Looking For a Reliable Stainless Steel Laser Cutting Service? KDM offers A Very professional Stainless Steel Laser Cutting Services

- Reliable Stainless Steel Laser Cutting Service

- New Improved Processing Efficiency

- Fully Automated Production

- Compact Storage Technology

Contact us today.

KDM 2D Laser Cutting of Finest Tubes is the most authentic cutting machine that works in the stainless steel process and many more materials. Cutting widths tinier than 20 microns represents the premium cutting edge qualities of our machines. KDM`s capacity to laser cuts with crisp edges, smooth, fast and amazing are highly recognized.

KDM 2D Laser Cutting of Stainless Steel provides excellent quality and high speed of operation and performance. 2D laser cutting of stainless steel can be used for a comprehensive range of applications. Let KDM custom the exact dimensions!

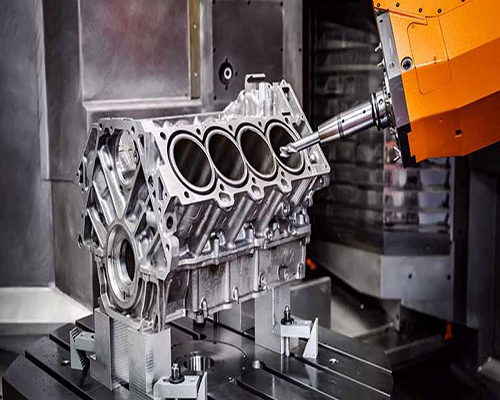

3D Laser Cutting of Stainless Steel are mostly applied in architecture such as pipes and many others. These can be furnished competitively with appropriate sections with the help of innovative system technology. KDM knows and understands your 3D Laser Cutting of Stainless Steel needs.

KDM Customized Signages Laser Cut is attractive, high-quality, and the precisely trimmed finishes have clean edges. Thanks to our ultramodern equipment used, we can etch and cut thousands of customized signages required by clients.

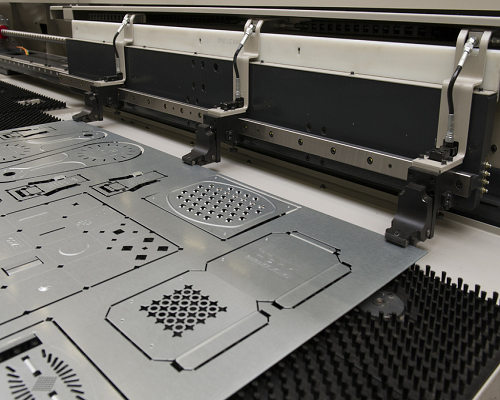

Stainless Carbon Steel Sheet Fiber Laser Cutting Machine equipped by KDM provides precisely trimmed or cut to the right and exact dimensions or sizes. We use this advanced technology to create signage, lettering and producing the finest products.

KDM Stainless Arts Custom Designs was trusted by many customers and clients. KDM specializing in both traditional and modern custom designs to skyrocket your needs. Using stainless steel as a material, this delivers durability and strength.

Sheet Metal Fiber Laser Cutting Machine using by KDM is innovative which equipped with domestic fiber laser cutting head and high-quality domestic fiber laser. This process is used by KDM professionals to ensure you receive your custom sheet metal cutting smooth and reliable.

KDM Laser Cutting for Wall and Door Decorations have efficient, accessible and newly precise finishes that will appreciate clients. Stainless steel works great in many various projects. Be creative now with KDM.

Related Products of Stainless Steel Laser Cutting Service

Send Your Inquiry on KDM Stainless Steel Laser Cutting Service Now.

- More Than 10 Years Of Expertise in Providing the Best Services

- Innovative Machinery Equipment Used in Fabricating

- Friendly Technical Staff Support 24/7

- Strict Quality-Control in High-Standard Materials

KDM Stainless Steel Laser Cutting Services

Are you searching one of the excellent and premier manufacturers who can provide you best standard stainless steel laser cutting services? If your answer is yes, then your search is over here in KDM.

KDM is one of the leading companies that manufacture, supply, and provides reliable stainless steel laser cutting services. For over 10 years of expertise, we know and understand your needs.

We are popular for delivering the best service for stainless steel laser cutting. Our finishes are widely appreciated due to their excellent features like high tensile strength, smooth internal finishing, and durability. Be one of our esteemed customers! For sure, you will never regret the result.

KDM Stainless Steel Laser Cutting power influence the cutting speed, cutting thickness, cutting width, and cutting quality. We have an innovative stainless steel laser cutting system that can cut certain thicknesses of stainless steel. And in the end, the result is clean and flush with precise lines nearly unnoticeable bead connections.

In fact, there are various processes in cutting using lasers, with different kinds utilized to cut assorted raw material. Some of the methods are melt and blow, vaporization, scribing, melt blow and burn, cold cutting, thermal stress cracking, and burning stabilized laser cutting.

The laser cutting machine used by KDM is a state-of-the-art generation product with modernized new appearance and various configurations according to the original model.

It’s mostly used in sheet metal hardware, automotive, working, electronics, advertising &sign, furniture, and any related industries. While classically utilized for industrial manufacturing applications, it is also starting to be used by small businesses, hobbyists, and schools.

Stainless steel can be customized based on customer’s specifications and a requirement on thickness, material surface treatments, length, and width. With the help of our flexible and high-precise laser cutting machine, it is possible to make your product perfect and suitable for many applications.

KDM makes use of a strict quality control process in order to certify the various properties and precise dimensions you required. Plus, the system of quality affirmation even assures that all the stainless steel laser cutting services products pass through different inspection and tests such as raw material tests, hardness tests, and certification and a supplementary test.

Our fully automated laser cutting machine means you get an ideally and perfectly smooth finish every time. Our latest machinery enables us to supply custom-made laser cut profiles up to 35mm thick speed and to your required stipulations.

All our stainless steel laser cutting finishes are designed and manufactured using the greatest quality of materials and innovative technology. With the help of it, all our finish products are well inspected and tested by quality experts. All KDM products are manufactured keeping in mind the international quality standards.

For over 10 years of machine R&D & manufacturing professionalism, KDM made the greatest attainment in stainless steel laser cutter intelligent equipment domain. We obtained many certifications such as ISO9001, UL, CE, and many more.

Whether its Sheet Metal Stamping, CNC Shearing Service, CNC Plasma Cutting, or any related services, KDM is competent and willing to assist you.

So, when you have any problem with stainless steel laser cutting, choose KDM for reliable services.

Feel free to contact our professional team. We are so happy to serve you 24/7.

For your next stainless steel laser cutting services needs, KDM is the right choice!

Stainless Steel Laser Cutting: The Definitive FAQ Guide

What is Laser Cutting?

LASER refers to Light أmplification by Stimulated Emission of Radiation.

And, laser light is monochromatic, coherent and highly directional light.

Implying, you can get laser light when electrons are “excited” as a result of absorbing energy from either another laser or electrical current.

Now, laser cutting, is a precise technique, of cutting a material design from CAD file (of any other file format), by directing laser light or beam to melt, vaporize or burn the material.

Laser cutting – Photo courtesy: Wikimedia

Laser cutting – Photo courtesy: Wikimedia

Learn more:

What is Stainless Steel Laser Cutting?

It is a subtractive metal fabrication technology that depends on the laser beam to cut stainless steel.

Stainless steel laser cutting produces an accurate and quality finish.

What are the Types of Stainless Steel Laser Cutting Machines?

There are many models, brands and designs of stainless steel laser cutting machines in the market.

However, the main classification criteria are based on the laser cutting technology where we have:

https://youtu.be/OLm8lIWAK8E

- CO2 laser for cutting stainless steel – It is suitable for cutting thick stainless steel materials.

- Fiber laser cutting machine for stainless steel – These laser machines are suitable for micro laser cutting processes.

- Nd:YAG – These are pulsed lasers that are suitable for micro stainless steel processing.

Learn more:

What Kinds of Stainless Steel Sheet Can be used for Laser Cutting?

Laser cutting is a versatile technology that you can use to fabricate virtually all grades of stainless steels.

It doesn’t matter whether you intend to use:

- 3CR12 stainless steel

- 304 stainless steel

- 310 stainless steel

- 316 stainless steel

- 321 stainless steel

- 430 stainless steel, or any other grades of stainless steel

Laser cutting stainless steel – Photo courtesy: STEEMIT

The stainless steel laser cutting technology can be customized to your unique needs and requirements.

How Does Laser Cutting Work?

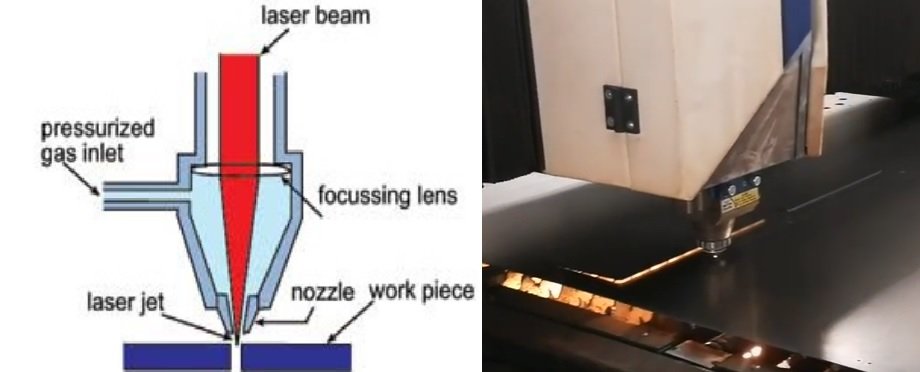

A laser cutting machine focuses onthe high powered laser beam on stainless steel to be cut.

The power of the laser beam may vary from 1 to 8kW for industrial lasers and 0.25 to 40W for “hobby laser”.

Before the high power laser beams reach the stainless steel surface, it travels through a beam path, from a laser beam resonator.

From the resonator, the machine redirects the beam using beam benders or optical fiber, then focuses it through the nozzle on the stainless steel surface you want to cut.

This beam has high power density, resulting in the cutting process through melting or vaporizing the material.

It is for this reason that you can refer to laser cutting as a thermal process.

At the nozzle, both the laser beam and laser gas reaches the stainless steel surface.

Depending on the cutting mechanism, the laser gas can be oxygen or nitrogen.

Laser cutting process

This gas will remove the “cut material” creating an accurate kerf with the best finish.

Generally, there are three main types of laser cutting techniques:

أنا. Fusion laser cutting – you’ll use nitrogen, which is an inert gas to remove the waste material on the cut surface.

It basically slows the cutting process, though suitable for some laser cutting requirements.

ii. Remote laser cutting – the laser cutting machine partially evaporates the materials.

It is a perfect laser cutting technique for thin sheets. Besides, you don’t need an assist gas.

iii. Flame laser cutting – you’ll use oxygen as an assist gas, which will then create an exothermic reaction.

It speeds up the laser cutting process.

Whichever laser cutting technique you choose, it will precisely cut the material into the desired shape.

Mostly, in the case of stainless steel, it laser cuts by melting (the region where the beam falls).

During the stainless steel laser cutting process, the machine will use pressurized nitrogen to blow away the molten material.

Depending on the shape or complexity of the cut, the laser head will move in different axes according to the preinstalled program.

As the laser head moves, it will create precise cutting lines that are accurate and consistent.

A good example is the CNC laser cutting machine.

Depending on the design of the stainless steel laser cutting machine, it generates the motions through:

- Rack and pinions

- Stepper motors and timing belts

- Liner motors

Out of the three, linear motors are the most accurate and fastest; however, they are very expensive.

On the other hand, rack and pinions offer reasonable speed and accuracy.

Learn more:

What Type of File do You Need for Laser Cutting?

Whether you want to cut simple or complex patterns, you must save all your graphics in vector format.

Remember, laser cutting machine will interpret drawings or designs in vector format.