Stainless Steel Casting: The Complete Guide

Are you looking forward to venturing into stainless steel casting business?

What is your experience in this field?

Today, I want to show you how to cast stainless steel successfully.

I know, it may seem a complex industrial process – but, I will make everything simple for you.

So, even before, going into details of stainless steel casting, here is a quick overview of what you will learn.

Look at these:

- What is the meaning of stainless steel casting?

- Best stainless-steel grades for casting

- Stainless steel casting methods

- Stainless steel casting step by step process

- Controlling stainless steel defects during casting

- Stainless steel casting standards and quality control

- Factors affecting stainless steel casting cost

- Applications of stainless steel casting

- Stainless steel forging vs. stainless steel casting

- Stainless steel casting FAQ’s

- Stainless steel casting company – KDM Steel

Well, this is going to be an in-depth guide on stainless steel casting.

Just keep reading to learn more – shall we commence?

What is a Stainless Steel Casting?

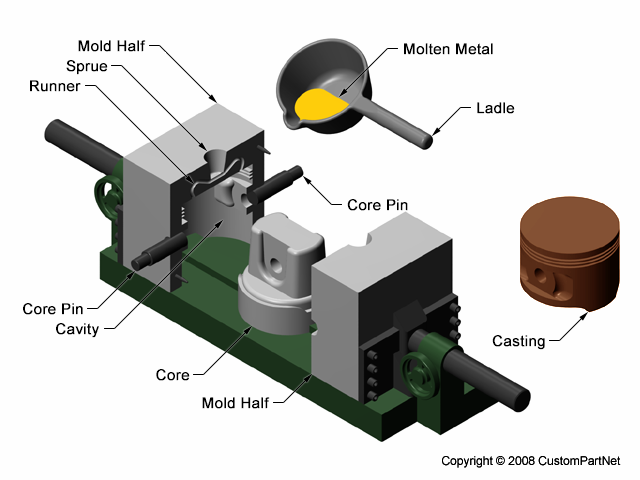

This is an industrial practice which involves the formation of a final product by introducing molten stainless steel into a mold or combination of mold cavities.

Initially, mold cavities are constructed into the intended shapes that the final product should assume.

Thereafter, the required type of stainless steel is heated under high temperatures till its due melting point.

This would subsequently turn the solid metal into a liquid state.

Finally, the molten metal is poured into the cavity, cooled and then it solidifies into the final shape.

The product is then extracted for cleaning.

Cast stainless steel parts – Photo courtesy: Off Shore Direct Metals

Some exemplary measures may be undertaken after solidification such as heat treatment.

Inspections are also vital to ascertain if products bear the desired properties as prescribed by the buyer.

As we shall later discuss, the casting process is sequential and entails different measures.

So how does stainless steel casting differ from wrought casting?

This is one of the most frequently asked questions.

Stainless steel casts maybe composed of numerous chemical compositions,unlike wrought casts which may just have one major chemical component.

Besides, wrought casts are mechanically produced through simple means such asrolling وforging into the final product.

This is opposed to steel casts which assume the shapes of molds just by pouring into the mold cavity.

Due to these reasons, steel casts exhibit exemplary qualities as opposed to wrought casts especially when they are exposed to varied harsh conditions.

Having known that, let’s move on to the next segment.

So,

What is the Best Stainless-Steel Grades for Casting?

Before that, note that steel is a metal alloy majorly comprising of iron and carbon together with other elements.

However, stainless steel is an alloy made up of a large quantity of chromium content usually not less than 10.5 % by mass.

The rest of the mass is composed of iron.

Notably, chromium is responsible for corrosion resistance and therefore any increase in chromium would make the metal more resistant to corrosion.

Additionally, apart from chromium, stainless steel is also made up of other ingredients like:

- Molybdenum

- Nickel

- Titanium

- Copper

- Nitrogen

- Phosphorous etc.

Among all these minor components, molybdenum is absolutely unique.

لماذا؟

It drastically enhances the corrosion resistance of the stainless steel.

Also, molybdenum is the distinctive chemical that differentiates the two most commonly available types of stainless steel.

These types are stainless steel 304 and stainless steel 316 – I will talk about the two later in this guide.

It is therefore evident that there exist several types of stainless steel apart from the two common ones mentioned.

The difference among them is their distinct alloy composition due to the difference in chemical composition and also their varied physical properties.

That aside.

Before you start casting process, it’s prudent you pick the most suitable kinds of stainless steel first.

Remember your premium goal for casting ‘is the production of quality casts.’

Coincidentally, the quality of the casts would depend upon the type of the stainless steel used.

Therefore, the best grades for casting are:

- Stainless steel 304

- Stainless steel 316

Note that these two types of metals all belong to class 300 series of the stainless steel.

Meaning that they are chromium-nickel alloys.

Let’s have a look at each.

a) Stainless Steel 304

This grade belongs to austenitic stainless-steel group.

What is austenitic stainless steel?

Well, this group consist of themicrostructured andface-centered cubically crystal structured stainless steel.

Incidentally,this is the largest category of stainless steels.

They actually account for 75 % of all the stainless steel.

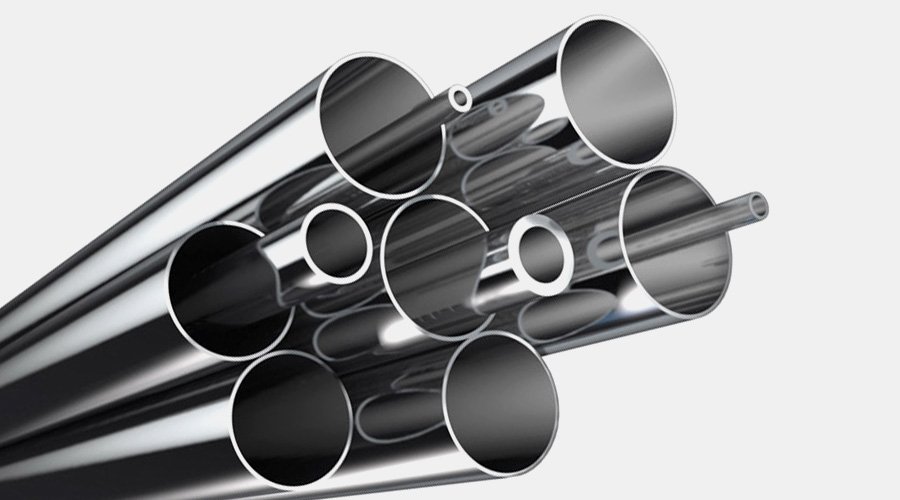

304 Stainless steel tubes

SS304 is also commonly referred to as group 18/8.

لماذا؟

Because it comprises of chromium and nickel as the major non-ironic contents of about 18%and 8 % composition respectively.

Some notable features of this grade are as follows:

It is highly resistant to corrosion resulting from various environmental or atmospheric conditions.

As a result, it’s able to withstand most of the oxidizing agents such as acidic solutions in the environment.

However, it is worth noting that, stainless steel 304 is susceptible to corrosion when exposed to some extreme conditions such as:

· Warm chloride solutions which in turn result into crevice corrosion

The chloride ions contained in this solution forms penetrative chemical areas that bypass the chromium oxidized barrier.

Note that, this barrier serves as a protective shield to any adverse external chemical reactions that might degrade the metal.

Due to the formation of the chemical areas, the internal parts beneath the protective layer are subsequently compromised.

· Saline climatic areas like the coastal plains

As a result of these limitations associated with stainless steel 304, the 316 type is a reliable substitute for you.

Especially in cases when severe chloride or saline conditions are involved.

Let’s now consider the common uses of this metal.

Applications of the Stainless Steel 304

This metal is widely used for the manufacture of:

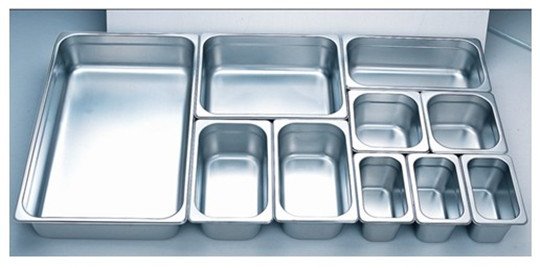

I. Household goods – majorly kitchen appliances and food processing equipment. This is due to the fact that this metal is durable and can as well be sanitized.

II. Industrial commodities – for example, machine parts, doors etc.

Stainless steel castings

There also exist some minor classes of stainless steel 304 namely: 304 H and 304 L.

However, they similarly bear the equal chromium and nickel components as the 304 type.

In addition, they are equally resistant to corrosion.

The ‘H’ here denotes that 304 H has slightly higher carbon content (0.04 – 0.1).

Making it suitable for use in procedures that involves applications of high temperature and that need some degree of strength.

The 304 L kind has got little or lower carbon composition at most 0.03 % of the total mass.

As a result, it’s widely less sensitized during welding.

Sensitization in this context refers to the formation of chromium carbides on the grain boundaries.

This occurs when the stainless steel is subjected to extreme temperatures same as that of welding procedures.

The resultant chromium carbides greatly minimize the corrosion resistance of the metal,especially along the grain boundaries.

For this reason, stainless steel 304 L is suitable for your welding procedures.

b) Stainless Steel 316

This type of metal is the most commonly available form of stainless steel after the 304 type.

Coincidentally, 304 and 316 possess most similar physical and mechanical properties.

The major difference as earlier mentioned lies in the possession of molybdenum.

The stainless steel 316 has got about 3 % molybdenum.

Just like 304, stainless steel 316 also has a distinct variety of different types including 316 L, F and H.

Cast stainless steel

Again, each type is slightly different due to their diverse chemical compositions.

The 316 L is the type with less carbon quantity.

Again, it is the preferred type for a lot of welding practices since it exhibits no sensitization at all as earlier discussed.

Apart from that, it is suitable for applications involving higher temperature ranges and greater risks of corrosion.

For this reason, it is commonly used in marine work and construction industries.

Grade 316 H, unlike L, has got higher traces of carbon hence its exemplary strong even at high temperatures.

The following are the features of stainless steel 316:

I. Perfect corrosion resistance – due to the molybdenum inclusion, it is more resistant to very chronic factors specifically chloride solutions and saline conditions. Remember, this property makes it ultimately superior to 304.

II. It has excellent forming and welding properties.

III. It is simple to roll and break particularly in the formation of different parts for use in industrial applications.

Applications of stainless steel 316

I. Chemical processing industrial applications – this is as a result of its resistivity and suitability for use in acidic conditions.

II. Manufacture of medical-surgical equipment in pharmaceuticals – this is so due to non-reactive nature of the metal.

III. Manufacture of heat exchangers, jet engines parts and pump parts.

Isn’t itstrains to easily spot the differences between SS316 and SS304?

If so, for comparison of the two, study the table below.

| Stainless Steel 304 | Stainless Steel 316 |

| Contains all other minor elements but not molybdenum | Contains 2 – 3% molybdenum |

| Corrodes when exposed to chlorides and saline conditions. | Resistant to chloride solutions and saline conditions. |

| Able to withstand corrosion from most common oxidizing agents | Withstands corrosion from all agents and adverse conditions |

| Easy to sanitize, therefore applicable in the manufacture of kitchen and food appliances. | Non-reactive hence suitable for medical-surgical equipment including pharmaceuticals. |

Which type is the most suitable between 304 and 316?

I would say, typically all these two types are very useful.

Your selection between the two would, however, depend on the circumstances under which you are planning to use the metal for.

For procedures that your applications would require good formability then pick on 304 as opposed to 316.

The latter has got poor formability.

Additionally, if you consider working in an environment with many corrosive agents such as marine and saline conditions then pick 316.

When we shift our focus to cost, 304 is then the better choice since its relatively cheaper compared to 316.

Lastly for applications requiring greater strength together with hardness choose 316 unlike 304.

Good luck with that.

We shall now proceed to the next segment.

I will take you through the different methods of casting stainless steel. Let’s move on.

Stainless Steel Casting Methods

We shall limit our discussion on the following methods of casting stainless steel.

Stainless steel casting

Also, this piece will be based upon stainless steel type only.

The following are the common methods of casting stainless steel:

Investment casting

- Centrifugal casting

- Continuous casting

- Sand casting

- Corner casting

- Pressure die casting

- Lost wax casting

We shall now venture into all of them.

Stainless Steel Investment Casting

This is a technical process that involves the use of mold cavities that are constructed and made of wax or foam.

The mold cavities are usually designed from a specific pattern to be assumed by the castings.

The pattern is usually coated using a refractory material in order which would then form the mold.

Later on, the wax gets melted away when the molten metal is poured into the molds.

Cooling and solidification then follow.

Lastly, the castings should be now ready.

Interestingly, the term ‘investment’ means ‘a complete covering’.

Therefore investment casting simply refers to the technique of fully covering the wax pattern with a refractory material.

Investment casting

Let’s quickly look at the steps involved in this procedure.

I. First, prepare a wax pattern. You may use plastics and foam in place of wax. However, the wax is the most preferred since it easily melts and it can be reused.

II. Depending on the number of castings you need to produce, you may attach several wax patterns for a single casting process. Additionally, you may connect the wax patterns to the wax bar. The bar will, later on, serve as central spruce.

III. Thereafter, it’s time now to fix ceramic cup at the end of the bar. At this point, we now have some sort of arrangement. This would include the wax bar fixed with patterns and the cup. A combination of these arrangement resembles a tree, for such, it’s called a ‘Tree.’

IV. Now dip the tree pattern in a ceramic slurry. Notice a layer of ceramic is consequently formed on the surface of the pattern. To thicken the layer, you should continually dip the pattern into the slurry until the desired thickness is achieved.

V. Once the ceramic coating is optimally thick, allow the tree pattern to air-dry.

VI. At this point, turn over the now hardened set and heat it at an average temperature ranging from 90ﹾ⁰ C – 180 ⁰ C. This heat melts down the wax which in turn flows out leaving behind the mold cavity.

VII. After that, heat the ceramic mold cavity at an extremely high temperature of about 1000 F – 2000 F (550 ⁰C – 1100 ⁰C).

Heating the mold at this stage is very vital since the heat:

- Strengthen the mold.

- Melts away any possibly trapped wax from the previous process.

VIII. Thereafter transfer the mold while still hot to a compartment. Pour the readily molten stainless steel into the mold.

So why is it important to pour the liquid metal while the mold is hot?

Two reasons stand out:

- To enhance the free flow of the molten metal through the mold cavity. In the process of filling every thin section of the cavity.

- Issues a perfect dimensional accuracy since the mold cavity would otherwise shrink together during the cooling process.

IX. Once the mold cavity is filled up, allow it to cool down in order to completely solidify.

X. Finally, break away the ceramic mold to have the investment casting.

XI. Cut out the parts from the ‘tree’ separating them distinctively.

That is it, your castings are now ready for use.

Simple, right?

https://youtu.be/UrUsaGussfc

Advantages of Stainless Steel Investment Casting

- It is simpler and easy to produce extremely thin sections. In fact, narrow parts as much as 0.15 inches can be produced.

- The resultant castings have got better dimensional accuracy with tolerances of 0.76mm.

- The process can be used to cast almost any metal. Additionally, it’s suitable for the production of little castings with a maximum mass of 75 lbs.

- It is capable of casting extremely complex parts with excellent surface finishing.

The major shortcomings associated with this technique are:

- Relatively expensive.

- Besides, it is labor and skill intensive.

Stainless Steel Centrifugal Casting

Among the casting methods, this one stands out.

Unlike the others which utilize the force of gravity and pressure to fill up the molds, this one uses strong centrifugal force.

As a result, it is very suitable in the production of cylindrical parts and hollow structures.

In this process, cylindrical molds are constructed and centrifugal force is employed to produce the castings.

In turn, these castings exhibit the cylindrical shapes of the molds.

Usually, these molds are permanent metals and commonly made of steel or iron.

Centrifugal casting

Centrifugal castings may be done in the following two ways.

I. Vertical centrifugal casting

II. Horizontal centrifugal casting

The difference between the two is based upon the position of inclination of the cylindrical molds.

For Vertical Centrifugal Casting, a combination of casting machines that rotates the cylindrical molds in a vertical axis is used.

On the other hand, the centrifugal casting machines rotate the molds through ahorizontal axis in the horizontal centrifugal casting process.

Though the production mechanisms may be different, the centrifugal casting process is similar for both the processes.

Have a look at the centrifugal casting procedure.

I. Preparation of the Molds

This step encompasses a series of measures undertaken to make the cylindrical molds ready for use.

You may dip the mold in a ceramic slurry to coat its walls and thereafter dry it.

When ready, fix the molds in the centrifugal machine and switch it on.

Let it rotate at its axis at an extremely high speed of about 1100 RPM.

II. Pouring.

Now Transfer the molten stainless steel from the furnace and straight away pour it into the rotating molds.

This step maybe difficult to conduct manually so you may involve an automated filler machine.

Withthe aid of centrifugal force, the molten metal is evenly distributed along the walls of the cavity as the mold fills up.

The dense liquid is drawn onto the walls while the less dense ones including impurities remain suspended or occupy the interior surfaces.

III. Cooling

Now that the molds are completely filled, ensure the rotation continues as the metal cools down.

You will observe that the material cools from the outer walls and eventually through the inner walls.

IV. Removal of the castings.

You may now halt the rotation.

But before that, you have to ensure that the material has cooled and fully solidified.

Extract the castings from the molds.

You may shake off the mold cavity or break it up to release the castings.

This should be easy.

V. Finishing

Inspect the castings to ascertain the quality of the castings.

Subsequently, remove any irregularity formed by grinding or sandblasting.

You can now use the castings in relevant applications.

Advantages of centrifugal casting

- This process can be used to form very large parts.

- It can produce parts with excellent surface finishing and highly accurate dimensions.

- Consumes lower labor cost

- Produces little wastes and scrap.

A major limitation is that this process is applicable to the production of cylindrical castings.

Stainless Steel Sand Casting Method

Unlike the investment casting, this method uses sand molds to produce complex and unique parts.

Thesand molds are made of silica sand.

sand as a mold material has got several benefits associated with it.

Have a look.

Sand casting

Benefits of using sand as a mold material:

- It is cheaply and readily available

- Sand is able to withstand high temperatures, therefore, it’s suitable for making metalswhich have got higher melting point compared to it.

Quickly let’s look at the methodology employed during this process.

i. Initially, you have to make the molds for the casting process.

Kick off this stage by designing a specific pattern.

Otherwise, you may select an appropriate type of pattern for use.

Again, your selection should vary according to:

- The material of the pattern.

- Allowances to be initiated in the pattern

- Costs of the pattern to be used.

The pattern here consists of two equal halves ie.

The upper and bottom half.

Thereafter, pack some sand into each half of the mold around the pattern.

Remember to mix the sand with a binder to stabilize the shape of the cavity.

Packing may be done manually or by use of an automated machine.

Be sure to confirm the quality and type of the molding sand since each type of sand has got its specific application.

A molding sand binds strongly and doesn’t easily lose its permeability.

It is as well composed of a mixture of silica sand, clay,and adequate moisture.

Therefore, it’s worth comparing and contrasting each with the kind of materials you want to produce.

Most commonly used types of sand molds are:

- Natural and synthetic sand

- Greensand mold – this is a mixture of sand, water,and

- Dry sand mold – composed of sand with an organic This type is strengthened by treating it to high temperature. In addition, it produces very accurate castings even though it’s very expensive.

Again, characteristics of the sand used would in turn directly affect the quality of the sand molds.

A good type of sand should bear the following traits:

- Optimum strength

- Better permeability

- Excellent thermal conductivity

- Should be reusable

ii. Once the pattern is well fixed in the mold, remove it carefully. What is now left is the mold cavity that will be essential in the next step.

Additional measures may be undertaken such as lubricating the surface of the cavity.

This would enhance the removal of the castings later.

iii. Now make a gating system or a pouring trough fixed onto one end of the molding cavity.

The gate has major purposes:

- To lead the molten metal injected into the mold cavity during casting.

- To provide a pathway for draining out pattern material when it is melted upon heating.

- To join the patterns to the runner

iv. Next, pour the molten stainless steel into the mold cavity. Prior to this step you should keep and maintain the alloy in a furnace.

Ensure to completely fill up the cavity channels and sections.

You are free to either do this manually or by use of an automatic filler machine.

Make sure you quickly fill the molds within a short time to avoid premature solidification of the metal in the cavity.

v. Cooling then follows. Having properly filled the casting, be patient and allow the mold to cool down and solidifies completely.

The cooling time would largely depend on the intended wall thickness of the castings.

Thick walls would require longer cooling time.

Failure to cater for enough cooling time would result in:

- deformation of the castings

- cracking,

- incomplete filled sections

- shrinking

vi. Once the appropriate cooling time has elapsed, you can now break the mold and withdraw the castings. For this process, you just need to shake out the mold.

Nevertheless, shake out procedure is done by the use of a vibrator machine.

This equipment is efficient in dragging off the sand leaving the final products.

Despite the use of the machine, it may not be explicitly accurate.

Some layers of sand may still be left trapped in the castings.

That’s why I advise you use a blasting machine.

Unlike the vibrator, blasting machine completely removes the trapped sand and clears any rough surfaces of the castings.

vii. After that, surface trimming and inspection follows. Check for any irregularity on the parts. If any, then you need to do the surface trimming.

The irregularly protruding surfaces do result from inefficiency in the cooling process.

As a result, excess materials may also occur on the casting surfaces.

You may use some mechanical equipment like a hammer, saw or trimming press to cut off these prolonged parts.

The cutting process need not be time-consuming.

Although it largely depends upon the size of the casting.

The bigger ones will surely take much time to trim.

Also, you may dispose or reuse these hammered parts in another sand casting process.

If you prefer the later treatment then it’s paramount you only reuse them together with the parts having similar chemical compositions.

Pros of Sand Casting

- Can be used in the production of very large parts.

- Formation of complex designs.

- The scraps and wastes produced are recyclable.

The disadvantages are:

- Poor material strength

- Labor intensive

- The castings produced have got higher chances of having good porosity.

Stainless Steel Continuous Casting

It is as well-known as strand casting.

This technique is usually used in the manufacturing industrial processes to cast stainless steel of a specific length.

For this case, the molten steel is fed into a trough-likea tundish where it, in turn, flows through a vertical mold.

The vertical mold is also supplied with a cooling system.

Thereafter the molten steel cools and solidifies.

Continuous casting process produces long strands of stainless steel casts.

Unlike other mechanisms of casting, it has got intermittent steps that take place correspondingly.

Different foundries may have varied designs and modifications of the continuous casting machines.

However, the good news is that all the steps and procedures are similar.

Continuous casting

Step by Step continuous manufacturing process

- Pour the molten metal into the tundish.

A tundish is a container that acts as a temporary reservoir for the molten metal.

Usually, it sits just above the mold.

In fact, it is fixed at about eighty feet above the ground surface.

The significance’s of the tundish are:

- Acts as a temporary reservoir for feeding the liquid stainless steel into the mold. Consequently, it’s always designed with large capacity in order to hold large quantities of the molten metal.

- It continuously and consistently supplies the liquid metal into the mold.

- It is responsible for precisely filling the mold into the correct proportions. To ensure this, the tundish is thus fitted with an automatic control system to ensure correct and optimum supply of the liquid.

Basically, the control system regulates the flow of the molten steel.

It does this by determining the level of molten metal available in the tundish.

Afterward, the control system defines the pre-required level needed in the mold and hence it regulates the metal – liquid output from the tundish.

A smooth transition of the casting is then guaranteed.

Importantly, the casting begins in the tundish.

You need also to ensure the tundish is constantly supplied with molten metal to avoid the molten metal solidifying at this location.

- Having done all those, purification of the molten stainless steel then follows. All the available slag and impurities are extracted at this stage.

Since steel is a very reactive metal to most external environmental conditions at higher temperatures caution must be upheld.

Consequently, the top of the mold may be fitted with a gas nozzle to spray inert gases specifically the argon gas.

Why argon?

This because:

- Argon expels any oxidizing gas such as oxygen which may react with the metal.

- Furthermore, argon doesn’t undermine the quality of the metal. Remember, inert gases are non-reactive.

- Now, the molten metal should easily flow into the mold. The molds are specially made of copper. This is vital since copper material easily conducts heat away into the surrounding.

Besides, the mold has got a system of water cooling fins.

The cooling mechanism helps solidifies the metal castings.

Additionally, the mold is made to move in a pattern of motion usually up and down.

This motion is essential to avoid any risk of the solidified metal from sticking onto the mold walls.

As earlier stated, a metal casting solidifies from the exterior walls and then towards the interior sections.

It’s worth noting that, the casting doesn’t solidify entirely at the mold cavity.

Therefore, to minimize this sufficient cooling time should be allowed.

Moreover, you may lubricate the mold using oil or slag.

Oiling is essential since it:

- Provides worthy lubrication to the mold cavity.

- Expels any trapped air in the cavity.

- Provide a thermal barrier to the mold cavity.

- The flow of the metal strand in the mold is coordinated and moves at a constant rate. Most importantly, the flow is regulated by rollers.

The rollers attached to guide the flow of the strand and direct it via the desired path.

Optionally two different sets of rollers may be included to twist the metal strand perpendicularly.

Another set also comes in to straighten it.

The Interco ordinated sets of rollers, therefore,change the direction of motion of the strand flow from vertical to horizontal inclination.

Subsequently, the casting now proceeds to flow in a horizontal manner.

- The whole strand having completed the passage through the rollers, it moves into the cutting table.

Usually, in the manufacturing industries, the cutting edge is a saw.

While the metal casting should still be in motion, meanwhile, the cutting edge initiates the cutting of the continuous casts.

There you are.

Advantages of this Process

- Little material wastage

- The operational costs in this process are greatly reduced.

- Produces high-quality castings

- Large production

Stainless Steel Corner Casting

The resultant casting procedure, in this case, produces the corner castings.

These products are designed to reinforce the shipping containers.

Corner casting

They are usually designed and sold in 8 sets.

Each set is fixed onto the top corners of the container ie.

Top left and right corners, bottom left and right corners.

Additionally, the dimensions of these products have to be aligned in accordance with the requirements of the international standard organization (ISO) 1161.

Due to the technical roles of the corner castings, the respective design drawings and specifications, therefore, have to be submitted for approval and verification by the ISO.

And any other integral procedures that would be essential in the casting process must be as well submitted by the manufacturer.

These procedures might include chemical analysis of the used metal alloy, weldability and heat treatment.

Once the verification process is completed, these corner fittings may be made using any stainless-steel casting methods.

In the process, they are heavily reinforced for a good strength.

Note that, all castings including corner castings have to be suitably heat treated.

In addition, the corner castings have to be designed to achieve suitable mechanical properties such as:

- Optimum yield strength

- Good tensile strength

- Better elongation

- High impact energy

Stainless Steel Pressure Die Casting

This is a suitable and cost-effective manufacturing process for the production of high-end metal castings with near net shape designs.

Interestingly, these productions have got good tolerances.

Ultimately, the pressure die casting process involves the introduction of a highly pressurized molten stainless steel into a mold cavity.

Here the mold cavity is created using a pair of tool stool dies which have got the suitable desired shapes.

Once the molten metal is filled in the molds, it cools and then solidifies quickly to form the required net shaped casting.

Thereafter, the castings are retrieved.

Engine block

Note that, for this procedure, a high pressure is used in the injection of the molten metal hence the name pressure die casting.

Lets’ proceed.

Types of Pressure Die Casting Processes

This casting process may be classified into two categories depending upon the size of the pressure of the poured molten stainless steel.

Hence, we have:

- High pressure die casting

- Low pressure die casting

We shall look into the specific categories later but before that lets deal with the basics.

Both these processes are used under different circumstances.

The factors that in turn result in these circumstances include but not limited to:

- The complexity of the components

- The quality of the castings to be produced

- Manufacturing financial budget.

Die casting system

High-Pressure Die Casting

We shall first consider the dies involved in this process.

The dies here are divided into two sections which are the two equal halves.

Each half of the die is fixed onto the machine plates.

The only difference between them is that one half is attached to a stationary plate while the other one is established onto a movable plate.

Normally, the machine should be maintained and aligned in a horizontal manner.

This technique of fixing the dies enables the die casting machine to be easily opened and closed.

There are two distinct categories of Die casting machine namely:

- The cold chamber Die casting machine

- The hot chamber Die casting machine

The molten metal is poured into the metal molds at extremely high pressure and with speed of up to 1100 bar.

The molten metal is injected into the shot chamber.

Afterward, a piston drives and introduces the liquid into the mold cavity.

After complete solidification, the two equal halves of the die are opened and the resultant castings are automatically ejected.

Low-Pressure Die Casting

This process produces high-quality castings.

However, it’s only used to produce metals with low melting points.

Consequently, it can’t be used to produce stainless steel.

For that reason, we won’t discuss much of it.

Advantages of Pressure Die Casting

- It is cheaper compared to other processes.

- Also, it produces castings with accurate dimensions and finer surface finishing.

- Appropriate for production of thin-walled castings as opposed to other processes. As little as 0.75 mm or 0.03 inches thickness walls can be produced.

- Can be used if numerous productions are involved up to a million parts.

Stainless Steel Lost Waxing Casting

This method involves the injection of molten stainless – steel into wax made models.

These waxed models are in turn contained in the molds.

Later on, the wax model is heated to melt away the wax which subsequently is drained away after the mold is ready.

Due to the fact that the wax is eliminated, the process is referred to as ‘lost wax casting.’

Essentially, the lost wax casts maybe prepared by two methods: direct and indirect method.

For the direct method, the casts are made from waxed models while in the indirect method the casts are made from a copy of a wax model.

Nevertheless, the copy needs not to be made of wax.

Lost wax casting

Quickly, let’s have a look at the lost waxing process

- Creation of the model – first, you need to create an initial model made of wax.

- Mold formulation – using the original model, make a mold.

- Waxing – having prepared the mold, pour the molten wax into the mold until a uniform coating covers the interior parts of the mold.

Ensure to repeat this step until the desired thickness is achieved.

- Wax removal –now extract the hollow wax duplicate of your original model carefully from the mold. Apparently, no material needs to be wasted here. You should rather reuse the mold to make other more duplicates. But re-using is limited to the lifespan of the mold.

- Spruing – before proceeding to pour the molten stainless-steel metal, make sure there is an opening from where the pouring needs to be undertaken. To do this, fix a sizeable ‘cup’ which would serve as our pouring entry.

Critically, we are dealing with a hollow shell, therefore as empty it might seem, it is entirely filled with air.

Incidentally, the air available in the shell would undermine the quality of the castings.

As a result, the air needs to be expelled.

To do the air expulsion, some tubes made of wax will be formed throughout the copy from which air gets expelled from through the tube vents.

Molten steel would in succession, runs through the hollow shell from the cup.

These tubes are called spruces or runners.

- Dipping into a slurry for shelling – the attached spread copy is consequently dipped into silica slurry, followed by cooling using silica sand of different sizes and texture.

This procedure is repeated severally until a ceramic shell is built up.

The shell is composed of slurry and the silica sand. It’s important to allow the shell to completely dry.

Thereafter, the step is repeated until the thickness of at least a half inch is achieved, covering the entire shell walls.

Only the surface of the cup is spared.

If you deal with a bigger piece then a thicker shell would be needed.

- Burning out – this is the ‘lost wax’ step. Place the dried coated shells in an inverted manner into the kiln where they are heated at high temperature for a long period of time.

What’s the purpose of the burnout?

- Melting the wax to make it flow out via the cup hence ensuring the wax is entirely lost.

- The adverse high temperature is important for baking, drying and hardening the shells.

Finally, burnout leaves a hollow strong cavity shell ready for casting, the sprues,and cup.

- Pouring the molten stainless steel.

Place the shell in a tub of sand with the cup facing upwards while it’s still hot.

Ensure you put the stainless-steel metal in a crucible and melt it in a furnace at extremely high temperatures.

Now you should pour the molten metal keenly into the shell.

Note that the shell needs to be maintained hot before pouring the molten metal.

It’s advisable to do the pouring in the hot shell to reduce any chances of the shell being shattered.

The shell may get shattered in cases when there is the difference in temperature between the two factors.

After pouring, allow the precisely filled shells to cool down.

- Releasing – once the filled shells have completely cooled down, it’s high time you removed the outer shell by hammering or sandblasting. What’s left is now to remove the rough castings.

Remember to cut off the original spruces which have as well now recreated.

The wastes from the cutting off need to be reused in another casting.

- Metal-chasing – this process involves working out and cleaning the castings to eliminate the unwanted surface projections due to casting and unnecessarily created marks. A variety of tools such as die grinders maybe used depending on your preferred one.

Chasing the metals would make them appear just as the originally constructed models.

Stainless Steel Die Casting

Verily, this a complex and precise manufacturing process that produces accurate dimensional stainless-steel parts.

For this casting, re-usable molds called dies are used hence the name die casting.

Moreover, this process utilizes some set of equipment such as the furnace, dies and die casting machines.

Fundamentally, the casting process here entails melting the stainless steel in a furnace at high temperature.

This is so since steel also has got the higher melting point.

Pouring the molten steel into the dies then automatically follows.

After pouring, the molten metal cools and solidifies into the final castings.

Just like most casting processes, the parts produced here have got varied size and weights from marginal pounds up to 100 pounds.

Die casting

Notably, Die casting machines are available in two different kind i.e.

- Hot chamber machines- used for the production of alloys with low melting points.

- Cold chamber machines- used for the production of alloys with high melting points.

For the sake of our discussion, we shall stick to the cold chamber machine because we are dealing with steel here.

Straight away, I shall take you through the die casting process.

1) Clamping of the two die halves.

To begin with, prepare and securely clamp the two equal halves of the die.

You may do some auxiliary practices such as:

- Cleaning the halves to remove trapped materials from the previous

- Lubricating the dies – to facilitate the removal of the castings later on.

Having done all those, enclose and securely clamp together the two halves of the die.

Don’t forget that they should be fixed and maintained inside the die casting machine.

2) Injecting the molten stainless steel

Now transfer the molten steel into a suitably stationed chamber from where the liquid metal can be injected into the die casting machine.

The molten metal is then introduced at extremely high pressures ranging from 1000 pa to 2000 pa.

The high pressure strongly embeds the metal onto the dies during solidification.

Dies need to be filled with the molten metal within a short period of time.

If the filling is dragged and consumes much time then ununiform early solidification will certainly occur.

3) Cooling and solidification

The injected molten metal into the die cavity should now begin to cool and solidify.

Ensure that the dies are completely closed during the entire cooling time.

4) Ejection of the castings.

After the elapse of the cooling time, you’re free to open both the die halves and withdraw the castings from the die cavity.

You will need to input a lot of force at this stage.

This because during cooling, most parts are likely to shrink or stick onto the dies hence requires a lot of pressure to break them away.

5) Trimming – now inspect the castings to check for any excess materials and flashings.

These unwanted materials then can be manually cut off using a saw or trimming press.

The resultant scrap materials can be disposed or

That’s it.

https://youtu.be/Pj_mjjUQad8

Below are the benefits that come as a result of using die casting process:

- The process produces castings with good dimensional tolerances.

- The castings also exhibit dimensional uniformity.

- The parts produced only need some slight finishing process.

Stainless Steel Vacuum Casting

It is as well commonly known as V-process.

The process entails the use of fully dry sand molds.

However, the internal cavity of the mold is designed to exhibit the shape of the castings.

Wondering how this occurs?

Well, the resultant pressure exerted due to the vacuum produces some force that makes the mold cavity to withstand the desired shaping.

Vacuum casting

The Mechanism of Vacuum Casting

For this mechanism, a distinct pattern is used.

Remember different varieties of patterns are locally available such as drag pattern or match plate.

The latter has got tiny holes which enhance the air suctioning in order to create a partial vacuum within the patterns.

- Place a walled plastic sheet over the casting pattern and turn on the vacuum pressure pump. The pressure exerted makes the sheet to firmly stick to the surface of the patterns.

- Acquire a specially designed flask drilled with holes, thereafter, place the flask over the casting pattern and completely fill it with sand. The holes on the flask provide a channel via which the pressure build up from the pump is exerted.

- Accurately cut a space at one end of the pattern for fixing the pouring cup and also the sprues.

The cup and the sprues provide a pathway for the flow of the molten stainless steel.

- Next, place another thin plastic sheet at the top of the mold.

Again, turn on the vacuum pressure pump so as to make the plastic adhere to the surface of the mold.

- After that, turn off the pump connection leading to the special casting pattern and extract the pattern.

Conversely, don’t disconnect the pump connection leading to the flask but leave it on.

The combination of these settings help maintains the adherence of the plastic sheet on the top of the mold.

While the other sheet initially on the pattern now sticks to the bottom part.

Check to confirm if the bottom sheet film now exhibits the outlook of the casting in the sand.

- Similarly, manufacture the drag portion of the mold.

- Having finished that, assemble both the halves in order to pour the castings. Ensure they correctly fit such that they leave a hollow cavity in between them assuming the shape of the initially designed patterns.

- Now pour the molten metal into the pouring cup until the cavity is sufficiently filled up. Consequently, the liquid metal will thus easily burn away the plastic coatings that might still be trapped.

- Finally, your products should be ready for extraction.

With that, you should be ready to perform any of the above casting methods.

Metal casting itself is an art and am sure you will really enjoy it.

Besides, you should constantly practice it to achieve the desired perfection.

Now you should fully understand the different mechanisms of the casting process.

In the next part, I will lastly take you through an exhaustive mechanism specially designed for the casting of stainless steel.

We shall discuss in details each step involved.

Lets’ do this.

Stainless Steel Casting Process – A Step by Step Process

Please study the simple flow chart diagram below.

The chart displays a brief summary of the steps and procedure undertaken during the casting process.

Flow diagram

We shall group the whole processes displayed in the chart into four distinct steps that we shall comprehensively discuss.

Let’s begin.

Step 1: Pattern making

Just a reminder, a pattern is an exact replica of the desired part to be cast.

In addition, the pattern is essential since it has got a cavity for adequately holding the molten stainless steel which would later cool down and solidify forming the castings.

As earlier mentioned, this is one of the most significant stages of the casting process.

The type of the pattern used would directly influence the quality of the steel castings produced.

Remember to make your pattern in a manner that considers finer details such as dimensions and some improvisations.

Pattern making

It’s vital to select a pattern that would produce the best quality you want to be replicated in the final castings.

To help you select the best patterns, here is a list of details to look for in a pattern.

- Suitable Drafts angles

- Good surface finishing which includes constant and smooth layers. The surfaces shouldn’t contain undercuts

- Should be able to be sealed since unsealed patterns may take up moisture.

Note that a pattern with faulty surfaces and poor finishing would produce unworthy castings.

So, the question is, what are the types of patterns available?

The pattern types largely vary depending on the material used to build them.

Therefore, the kinds of patterns include:

- Metal patterns

- Wax patterns

- Plastic pattern

- Foam patterns

- Wood patterns etc.

Having known that, remember that before you pick a specific pattern, consider the following factors.

We have formatted them into question forms.

- What is the quantity of parts you want to produce?

- What Size of the castings do you need?

- Which is Your preferred molding method?

- Do you need high casting tolerances?

- How flexible is your budget?

Ask yourself these questions to assist you to choose the best pattern.

Molding pattern

Be sincere and have clearly set objectives to assist you to determine the best.

We now discuss the types of patterns.

Metal Patterns

These kinds of patterns are made of aluminum, iron, brass, steel etc. they are popular in the industrial practices.

لماذا؟

Since they can be used for large and bulky productions with large capacities.

For optimum volume productions, cast aluminum is the most used.

Metal pattern

Let’s look at the advantages of these patterns:

- They are long lasting

- They are not easily attacked by moisture

- Have got smooth surfaces

- Have got high strength and can withstand mechanical strains

Some of the disadvantages are:

- Metal patterns are not easy to repair.

- Ferrous patterns are prone to corrosion.

- These patterns are bulky and heavy.

Wood patterns

These ones are relatively cheaper compared to other patterns.

Several types of woods are used to build these patterns, but the common ones are plywood and pine boards.

Wood mold

Several Pine boards are usually combined to produce a good thickness of the pattern.

Plywood is suitable too since it can be used in the production of numerous patterns with wider diameters.

However, plywood requires some slight modifications like filling up the voids with wood putty before use.

The patterns can as well be painted to protect them from excess heat and humidity during storage.

The pros of the wood patterns are:

- Light in weight

- Relatively inexpensive

- Easily repaired

- Simple to glue and join together

The associated limitations are:

- Vulnerability for attack by moisture hence degrading their quality.

- They get worn out after several usages, as a result, they have got a limited lifespan.

Wax patterns

This equipment is mostly used in the investment or lost waxing casting.

Later on, the wax is lost from heating.

The wax patterns are made by introducing wax into the dies.

Importantly, these dies should resemble the parts to be cast.

A notable advantage is that they are reusable.

On the other hand, wax patterns are susceptible to high temperatures.

Foam patterns

Foam is a better alternative to wax.

This because the foam has got the lower boiling point.

Hence, they are used in the modification of investment casting when the wax need not be melted out of the mold.

Foam pattern

Foam patterns are made from polystyrene foam.

Essentially, the foam is easy to manipulate, cared for and glued.

Moreover, foam patterns are flexible and therefore they can be consolidated.

In spite of that, these patterns are easily distorted since they have got poor strength.

Plastic Patterns

They are made of plastic materials.

Rewards of these types of patterns are that they are:

- More economical due to their lower cost.

- Highly resistant to corrosion.

- Light in weight and stronger.

- Not susceptible to moisture.

- Smooth

With that, we move to the next step.

Step 2: Casting process

In this section, we shall talk about the following:

- Sand casting

- Shell mold casting

- Investment casting

- Ceramic mold casting

Keep reading.

a) Sand Casting

The simplest basic steps in making sand castings are as follows:

- pattern making,

- Constructing the cores,

- Molding,

- Melting and pouring,

- Inspection and Cleaning

Sand casting technique

Pattern Making

In this procedure, a pattern made of either wood or metal is suitable. Remember, the pattern is the structure used to make the mold cavity.

The mold, in this case, would be made by packing molding sand to completely cover the pattern.

Withdrawing the pattern, later on, leaves its actual replicate which now forms the mold cavity.

It’s the cavity that holds the molten stainless steel which in turn becomes the casting.

Constructing the cores

In cases whereby, you would want a hollow casting, cores are used to additionally form the mold cavities.

It’s therefore good to Place the cores into the mold cavity.

They shall then form the interior surface of the castings.

The resultant void will then hold the molten metal.

Molding

This is a straightforward activity and comprises of:

- Using the selected sand mold to cover the pattern.

- Ejecting the pattern to leave behind mold cavity and cores if need be.

The mold cavity is the negative replica of the final product.

You may fix the sprues and runners within the mold cavity.

Melting and Pouring

Here you just need to prepare the molten metal and transfer it to the pouring section for proportionally filling the molds

Inspection and cleaning

It’s now time to:

- Remove trapped burned sand to improve the beauty appearance of the parts.

- And the waste metals also removed from the castings.

Finally, inspect the parts for any deformation and to ascertain the achievement of the desired quality.

The sand-casting process avail for you the following advantages.

- Very cheap when dealing with little productions.

- This process can be used to cast both ferrous and non-ferrous metals.

- It can be used in the casting of very big sized parts.

- It only requires simple tooling

b) Shell Mold Casting

This technical and precise method involves the creation of a super thin and fine mold whose shell is usually about 8 -9 mm thick

The shell mold is made of sand mixed together with a resin binder.

This process may be done in a set of equipment including oven.

The process should be as simple as indicated below:

a. Heat a metal pattern in a furnace.

b. Place the metal pattern over a dump box whose contents are sand correctly mixed with a resin

c. Now, invert the box such that the sand mixture may stick onto the surface of the hot metal pattern. You will notice that a small layer of the sand mixture partially solidifies and gels on the surface of the pattern thereby forming a hard shell.

d. Having done that, invert the box again so that it resumes its natural standing position. Notice, the loose sand mixture particles not gelled dropping off.

e. Now remove the gelled sand mixture and the metal pattern which will be used to make our shell mold.

f. Heat the now gelled metal pattern in an oven or a furnace to ensure complete gelling of the sand.

g. After the heating time has elapsed, separate the now freshly formed shell mold from the pattern.

h. Assemble together two equal halves of freshly prepared shell molds. Support them by use of sand in a box.

i. To increase their stability, clamp the two ends of the shell molds dipped in the box.

j. Take your molten stainless steel and pour it into the shell molds. Allocate for it adequate cooling time until it solidifies.

And that’s all for the shell molding process.

Pros of shell mold casting

- The shell mold surface is fine and smooth enhancing the easier flow of the molten metal. Consequently, produces parts with good surface finishing.

- Produces castings which have got good tolerances

The major limitation of this process is that quite expensive metal patterns are needed.

c) Ceramic Mold Casting

Here, the mold to be used in the casting process is made of refractory ceramic materials, ie hydrolyzed ethyl silicate,and a suitable catalyst.

A combination of these chemicals is poured over the pattern.

The ceramic shell formed is retrieved and set up in a box, heated similarly in the shell molding process.

Later on, assembled and the molten stainless steel poured.

Ceramic mold casting

Advantages of ceramic mold casting

- Produces surfaces with excellent finishing and appearance.

- The castings have got accurate dimensions.

- Suitable for casting alloys with high boiling points eg steel

The investment casting, vacuum molding process is discussed in the previous segment.

Step 3: Melting and Pouring

Melting simply means all the processes and activities involved in preparing the molten stainless steel for casting.

The process begins by first melting the stainless-steel metal into a liquid state.

This is done in a furnace at extremely high temperature since steel has got the high melting point.

Additionally, melting is done in a specific different location in a foundry.

The total heat energy needed for melting is the overall summation of:

- The amount required to achieve the melting point of the steel

- Heat of fusion used to convert the metal from solid steel to the molten state.

- Heat needed to raise the temperature of the molten metal to the suitable temperature for pouring.

For steel castings, varied types of melting furnaces maybe used.

They are Electric Arc Furnaces (EAF) and Electric Induction Furnaces.

We shall discuss them in details.

i. Electric Arc Furnaces

This is the commonly used type of furnace.

In fact, it’s used in the production of more than three-quarter of steel castings.

Furthermore, Electric Arc furnace is flexible in that the charge material can be varied depending on the amount of heat required for melting the steel.

Electric arc furnace

Also,it’s possible to refine the stainless steel in the furnace just before tapping.

This machine comprises of the following parts:

- Steel shell

- Electric arc – produces the sufficient heat for melting the stainless steel.

- Refractorily lined roof – the roof has got three holes designed specifically for graphite electrodes.

- Refractory Lining

ii. Electric Induction Furnaces

If you deal with smaller productions of casting quantities then this type is the most suitable one.

Electric induction furnace

Similarly, to EAF this machine has got a steel shell and a refractory lining.

The only difference is, the refractory lining is surrounded by the copper coil.

The heat generation occurs from the electric current in the coil.

Step 4: Finishing

This is the final procedure in the casting process.

Again, it combines a set of activities that are done once the castings have completely cooled down and solidified.

You should, therefore, shake out the mold to take away the castings or break up the mold cavity and eject the castings.

After the ejection, it’s necessary to do some finishing or clean up to the castings.

To kick off the finishing activities, perform a rough blast.

This technique helps cleans the castings surfaces from any externally trapped material from the mold.

The gating, sprues,and runners should also be cut off together with other irregular surfaces.

For the cutting you may either use a saw, trimming press, or a grinder.

If not, you may weld any other unworthy discontinuities.

Not only that, but heat treatment is also essential.

Heat treatment assists in the reconditioning of the castings to achieve worthy properties of specific alloys.

Moreover, any formed irregularities during casting need to be removed by blasting.

If war page occurred on the steel castings during processing, they can be flattened by pressing.

This is a significant activity to ensure clear cut dimensional accuracy on the castings as preferred.

Summary of casting process

The next part of our discussion is much important as well as interesting.

Sowe advance together.

Controlling Stainless Steel Defects during Casting

Almost all technical procedures involving both human and machines input have got some degree of errors.

The errors may be adverse but, in some cases, they might just be little enough.

Unfortunately, the casting process isn’t spared.

Don’t worry.

In the casting process, the errors are evident in form of the defects that finally occur on the castings.

The good news?

These defects can just be regulated and hugely minimized in order not to significantly undermine the quality of the castings.

Therefore, in this section, I shall show you the different defects that may feature and how to control them from occurring.

The defects here are due to:

- Casting shrink rate

- Appearance

- Thermal variations

- Filling

- Porosity

- Shaping

Casting Shrink Rate Defects

Shrinking in the casting process usually occurs after pouring of the molten metal into the mold cavity during solidification.

The material tends to hold back itself thereby reducing in size.

This process is called shrinkage.

Therefore, shrinkage defects occur when the feed metal is inadequate to cover up for the shrink rate.

Cast shrink rate defects

Shrink rate casting defects can be classified into two categories i.e.

- Open shrink rate defects- these ones are dependent on the atmosphere. When the molten stainless-steel shrinks, the cavity left is filled up by the air.

As a result, there are two main air defects namely pipe and caved surfaces.

Pipes form at the casting surfaces while caved surfaces are the cavities that occur across the casting surfaces.

- Closed shrink rate defects – also known as shrinkage porosity. For this kind, the defects from within the casting.

An example is the formation of some liquid just within the solidified metal usually called hot spots.

Likely Causes

The difference in density of a die casting stainless steel in a molten state from that in the solid state.

Meaning, shrinkage occurs if the density of molten metal is less than its corresponding density in the solid state.

Consequently, when stainless steel transforms its state from molten to solid, it shrinks and the size decreases.

Solutions

Ensure continuous injection of the pressurized liquid metal into the mold to fill up the formed void cavities.

Appearance Defects

Numerous defects might be portrayed in the casting appearances.

Some are metallic protrusions, discontinuities, incomplete casting, inaccurate dimensions or shape, substandard surfaces.

Appearance defects

a. Metallic protrusions

Usually, they are joint flash or fins.

They are flat protrusions of the ununiform degree of thickness, having lacy edges and at right angles with a face of the castings.

Causes

- The clearance between mold and cores.

- Defectively fit mold joints.

Solutions

- Precautious manufacture of patterns, molds and cores.

- Regulation of the patter, mold and cores dimensions.

- Careful setting of molds and cores.

b. Discontinuities

Hot cracking: this is a crack not really visible but results from the constraints that occur during cooling.

Interestingly, hot cracks may exist even if the casting isn’t fragmented.

Possible Causes

Physical damage to the castings when mishandled while hot or during shake out to eject them.

Solutions

- Carefully do the shakeout procedure.

- Handle the castings with a lot of care especially while still hot.

- Allow sufficient cooling time.

c. Incomplete Casting

Poured shot:forms due to the missing upper parts of the castings.

Likewise, the edges in line with the lost sections are a little rounded, all other contours match the pattern.

Likely Causes

- Inadequate molten metal poured into the ladle.

- A lapse in the pouring process.

Possible solutions:

- Constantly supply the ladle with molten metal.

- Ensure the pouring process is smooth and no lapse interjects.

d. Inaccurate castings dimensions or shaping

Leading to the production of deformed castings.

The distortion majorly occurs in terms of irregular thickness.

Potential Causes:

Low pattern strength and rigidity hence fails to tolerate ramming pressure applied on the sand.

Likely solutions

Always select patterns with adequate rigidity capable of with standing a high amount of pressure.

e. Substandard surfaces

This is evident by the presence of flow marks: defects that appear in form of lines that tend to trace the molten stainless-steel flow.

Potential Causes

Presence of oxide layers at the castings surfaces thereby creating some kind of pathway for the flow of the molten stainless steel.

Solutions

- Raise the mold temperature.

- Drop the pouring temperature.

- Tilt the mold while pouring molten stainless steel.

- Adjust gate size and its position.

Thermal defects

These defects arise from errors from heat temperature.

Some of these errors are evident from the presence of cracks and tears: these defects appear in die castings as a result of a number of reasons such as mishandling of molds etc.

Casting defects

Most of these cracks are usually very visible and occur on the surface of the castings.

However, some tears are invisible to ordinary viewing.

Possible Causes

- Shrinkage of the castings in the die molds.

- Insufficient and unequal ejection forces.

- Damaged cavities.

- Uneven thermal balance in the die molds.

- Defective die casting.

Remedies

- Lower the pouring temperature.

- Avoid excessive molten metal heating.

- Make use of the chills.

- Allow adequate cooling time.

- Minimize sharp pointed corners.

Filling Defects

The following are the resultant defects due to the filling.

Casting defect

- Blowholes

- Sand burning

- Cold lap or cold shut

- Misrun

- Sand inclusion etc.

The above defects are discussed below.

a. Blowholes

This is a defect that occurs in the mold cavities.

Two major forms of blowholes are pinhole and subsurface blowhole.

The pinhole is a minute hole while subsurface blowhole is only visible after the machining the castings.

Likely reasons for the formation of blowholes are:

- Inadequate vents in the cores

- Excessive moisture absorption in the cavities

- The improper gas permeability of the cores

- Extreme sand temperature

Plus, the Solutions are:

- Build more core vents and fix more vent channels.

- Minimize trapped gas.

- Use a low moisturized sand.

- Occasionally dry cores and store them in a dry place.

- Decrease the sand temperature

b. Sand burning

Generally, this is burned on defect resulting from chemical burns and metal penetration.

Possible reasons for sand burning defects:

- Presence of too low lustrous carbon content in the clay bounded sand.

- Imbalanced mold compaction.

- The adverse high temperature of the molten metal.

- Irregular pouring of molten metal.

Remedies

- Intensify amount of lustrous carbon content in the clay-sand

- Use pure silica sand or add fresh sand.

- Ensure equivalent compactness.

- Lower the rate of pouring the molten stainless steel/

c. Cold lap or cold shut

This is a crack which got round edges.

Cold lap also known as cold shut is caused by minimal melting temperature or poor construction of the gates.

Likely Causes could be:

- Highly viscous molten metal

- Defective design

- Defective gating

The following Solutions are worthwhile:

- Use a perfect design

- Employ the use of proper gating system

- Modify the pouring temperature of the molten metal.

d. Misrun

Though this is a kind of incomplete casting, it falls under filling related defects.

Misruns occur when the molten stainless steel doesn’t fill up the mold cavity thereby leaving incomplete filled sections referred to as misruns.

Apparently, the edges of the misrun are always smooth, round and fine.

Likely Causes for misrun include:

- Highly viscous molten metal

- Defective design

- Defective gating

The Solutions for these defects are:

- Use a perfect design

- Employ the use of proper gating system

- Modify the pouring temperature of the molten metal.

Gas porosity Defects

Remember that the mold cavities are never empty but full of large chunks of air.

Therefore, when the molten metal is poured, the air still remains trapped since it’s pressed down by the in flowing metal.

Also, the gas may come from hydrogen dissolved in the steel alloys, moisture from water-based lubricants. Etc.

What are the possible causes?

- Longer pouring time

- Decreased pouring temperature of the molten metal

- Interrupted pouring of the molten metal.

- Improper heated metallic molds

- Thin metallic section.

The solutions to these causes are:

- Increase the molten metal pouring temperature.

- Pour the molten metal within a short period of time.

- Adjust the chemical composition of the stainless steel to increase fluidity.

- Extract slag from the stainless-steel surface.

- Adequately vent both the molds and cores

- Lower the mold gas pressure. This is done by appropriately adjusting the properties of the molding material.

Shape Related Defects in Stainless Steel Casting

Some several defects related to shapes are:

- Mismatch

- Warp or distortion

- Flash

a. Mismatches

Mismatch in molds comes from the shifting of flash molds.

The shifting consequently causes the dislocation within the parting lines.

Possible reasons

- The mismatch result from the cope and drag sections of the mold unable to maintain their right position.

- Improper handling of the cope when being stationed over the drag.

Solutions

- Correctly mount the patterns on the match plates.

- Make use of suitable molding box.

b. Warp or distortion

Likely Causes

- Liberation of residual stresses.

Solutions

- Normalizing heat treatment to eliminate residual stress.

- Leveling the section in between quench and aging.

c. Flash

This is any surplus undesired metal which penetrates out of the die.

Usually, the flash is connected to the cavity or runner.

Essentially, flash forms a thin sheet of metal on the surface of the parting.

Likely Causes include:

- Insufficient strength of numerous parts of the die.

- Destruction to die faces

- Excessive pressure

- Hydraulic machine malfunction

- Inadequate pouring and cooling time

Remedies:

Generally, the best solution is to reduce the weight of the mold.

I trust you are able to deal with the various casting defects.

Importantly, you should take all measures to control them.

Note that prevention is better than cure.

The next segment of our discussion is equally critical.

Stainless Steel Casting Standards and Quality Control

The casting process involves several workmanship processes.

All these techniques are used to precisely manufacture stainless steel parts.

Nevertheless, there exist some factors that might undermine the qualities of the castings during the production.

Therefore, to guarantee perfect productions of the parts, standardization and quality assessment tests have to be undertaken before final packaging and use of the castings.

Stainless steel castings undergo several quality verification’s and tests that we shall comprehensively discuss.

Go on studying.

Some of the quality control measures and standards used are:

Stainless Steel Casting ASTM A995

This mode of standardization is used to ascertain the quality of austenitic – ferrite stainless steel also known as Duplex.

This metal casting is applied in making valves, fittings and flanges etc.

Duplex stainless steel

Again, the duplex stainless steel when chemically balanced provides both suitable mechanical properties and high resistance to corrosion.

The duplex stainless steel is subjected to the following conditions in order to verify their quality:

- Optimum heat treatment to requisite temperature.

But the temperature shouldn’t exceed 600 F (315⁰ C)to avoid the formation of precipitates on the embrittled casting phases.

- Thereafter it is cooled rapidly.

- Heat and product analysis – this is performed to ensure that the products match the necessary chemical configuration of all the ingredients of carbon, manganese, silicon, phosphorus, sulfur, chromium, nickel, molybdenum, copper, tungsten, and nitrogen.

- Tension test to confirm the possession of some vital mechanical properties such as tensile and yield strength,elongation.

Stainless Steel Casting ASTM A890

This specification is aimed at covering a set of austenitic/ferritic stainless steel.

For this again the castings are optimally heat treated to requisite temperature.

This is vital to enable the metal to achieve the desired mechanical properties and also to achieve corrosion resistance.

Stainless steel casting

The stainless steel should, therefore, conform to the right proportion of its chemical elements of carbon, manganese, phosphorous, silicon, sulfur, nickel, chromium, copper, molybdenum, tungsten, and nitrogen.

In addition, the castings are then marked for easier material identification in accordance with their respective grades and designation.

Stainless Steel Investment Casting Tolerances

This technique refers to the dimensional range that can be achieved by an investment casting process.

Apparently, tolerances differ among the foundries and the type of investment casting process used.

However, there is a tolerance standard that should form the guideline for every foundry.

Despite the tolerance standardization table, it’s still unlikely for the foundries to stay marginally within the guidelines.

This so because different foundries have got varied areas of specialization especially depending on the sizes of the castings produced.

The mechanization also matters.

Some equipment has got a direct influence on the casting tolerances.

Needless to say, tolerances are affected by the following factors:

- The temperature of the die

- Wax, foam or plastic temperature

- Amount of injection pressure

- Mold material composition

- Cooling time

- The temperature of the heat treatment.

Investment casting tolerances are grouped into two divisions:

- Linear tolerances

- Geometric tolerance

We shall briefly discuss the two divisions.

Linear Tolerance

It is largely dependent upon the following parts of the castings: length, flatness, concentricity, holes, fillet radii, straightness etc.

Geometric tolerance

Applies to the following sections of the investment castings: parallelism, roundness, straightness, hole tolerance, roundness,flatness, internal radii,and fillets.

We shall discuss some of these parts for clarity.

Stainless steel casting

a. Roundness

Roundness tolerance is determined by working out the difference between the radii of a true circle and the circumference of the negative model.

A number of ways can be used to determine the roundness.

However, the most efficient method is by taking the difference between the maximum and minimum radii of the circular section.

b. Flatness

This tolerance is the allowed deviation from a flat plane within the casting.

Consequently, the cast surfaces must vary depending on the dimension of the flattest plane and the plane which exhibit the maximum allowed deviation.

The flatness of investment castings is affected by the amount of volume shrinkage of both the molten stainless steel and wax.

Unfortunately, general flatness tolerance cannot be standardized due to the different configurations and varied alloys of investment casting used.

c. Straightness

This tolerance seems so close to flatness one but they are quite different.

Therefore, straightness tolerance refers to the maximum allowed deviation of a part from an entirely straight line of the casting part.

Straightness is often not easily achieved in most castings.

This because most of these parts are easily bent from their fairly thin sections and small parts.

d. Concentricity

It is ascertained by two cylindrical surfaces that share a common axis as their center.

The degree of eccentricity is arrived at by confirming the difference in dimensions of the location of one center to another one.

The middle of a bore to the exterior diameter of a particular part is concentric within 0.003 inches for every 0.5inch wall thickness.

e. Hole tolerance

This is the required roundness of a cast hole.

The neighboring metal of the hole needs to be symmetrical in order to properly fit together and provide adequate clearance.

Hole tolerance is good for interior shrinkage and also for the diameter of up to 0.5 inches.

Hole clearance should vary in the range of +/- 0.003 inches.

f. Curved holes, fillets,and internal radii

The curved holes should portray a diameter tolerance of about +/- 0.005 inches.

For the internal radii and fillets, they are difficult to inspect and control thus when designed, they need to be maximally wide.

Stainless Steel Casting Tolerances

The different stainless-steel casting tolerances are discussed below as follows:

a. Dimensional Tolerance

Frequently the dimensional tolerances should be discussed and agreed upon by both the manufacturer and the buyer.

But most importantly the tolerance selected should be able to just fit and be compatible with the process they are to be used for.

The International Organization for Standardization (ISO) issues a list of system tolerances and allowances for all the castings.

b. Weight tolerances

If there is a need for weight tolerance, then certain important allowances are vital.