An effective and properly designed electrical enclosure starts with the manufacturing operation.

Every step is vital, from the design, selection of material to the selected technique and equipment quality.

This guide will help you understand the electrical enclosure manufacturing process, thus ensure you have a successful purchasing experience.

Let’s dive right in.

Step 1: Be Clear On Specification Of Electrical Enclosure Design

Sizes of Electrical Enclosures

Most people consider electrical enclosure as a simple box used for storage of electrical parts or connections.

They assume the specification process should not take more time than is needed to select the correct size.

Nonetheless, with the many options available in the market, it is clear that there exist several parameters that you should consider.

Here are the key specifications of electrical enclosure that you need to your chosen manufacturer:

Rating For Electrical Enclosure

IEC, ATEX, UL, IP and NEMA standards are modelled to minimize safety hazards and guarantee regular product performance. It is critical to let your electrical enclosure manufacturer know where it will be used.

Type Of Electrical Enclosure

Wall-mounted enclosure is fit for housing electrical components indoors and protecting delicate equipment in locations that might be subjected to excessively wet conditions.

Similarly, floor-mount and free-standing electrical enclosures are suitable for systems including large components or sophisticated mounting configurations.

Besides, trough enclosures house and guard cables from corrosive elements and water in various applications.

Custom electrical enclosure is designed and constructed to satisfy your distinctive and exact specifications.

Material For Electrical Enclosure

There are a number of electrical enclosure materials ranging from plastics, stainless steel, carbon steel, aluminum among others.

These materials are ideal for both outdoor and indoor applications in any kind of environment.

Features Of Electrical Enclosure

Some of the options comprise of gaskets, windows, vents, hinges latches, cutouts and holes.

Moreover, you can specify that the electrical enclosure be branded with safety messages, company colors, or to match with your premise environments.

Dimensions Of Electrical Enclosure

You can manufacture electrical enclosure of any size in terms of length, width and height.

Also, if you do not want the manufacturer standard sizes, you can order for custom enclosures meeting your desired specifications.

Power Supply For The Electrical Enclosure

It is recommended to specify supply phases, voltages and frequency, in addition to mentioning any limitations.

Location Where To Install Electrical Enclosure

State whether electrical enclosure will be used indoors or outdoors.

Enclosure cabinets installed outdoors might become hot due to solar heating during the day. Likewise, they can cool to lower than dew point in the night.

Step 2: Design Electrical Enclosure Using Appropriate Software

Before making any decisions on the electrical enclosure design, you must understand the design of electrical panel. Employ a schematic sheet for the estimation of all the enclosure components.

Before creating the schematic drawings, it is advisable you first prepare physical layout drawing.

Note that, the correct control panel design takes care of electrical and physical requirements to know all potential issues.

The control panel physical layout will aid you in designing an accurate electrical enclosure.

You will be able to detect likely issues and delivery delays that you will realize during manufacturing and testing.

The main operation in the design phase involves creating a 3D image of the electrical enclosure with the help of AutoCAD software.

This helps in saving money by enabling testing of various options prior to machining or welding a single part of the enclosure.

After choosing a design that will satisfy all your specifications, you move to the next step in the electrical enclosure manufacturing process.

However, the designer needs to understand the metal bending concept and bend radius when dealing with metal electrical enclosures.

It is common knowledge that all parts of metal enclosure are bent with a folder or press brake.

During bending, the corners of the metal tend to feature a radius because you cannot bend them into 90 degrees edges.

The designer has the responsibility of controlling this by designating a bend radius

The designer controls this by specifying a bend radius (radius of inner bend surface calculated by adding metal radius and inner radius).

Therefore, it is vital to choose an appropriate bend radius that meets your needs.

Furthermore, factor in the intersection of 2 bend lines and ensure that you eliminate to refrain the bends from meddling with one another.

Ensure to place cutouts at regulated distance away from bending radii since it may increase the probability of cutout stretching or flaring.

When designing electrical enclosure, it is also essential to consider dimension variations, which are an unavoidable part of electrical enclosure manufacturing process.

Main causes of variations in dimensions are kerf variation and positional error during cutting. Also, variations as a result of metal composition and poor modelling of stretching when bending.

Remember that the dimensions referred to are for plain metal. Hence, in case you incorporate powder coating, leave 0.003” to 0.005” allowance.

Step 3: Choosing The Right Material For Electrical Enclosure

The first and most important decision to be made during electrical enclosure manufacturing process is the type of enclosure material to be used.

The two common options are metal and plastics, where the two categories can be grouped further into:

Metals

The three most popular metals for construction of electrical enclosures are:

Carbon Steel

Carbon steel is ideal for hard and dirty surroundings, both outdoors and indoors. It is less costly and easy to redesign after fabrication for expansion or installation.

Nevertheless, this type of steel does not provide superior corrosion resistance, though you can solve this through powder coating finish.

Moreover, you may as well galvanize carbon steel to offer extra protection, implying you coat it with a zinc layer for corrosion resistance.

Stainless Steel

Stainless steel can provide exceptional strength, heat resistance, corrosion resistance and durability.

Because of its longevity, stainless steel electrical enclosure provides great long-term benefit.

Electrical enclosures made of stainless steel are often fit for hygienic applications such as pharmaceutical, food and beverage industries.

Also, stainless steel enclosure is perfect for applications where chemical resistance is key, as the case in oil and gas sector.

Stainless Steel Electrical Enclosure

Aluminum

Aluminum electrical enclosures are lightweight yet very strong. Aluminum is usually alloyed or cold rolled using other elements to enhance its tensile strength.

Using aluminum material in the electrical enclosure manufacturing process guarantees high heat dissipation and excellent corrosion resistance.

Additionally, aluminum enclosures are equally cost effective.

Compared to fiberglass or thermoplastic, the three metals offer less resistance to moisture. However, they are the simplest to customize when designing and fabricating because of the broad availability and flexibility of metalworking tools.

Thermoplastics

Thermoplastics comprise of PVC, ABS, polyesters, polycarbonates, and more.

Majority of plastics are exceptionally resistant to corrosion and easily redesigned for installation or expansion.

Plastics are exceptional at insulation, therefore select them for highly temperature-sensitive electrical controls.

Nonetheless, customization of thermoplastics is limited during design and construction stage, which may limit your base shapes and sizes available.

Moreover, plastic electrical enclosures are predisposed to weathering and UV ray degradation, particularly in hot and humid environments.

Choose plastics having added ingredients and specific formulations to minimize degradation issues.

Additionally, plastics enclosures are not fit for rugged applications such as quarries, mines and building sites.

Fiberglass

This electrical enclosure material has advantages and disadvantages on both spectrum extremes.

Fiberglass is unsusceptible to oxidation or rust from corrosive environmental elements and provides the greatest chemical resistance.

Nonetheless, fiberglass electrical enclosures are extremely hard and corrosive to equipment, making them difficult to shape and redesign.

Fiberglass also disintegrates fast in sunlight and extended heat exposure, thus fiberglass enclosure applications are very specific.

In summary, your selection of electrical enclosure material will be based on several parameters including:

- Cost

- Heat dissipation

- Temperature

- Weight

- Moisture levels

- Enclosure contents

- Security concerns

- Weather and corrosives concentration in the environment.

You May Be Interested In:

- Aluminum Electrical Enclosures

- Stainless Steel Electrical Enclosure

- Mild Steel Electrical Enclosure

- Galvanized Steel Electrical Enclosure

Step 4: Fabricating And Machining Electrical Enclosure

Cutting Material For Manufacturing Electrical Enclosure

Cutting is the initial step in the electrical enclosure manufacturing process.

During cutting, it is critical to ensure that design drawing dimensions are cut to size precisely.

Technique Of Making Cutouts And Holes In Non-Metallic Electrical Enclosure Materials

Cutting of fiberglass and plastic materials have specific nuance, the same way metals have particular machining considerations.

Polycarbonate electrical enclosure material is easier to work with due to its even resin build-up to create a pre-set thickness.

On the contrary, fiberglass is a sophisticated material composed of random strands of glass within a polyester resin. This random complexity is an advantage though it impacts the manner in which drill bit or cutting tool passes across the fiberglass.

Here are the common methods of making cutouts and holes in non-metallic enclosure materials:

Hole Saw

This is the simplest and least sophisticated technique of creating openings in non-metallic electrical enclosures.

First, layout the size and position of cutout/hole, pre-drill a tiny hole in the middle of cutout region for hole saw to begin. Subsequently, keenly cut out the section to be eliminated.

Observe the following to achieve a cutout of the highest quality having minimal edge chipping:

- Maintain the saw at right angle to cutting surface

- Sustain a constant sawing action

- Use a fine-toothed saw or carbide/diamond impregnated saw.

However, this method consumes more time and offer the least accuracy though you can employ it in nearly any environment.

Drilling, Boring

Creating circular holes through the electrical enclosure door or walls is the most popular kind of cutout.

The preferred tool for the operations is diamond or carbide tipped hole saw or coiled drill bit, which will ensure sharp cutting edge.

You can also use HSS tools although they will get dull leading to excess edge chipping and holes with poor appearance.

Moreover, if using drills, it is advisable to use low feed rates and high RPMs as this minimizes chipping about the cutout.

The most crucial parameter to ensure is maintaining an exceptionally sharp tool. To minimize cutting pressure, you can employ a drill having split points or thin points and positive rake angle.

Also, ensure constant feed rates or you may even decrease when exiting a hole to minimize part flexing as the drill exits.

When drilling, always support the part with a firm back surface to minimize chipping and delamination.

Lastly, make sure that the polycarbonate does not produce sufficient heat to make it start stringing or melting.

Hole Drilling of Plastic Enclosure Material

Routing

This cutting method applied in the electrical enclosure manufacturing process utilizes a router and router bit, which creates very clean cutouts and holes.

However, the technique needs you to manually lay out the cutouts and holes in advance and maintain steady hand in the layout lines.

You can use CNC machining centers to maintain clean cutouts and straight edges. Furthermore, use a jig/fixture to aid in guiding the handheld router.

For durability, utilize diamond impregnated bits though carbide router bits can equally serve the purpose.

Also, be cautious with polycarbonate electrical enclosure material not to develop adequate heat to cause melting or stringing.

Punching

In this method, you can use ordinary hole punch same as those applied with metal electrical enclosures.

This forms perfect clean holes though might leave chipped margins if you utilize a dull punch.

Again, to produce clean cutouts, you must maintain sharp tools. You will need a pilot hole prior to utilizing ordinary hole punch.

You can use both hydraulic and manual punch actuators with composite enclosure materials. Nonetheless, punching is not a suitable method for polycarbonate materials.

Optional Techniques

Some alternative cutting methods applied during electrical enclosure manufacturing process are laser cutting and waterjet cutting.

Both techniques will form exceptionally accurate, clean cutouts or holes but require high capital in both tools and personnel training.

With water jet cutting, you thrust a high-speed stream of abrasive material and water via a small diameter, typically 0.010”.

The water stream rapidly erodes the enclosure material applying pressure of about 60,000 psi.

Similarly, laser cutting employs a focused beam of raw light onto the section you want to cut.

The cutting process happens through chemical degradation and vaporization for the case of thermosets and composites, and local melting for thermoplastics.

Cutting Techniques For Metallic Electrical Enclosure Materials

Here are the best metal cutting methods applied in electrical enclosure manufacturing process:

Shearing

Shearing is a less accurate cutting method, in that you cannot use it making intricate, small cuts into the material.

This technique is typically applied for cutting large sheets of metal down to workable size.

It utilizes a blade to perform the cuts, which are often parallel to the other cut margins. Nevertheless, it is possible to do the cutting on an angle.

Punching

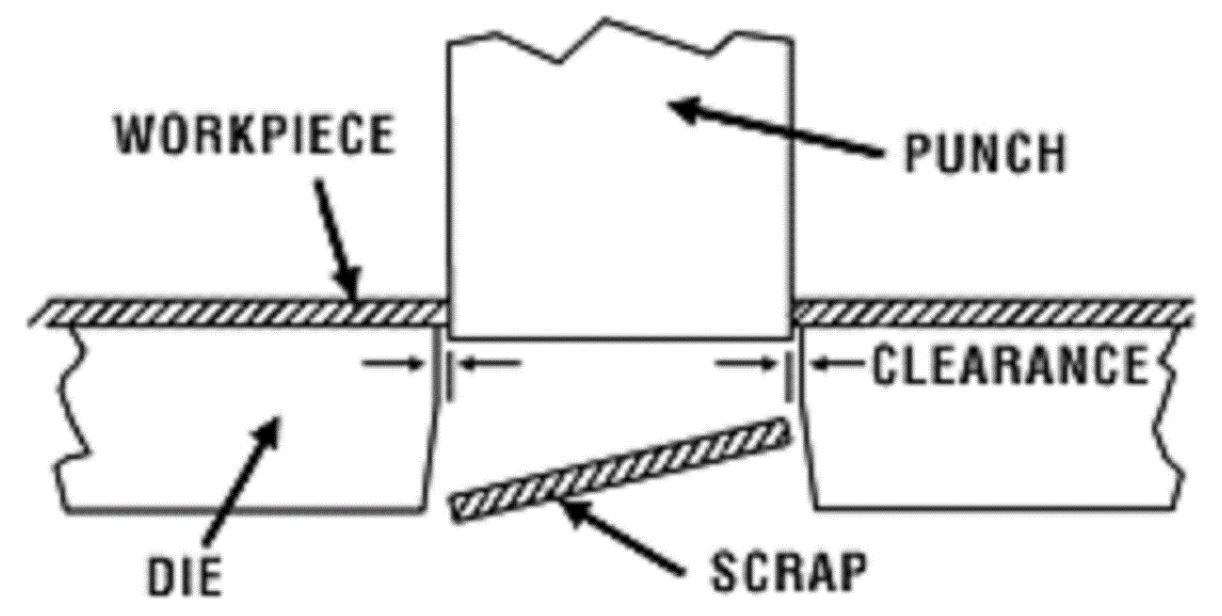

Punching entails making cutouts from the center of the enclosure materials. You punch out the section you want to form a hole in by exerting force.

This cutting technique does not leave clean edges, although you can polish the edges in succeeding processes.

Blanking

Blanking is simply the contrast of punching.

The piece that you punch out is considered scrap in punching while that piece is the required part in blanking.

The remaining material is the scrap.

Similar to punching, the blanked pieces will always undergo finishing during subsequent steps to polish out the rough borders due to blanking operation.

Waterjet Cutting

This technique employs a high-powered water stream to cut across the metal rather than applying heat.

Owing to that, the process does not create any heat impacted sections on the enclosure material.

Waterjet cutting ensures very precise cut in addition to leaving a neat finish to the enclosure material.

There are 2 forms of waterjet cutting, water-only/pure water and abrasive jet cutting.

Abrasive jet cutting incorporates an abrasive material like metal or granite to the water. On the other hand, water-only cutting utilizes only water and absolute jet power to cut the metal.

Plasma Cutting

This technique utilizes hot plasma to enable cutting through the electrical enclosure material. The high-speed plasma jet forms an exceptionally precise cut.

plasma cutting is very economical, making it one of the suitable cutting techniques to use during electrical enclosure manufacturing process.

The method is fast, though not as fast as laser cutting.

Laser Cutting

This metal cutting method applies a laser beam to burn across the material and produce a precise cut.

With laser cutting there is no occurrence of warping, it guarantees a clean, constant cut all through to the end.

Laser beam cutting technique is very fast, economical and environment-friendly since it utilizes less energy.

Bending Material For Making Electrical Enclosure

Bending describes the procedure of converting the straight electrical enclosure material into an arched shaped.

The process happens when you apply forces to localized portions of the material.

Here are the common types of bending used when handling metallic electrical enclosure materials:

Channel Bending

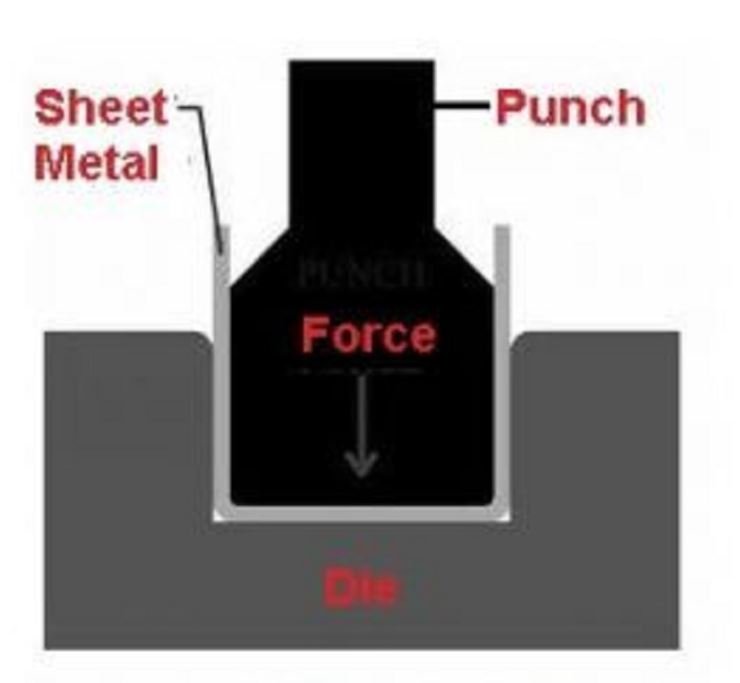

With this operation, you exert force that pushes the punch into the die.

The metal piece in the middle of the die and punch, assumes the channel shape of the die and punch.

Channel Bending of Metal Enclosure Material

Offset Bending

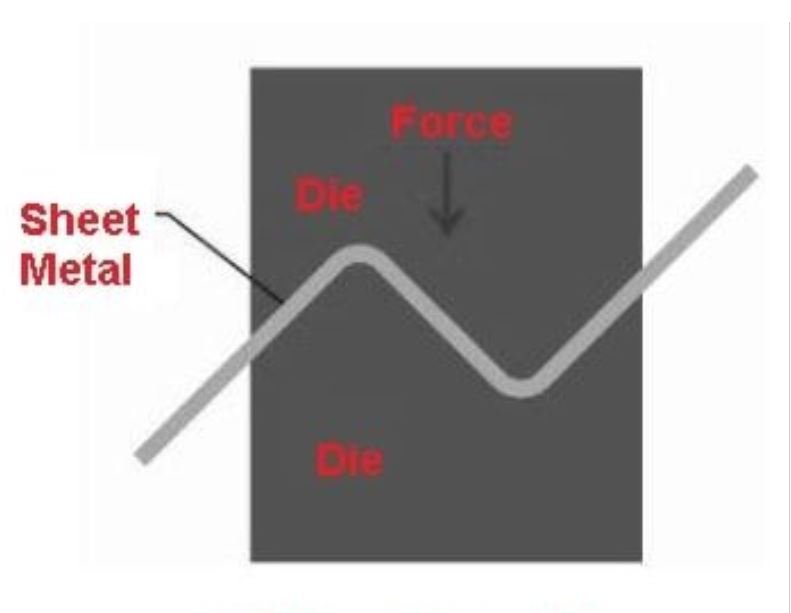

Here, you transform the metal to an offset shape by the assistance of a die and punch.

Offset Bending of Sheet Metal Enclosure Material

Edge Bending

In this sheet metal bending technique, you fix the material between 2 dies from one side, as exhibited in the diagram.

Then you force the other edge to strike on the unfixed punch, which consequently causes the unfixed side of sheet metal to bend.

Edge Bending of Sheet Metal

U-Bending

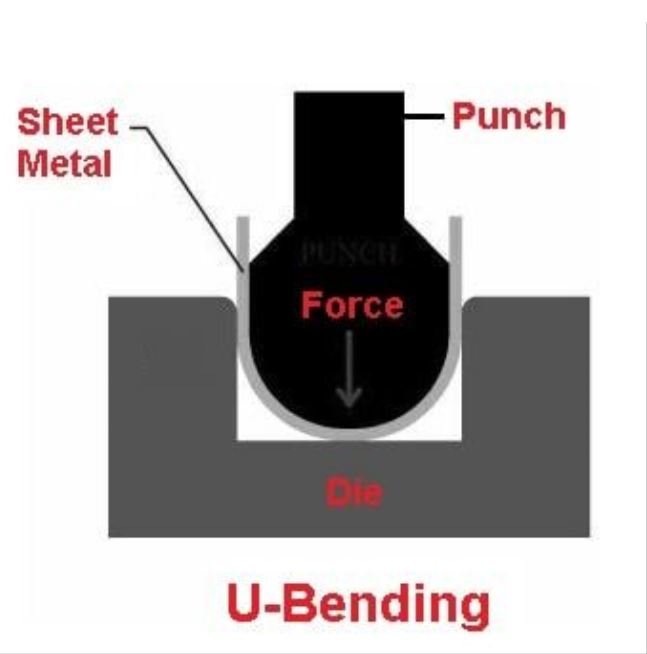

Here, when the force presses the punch in the die, it causes the sheet metal to develop a U-shaped part.

U-Bending of Metal Enclosure Material

V-Bending

In this bending type, the sheet metal forms a V-shape when you press it between the die and punch.

V-Bending

Assemble Electrical Enclosure

There are a number of techniques used for joining parts during electrical enclosure manufacturing process.

Let’s discuss the common assembling methods used in metal electrical enclosures:

Mechanical Joining

This is usually considered a temporary fastening technique because you can easily separate the parts.

Mechanical joining of electrical enclosure parts includes:

- Riveting

- Bolting

- Caulking

- Folding

- Shrink fitting

Welding

Welding describes the operation of melting a filler and metal workpiece to create a molten firm joint.

It is a permanent joining technique for metal enclosure cabinet parts.

Some of the popular methods of welding applied in electrical enclosure manufacturing process comprise of:

- Arc welding

- Laser Welding

- Electron beam welding

- Flash welding

- Seam welding

- Resistance spot welding

- Explosion welding

- Friction welding

- Cold pressure welding

- Diffusion welding

- Friction stir welding (FSW)

- Upset welding

- Projection welding

- Ultrasonic welding

Adhesive Joining

Moreover, you can equally use adhesives to bond and assemble electrical enclosure parts.

This joining and assembling techniques is always advancing, with new alternative continually in development.

Some of the recognized adhesive choices consist of tapes, epoxy, silicone and polyurethane.

Nonetheless, adhesive do not form strong bonds as the other fastening techniques mentioned earlier but they provide cost-effective solution.

Grinding Electrical Enclosure

Grinding is a common technique that utilizes wheels to smoothen roughness due to machining, welding, or other electrical enclosure manufacturing processes.

There exist various kinds of grinding machines, consisting of die grinders and surface grinders.

Nevertheless, all the equipment employs similar operating mechanism, employing an abrasive rotating substrate for polishing out imperfections.

Punching Holes On Electrical Enclosure

At times called piercing, punching process forms holes in the enclosure part utilizing die and punch.

You position the component between the 2 parts, and the punch thrusts itself across it to the die.

During punching, the punched round pieces of eliminated material are considered as scrap.

But you can as well use them as new workpieces, a process referred to as blanking.

The common punching methods used during electrical enclosure manufacturing process include:

- Piercing– Involves cutting small, cylindrical openings in the metal enclosure material while removing very minimal material quantity.

- Dinking – A modified shearing process helpful in blanking shapes out of low-strength electrical enclosure materials, like fiberglass. The die works similar to a cookie cutter.

- Slotting – Entails forming rectangular holes on the metal enclosure, at times unfinished.

- Slitting – Involves creating straight lines of narrow width on the metal electrical enclosure material. This punching process generates no scrap.

- Nibbling – The punching technique entails formation of overlapping holes. Blending of overlapping holes may help in creation of all forms of contours and cutouts.

- Parting – This involves cutting the material using a punch having 2 cutting sides that match the facing blank sides.

- Perforating – similar to piercing, however the punched holes normally do not have circular shape. Perforating often makes more than a single hole, with the punching done in a pattern.

- Lancing – A punching process where you make one line slit or cut on part way throughout the enclosure part, without eliminating any metal.

- Shaving – Also referred to as trimming, shaving is a finishing operation that eliminates burrs out of the cut borders. This forms smooth edges and also ensure dimensional accuracy.

- Notching – Involves cutting of shapes from the metal enclosure material edges (removing, trimming and forming notches at the margins).

- Cutoff – Shearing procedure in which you separate blanks from the metal enclosure material through cutting its opposite side in sequence. You produce a new part with every cut.

Punching of Electrical Enclosure

Step 5: Apply Surface Finish On Electrical Enclosure

The following are the common surface finish operations applied during the electrical enclosure manufacturing process:

Coating

Powder coating or wet painting will protect the electrical enclosure from corrosion and additional environmental elements.

Powder coating is presumed to be long-lasting, affordable and eco-friendly compared to wet painting for metal enclosures.

In most cases, the powder coat is cured using UV light or heat to give additional protection layer from the elements.

This guarantees superior protection within the most extreme outdoor environments.

Powder coating enables quick and easy painting of enclosures to your specifications with RAL colors, your country’s standard colors, or other customized colors.

You can apply several different colors having varying textures and with different levels of gloss, to satisfy your styling desires.

The applications of high-quality polyester powder-coating guarantees enhanced UV protection.

Some electrical enclosure manufacturing processes also employ nano-coating operations, which are specifically applied to the enclosure interiors.

This expels water from the electrical enclosure.

Wet painting predominantly applies solvent-based paints because of the high chemical resistance and corrosion protection they offer.

The electrical enclosure can be painted to your special requirements, in several color options. Be it a more aesthetically bold paint or more standard type.

Engraving Or Printing

If required, you can customize your electrical enclosure with legends, a special label, or company logo. This are several methods for enabling this, including pad or screen printing and engraving, in color if needed.

With screen-printing, you press the printing ink onto the base material via a fine-screened fabric mesh utilizing a rubber blade (porous printing procedure).

On the contrary, pad printing refers to an indirect etch printing operation.

The location of the ink is in an underlying print section within the printing plate surface.

A printing pad soak up the ink on behalf of the print sector and transmits it to the enclosure part you want to print.

Anodizing

This refers to a passivation procedure often employed on aluminum that increases the thickness of natural oxide layer.

Consequently, anodizing provides aesthetics and protection to the surface of metal electrical enclosure.

Anodizing process is carried out by submerging the metal enclosure inside an acid bath, then you pass electric current through it.

Plating

There are 3 forms of plating: immersion plating, electroless plating and electroplating.

The electroplating technique produces an electric current that is used in coating the enclosure part.

On the contrary, electroless plating utilizes an autocatalytic procedure where the part catalyzes the reaction.

Immersion plating differs since the reaction is caused by the metal substrate instead of the blend of chemicals inside the bath.

It forms a narrow metal deposit, normally silver or zinc.

Since plating is a chemical procedure, it is often available in specialized fabrication facilities.

Special Coatings

The special coatings are applied to offer the electrical enclosure protection against specific elements.

RFI/EMC Shield Coating

You require protection you can rely on if the success is based on the operation of mission-essential electrical and electronic equipment.

RFI/EMC coatings are applied on fiberglass or plastic electrical enclosures to shield them from radio frequency radiation or interference.

Most fabricators utilize both nickel- and copper-based systems, that provide coatings to fulfil customer-specific shielding needs. You can as well mount RFI gaskets if necessary.

Electrical Enclosure Shield Coating

Chemical Conversion Coating

Alternatively referred to as chromate coating, chemical conversion coating applies chromate to the electrical enclosure surface.

As a result, the applied layer gives a surface that is corrosion-resistant, durable and exhibits steady electrical conductivity.

Step 5: Electrical Enclosure Quality Inspection Process

Quality inspection is done from the very start to the ultimate electrical enclosure manufacturing process step, to guarantee best practical product quality.

The IEC, ISO, NEMA, NEC, IPCEA, ANSI, UL and CI standard requirements always are applied for assessment and testing in fabrication shop.

Some of the crucial quality analysis tests carried out during electrical enclosure manufacturing process include:

Accelerated Aging Testing

Accelerated aging describes the hastened aging process of enclosure.

You conduct this by exposing it to escalated environmental and operational conditions like vibration, humidity and temperature.

The aim of the test is to attain extended lifespan exposure within a shorter period to understand likely failure issues.

Sand And Dust Testing

This is the most vital environmental testing for electrical enclosures to be used in environments exposing them to sand and dust.

These elements could significantly affect the enclosure performance.

The test simulates the impacts of dust and sand on the electronic enclosure to establish its particulate matter resistance.

High Accelerated Stress Screening (HASS) And Highly Accelerated Life Testing (HALT) Testing

Both HASS and HALT are enclosure reliability testing procedures that assesses its design limitations and fabrication weaknesses.

Both testing techniques employ similar approach.

HALT is done during the design stage before fabrication.

It applies a stepped escalated stress strategy to determine the physical limitations of the electrical enclosure design under different stressors.

You perform HASS when the enclosure is ready for production.

The test examines any product weakness developed during fabrication operation.

Both methods for accelerated lifespan tests may help you handle crucial design and production issues in advance.

This helps in avoiding costly redesign or manufacturing costs during electrical enclosure manufacturing process.

Thermal Shock Testing

Thermal shock testing replicates conditions for electrical enclosure applications that undergo fast temperature change cycles.

The test helps in characterizing the durability of the enclosure cabinet.

Testing is done in single or dual chambers based on the temperature fluctuation rate expected for the enclosure or industry standard.

Accelerated Weathering Testing

Accelerated weathering testing models the long-term impacts of common external elements such as wind, moisture, UV radiation, sand, and dust.

The test gives crucial information for manufacturing and enclosure specification.

Ingress Protection (IP) Testing

IP testing is carried out to assess the ability of the electrical enclosure to impede penetration of dust, water, and other foreign substances.

This guarantees safety, functionality and compliance of the enclosure cabinet.

Temperature Variation Testing

This is a sequence of environmental tests that replicate the impacts of gradual or quick temperature changes on the enclosure.

It consists of rapid temperature tests, temperature cycling, and thermal shock testing, and is performed from -65 to 300 degrees Celsius.

Humidity Testing

Humidity testing examines the prolonged impact of humidity on the electrical enclosure.

It is vital in product design, material selection, reliability testing and guaranteeing regulatory compliance for enclosure.

Hail Impact Testing

This test aids in assessing the electrical enclosure material longevity if subjected to hail strike.

Test outcomes can help in selection of the appropriate material to use in the electrical enclosure manufacturing process.

Solar Radiation Testing

Solar radiation testing entails understanding the photochemical and thermal degradation impacts of sunlight on enclosure materials and components.

The test assists in making decisions concerning material selection, fabrication and purposed use of end product.

Salt Spray Corrosion Testing

Also referred to as salt fog testing, this accelerated corrosion testing is performed to examine the electrical enclosure performance during its lifespan.

The testing method assesses corrosion resistance of protective coatings, paints and finished surfaces of the enclosure.

Vibration Testing

Vibration testing examines the performance or deterioration of the electrical enclosure if exposed to mechanical motion.

The electrical enclosure is exposed to controlled transient, sinusoidal, or random vibrations utilizing mechanical, electrohydraulic, electromagnetic or electrodynamic shakers.

The test is a vital component of quality control, performance evaluation, fatigue testing, quality assurance and regulatory compliance.

Step 6: Package Electrical Enclosure For Shipping

Small electrical enclosures are packaged in superbly sized and matched cartoon packages, with suitable corner edging and carboard spacers for additional protection.

Similarly, medium-sized enclosure cabinets can often fit on conventional 48” by 40” wooden pallet.

Packaging of large electrical enclosures is relatively challenging. For that matter, some are shipped as components that are later assembled at the final destination.

Most manufacturers will offer after sale service for the assembly and installation of electrical enclosure.

They will provide training on how to assemble and install the enclosure at your premise.

Similarly, some large electronic enclosures can also be packed in a wooden structure that is constructed and sized for the precise enclosure dimensions.

It is ideal to band the enclosure to the skid as shown in the image below.

Electrical Enclosure Banding

Useful Resources:

How To Ground Electrical Enclosure

Types Of Electrical Enclosures

How To Package Electrical Enclosure

Electrical Enclosure Accessories

For any questions or inquiries about the electrical enclosure manufacturing process, contact KDMSteel now.