Custom Any enclosure for Your Industry, IP65/IP66 Certification, Low MOQ from 1 PC.

Free Drawing and Design, Mild Steel, Stainless Steel, Galvanized Steel Material Turn-Key Solution for Your System

Your Specialist for Custom Electrical Enclosure Fabrication

KDM specializes in customized electrical boxes. Solutions include but are not limited to custom patterns, cutout, color matching, sizing, assembly. Productions are subjected to rigorous quality checks before shipping.

KDM Custom Electrical Enclosure with a ventilation system, protects electronic switches, fuse, cables, or switch gears from overheating, increasing the service lifespan.

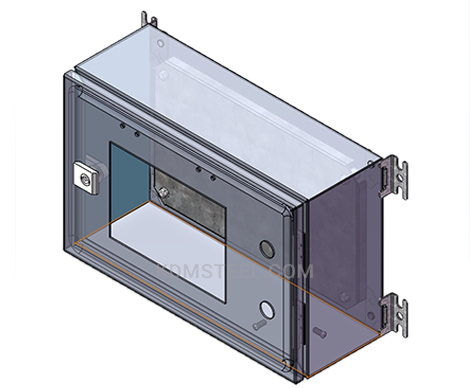

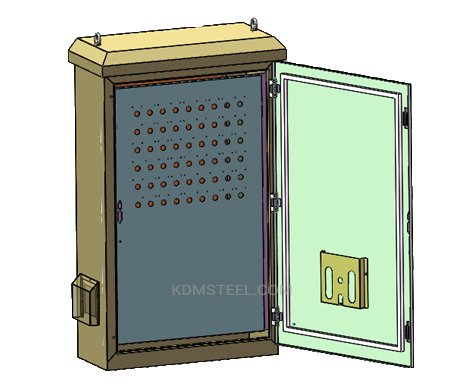

KDM provides a lot of options for your custom NEMA enclosure. We can powder coat your enclosure in any color of your choice. Upon request, KDM custom NEMA electrical enclosure may feature key insert lock, standard locks, cam locks, tamper-resistant latch kits, door interlock, or surface mounting options. Thus, these enclosure comes with different hinges upon request such as adjustable, spring-loaded, pin on, offset, continuous or concealed hinges. Furthermore, our wide range of functional accessories, adds extra protection and functionality to your enclosures.

Just send us your requirement to design your enclosure now.

KDM Custom Electrical Enclosure Serious

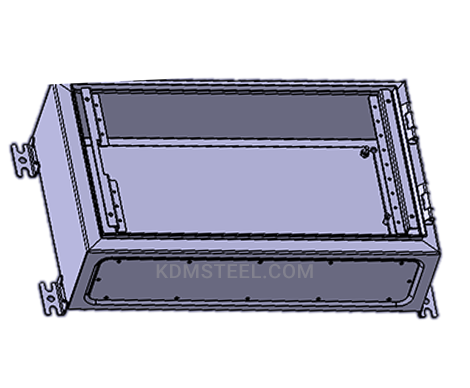

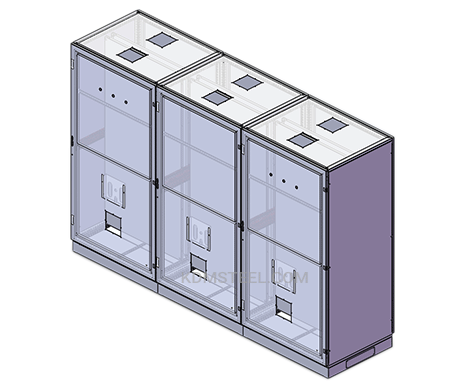

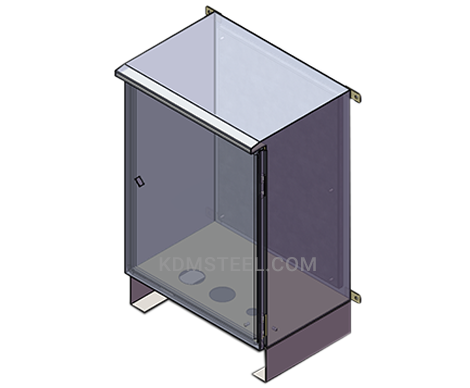

The Modular enclosures from KDM are constructed from high graded materials. They completely offered typical flexibility and easy controlling of electrical equipment within the enclosure.

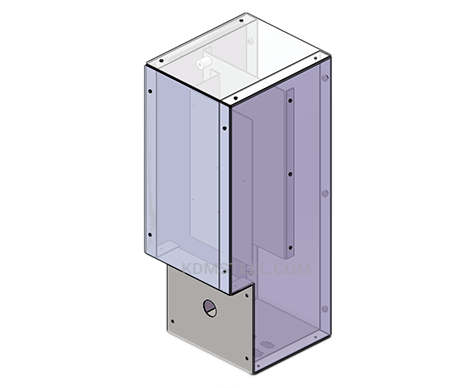

KDM electrical pedestal enclosure provides the flexibility, durability and reliability to be a cost-efficient enclosure for small pair-count terminations and splices.

These enclosures are suitable for use in some areas like petrochemical plants, pulp and paper processing, pharmaceutical and packaging applications, dairies, breweries, food processing areas.

One Stop Customized Enclosure Solution

KDM Custom Electrical Enclosure comes in different configurations such as custom freestanding enclosure, floor mount electrical enclosure, wall mount electrical enclosure, modular electrical enclosure, junction boxes, and many others.

For safety and to prevent unauthorized access to the contents of the enclosure, KDM Custom Electrical Enclosure has customized locking mechanisms and handles. Upon request, KDM Custom Electrical Enclosure may feature key insert lock, standard locks, cam locks, tamper resistant latch kits, door interlock, etc. There is a range of custom KDM Lockable Electrical Enclosures.

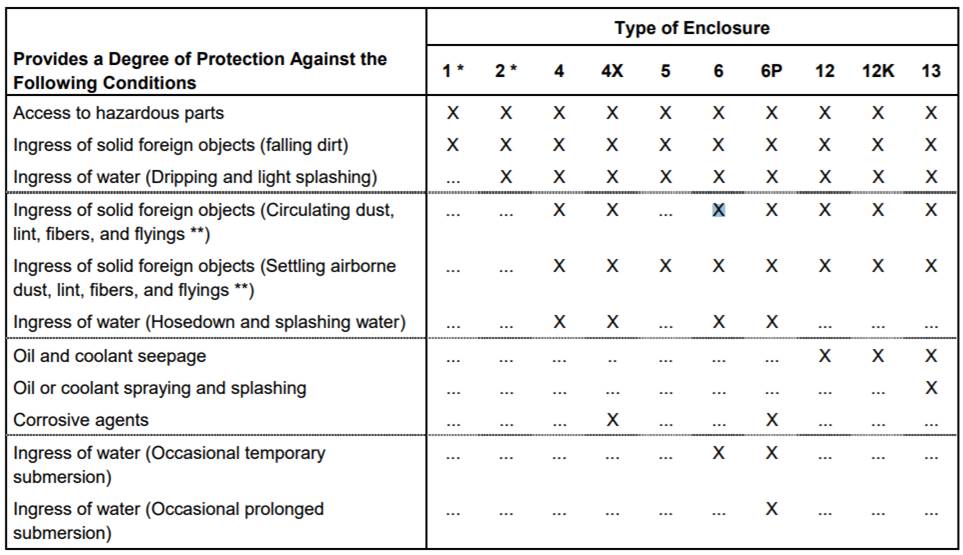

Any NEMA Rated Enclosure for Your Industry

Whether you want NEMA 1 enclosure, NEMA 2 enclosure, NEMA 3 enclosure, NEMA 3R enclosure, NEMA 3S enclosure, NEMA 3X enclosure, NEMA 3RX enclosure, NEMA 3SX enclosure, NEMA 4 enclosure, NEMA 4X enclosure, NEMA 5 enclosure, NEMA 6 enclosure, NEMA 6P enclosure, NEMA 7 enclosure, NEMA 8 enclosure, NEMA 9 enclosure, NEMA 10 enclosure, NEMA 11 enclosure, NEMA Type 12 enclosure, NEMA 12K enclosure or NEMA 13 enclosure; KDM Steel engineers will help you.

How KDM Design Your Electrical Enclosure

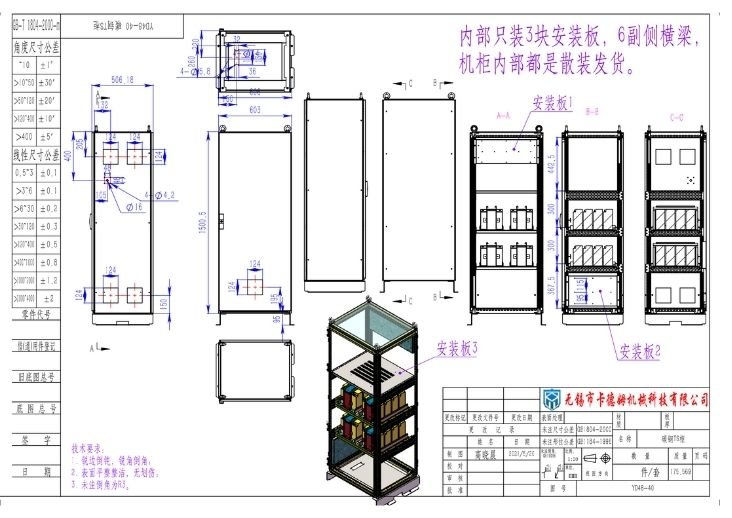

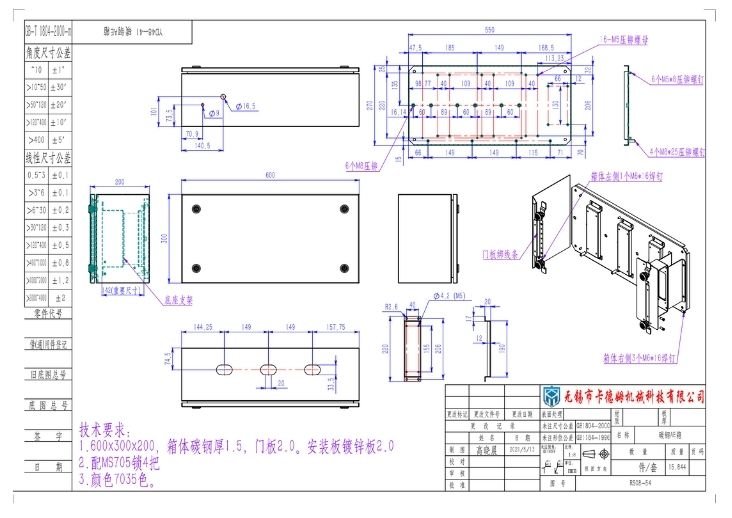

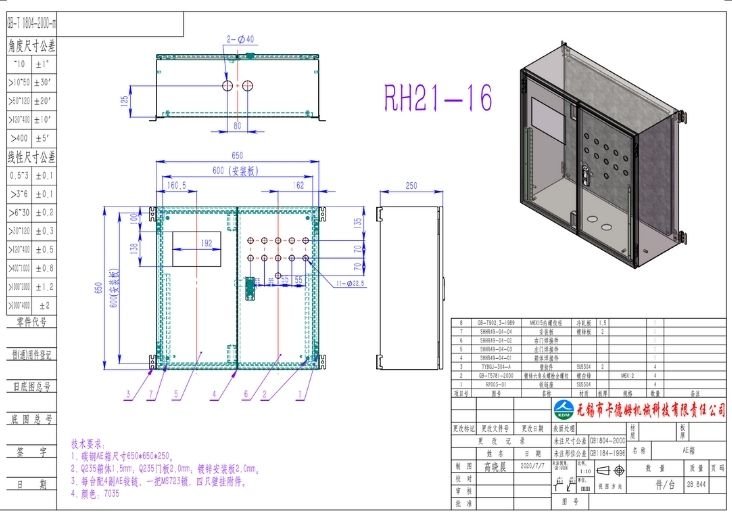

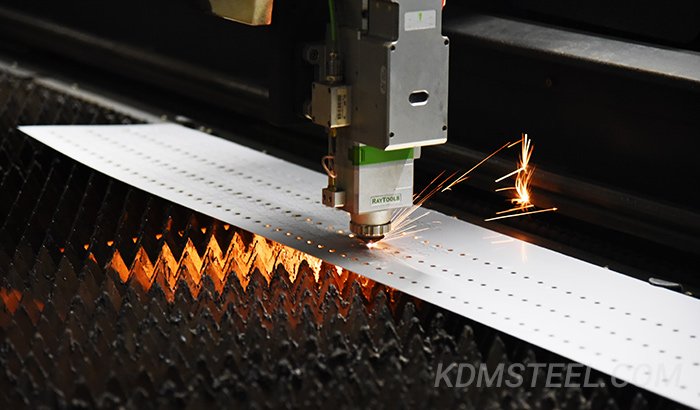

At KDM, we have simplified the process of making custom electrical enclosure – send us your CAD design in appropriate format (.sldasm, .x_t, .stp, .igs, .asm, .sat, .dwg or .dxf). Alternatively, KDM Steel offers free CAD template design for custom electrical enclosures, or our team of engineers will help in the custom electrical box design recommendations.

KDM works with you to design a custom electrical enclosure to your satisfaction, starting from concept design, CAD drawing, choosing the high-quality material, and quality inspection.

Talk to our technical team today, for faster delivery of your custom electrical enclosure.

Resource to Customize Your Electrical Box

- Electrical enclosure Materials

- Electrical enclosure manufacturing process

- Electrical enclosure CAD design example

- Electrical enclosure Size Guide

- Electrical enclosure safety guide

- Electrical Enclosure Assembly Guide

More Manufacturing Process for KDM IP65 Enclosure

Ability to open custom electrical box is equally important. Thus, KDM Custom Electrical Enclosure comes with different hinges upon request such as adjustable, spring-loaded, pin on, offset, continuous or concealed hinges.

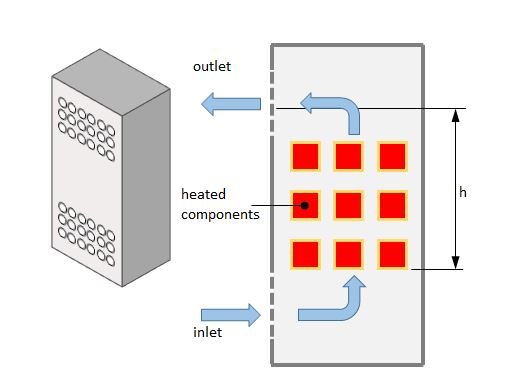

Furthermore, KDM Custom Electrical Enclosures may have ventilation systems. KDM engineers design Custom Vented Electrical Enclosures to allow for free circulation of air, thus preventing overheating, while removing excess heat, fumes or vapor.

Additionally, KDM Custom Electrical Enclosures may have transparent windows made from polycarbonate. These are precisely designed electrical cabinets, useful when monitoring processes without opening the Electrical Enclosure with Window.

Depending on the unique application and environmental conditions, KDM Custom Electrical Enclosure conforms to the CE, UL, NEMA 250-2014, IECEx, RoHS, ATEX, CSA, and EN/IEC 60529 standards.

Why KDM is Trusted By Over 1000 Global Clients

- Enclosure Manufacturing

- 2D Drawing

- 3D Drawing

4000W high performance laser cutting machine, +/- 0.05mm accuracy. No burr, no scratching.

Multi-Functioning flexible welding equipment, high accuracy, no deformation.

Expert assembling team, consistent assembly quality on every KDM enclosure

Related Product

KDM: Your Professional Custom Electrical Enclosure Manufacture

As an industry leader in custom electrical enclosure manufacturing, KDM Steel engineers will walk you through the custom electrical enclosure design process.

custom electrical box welding

KDM custom NEMA enclosure can be built in steel, galvanized steel, 304 or 316 stainless steel. These enclosures can be fabricated in various sizes, shapes, and configurations, depending upon your request. Whether you need it for indoor or outdoor applications, we have the capability to build the perfect enclosure for your specific application.

KDM custom NEMA enclosure has the ability to protect the enclosed equipment against the elements when it’s stored outside and most vulnerable things like dust, heat, water, or other environmental hazards. KDM manufactures NEMA-rated enclosures for a variety of applications where it needs extreme protection.

KDM custom NEMA enclosure comes in different configurations including custom freestanding enclosure, floor mount electrical enclosure, wall mount electrical enclosure, modular electrical enclosure, junction boxes, and many others. Depending on what size, shape, and type of NEMA enclosure you’re looking for, we have various products that will be the perfect fit.

custom electrical box

Custom NEMA enclosure can be offered in type 1, 2, 3, 3R, 4, 4X, 12 and 13 NEMA ratings, but we can also build any type of custom NEMA enclosures depending on your specific needs.

Aside from the indoor and outdoor application of our custom NEMA enclosures, it can be further designed and fabricated for hot and cold temperature environments, solar powered applications, corrosive environments, hotspot installations and other applicable environments it could be fitted.

At KDM, we have strict standards with high attention to quality, when manufacturing your custom NEMA enclosure. KDM custom NEMA electrical enclosure conforms to the CE, UL, NEMA 250-2014, IECEx, RoHS, ATEX, CSA, and EN/IEC 60529 standards. Our professional team ensures that enclosures meet their standards, and while each custom NEMA rated enclosure different specifications, they’re all intended to protect electronic property from potential damage.

As a premier manufacturer of NEMA enclosure, KDM can quickly design and fabricate custom NEMA enclosure precisely what you need. Our experienced engineers and design professionals will be with you every step of the process. Our experts will help on the exact configurations of what your equipment must be.

With over 10 years in the industry, KDM is your ideal electrical source for your NEMA enclosure. Custom NEMA electrical enclosure offered at a competitive price. These NEMA enclosures protect your components, no matter what external environment may be. We, at KDM, provide the right product for your field demands.

Whether you’re looking for custom NEMA enclosure, NEMA cabinet, or other specific enclosure, you’ll find it here at KDM.

Get started on your custom NEMA rated enclosure today!

Custom Electrical Enclosure: The Ultimate FAQ Guide

At times, you may need a custom electrical enclosure that meets your unique NEMA or IP requirements.

It can be an overwhelming task.

This FAQ guide answers all possible questions you may have about the customized electrical enclosure.

Read until the end to be an expert in this area.

- What is Custom Electrical Enclosure?

- How does Custom Electrical Enclosure compare to Standard Electrical Cabinet?

- What are the Uses of Custom Electrical Enclosure?

- What is Custom Electrical Enclosure NEMA Rating?

- Which Types of Latches and Locks are in Custom Electrical Enclosure?

- What are the Benefits of Custom Electrical Enclosure?

- Do Custom Electrical Enclosures have disadvantages?

- Are there Size Limitation for Custom Electrical?

- Which Custom Electrical Enclosure Designs are there?

- Which Material is ideal for Custom Electrical Enclosure Window?

- What is Custom Junction Box Enclosure?

- Which Hinges can you use for Custom Electrical Enclosure Cabinet?

- How should you Choose Custom Electrical Enclosure?

- What is the Best Material for Custom Electrical Enclosure?

- What are IP Ratings for Custom Electrical Enclosure?

- What is Custom NEMA Electrical Enclosure?

- When should you use Custom Vented Electrical Enclosure?

- What are Custom Electrical Enclosure Certification and Rating?

- How do you Choose Cooling System for Custom Electrical Enclosure?

- Which Types of Electrical Enclosure Cooling Systems are there?

- How Does Inadequate Cooling Affect Custom Electrical Enclosure?

- What is UL Listed Electrical Enclosure?

- Why Vent Custom Electrical Enclosure?

- When should you use Recessed Electrical Enclosure?

- Can you get Weatherproof Electrical Enclosure?

- Does Custom Electrical Enclosure have Warranty?

- What Additional Accessories are in Custom Electrical Enclosures?

- What is Cable Enclosure?

- Which Gasket can you use for Custom Electrical Enclosure?

- Which Custom Electrical Enclosure is a suitable Hazardous Environment?

- What is the Best Insulation Material for Custom Electrical Enclosure?

- What is Custom Electrical Enclosure Heater?

- Are Custom Electrical Box Made from Polycarbonate?

- How can you Ensure Free Air Circulation in Custom Electrical Enclosure Cabinet?

- How do you Choose Custom Electrical Enclosure Windows Kit?

What is Custom Electrical Enclosure?

A custom electrical enclosure is specially fabricated according to your unique requirements.

With your manufacturer, you will come up with unique drawing and fabrication procedures that will meet your specific application requirements.

Remember that leading manufacturers are the best-paced to provide the best custom electrical enclosures.

And on this, KDMSteel can guarantee the best electrical enclosure according to your specifications.

How does Custom Electrical Enclosure compare to Standard Electrical Cabinet?

Electrical enclosure

Looking at custom electrical enclosure and standard electrical cabinets, you may not notice the difference.

However, the difference is from the fact that you have control over everything in the electrical enclosure.

The only difference lies in:

i. Dimension requirements

ii. Accessories in the electrical enclosure such as air conditioners, fan, ventilation systems, door locking mechanism, DIN rail, etc.

iii. Finish surface – you may opt for painted, polished or galvanized surface finish

iv. Branding – for OEM business, you may require your branding.

However, quality standards and requirements such as NEMA specification or IP rating will remain the same.

Even for these personalized electrical enclosures, they must conform to specific safety standards and requirements.

What are the Uses of Custom Electrical Enclosure?

Some of the primary uses of electrical enclosures include:

i. Protect electrical components from harsh environmental conditions such as water or dust

ii. Prevents users from electrical shock since they act as barriers

iii. Ensures safety of electrical components since only authorized personnel can access the panel

iv. Makes management of electrical and electronics components easier. This is because several parts can be installed in one electrical enclosure.

v. Reduces costs of managements – You can use one heater to heat the entire enclosure or a single cooler to lower temperature

vi. They make troubleshooting and distribution of power easier since all components are in a central place

What is Custom Electrical Enclosure NEMA Rating?

These are electrical cabinets that conform to the National Electrical Manufacturers Association (NEMA) protection standards or regulations.

The NEMA rating acts as a guide that will help you make enclosures that conform to specific protection standards.

Of course, you don’t have to take you electrical enclosure to NEMA for approval, test or certifications.

These are voluntary standards that outline whether an electrical enclosure is fit for various environmental conditions.

They indicate whether the electrical enclosure can protect its content from particles such as dust and liquids.

NEMA Electrical enclosure rating

Which Types of Latches and Locks are in Custom Electrical Enclosure?

There is a range of electrical enclosure locks and latches.

It will depend on how you want to lock your electrical enclosure.

You can choose from any of the following options:

i. Compression latch

ii. Quarter turn latch

iii. 3 point turn latch

iv. Tamper-resistant locks and latches

v. Latches and locks with an alarm system

Electrical enclosure locking mechanism

In short, you can choose a locking mechanism that is safe for your electrical enclosure.

What are the Benefits of Custom Electrical Enclosure?

When you choose custom electrical enclosures, you’re likely to benefit from the following:

i. The electrical enclosure will meet your specified quality standards, such as IP rating, NEMA classification, RoHS standards, UL listing, and CE specifications, amongst others.

ii. You have the freedom to organize electrical equipment and accessories according to systems requirements

iii. For OEM businesses, a custom electrical enclosure is a perfect branding technique that will help skyrocket your business.

Do Custom Electrical Enclosures have disadvantages?

The answer is a resounding, yes!

Remember that there is some extra work that needs to be done in the development of the custom electrical enclosures.

That means you will have to incur some extra costs to benefit from the modifications your manufacturer makes to your Custom Electrical Enclosure.

Are there Size Limitation for Custom Electrical?

Electrical enclosure sizes

Size limitations are probably there for several factors.

The first limitation could be to do with the amount that you are willing to pay to obtain a particular size of the Custom Electrical Enclosure.

The capabilities and the experience of the manufacturer that you choose is the other determinant factor.

A well-equipped manufacturer has sufficient resources and an able workforce to accomplish the tasks at hand.

On the contrary, there is that manufacturer that won’t manage to develop large sizes and particular volumes of work because of the lack of enough resources and equipment.

You could also possibly think about your needs.

Your needs might end up not conforming to what the manufacturer can provide in terms of size.

In short, you can make an electrical enclosure of any size as long as it meets the above criteria.

Which Custom Electrical Enclosure Designs are there?

The classification criteria for custom electrical enclosure design depends on a range of factors.

Some of the most common classification criteria include:

i. Type of material – You can choose from aluminum, plastic or stainless steel custom electrical enclosure

ii. Mounting mechanism – Here, you have many options such as floor mount electrical enclosure, wall mount electrical enclosure, or free-standing electrical enclosure.

Other classification criteria will depend on unique features such as recessed electrical enclosure, hinged electrical enclosure, vented electrical enclosure, etc.

The good thing about custom electrical enclosures is that you can get any design that is suitable for your clients.

Custom electrical enclosure panel

Which Material is ideal for Custom Electrical Enclosure Window?

Determining the best materials for use in the development of the custom electrical enclosure challenges a lot of people.

The rule of the thumb is to consider some of the factors that matter.

Some of these include:

- Heat dissipation

- Weight

- Exposure to corrosive elements

- Cost

- Security

The different materials that you settle for have their pros and cons, and you have to get what serves your needs the best way.

At KDMSteel, depending on your unique requirements, our technicians will advise you on the best material.

Quite a number of custom electrical enclosures are transparent plastic.

This allows you to view the internal section of the electrical enclosure, even without opening the door.

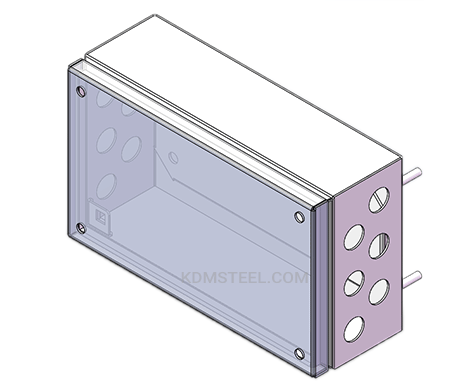

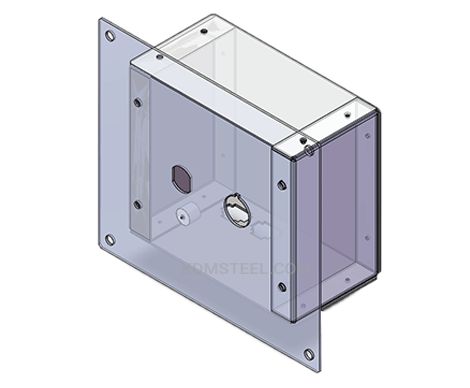

What is Custom Junction Box Enclosure?

Custom junction box enclosure

You can fabricate junction box enclosure from either plastic or metal.

The junction box enclosures can help you house your wiring connections.

It is here that you find connections that are commonly referred to as branch circuits.

The good thing about the custom junction box enclosure is that you end up with a product that serves your needs the best way possible.

You will determine the size, type of finish, installation site, etc.

Which Hinges can you use for Custom Electrical Enclosure Cabinet?

The designing of the custom electrical enclosure cabinet has the hinges as an integral part.

Remember that the hinges are vital when it comes to holding the protective housing in place.

My advice to you is that you check out for the most appropriate specifications since those are the ones that will spell out the difference in performance.

Additionally, the hinges also determine the general appearance of your custom electrical enclosure as well as its longevity.

You will come across many types of hinges in the market, and the challenge pops up when it comes to selecting what works best.

Some of the standard options include the offset hinges, lift-off hinges, concealed hinges, piano hinges, and many more.

You should consider the kind of materials used in the manufacture of the hinges as well as the associated strengths.

Electrical enclosure hinges

How should you Choose Custom Electrical Enclosure?

When choosing a custom electrical enclosure, you should consider the following aspects:

i. Specify the application or purpose of the electrical enclosure

ii. Design of electrical enclosure

iii. Size of an electrical enclosure

iv. Safety features such as locks and latches

v. Quality standard requirements such as CE, RoHS, IP rating, NEMA classification, UL listing, etc.

vi. Type of material

What is the Best Material for Custom Electrical Enclosure?

You are probably looking forward to obtaining a custom electrical enclosure that matches your placation perfectly.

The mistake most people make is compromising on quality at the expense of paying low areas.

Some materials you can use to manufacture custom electrical enclosures include galvanized steel, stainless steel, aluminum, and polycarbonate, amongst others.

Remember that you need the custom electrical enclosures that offer the best protection for your electrical components.

That is regardless of whether you want to sue them for outdoor or indoor applications.

Working with trusted manufacture is a good thing.

That is because such manufacturers collaborate with some third party agencies and thus end up developing leading products.

The custom electrical enclosures are such that they conform to the set industry standards, including IEC Ingress Protection and the UL Certifications.

I wish to recommend stainless steel, mild steel, carbon steel, and aluminum as part of the best materials for use.

These guarantee you longer lasting custom electrical enclosures.

Electrical cabinet

What are IP Ratings for Custom Electrical Enclosure?

IP Rating or ingress protection refers to the degree of protection custom electrical enclosures provide for:

i. Solid particles, which is typically represented by the first number

ii. Liquid substances which are represented by the second number

Here is a complete guideline for the IP rating standards:

IP protection code

What is Custom NEMA Electrical Enclosure?

These are custom electrical enclosure manufactured according to NEMA requirements and specifications.

They can be NEMA Type 1, NEMA Type 2, or NEMA Type 4.

When should you use Custom Vented Electrical Enclosure?

Excessive heat can be destructive, and thus you require the custom vented electrical enclosure.

You must ensure you are working with a product with proper ventilation.

That is where the custom vented electrical enclosure comes in.

The ventilations are set in place to ensure that air flows freely.

There are also the ventilation fans set in place to promote air circulation.

The high activity processes are the ones that require the custom vented electrical enclosures.

Air circulation in an electrical enclosure

Go for a custom vented electrical enclosure of high quality and also the one that suits different temperatures.

An experienced company will make your custom vented electrical enclosures with more enhanced fans that can eliminate the hot spot.

What are Custom Electrical Enclosure Certification and Rating?

These are certifications that indicate that the custom electrical enclosures have passed quality test standards and ratings.

They may include EMC, RoHS, NEMA, IP, UL, CCC, and CE.

How do you Choose Cooling System for Custom Electrical Enclosure?

Electrical enclosure cooling system

Before you choose a cooling system for an electrical enclosure, it is crucial to consider the following:

i. Know the size of the electrical enclosure

ii. Evaluate the type of enclosure cooling options in the market – you should focus on the cooling technology

iii. Calculate the heat load in the custom electrical enclosure

iv. Evaluate the surrounding environmental conditions that may affect the temperature of the custom electrical enclosure

v. Check whether the electrical enclosure has an insulation system or not

vi. Determine the cost of cooling the electrical enclosure

Which Types of Electrical Enclosure Cooling Systems are there?

Some of the most cooling systems for electrical enclosures include:

- Air conditioners for electrical enclosure

- Filter fan or cooling fan for electrical enclosure

- Vent and louvers systems for cooling

- Vortex A/C cooling system

How Does Inadequate Cooling Affect Custom Electrical Enclosure?

Inadequate cooling can be catastrophic since it may result in:

i. Hot spots within the electrical enclosure

ii. Overheating of an electrical enclosure

iii. A total failure of electrical components

iv. Fast wear and breakdown of electrical enclosure components

v. Fire outbreak within the electrical enclosure

What is UL Listed Electrical Enclosure?

A UL listed electrical enclosure refers to a type of enclosure that conforms with the safety certifications of Underwriter Laboratories (UL).

This happens to be an independent body focused on the development of quality and safety standards that guide you in the purchase of electrical enclosures.

The organization also focuses on the high-voltage equipment and the industrial control panels.

A UL listed electrical enclosure is thus equipment in conformity to top quality standards and is therefore valuable for money.

Why Vent Custom Electrical Enclosure?

You probably understand the role of a vent, and that is almost the same purpose here.

The custom electrical enclosure requires a vent to facilitate free airflow.

With vents, you can cool the custom electrical enclosure system efficiently.

As a result, it will prevent the destruction or malfunctioning of parts due to overheating.

Remember that venting your custom electrical enclosure is about balancing the cooling capacity and the heat load.

Speed drives and the other wide-ranging controllers are known to emit significant heat levels.

You need proper working cooling systems and full-fledged vents that ensure a stable system.

Effective cooing extends the life of your electrical enclosure.

It also guards you against the unscheduled outages.

Tip: You don’t need to suffer from catastrophic failures.

It is thus essential that you get good advice from leading firms specializing in keeping electrical equipment and cabinets cool.

Electrical enclosure vents system

When should you use Recessed Electrical Enclosure?

The recessed electrical enclosure is about putting in place additional protection to the electrical device.

Hard impacts are significant threats to electrical devices, but the recessed electrical enclosures will help you out.

A top quality recessed electrical enclosure means that you won’t have to worry about rain.

Your electrical cords are safe, and I like the versatility of these enclosures.

The ease of use is something to smile about, not forgetting the attractiveness attribute.

Most of them area characterize with transparent covers and come in wide-ranging sizes, finishes, and designs.

Can you get Weatherproof Electrical Enclosure?

Yes, there are quite many weatherproof custom electrical enclosures.

Depending on the type of weather you want to protect the electrical enclosure, there are standards and fabrication regulations.

The best way to go about this is following the NEMA Rating and IP classification requirements.

Take, for example:

- An IP 65 custom electrical enclosure is one that is dust tight (does not allow dust particles to enter the enclosure) and offers limited entry of liquids. That is, it will protect the electrical enclosure content from jets of water from all directions.

- NEMA Type 3RX custom electrical enclosure protects against falling dirt ingress, entry of sleet, water, and snow. Additionally, it protects components from corrosion.

- NEMA Type 10 custom electrical cabinet is specially designed for the marine environment.

NEMA Type 4X enclosure

Does Custom Electrical Enclosure have Warranty?

Yes.

All custom electrical enclosures should have a warranty.

However, the warranty may be on specific accessories or design specifications.

What Additional Accessories are in Custom Electrical Enclosures?

Some additional accessories you will find in electrical enclosures include:

- Racks

- Cooling systems

- Heating systems

- Metal boxes

- Open racks

- Mountable chassis

- Cable management accessories

- DIN rail

- Locking mechanisms, etc.

What is Cable Enclosure?

A cable enclosure is a critical appliance that keeps your wiring solutions safe from damage.

It also helps to keep your workplace tidy.

If you use top-rated cable enclosures, your wires will remain safe.

Adverse weather conditions or liquid will not damage the cables.

Which Gasket can you use for Custom Electrical Enclosure?

You require the high-performance gaskets for the manufacture of your electrical enclosures.

Leading manufacturers will recommend that you buy gaskets made using top quality materials.

It is these gaskets that will help your custom electrical enclosure conform to the NEMA and IP rating.

They offer an appropriate sealing mechanism.

The gasket material should protect against dust particles, UV light, harsh weather, oil, and harmful chemicals.

Which Custom Electrical Enclosure is a suitable Hazardous Environment?

Many factors make the environment to be classified as hazardous.

Therefore, there different NEMA ratings that will help you order for such custom electrical enclosures.

You can consider the following:

- NEMA Type 7 custom electrical enclosure

- NEMA Type 8 custom electrical enclosure

- NEMA Type 9 custom electrical enclosure

- NEMA Type 10 custom electrical enclosure

Usually, they are suitable for hazardous environments as classified by the NFPA 70Class I, Division 1, Groups A, B, C, or D.

Of course, the word “hazardous environment” can be used differently depending on the degree of performance you expect from an electrical cabinet.

What is the Best Insulation Material for Custom Electrical Enclosure?

Polyyurethane and polyisocyanurate happen to be some of the materials that you could settle for in the manufacture of your custom electrical enclosure.

What is Custom Electrical Enclosure Heater?

The custom electrical enclosure heater is a product modified to suit your needs.

It helps to protect components of the electrical enclosure from possible freezing and subsequent corrosion.

Electrical enclosures achieve this by maintaining the optimal operating temperature within the electrical cabinet.

However, as you choose a custom electrical enclosure heater, it must be explosion-proof.

Are Custom Electrical Box Made from Polycarbonate?

The answer I a resounding yes!

Polycarbonate custom electrical enclosure come in a range of sizes, shapes, and design.

It is a popular plastic in electrical enclosure fabrication.

How can you Ensure Free Air Circulation in Custom Electrical Enclosure Cabinet?

Air circulation in the electrical enclosure

Free flow of air will depend on the following:

- Position of the ventilation system

- Electrical enclosure fans

Depending on the design of the electrical enclosure, it must allow for a free flow of air.

Whether it is an open-loop cooling system or closed-loop cooling system, the free flow of air will depend on the design.

You should discuss this with the technicians to get a viable option.

How do you Choose Custom Electrical Enclosure Windows Kit?

Choosing the best custom electrical enclosure windows kit is easier said than done!

It is thus essential that you adhere to the right principles to get the best.

The cost of purchase is something that we can’t ignore.

It is essential to go for affordability, but that shouldn’t be at the expense of quality.

Ensure that you check out the following attributes:

- It should be of outstanding quality

- The design should be NEMA and IP compliant

- Check out for the quality-checked finishes

- Consider durability, and that has to do with the materials used in the production

- Check out whether you are going for an ISO certified product

Getting personalized electrical enclosure requires you to state various specifications, from dimensions, cooling, NEMA rating, heating to cooling systems, amongst others.

Here at KDMSteel, our engineers can help you get the best custom electrical enclosure.