KDM is a premier electrical enclosure air conditioner manufacturer in China.KDM electrical enclosure air conditioner is a powerful and best cooling solution in any heating problem, this can be make as a perfect choice for many applications.

Electrical enclosure air conditioner is also can be used in both indoor and outdoor purposes and applications.Our electrical enclosure air conditioner is approved for NEMA ratings 12, 4 and 4X, as well as hazardous locations.If you having components which is possible to overheat, you should consider to install electrical enclosure air conditioner.

Electrical enclosure air conditioners are the best solution to cool rooms in your home or business to avert dust made up and more.Electrical enclosures air conditioner at KDM is including expensive equipment which required to be cooled in command for them to carry on to operate neatly.

- Custom professional electrical enclosure air conditioner

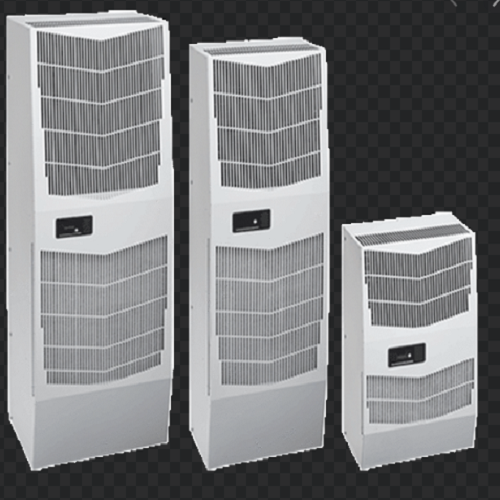

- Various Selection of Electrical enclosure air conditioner

- Affordable and strong electrical enclosure air conditioner

- One-stop solution for all your electrical enclosure need

KDM Electrical Enclosure Air Conditioner Series

KDM custom metal electrical enclosure air conditioner can be used for operation in the hottest environments. KDM can make custom metal electrical enclosure air conditioners with great quality.

At KDM, we offer affordable but durable aluminum electrical enclosure air conditioners. Which is designed for hazardous location enclosures.

Send your Inquiry on KDM Electrical Enclosure Air Conditioner

KDM electrical enclosure air conditioner has a capacity to eliminate moisture from the air.If you install electrical enclosure air conditioner you don’t need to make anxious about applying a big space to a cooling device.This is a kind of unit which gives the users a chance trying to customize their desire temperature.

Electrical enclosure air conditioners are available for variety operating voltages and cooling capacities.Working closely with our customers, EIC creates engineered products designed to meet the unique needs of specific projects.

- Specializing electrical enclosure air conditioner production for 10 years

- Custom-built according to specific requirement

- On-time delivery, full technical support

- All products manufactured and tested in quality control

Related Product with Electrical Enclosure Air Conditioner

KDM Electrical Enclosure Air Conditioner

We have flexible production capabilities that allow us to provide standard and custom solutions for orders ranging from a single piece up to large-scale production roll outs.

We can stand as a leading global supplier of electronic care solutions.

We, KDM can manufacture unique version of electrical enclosure air conditioner.

We always provide quality but valued price electrical enclosure air conditioner.

And all our electrical enclosure air conditioners are having ISO certificate.

We use quality control to distribute our finish products in good condition.

We have a great team which treating each other with respect and good manners while serving to our customers.

We are the team that giving full efforts to meet your expectations about our products.

If you are interested in our electrical enclosure air conditioner, email us!

Electrical Enclosure Air Conditioner: The Ultimate FAQ Guide

- What Does UL Listed Enclosure Air Conditioner Mean?

- What Are the Benefits of Using Enclosure Cooling Unit?

- How Does Electrical Enclosure Air Conditioners Work?

- Can You Use Air Conditioner in NEMA 4 Enclosures?

- What is Closed-Loop Cooling System in Enclosures?

- For Optimal Cooling, Should You Install Electrical Enclosure Air Conditioner or Fans?

- How Much Power Does Panel Air Conditioner Use?

- Why Use Electrical Enclosure Air Conditioner for NEMA Type 4X Rating?

- What is Thermal Management in Electrical Enclosures?

- What Does BTU Mean?

- What Does BTU Mean in Enclosure Air Conditioning?

- Can NEMA 3r Enclosures Use Air Conditioners?

- How Does NEMA 3 Enclosure and IP54Compare?

- How Do You Choose Electronic Enclosure Cooling System?

- Can Heat Exchangers Replace Air Conditioner in Electrical Cabinets?

- Are Electronic Enclosures with Cooling Fans More Effective than A/C System?

- What is a Sealed Enclosure Cooling System?

- What are Common Mistakes in Electrical Cabinet Cooling Systems Installation?

- How Much does Operating Electronic Enclosure Air Conditioning Cost?

- Can KDM Recommend Enclosure Air Conditioner Sizing for Custom Designs?

- Which Enclosure Cooling Systems Can You Get at KDM?

- What Enclosure Cooling Units and Accessories does KDM Offer?

- How Does KDM Control Quality of Electrical Enclosure Air Conditioner?

What Does UL Listed Enclosure Air Conditioner Mean?

UL listed enclosure air conditioners meet internationally accepted safety and performance standards.

The safety and performance tests cover all parts and components of the enclosure air conditioners.

That is, from the refrigerant gas, design, material choice, etc.

Such air conditioners will guarantee optimal electrical enclosure thermal management at all times.

UL listing and classification – Image credit: UL

What Are the Benefits of Using Enclosure Cooling Unit?

- Prevents overheating of the enclosure systems

- Protects temperature-sensitive electronic components from possible damage through overheating

- Increases lifespan of electrical enclosure components

- Ensures the safety of enclosure, components, and technicians

- Improves energy efficiency

- Reduces maintenance cycles

- Closed-loop enclosure cooling systems isolate content of electrical enclosure from the external environment, thereby protecting it from dirt, moisture, fluctuating temperature, splashing water, etc.

- Ensures silent cooling process

- With fully automated cooling systems and alarms, it is easier to detect possible malfunctions

- Reduces overall costs of operations

- With enclosure air conditioners, you can confidently install electrical cabinets in hot environments such as near boilers, ovens, etc.

- Reduces downtime due to overheating, thus increasing productivity

How Does Electrical Enclosure Air Conditioners Work?

An electrical enclosure air conditioner provides a closed-loop cooling system.

Implying, it completely isolates the internal components of the electrical enclosure from the external environment.

Therefore, your electronic components will not be affected by surrounding elements in the environment, such as dirt, water vapour, etc.

Basically, the electrical enclosure air conditioner will “suck” heated air around the enclosure.

The air around the components become hot as a result of heat dissipated by the electronic components.

It results in high heat load that can eventually damage components.

After “sucking” the hot air, the enclosure air conditioner directs in into an evaporator coil.

The evaporator coil cools the hot air and recirculates it within the electrical enclosure.

This air will then cool the hot electrical components in the enclosure, maintaining their temperature to a suitable level.

Remember, this cycle will continue automatically until you stop it.

In case of any fault, the electrical enclosure alarm will automatically turn on.

Electrical enclosure air conditioner – Image Credit: Delvalle

Can You Use Air Conditioner in NEMA 4 Enclosures?

Yes.

An air conditioner will maintain suitable conditions of the enclosure without compromising the NEMA 4 specifications.

Electrical enclosure air conditioner offers a closed-loop cooling system, which is suitable for both indoor and outdoor applications.

NEMA 4 Enclosure

Enclosure air conditioners maintain a cool and clean environment within the enclosure.

This is because no unwanted particles or heat will enter the enclosure.

Furthermore, for highly contaminated areas, or when the ambient temperature is extreme, you can opt for a water-cooled air conditioner.

Still depending on the enclosure NEMA standards, the electrical enclosure manufacturing company will customize cooling systems to your unique specifications.

What is Closed-Loop Cooling System in Enclosures?

The closed-loop cooling system is the process of maintaining an optimal operating temperature within an enclosure, while completely isolating the external and internal environments of the electrical enclosure.

Implying, electrical enclosure cooling systems, should maintain the temperature of the enclosure, within a suitable range.

At the same time, it should prevent ambient air from entering the enclosure.

As you can see from the figure below, the working principle is straight forward:

Methods of cooling electrical enclosure – Photo credit: Automation Notebook

- Step 1: Cooling system sucks hot air electrical components produce within the electrical enclosure

- Step 2: Air conditioner dehumidifies and cools the air in a single process

- Step 3: It forces cooled air back into the enclosure

From the figure above, you can see no air leaves the enclosure, unlike the electrical enclosure natural convection cooling and enclosure forced convection cooling.

The main benefits of an electrical enclosure closed-loop cooling system include:

- Suitable for specific NEMA enclosures

- Although the initial installation cost is high, they are cost-effective in the long run

- Suitable for enclosures in hostile environments such as extreme external temperature, acid rain, splashing water, etc.

- Saves energy

- Eliminates the possibility of hot spots in the electrical enclosure

- Suitable for both indoor and outdoor applications

For Optimal Cooling, Should You Install Electrical Enclosure Air Conditioner or Fans?

Whether to choose electrical enclosure fan or air conditioner will depend on the prevailing environmental conditions.

Moreover, the cooling requirements also play a significant role.

The guiding principle should be achieving optimal heating, which is cost-effective at all times.

Electrical enclosure fan and A/C

For optimal cooling, you should focus on the following:

· NEMA Rating

NEMA rating will help determine the type of cooling system you should use.

For example, a closed-loop enclosure air conditioner is suitable for NEMA 4x enclosures.

Such enclosures require a cooling system that completely isolates them from the external environment (ambient air).

On the other hand, for NEMA 1 enclosure, an enclosure fan will provide a cost-effective cooling process.

· Enclosure Cooling Mechanism

When it comes to closed-loop cooling requirements, you need an electrical enclosure air conditioner.

However, for forced air cooling, a fan will be a perfect choice.

· Internal Heat Load

In most cases, if the internal heat load is high, go for an enclosure air conditioner.

Otherwise, you can use an electrical enclosure fan.

· Installation Environment

Some environments such as oven, sea or chemical production areas may require complete isolation of electrical enclosure interior.

In such situations, the best option is an electrical enclosure air conditioner.

However, for indoor or where you need NEMA type 1 enclosure, an electrical enclosure fan will work.

To optimize the electrical enclosure thermal management process, discuss your requirements with the electrical cabinet manufacturer.

How Much Power Does Panel Air Conditioner Use?

The amount of power a panel air conditioner consumes depends on many factors, such as:

i. Power rating of the air conditioner

ii. Duration enclosure air conditioner will be working

iii. Size of the panel

iv. Energy rates your power supplier charges per unit

v. Efficiency of the cooling process

Of course, these are just a few parameters.

You should request for the power consumption estimates from the electrical enclosure air conditioner manufacturer.

Why Use Electrical Enclosure Air Conditioner for NEMA Type 4X Rating?

First, you need a cooling system that will protect electrical and electronic components, without compromising the key features of a NEMA 4x enclosure.

Remember, NEMA Type 4x enclosure must protect its electronic content from:

i. Splashing water

ii. Falling dirt

iii. Windblown dust

iv. Rain and snow

v. Corrosive conditions such as salty environment or exposure to chlorine.

You can use NEMA 4x enclosures in both outdoor and indoor applications.

NEMA 4x Enclosure

Clearly, most NEMA 4x enclosures are suitable for hostile environmental conditions.

Therefore, you need an electrical enclosure air conditioner because:

i. They are easy to program; hence, you can control or monitor their performance remotely. Alternatively, you can integrate it with the existing SCADA or DCS systems.

With this, you can monitor and maintain the temperature within the electrical enclosure.

ii. It offers closed-loop cooling systems; thus, dirt particles, corrosive agents, humidity, etc. will not enter the enclosure. Basically, it “isolates” external environment from inside the electrical enclosure.

iii. With the condensate evaporator, you don’t need extra external tubing or drainage systems. It offers better service in remote and hostile environmental conditions.

What is Thermal Management in Electrical Enclosures?

Electrical enclosure thermal management is the process of maintaining a suitable working temperature within the enclosure.

It involves monitoring and controlling the temperature dissipated by electrical components in the electrical enclosure.

To adopt a good electrical enclosure thermal management procedure, you need to:

i. Choose suitable electrical enclosure cooling mechanisms such as air conditioner, forced convection fans, ventilation systems, heat exchangers, etc.

ii. Understand operating temperature of every component in an electrical enclosure

iii. Know all environmental conditions and parameters within an area where you intend to install the electrical enclosure

iv. Know electrical enclosure material and dimensions

v. Calculate the total power loss

Thermal management in an electrical enclosure – Image credits: Global Spec

Remember, electrical enclosure thermal management is a tricky affair more so when dealing with heat-sensitive electrical and electronic components.

What Does BTU Mean?

BTU refers to British Thermal Unit.

The amount of heat you will need to raise the temperature of 1 pound of water to one degree Fahrenheit is equivalent to 1 BTU.

What Does BTU Mean in Enclosure Air Conditioning?

BTU is basically a measure of energy; therefore, you can use it to measure the capacity of the enclosure air conditioner.

Implying, BTU is the amount of heat air conditioner can remove in an electrical enclosure per hour.

For instance, when you want to determine how many BTUs you will need for an electrical enclosure, you have to:

- Determine the size of the electrical enclosure

- Know the electrical components in the enclosure

- Where you will install the electrical enclosure

Depending on these specifications, you can choose an enclosure air conditioner with a low BTU rating (small) or high BTU rating (large).

Therefore, an increase in BTU rating will mean the size, cost, and weight of enclosure air conditioner will also increase.

Can NEMA 3r Enclosures Use Air Conditioners?

Yes.

Remember, NEMA 3r enclosure should protect electrical and electronic components used in both indoor and outdoor applications.

They should provide protection against dirt ingress, water, snow, and rain.

Most NEMA 3r enclosures have side mount air conditioners.

NEMA 3r electrical enclosure

How Does NEMA 3 Enclosure and IP54Compare?

|

NEMA 3 Enclosure |

IP 54 Rated Enclosure |

| · You can use it either indoor or outdoor

· Provides protection from windblown and falling dirt · Ensures protection from ingress rain, snow, and sleet |

· Suitable for extreme outdoor conditions

· Offers dirt protection (but not total dirt protection) · It offers protection against splashing water. However, it does not offer protection for wash-down water · Offers protection from corrosive substances |

How Do You Choose Electronic Enclosure Cooling System?

You should consider the following when choosing an electronic enclosure cooling system:

Cooling system – Image credit: Frozen Tec

i. Calculate the total heat load – you need to know the amount of heat all components in the electrical cabinet will dissipate. Through this, you’ll be able to choose a suitable enclosure cooling system.

ii. Know the surrounding environment – Establish whether you will use the enclosure indoors or outdoors. Moreover, you should take note of the prevailing environmental conditions. With this, you will be able to tell whether to use closed-loop cooling system or fans.

iii. Consider both NEMA rating and IP rating for the enclosures – The cooling system you’ll choose for the electrical enclosure must not compromise these standards.

iv. Calculate the cooling capacity requirement in the enclosure – You will evaluate the total size of the enclosure and all its components.

v. Evaluate the enclosure cooling system capacity

vi. Consider possible installation options – You should consider where you will install the enclosure, and whether there is enough space for optimal circulation.

vii. Remote monitoring capability – Can you monitor the cooling process remotely? Can you integrate the enclosure cooling with the existing automation system?

viii. Maintenance and operation cost – You should choose an efficient and cost-effective cooling system. This requires proper evaluation of where you will install a heat exchanger system, air conditioner or fans.

Also, you should consider additional features of the enclosure cooling system that will improve efficiency.

Can Heat Exchangers Replace Air Conditioner in Electrical Cabinets?

Yes.

However, before you replace an air conditioner with enclosure heat exchanger, you must be sure that it will guarantee optimal enclosure cooling.

Therefore, you should consider the following:

- Enclosure cooling requirements

- Cooling efficiency and capacity

- Cost of maintenance and operation

- NEMA rating

- IP rating requirements

- Surrounding environmental conditions such as humidity, dirt, etc.

- Ambient temperature

- Enclosure internal temperature

Electrical enclosure heat exchanger – Image credit: Electronics Cooling

Note: In case you buy an electrical enclosure with an air conditioner, don’t replace it with a heat exchanger before contacting the manufacturer.

Are Electronic Enclosures with Cooling Fans More Effective than A/C System?

The level of efficiency will depend on the situation at hand.

For instance, for NEMA 4x enclosures, an air conditioner will be more efficient.

On the other hand, for NEMA 1 enclosures, installing a fan cooling system will be more efficient.

Therefore, both enclosure fans and enclosure air conditioners are efficient cooling mechanisms.

You only have to evaluate the enclosure thermal management requirements and choose a suitable cooling system.

What is a Sealed Enclosure Cooling System?

Sealed enclosure cooling system is cost-effective and requires small space in an enclosure thermal management system.

It is perfect for situations where the temperature within the enclosure is higher than the temperature outside the enclosure.

Therefore, sealed cooling systems is an example of the above ambient enclosure thermal management system.

Although sealed cooling systems can work in both indoor and outdoor electrical enclosures, their capacity is normally limited.

Furthermore, with sealed enclosure cooling systems, the internal section of the enclosure is completely isolated from the surrounding environment.

A practical example of a sealed enclosure cooling system is a closed-loop air conditioner.

Closed-loop cooling system – Image credit: Automation Notebook

What are Common Mistakes in Electrical Cabinet Cooling Systems Installation?

When installing electronic cabinet cooling systems, you need to avoid the following key mistakes:

- For overheating electrical enclosures, going for the oversize enclosure air conditioner may not be efficient. This is because it may cause fluctuations in enclosure temperature and controlling humidity can be a problem.

- Never install closed-loop air conditioner in vented electrical enclosures. It will make it impossible for effective thermal control and in some cases, the air conditioner may work continuously. Obviously, this causes fast wear and frequent maintenance.

- Do not buy an electrical enclosure without a latching and locking mechanism. Such electrical enclosures will not meet the set NEMA and IP

Enclosure locking mechanism

- Replacing components of enclosures after purchase. Never replace the enclosure cooling system, hinges and door locks without consulting the manufacturer.

Remember, the enclosures are tested and certified to conform to certain IP or NEMA classifications. Therefore, changing some of the components may compromise performance.

- Failure to review the heat load after adding new electrical component – Remember, the specifications of the enclosure cooling system depends on specific heat load.

Therefore every time you add a new component, calculate the heat load to ensure it matches cooling capacity.

- Do not forget to maintain the enclosure cooling system. It is the only sure way of ensuring efficiency and reliability while eliminating unnecessary downtime.

How Much does Operating Electronic Enclosure Air Conditioning Cost?

It will depend on 4 major aspects:

- Rating of the air conditioner

- The duration air conditioner operates

- Cost of electricity

- Surrounding temperature

Can KDM Recommend Enclosure Air Conditioner Sizing for Custom Designs?

Yes, KDM technical team will guide you through the heat load calculation, NEMA rating and electrical enclosure design.

This way, you will get an enclosure air conditioner sizing that is efficient and cost-effective.

Which Enclosure Cooling Systems Can You Get at KDM?

KDM offers a range of enclosure cooling systems depending on your specific requirements. You can choose from:

- Electrical enclosure air conditioner – both a thermoelectric air conditioner and compressor-based air conditioner.

- Air to air heat exchangers

- Vortex enclosure cooling system

- Enclosure fans

These are the main enclosure cooling systems KDM electrical enclosures come with.

What Enclosure Cooling Units and Accessories does KDM Offer?

At KDM, we can offer the following enclosure cooling accessories:

- Electrical enclosure air conditioner replacement

- Enclosure fan

- Enclosure air to air heat exchanger system

- Enclosure air to the water heat exchanger

- Variable-speed air conditioners for enclosures

- Top and side mount air conditioners

- Liquid cooling system for the enclosure

- Enclosure exhaust fans

- Thermal control accessories

- Thermal management software

- Sealed enclosure heat sink

- Vortex cabinet cooler

Basically, we offer a complete solution in enclosure cooling unit solutions.

How Does KDM Control Quality of Electrical Enclosure Air Conditioner?

At KDM, we pay attention to quality control and compliance.

All our electrical enclosure air conditioners are designed and tested according to international standards and requirements such as:

- CCC

- CE

- NEMA

- UL

- CE

- RoHS

- TÜV NORD

- EN

- IEC

- IP

- SASO

KDM can meet your local quality compliance standards.

Simply contact our engineers to learn more about our capability.