through a screened cable entry gland or screened connector.

Besides, when designing EMC enclosures, you have to think of the next things.

# 1. Design of flange/gasket

Gasket joint has its special requirements when manufacturing EMC boxes and enclosures.

There must be good electrical conductivity between opposing flanges through the gasket.

Poor conductivity or high resistance will result in poor shielding.

In areas, there is no contact with the gasket this can result in a gap that could possibly act as a slot antenna making things worse.

Therefore, it is necessary to consider fixing pitch and gasket compression forces to ensure a good continuous seal.

# 2. Surface-mounted gaskets

Some form of compression stop or limit is essential with surface mounted gaskets to eliminate the possibility of over compression.

Such compression stops can be built into many styles of gaskets or made as an integral part of the flange.

The height of these stops should be equal to that of the maximum compressed height of the gasket.

# 3. Gaskets in grooves

For the typical electronic enclosure, groove mounted gaskets such as “O” rings are generally a better option than surface mounted gaskets.

They are much more cost-effective and secure: the groove also acts as a compression stop, thus protecting the gasket.

However, the groove needs to be the same volume or more as the gasket to let the gasket material fill the space provided for it.

If the gasket overfills the groove, damage and gasket failure can occur when the mating flanges are closed together.

# 4. Corrosion

An EMC gasket that is placed between conductive surfaces is generally made of a different material compared with the mating surfaces.

This can lead to severe problems of bimetallic galvanic corrosion and degradation in shielding effectiveness.

To avoid such a situation, you can try to use a separate non-conductive environmental seal outboard of the EMC seal, isolating the joint from its surroundings.

This would allow the use of materials that would otherwise be unsuitably matched.

However, limitations on flange widths and the increased cost of using two gaskets can make this impractical.

How to calculate the shielding effectiveness of the EMC box?

When designing an EMC box, the amount of attenuation (reduction of radio waves passing into or out of the box) is required to be figured out.

If you have a prototype available, you can test it unshielded for immunity/susceptibility.

If the circuit malfunctions, when subjected to electric fields of 1 V/m and the device must pass at 10 V/m, you simply need more than 20 logs (10 V/1 V) or >20 dB of shielding.

For emissions, an unshielded prototype can be computed or measured without cables.

Knowing the regulation and the emissions, you can again determine the amount of shielding needed.

You can estimate the amount of shielding needed by calculating the emissions from design making a few assumptions.

Enclosures seldom require shielding of more than 15 dB to 30 dB for civilian (FCC and EU) emissions/immunity applications.

When designing products for the military or commercial aviation, you need shielding effectiveness (SE) of 30 to 60 dB and perhaps more.

Can you name the main applications of EMC boxes and enclosures?

E.g., KDM EMC boxes and enclosures can be effectively used in the following cases:

- Defense and security applications.

- External plant equipment.

- House electronic equipment.

- Industrial process control.

- Medical applications.

- Telecommunications equipment.

- Transportation (rail, air, and road).

What kind of customization options are available for your EMC boxes?

There is a huge customization of freedom when we are talking about enclosures and boxes from KDM.

For example, you can order an EMC box with a door or window to gain a good display of the inner equipment.

If you want to secure inner devices from theft, you can order a lockable EMC box.

All our enclosures can be put on rollers so you can move them freely.

As an alternative, KDM boxes and enclosures can be wall-mounted.

Note: KDM Steel abilities are practically endless.

If you have unique customization requirements, please, contact our support service so we can come up with the best solution possible.

Besides electromagnetic shielding, what kind of protection can your EMC boxes provide?

Since the better part of KDM EMC boxes are made from stainless steel, such cabinets have a great level of protection from physical impact.

Besides, some of our EMC boxes and enclosures are NEMA and IP rated, which make them water and weatherproof.

We’ll speak about NEMA and IP ratings later in this FAQ.

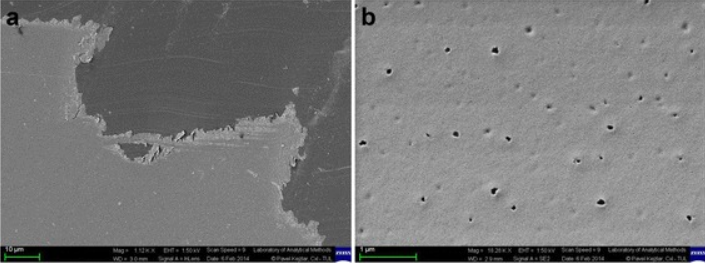

What kind of coating is used when manufacturing KDM EMC boxes?

The degree of absorption and reflection of signals is dependent upon the coating thickness, the thinner the coating the less absorbent it will be.

At the lowest level of performance ESD coatings (electrostatic dissipative coating) are generally used on the outside of enclosures for anti-static purposes.

A 30μm ESD coating is typically applied.

Nickel coatings are 30-50μm thick and are particularly good at absorbing RF at the lower frequency range.

Silver-coated copper or copper/silver hybrid coatings are used rather than a pure copper coating.

The advantages being improved conductivity, whilst keeping the costs at a competitive level.

30μm Copper/Silver hybrid coatings are commonly used as a general-purpose coating.

Improving paint technology is giving performance levels that are close to that of silver coatings.

Silver coatings produce very high conductivity and hence high levels of shielding.

The high cost of silver can limit the economic size coated, however, when applied correctly, silver is a very effective option.

With a typical low film thickness of 6-12μm, this allows for complex parts to be coated with minimal loss of detail.

Can the EMC box have holes? Does it influence its electromagnetic shielding properties?

Yes, EMC boxes and enclosures can have holes, however, some strict rules have to be followed in this matter.

First of all, any holes in the shield or mesh must be significantly smaller than the wavelength of the radiation that is being kept out, or the enclosure will not effectively approximate an unbroken conducting surface.

Besides, all holes have to be secured with gaskets.

What is the difference between RFI and magnetic shielding?

The terms EMI and RFI are often used interchangeably.

EMI is any frequency of electrical noise, whereas RFI is a specific subset of electrical noise on the EMI spectrum.

There are two types of EMI.

Conducted EMI is unwanted high frequencies that ride on the AC waveform.

Radiated EMI is similar to an unwanted radio broadcast being emitted from the power lines.

There are many pieces of equipment that can generate EMI, variable frequency drives included.

In the case of variable frequency drives, the electrical noise produced is primarily contained in the switching edges of the PWM controller.

As the technology of drives evolves, switching frequencies increase.

These increases also increase the effective edge frequencies produced, thereby increasing the amount of electrical noise.

How to test EMC boxes for electromagnetic shielding capabilities?

There are two main categories of EMC testing that you should know about:

# 1. Emission testing

The electromagnetic interference and disturbances emanating from electronic devices can cause other electronic gadgets to potentially malfunction.

This is more so if the electronic devices co-exist in the same environment.

The emissions part of the testing covers this in the EMC testing and certification process.

During the testing process, two types of emissions are tested:

- Radiated emissions (in this test, the magnetic components of the electromagnetic waves use a spectrum analyzer, a measuring antenna, and an EMI receiver. The testing unit uses a particular antenna known as the Van Veen Loop that measures the magnetic field emissions of the electronic gadget on three different axes.

- Conducted emissions (these are the electronic interferences that start from the various frequencies generated by the electrical device. The emissions from the gadgets can either be continuous meaning they emit at a specific frequency or non-continuous where the rate of emission varies from time to time.)

# 2. Susceptibility and immunity testing

Immunity of the electronic device is its ability to withstand the interferences and work normally without affecting or getting affected by other electronic products.

The emissions of other devices shouldn’t affect the device that is undergoing the EMC test.

Susceptibility, on the other hand, is the opposite of immunity.

It tests if the device is less immune to other electromagnetic interferences.

Less electromagnetic interference value means the device is more susceptible.

Immunity testing is often not required on commercial electronic products meant for sale in Australia.

The EMC immunity test is often transient or continuous depending on the type of electrical product.

Transient tests are done on gadgets that may involve sudden outbursts of energy while continuous testing applies to devices that stimulate RF proximity.

Some of the common tests involved in continuous immunity testing are conducted immunity, radiated immunity, and power-frequency magnetic field community.

The transient immunity testing includes electrical fast transient burst, electrostatic discharge, surges, short interruptions, voltage variations, voltage dips, and pulsed magnetic field.

What types of EMC boxes/enclosures are available in the KDM Steel catalog?

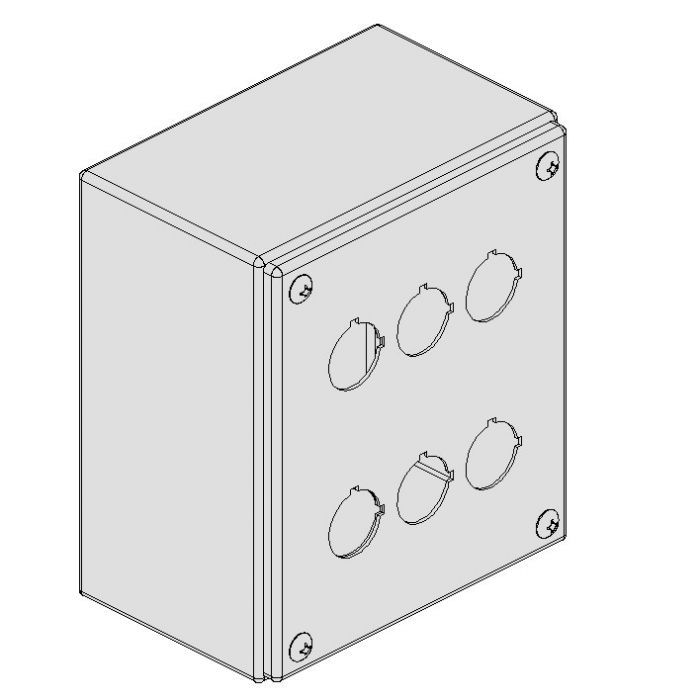

# 1. EMC box

EMC box is a small enclosure that can be used to store various electrical distribution devices, switchgear, electrical panels, etc.

# 2. EMC junction box

Junction boxes are used to form part of an electrical conduit or thermoplastic-sheathed cable (TPS) wiring system in a building.

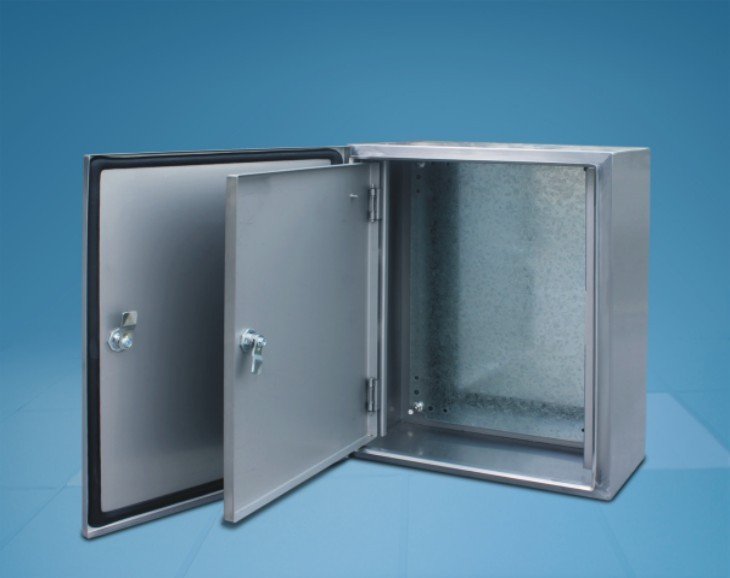

# 3. EMC electrical enclosure

The enclosure is typically bigger than boxes and can store massive equipment and electrical systems.

# 4. Weatherproof EMC box

If you want to use EMC boxes outdoors, you have to be sure that they are weatherproof, meaning to have a high NEMA/IP rating.

# 5. EMC wall-mount enclosure

All KDM enclosures and boxes can be fastened to walls, saving additional space inside your facility.

# 6. EMC free-stand enclosure

Free-stand enclosures can be put on the ground and easily moved, especially if they have rollers.

# 7. EMC stainless steel box

Stainless steel is a perfect material that shows great durability and resistance to natural forces and aging.

# 8. Custom EMC box

As was said previously, at KDM you can order customized electrical boxes and enclosures that meet practically any possible requirements.

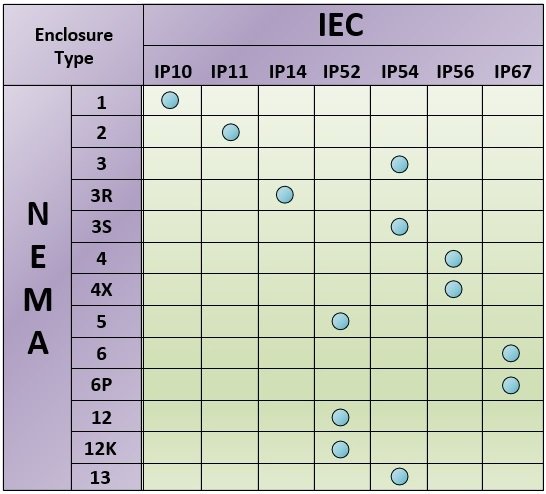

Are KDM Steel EMC boxes NEMA/IP rated?

Yes, KDM catalog contains NEMA and IP rated enclosures.

It is fair in the case of EMC boxes as well.

For example, you can order an IP68 EMC box that has great resistant against water and dust.

If you want to learn more about IP ratings, click the following link.

For the NEMA guide, use this link.