For electrical systems, people use and confuse the terms distribution box and distribution board for each other. However they feature unique applications and features. Having a good understanding of these differences is very important for achieving proper distribution of electricity, and ensuring compliance and safety in industrial, commercial, and residential areas.

What is a Distribution Board?

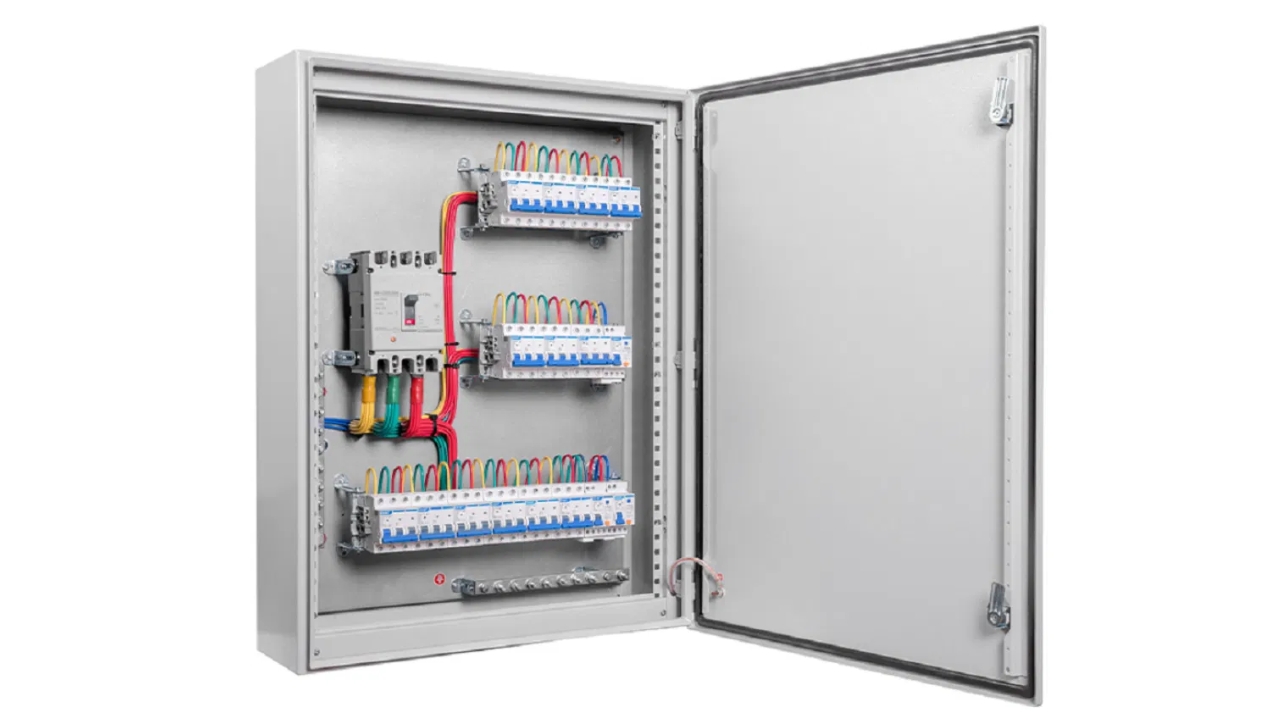

Definition board, which is also called a breaker panel or panel board is an electrical component which helps in dividing electrical power feeds into other circuits offering protective circuit breakers or fuses. They are useful in industrial facilities, commercial and residential buildings, huge infrastructure projects, and data centers.

What is a Distribution Box?

A distribution box is an enclosure which covers electrical components and connections, thereby ensuring safe distribution of power to different circuits and devices. Distribution boxes are useful in several applications including outdoor lighting, connections for industrial equipment, and more.

Main Differences: Distribution Board vs Distribution Box

Proper distribution of power is important in every electrical system to ensure safety. There are two common components responsible for the distribution of electrical power. These components are the distribution box and distribution board. Since they sound similar, people often interchange these components. However, it is important to understand that these two components are different in various aspects.

Function

The significant difference between a distribution box and a distribution board is evident in their function. The main function of a distribution board is to manage and discharge electrical power to different circuits within your entire property.

This box includes protective devices like circuit breakers and fuses to ensure proper distribution of power to different areas and above all safety. A distribution board protects your electrical system from short circuits and electrical overloads.

A distribution box functions differently as it acts as a housing that shields all electrical connections and wiring systems in your building. Its primary function is to offer protection against dust, external damage, and humidity. Although a distribution box may feature connection terminals and switches, it helps to organize and protect your wiring system. It doesn’t distribute power like a distribution board.

Size

Distribution boards are bigger in size and are built to handle higher power loads. You can use these boards in industrial or commercial settings as they can manage complex electrical systems. They can contain multiple circuit breakers while ensuring proper power distribution and management.

Distribution boxes, on the other hand, are small in size and can only house a few electrical components. Due to their compactness, you can use them for simpler applications like home appliances and lighting. They can’t cater to large electrical loads or multiple circuits. Therefore, they have limited capacity.

Installation Areas

The installation areas of these two components differ. You can install distribution boards in utility areas and electrical rooms for easy access. Accessibility is key when installing your distribution board so that you can carry out maintenance easily and as well avoid possible hazards. If you are installing distribution boards in your home, the place to mount them is close to your main electrical supply.

For distribution boxes, you can install them in different areas like ceilings, walls, and outdoor areas. Since they are small in size, they can fit into different places. You can install them in areas where you need to protect your wiring.

Material Composition

Although distribution boards and distribution boxes come from high-quality materials, their material composition differs. Robust materials like steel or aluminum are useful in constructing distribution boards. These materials offer a high level of fire resistance and durability. Also, they can tolerate electrical loads and protect your electrical system against damages.

You can manufacture distribution boxes from different materials like metal, polycarbonate, and even plastic. The application environment usually determines the choice of material to use. If you add using your box for indoor settings, you can consider PVC or plastic boxes.

Such materials are lightweight and usually corrosion resistant. However, if it is for industrial settings, it is advisable you go for metal distribution boxes due to their strength and capabilities to handle environmental conditions.

Application Requirement

You need distribution boards in applications that require proper management of multiple circuits and distribution of power. Such applications include offices, commercial buildings, residential properties, and industrial facilities. These boards manage power distribution on HVAC systems, home appliances, lighting systems, and other electrical devices.

Distribution boxes operate on simpler applications where you need to put all electrical connections in an enclosure. Common applications where you need distribution boxes are outdoor lighting systems, housing junctions, and small machines. You can as well use these boxes in demanding environments like construction sites where there is a need for secure electrical connections.

Safety Features

Both distribution board and distribution box offer safety, but their safety features are different in some ways. Distribution boards have enhanced safety features like surge protectors, circuit breakers, and current devices. These devices avoid issues like ground faults, electrical faults, and over-currents from occurring. Also, they protect your electrical equipment from electrical shocks and fires.

Distribution boxes protect all your electrical connections by shielding them in an enclosure. Although they don’t have protective devices like circuit breakers, they are resistant against harsh weather, dust, and mechanical impacts. Some models feature gaskets or seals that prevent water buildup.

Maintenance Needs

Your distribution board and distribution box need proper maintenance to prolong their lifespan and ensure smooth functioning. However, these two components differ in terms of their maintenance needs.

You need to inspect your distribution boards regularly to keep the circuit breakers in the right working conditions. Also, you need to check for any loose connections or possible wear. Your maintenance routine might include checking the load balance and testing protective devices. It is also important you check the insulation resistance.

Your distribution box requires minimal maintenance. The maintenance routine is very simple. All you just need is to check for any insecure connections, moisture ingress and damage. If you are using your distribution box for outdoor or industrial settings, check the gaskets and seals to ensure proper protection against environmental conditions.

Cost

Cost is a major aspect that differentiates your distribution board from your distribution box. Distribution boards are costlier due to their higher capacity and the presence of built-in protective devices. However, this price may vary based on the type of protective devices and the number of circuits they feature.

On the other hand, a distribution box is less pricey. However, a lot of factors like material type, size, and other features determine their price. Since it doesn’t have internal components you can use it for simpler electrical demands.

Lifespan

Distribution boards can last up to 20 years if you take proper care of them. These boards come from high-quality materials that can cater to high electrical loads. Also, they are very sturdy and durable.

Distribution boxes can’t last up to distribution boards, although they are durable. If you are using a distribution box in industrial or outdoor settings, expect them to last for some years. However, regular inspection and proper maintenance will contribute to their longevity.

Regulatory Compliance

They are safety standards guiding the production and use of distribution boards. Manufacturers must comply with the standards provided by both local and international bodies. These standards are set to ensure there is protection against electrical issues. Safety is also important during installations, therefore, you need to follow installation guides properly.

Although distribution boxes have fewer regulations, there are some electrical safety standards manufacturers must comply with. Distribution boxes used for outdoor and industrial settings must meet the IP rating to ensure they offer the required protection.

Conclusion

Understanding what differentiates distribution board vs distribution box will help you make the right decision for all electrical needs. Although boards help in managing extensive circuits, the distribution boxes serve both temporary and localized applications. Making the right selection enhances reliability, efficiency, and safety. KDM Steel provides high-quality distribution boxes and boards, thereby ensuring efficient, safe, and reliable solutions that suit different applications.

FAQ

How is a distribution board different from a distribution box?

A distribution board is entirely different from a distribution box in terms of their function and application. A distribution board functions as a power distribution system to different circuits while a distribution box acts as an enclosure that houses several electrical connections. While a distribution board offers protection a distribution box manages and distributes power.

Can I use a distribution box in place of a distribution board?

No, you can’t use a distribution box in place of a distribution board. A distribution board helps to manage higher loads and cater to multiple circuits while a distribution box can protect wiring connections. Their names may sound alike, but the functions of each component are entirely different.

Which should I consider for outdoor settings, distributing board or distribution box?

For outdoor settings, it is advisable you use a distribution box. This is because it has dust proof and weatherproof features. Also, their main function is to keep all connections and wiring safe in an enclosed space.