Are you looking for a control box for protecting your electrical components? Then you are at the right place. Whether in an industry, agriculture, or at home, it helps in keeping the operation running smoothly for it.

The article helps to explain what control boxes are, their types and what they are used for.

Let’s get started!

What is a Control Box?

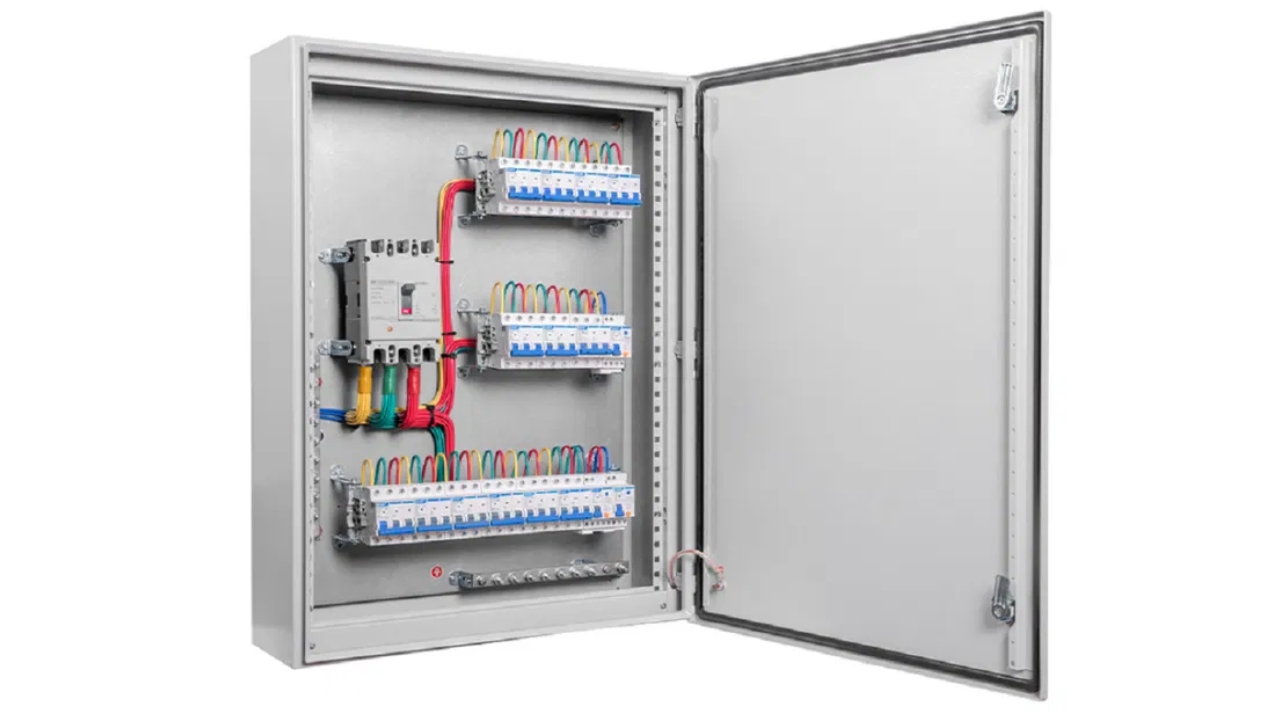

A control box is an enclosure for housing electrical components for controlling and directing the machinery or device. It helps to protect all the electrical components from water, moisture and dust. It organizes and allows the easy access and maintenance of these components.

Control boxes are essential to ensure that systems will operate properly in the industrial, residential or agricultural field. Fault prevention and increased efficiency are what they help them achieve.

Types of Control Box

There are many types of control boxes and each type is made for specific needs. There is a control box ready to manage pumps, industrial equipment or even a lighting system. Here are some common types:

- Wall Pump Control Box: Water pump systems are normally controlled from wall pump control boxes. Among them is where the electrical components that make pumps operate are housed. These boxes mount on a wall and, along with protecting against electrical overload, control the pump’s on/off cycles and pressure settings, and are mounted in easy access.

- Industrial Control Box: Industrial control boxes are built to manage complicated and heavy equipment that are usually found in factories or plants. These boxes can contain complicated circuits controlling motors, conveyors, automated systems and the like.

- Hydraulic Control Box: Equipment which uses fluid power uses hydraulic control boxes. They regulate the flow and pressure of the hydraulic fluids to deliver safe and smooth running of the machinery. They come ready to take the rough and tough conditions.

- Electrical Control Boxes: Electrical control boxes control electrical electrical systems like lighting to HVAC units. Inside they have switches, and controllers that take control of electricity flow. By centralization, they are able to monitor and operate the electrical equipment as well as protect everything.

- Floor Mounted Control Box: In industrial settings where floor space is scarce, the control boxes are usually floor mounted. These boxes are more often than not placed on the floor and also larger in size in order to fit in more complex control systems. This offers easy use and is suitable for the use in heavy duty applications.

- Lighting and A/V Control Box: Electrical systems for audio-visual setups and lighting are managed in lighting and A/V control boxes. They do power flow control, set the conditions, and protect sensitive equipment from electrical surges. Theaters, event venues, and commercial buildings usually contain these boxes..

- Circuit Breaker and Other Control Box: Circuit breakers are a type of protection found in circuit breaker control boxes. These boxes are used in residential, commercial, and industrial applications and allow for shocks and other potential hazards if fires to be prevented by cutting power when faults occur.

Working of Control Box

Signal Input

Input signals come to the control box, usually received from sensors or control devices. The signals can be electric or mechanical, depending on where the hardware it’s attached to resides. With the increase in temperature the temperature sensor might be alarmed and send a signal.

Processing

The control box processes the input signal once it is received. Controllers or relays analyze the input data inside the box. The box is the entity that decides the response to be given on the basis of particular preconditions or programmed instructions. This step ensures that the system does the right thing.

Output Control and Operating

The equipment is operated by an output signal sent by the control box after processing the input signal. The system is in safe control, with the output signal in turn controlling the operation of the system as it should be.For instance, turning on a pump once water pressure has dropped or adjusting a conveyor belt’s speed.

The control box functions as the thinking part of the system by receiving inputs, processing them, and sending the output command to control devices to ensure everything runs safely.

International Standards of Electrical Control Box

- Key Regulatory Bodies: Control boxes have been set with different standards, which include International Electrotechnical Commission (IEC) and National Electrical Manufacturers Association (NEMA), to ensure safety and reliability in different regions.

- Regional Variance: There may be other standards to be followed. For example, IEC standards are regularly used across Europe whereas NEMA standards are generally the norm for the USA.

- Compliance Requirements: To minimize risks such as fire hazards and electrical failures, control boxes as a whole are under the control of codes and safety regulations.

- Difference between EC and US (NEMA Standards): The European standard IEC standards are more of universal safety measures and environmental consequences. NEMA standards (used in the U.S.) are more oriented to particular weather, for example rain, scarp, or dust.

Benefits of Control Box

Here are some benefits you can experience in control box:

- Safe and Reliable: control boxes are safe and reliable as they prevent the systems of electrical from being overloaded and short circuits.

- Automation Control: They are capable of automating the processes along with centralized control, by means of controlling several systems from one central location to enhance control and efficiency.

- Remote Monitoring: A lot of control boxes employ it, allowing users to monitor their system and troubleshoot problems wherever they may be.

- Easy to handle: Control boxes with their user friendly interfaces offer the ease to govern the system effortlessly even by anyone.

- Space Management: This allows control boxes to keep systems organized and neat, so valuable space is not used up in industrial as well as in residential areas.

- Cost Effective: Prevent electrical failures, system malfunctions increase and reduce repair costs and downtime.

- Ability to work in different environments: They can be employed across different industries including manufacturing, agriculture, providing diversification of usage across varied environments.

Applications of Control Box

Industrial Automation Systems

Factory or manufacturing plant control boxes control automated systems such as robotic arms, assembly lines and production equipment. Controlled Machines of speed, operation and safety features through them. For instance, a winch control box can control the operations of cranes, lifting equipment or other types of heavy duty equipment.

HVAC Systems Control

Control boxes serve an important job in controlling heating, ventilation and air conditioning (HVAC) systems in residential and even commercial buildings. With the use of motors and valves, the temperature and airflow is managed. This is a thermostat control box that enables you to perfectly blend temperature control in an environment with ease.

Conveyor Belt Operations

In food processing, packaging and warehousing industries, conveyor belts are managed by control boxes. The speed and direction of the conveyor entering the production line is regulated by these boxes for the materials to travel smoothly. So, a conveyor control box allows you to adjust the belt speed according to load so that the productivity is increased and waste is reduced.

Machine Tool Operations

Control boxes are used in CNC (Computer Numerical Control) machines that operate various machine tools with regard to movement. The input data is processed by these control boxes to automate motors, gears and tool settings to machine accurately and efficiently. As an example suppose the CNC control box handles automated lathes or milling machines in a factory.

Treatment Plants

Control boxes, which manage pumps, valves, and other equipment in water and wastewater treatment plants, are the objects that a variety of other sensors, especially standard sensors, monitor. To keep them operational 24/7 they need to act as a force to get clean water to those who need it or treat waste effectively. With a well pump control box or sprinkler control box, these pumps get a flow guard to keep the water flowing smoothly without starting and stopping the wrong times leading to system failure.

Renewable Energy Systems (Solar, Wind)

The solar panels and wind turbines completely depend upon the control boxes. The control boxes are helpful in managing the energy flow and monitoring overall system performance.. For example, a solar panel control box takes part in regulating the power output and shielding the system from harm originating from electrical faults or irregularities.

Power Distribution Management

Control boxes are in power grids and electrical systems to ensure efficient distribution of electricity. They take control of circuit breakers, keep an eye on power flow and make sure of the system stability. If a fault occurs, a circuit breaker control box can tamper with the power, preventing the damage of the entire system. Control boxes have a major role to play in avoiding overloads and maintaining the power quality.

Building Management Systems

Today control boxes control different systems in modern buildings such as fires, security, and lighting. It allows the building managers to centrally control everything such as the lighting brightness control and the control of the HVAC system. In large offices and shopping malls, you can schedule light.

Agricultural Automation Systems

In the field of agriculture, irrigation systems, machinery and livestock monitoring equipment can be controlled via control boxes. An instance is exemplified by using a sprinkler control box to automate the watering schedule on a farmer’s field, eliminating any waste through water and boosting the yield of the crop. A feed control box similarly can feed livestock in a more efficient manner.

Oil and Gas Industry Operations

Control boxes are essential in the oil and gas industry to control pumps, valves, compressors and other critical equipment used. Pipelines and rigs can be operated safely and efficiently if they are controlled boxes. In fact, a hydraulic control box can monitor the functioning of big machinery that is used for drilling and extracting activities such that everything runs smoothly.

Transportation Systems (Railway Signals, Traffic Lights)

Control boxes are used in the transportation for controlling the traffic lights, railway signals and various other systems for controlling the flow of traffic. For example, a railway signal control box guarantees the safe operation of the signals while a traffic light control box operates on changing the signals so as to maintain a good traffic flow. These control boxes prevent such accidents and help the systems operate at optimum levels.

Conclusion

Many electrical and mechanical systems have control boxes within themselves. Automated manufacturing systems using them are responsible for enhancing automation, safety, and efficiency in industries such as agriculture and industrial automation.

FAQs

What components are inside a control box?

A control box is filled with electrical components including fuses, relays, circuit breakers, as well as controllers to manage and preserve electrical systems.

Are control boxes weatherproof?

Outdoor used control boxes are made weatherproof since the internal components need to be protected from the elements.