Looking for a Dependable Gas-insulated Switchgear Manufacturer for your Project?

KDM is top-leading China-based Gas-insulated Switchgear Supplier

Premier Gas-insulated Switchgear Supplier in China

KDM is one of the largest manufacturers and distributors of gas-insulated switchgear for over a decade with sufficient engineering and modern laser machines. Our gas-insulated switch gears can be installed in any place or area with moisture and dust pollution. We can create or install an intelligent control device for gas-insulated switch gears to support the automation of the power distribution systems and avoid remote control monitoring systems.

Over a decade of practical experience, we are one of the versatile manufacturing companies of Gas-insulated Switchgear

High operational performance, portable and flexible Gas-insulated Switchgear

Free sample of design in 3 days

For Inquiries, Contact Us Today!

KDM Gas-insulated Switchgear Series

KDM High Voltage Gas-insulated Switchgear offers the highest performance and reliability. They can be of great use for the most challenging power distribution and transmission applications.

Highly compact with a flexible solution to suit different network configurations our MV Gas-insulated switchgear is constructed of. Strong resistance to corrosive and harsh environmental conditions.

Our range of SF6 Gas-insulated Switchgears options can widely cover up a number of growing industrial applications. Full of advantageous features such as safety, space-saving, less maintenance required, and high reliability.

KDM Design and manufacture gas-insulated switchgear for outdoor substations with more attention to its functionality, reliability, and protected measures. In order to guarantee its safety and solidity, our QC team strictly check and inspect gas-insulated switchgear during production.

Our 33kV Gas-insulated Switchgear has been designed and tested in accordance with the highest national and international standards. Maximum protection from the environment, plant, and personnel. The highest performability which enhances the component’s life span meets with KDM 33kV gas-insulated switchgear.

HVDC Gas-insulated Switchgears are made of premium quality raw material. Plus, it meets and exceeds international standards of quality requirements, methods, and tests. This equipment has been developed together with our professional operational experience.

Send your Inquiry on KDM Gas-insulated Switchgear

KDM gas-insulated switchgear is the best solution for distribution networks and ultra-high voltage power transmissions. Our products can be delivered around the world. Our gas-insulated switch gears are tested to last up to more than 30 years of service. We strictly inspect and upgrade our products to meet the customer’s needs.

- Long life cycle and free of maximal maintenance of the system

- Team of talented experts to fabricated and develop Gas-insulated Switchgear

- Professional after-sales support of your orders

- 100% operationally-tested, type-tested product

Related Products of Gas-insulated Switchgear

KDM Gas-insulated Switchgear

KDM gas-insulated switchgear is designed with highly advantageous key features. We manufacture all series for gas insulated switchgear welded by premium quality raw material. We designed gas-insulated switchgears with high reliability and personal and space safety. In KDM, we installed further features into the equipment to make sure air chambers our gas insulated switch gears have a long life cycle and free of maximal maintenance.

Gas insulated switch gears in KDM are installed with a standard casing that is connected to fully sealed and insulated cables. We technically made it prevent cables from straying and charge effectively. KDM has the most advanced manufacturing technology, sophisticated equipment, and reliable production management system. We only rely on the high skilled engineering team to continuously update our products structures.

KDM gas insulated switch gear can be installed even in limited spaces. It can be used in power transmissions, railways, power gens and more. Our gas insulated switch gear is available from 12 kV system up to 800 kV system. KDM keeps developed standard series of phase segregated type for gas insulated switch gears to make it fully earthed, small overall dimensions and applied with modular design principle.

Our gas insulated switch gear is a successful product concept. We always based our products on our latest research to manufacture the highest possible quality and cost-effectiveness. KDM assures you that we manufacture gas insulated switch gears that meet all performance. Our products are designed to be installed in the most confined spaces such as buildings, industrial plants, mobile container, and department stores.

KDM gas insulated switch gear features a high degree of gas tightness, modular structure, safe encapsulation, good accessibility and ergonomics and environmentally compatible designs. We create gas insulated switch gear with very flexible designs and extensions. Our product also provides customer-oriented support, can be operated safely under extreme environmental conditions and available in all specifications you need.

KDM is a practical resource and manufacturer that will support you in your work in transmitting, generating and distributing energy. We make sure that here in KDM you can always find great deals in gas insulated switch gears. We are your solutions in this industry. We are so eager to be your reliable business partner. Contact KDM now!

Gas Insulated Switchgear: The Ultimate FAQ Guide

- What is Gas Insulated Switchgear?

- What are the Benefits of Gas Insulated Switchgear?

- Are there Disadvantages of Using Gas Insulated Switchgear?

- What is the Function of Gas Insulated Switchgear?

- What are the types of Gas Insulated Switchgears available?

- What are the Advantages of Superior Dielectric Gas, SF6?

- Gas Insulated Switchgear uses which type of gases?

- Where can you Use Gas Insulated Switchgear?

- How do you Install Gas Insulated Switchgear?

- Does Gas Insulated Switchgear have Voltage Range?

- How do you Test Gas Insulated Switchgear?

- What are the main Features of Gas Insulated Switchgear?

- How does Gas Insulated Switchgear Work?

- What are the Main Components of Gas Insulated Switchgear?

- Gas Insulated Switchgear should conform to Which Quality Standards?

- How does Gas Insulated Switchgear compare to Air Insulated Switchgear?

- Is there a difference between Gas Insulated Switchgear and Substation?

- How do you Size Gas Insulated Switchgear?

- What is Screened Gas Insulated Switchgear?

- How do you Troubleshoot Gas Insulated Switchgear?

- How many types of circuit Breakers are there?

- Is the Gas in Gas Insulated Switchgear Harmful to the Environment?

- How does Arc Quenching Switchgear Improve Safety?

- How does Disconnecting Switches compare to Earthing Switches in Gas Insulated Switchgear System?

1. What is Gas Insulated Switchgear?

A Gas Insulated Switchgear is a class of switchgear, which uses a special gas, superior dielectric gas (SF6), as the main insulation material.

The SF6 insulates circuit breaker interrupters, switches, high voltage conductors, current transformers and voltage transformers.

Gas insulated switchgear

2. What are the Benefits of Gas Insulated Switchgear?

Among the benefits of using Gas Insulated Switchgear include:

· Environmentally Safe

The use of Sf6 gas minimizes environmental pollution since it does not react with the environment.

Also, the gas is non-react with the switchgear materials preventing any negative effect such reactions can have on the environment.

· Less Maintenance Cost

The general maintenance cost of using a Gas Insulated Switchgear is less since there are fewer blackouts.

Also, the non-reaction with the switchgear components ensures that they are durable, reducing the overall cost.

· Minimizes on Space

A Gas Insulated Switchgear utilizes less space when you as compared to Air Insulated Switchgear.

It implies that the Gas Insulated Switchgear uses 10% of the space that Air Insulated Switchgear uses.

You can, therefore, use this switchgear in areas with less space.

· Reliable

Gas Insulated Switchgear offers a reliable option than Air Insulated Switchgear.

You expect fewer outages when using Gas Insulated Switchgear.

Also, the rate of maintenance is very low, which means there is less switching off of the switchgear for maintenance purposes.

· Easy to Assemble

A Gas Insulated Switchgear is easy to assemble at the shop.

Also, there is the customization of the modules which facilitate the assembling process.

3. Are there Disadvantages of Using Gas Insulated Switchgear?

Yes. There are several disadvantages of using GIS such as:

· High Initial Cost

The initial cost of purchasing a Gas Insulated Switchgear is relatively higher when you compare to purchasing Air Insulated Switchgear.

· Requires Maximum Care

Dust contamination of live parts of a Gas Insulated Switchgear is easy, which affects its performance.

There is, therefore,a need for maximum care to prevent dust contamination which can be tedious.

· High Outage Time

It takes a lot of time to identify ad diagnosis a fault when it occurs.

This results in high power outages, which affect the plant operation.

· Frequent Flashovers

A decrease in the pressure of the SF6 gas in any compartment of the Gas Insulated Switchgear results in flashovers.

There is a need for frequent monitoring of the pressure level to ensure it does not drop.

4. What is the Function of Gas Insulated Switchgear?

The functions of Gas Insulated Switchgear include:

GIS

- Connection and disconnection of electric induction motors

- Performing quantitative and qualitative power supply measurements.

- It has devices that offer protection against overloading and short circuits. This helps in ensuring the safety and functionality of the electrical equipment.

- Isolation of electrical circuits from the main power source, which helps in safe clearance of

- It has devices that help in the distribution and controlling of electric current.

- Electrical faults and general maintenance.

5. What are the types of Gas Insulated Switchgears available?

The following are the types of Gas Insulated Switchgears available:

i. Isolate Phase Gas Insulated Switchgear

The configuration of this type of switchgear consists of a separate assembly of each bay phase.

Each phase has a single-pole circuit breaker, a single electrical isolator, and a single current transformer.

Isolated Phase Gas Insulated Switchgear uses a large bay width than the other types of Gas Insulated Switchgears.

ii. Integrated 3 Phase Gas Insulated Switchgear

This type has three disconnector phases, three current transformer phases, and three circuit breaker phases enclosed in a single metal enclosure.

This configuration results in a three-phase module whose size is a fraction of the Isolated Phase Gas Insulated Switchgear.

iii. Hybrid Gas Insulated Switchgear

This type of switchgear combines the elements of both the Isolated Phase Gas Switchgear and an Integrated 3 phase Gas Insulated Switchgear.

The 3-phase common busbar aids in busbar connections.

Isolated phase equipment reduces the occurrence of faults between phases.

It is the best alternative when you compare to the other types in terms of space and maintenance requirements.

iv. Compact Gas Insulated Switchgear

In this type, one metal enclosure encloses a functional element.

For instance, one single metal capsule encloses a 3-phase circuit breaker, earth switches, and current transformer.

v. Highly Integrated System

Here, a single enclosure housing encapsulates the whole substation equipment.

It is a single unit outdoor substation.

It is the latest configuration of gas Insulated Switchgear and is an ideal alternative for an outdoor switchgear yard.

6. What are the Advantages of Superior Dielectric Gas, SF6?

Among the advantages of Superior Dielectric Gas, SF6 include:

- It is a non-conductive gas that offers better insulation material for Gas-insulated switchgear.

- Due to its non-conductive feature, it helps in reducing arcing in switchgear.

- SF6 is non-inflammable. Due to the current flowing through the switchgear, the insulating material must be non-flammable

- The gas is chemically stable. This is advantageous since it does not react with components within the switchgear. This helps in maximizing the function of the switchgear.

- SF6 gas is environmentally safe. It is a non-toxic, colorless, and odorless gas that has a minimal negative effect on the environment.

7. Gas Insulated Switchgear uses which type of gases?

The type of gas found in Gas Insulated Switchgear is called Superior Dielectric Gas, SF6.

8. Where can you Use Gas Insulated Switchgear?

The use of Gas Insulated Switchgear is common in the following areas:

- Environmentally sensitive installation

The characteristics of Gas Insulated Switchgear makes it an ideal option for environmentally sensitive installation.

This is because they can be enclosed, and they are resistant to lightning since the materials belong to Faraday Cage.

- Urban installations

You can use Gas Insulated Switchgear in areas where there is an appeal for real estate and price a critical component.

- High Voltage Installation

A Gas Insulated Switchgear is common in common in applications that require high voltage since it utilizes a smaller space.

- Underground stations

They are ideal for use since they allow for a metal enclosure.

9. How do you Install Gas Insulated Switchgear?

The installation process for a Gas Insulated Switchgear involves the following steps:

Gas insulated switch gear

· Safety Precautions

You need to ensure that you adhere to all the safety precautions before you install a Gas Insulated Switchgear.

Safety involves the gas handling procedure and the commissioning of the equipment.

· Site Preparation

Site preparation should include setting the foundation for the installation of the Gas Insulated Switchgear.

It also includes welding of the different parts of the switchgear.

Cleaning of the busbars should be a priority as well as lubrication of the moving parts of the switchgear.

· Installation

The installation includes fixing of the circuit breakers.

Check on the manufacturer’s guide on the elevation control for the circuit breaker.

Install the circuit breakers to the coupling units.

You need to clean and lubricate these parts before and after installing them.

Install the busbars phase by phase.

Ensure that the pressure of the SF6 gas is stable for the effective operation of the switchgear.

10. Does Gas Insulated Switchgear have Voltage Range?

Yes.

Gas Insulated Switchgear has a voltage range.

Here you have a small Gas Insulated Switchgear, Medium Gas Insulated Switchgear, and High Voltage Gas Insulated Switchgear.

https://youtu.be/WaRC3wy1VSU

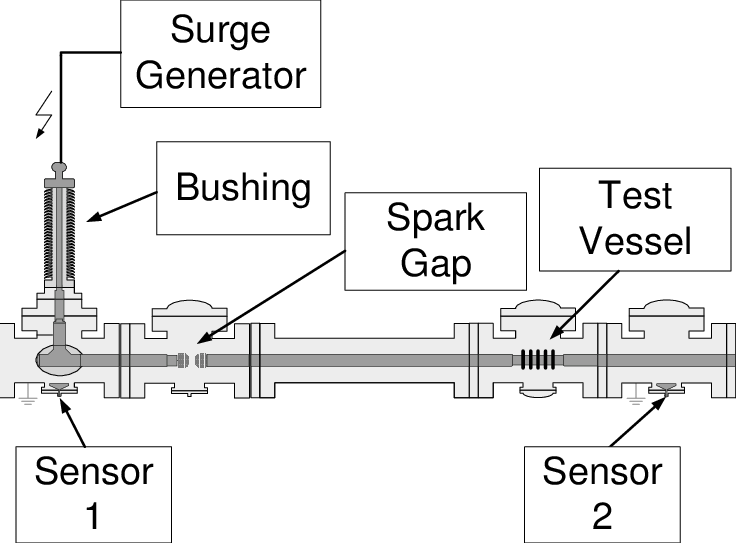

11. How do you Test Gas Insulated Switchgear?

There are different tests necessary for Gas Insulated Switchgear.

These tests include:

· Test of the Measure of the Gas Condition

You need to measure the pressure of the gas as well as the moisture content of the Gas Insulated Switchgear.

Ideally, the gas should be 100ppm for the components and 50ppm for the circuit breaker poles.

This test ensures that the switchgear functions appropriately.

· Resistance Test

You need to check the resistance for every busbar and outgoing terminals during the erection process.

You need to check the results against those prescribed by the manufacturer.

· Current Transformer Core Test

You need to test the ration and polarity of the current transformer core and compare the results to the primary current injection.

You need to perform this test phase by phase.

· Gas Tightness Test

This test analyzes any leakages within the switchgear using a gas leak detector.

· Dielectric Test

The dielectric test is on the auxiliary circuits.

For this test, apply 500 voltage DC between the terminal blocks and the earth point.

· High Voltage Tests on the main Circuit

You need to check on the dielectric strength to remove causes like damage during handling, wrong fastening and presence of foreign bodies.

Such issues may result in an internal malfunction of the switchgear of not addressed.

12. What are the main Features of Gas Insulated Switchgear?

The main features of a Gas Insulated Switchgear are:

GIS System – Photo courtesy: Electrical Engineering Tutorials

· Reliability

A gas Insulated Switchgear offers a reliable option against power interruption.

This is due to the availability of the SF6 gas that is not prone to faults.

The zero-maintenance feature allows for fewer power interruptions which ensure that individuals and plants get to enjoy power services.

· Creepage Distance

This is a measure of the smallest distance on the surface of the insulation between two conductive materials.

Due to electric discharge, corrosion takes place around the surface of this region.

It is therefore important that you maintain the creepage distance through a process called tracking.

You need to consider the comparative tracking index and the level of atmospheric pollution when checking on tracking.

· Clearance Distance

Clearance distance is the smallest distance through the air between two conductive materials.

It is critical in preventing dielectric breakdown that occurs between two electrodes due to air ionization.

· Space

Gas Insulated Switchgear is a space utilizing switchgear.

The small size reduces the installation space when you compare to Air Insulated Switchgear.

Gas-insulated uses 10% of the space that Air Insulated Switchgear uses.

This feature increases its applicational areas.

· Maintenance

Gas Insulated Switchgear requires less maintenance which helps in reducing the overall cost of the switchgear.

This is because of the fewer faults that occur and the inert nature of the SF6 gas.

13. How does Gas Insulated Switchgear Work?

Overloading of the line inhibits the current from making an electromagnetic release action.

However, it initiates the production of heat by the thermal element.

The heater heats the bi-metal sheet causing it to bend upwards.

This pushes the lever upwards, making the hook to lock off.

This breaks off the primary contact, cutting power supply off.

By doing this, when there is an overload, it exceeds the set current causing the electromagnetic tripper to produce suction.

A combination of the suction and the impact lever results in the lap hook to rotate upwards around the

Shaft seat, thereby releasing the lock.

14. What are the Main Components of Gas Insulated Switchgear?

Some of the main components include:

· Busbar

A busbar is a metallic bar or strip whose function is to connect voltage equipment to the switchgear.

They carry the current within the switchgear.

They are uninsulated and stiff enough to hang in the balance with support from insulated pillars.

· Current Transformer

The function of a current transformer is to multiply or reduce the electrical current in a Gas Insulated Switchgear.

It helps in maintaining the current between the primary and secondary circuits of the switchgear.

· Earthing Switch

Earthing switch helps in directing excess electrical current in the switchgear to the ground.

This helps in reducing electrical overload and the occurrence of electrical faults.

· Disconnecting Switch/ Isolator

The function of a disconnecting switch in a Gas-insulated Switchgear is to interrupt small currents which are capacitively coupled or induced.

They are a crucial part, especially during maintenance of the Gas Insulated Switchgear.

· Circuit Breaker

A circuit breaker helps in stopping excess current flow in the electric circuit.

This helps in preventing faults from occurring withing the switchgear

It is a metal-clad that uses SF6 gas for fault interruption and Insulation.

15. Gas Insulated Switchgear should conform to Which Quality Standards?

A gas Insulated Switchgear should conform to the following quality standards:

- American National Standards for Insulators (ANI) standards.

- International Electrotechnical Committee (IEC) standards.

- National Electrical Manufacturer Association (NEMA) standards.

- Institute of Electrical and Electronics Engineers Standards Association (IEEE-SA)

- ISO standards

16. How does Gas Insulated Switchgear compare to Air Insulated Switchgear?

Air insulated switchgear vs gas insulated switchgear

Air-insulated switchgear uses air as an insulation material for its electrically conductive parts.

Gas-insulated switchgear uses gas as an insulation material for its electrically conductive parts.

Installation of Gas-insulated switchgear is quite easier and faster than installing air-insulated switchgear.

This is because Gas-insulated switchgear is relatively smaller in size and requires a small space for installation.

Gas-insulated switchgear is relatively easier to operate than Air-insulated switchgear.

This is because of its front access feature. Also, they consist of integrated testing tools that facilitate operations.

The occurrence of arc flashes during operation is rare in gas-insulated switchgear that occurs in air-insulated switchgear.

This is because of the total insulation of the inner parts of the gas-insulated switchgear.

The maintenance process of gas-insulated switchgear is cheaper when you compare to air-insulated switchgear.

This is due to copper corrosion, which is prone to air-insulated switchgear.

Normally, the cost of air insulated switchgear is slightly lower than the gas insulated switchgear.

However, the cost of using a system with an air insulated switchgear is quite higher than that of the gas insulated switchgear.

17. Is there a difference between Gas Insulated Switchgear and Substation?

Yes. There is a difference between Gas Insulated Switchgear and Sub-station.

A Gas Insulated Switchgear consists of circuit breakers and relays.

Its function is to switch, control and measure the electrical current flowing through electrical equipment.

A switchboard is an area where there is stepping up and down of High voltage using step-down and step-up transformers.

The manufacturing and testing proceduresfor gas insulated Switchgear are different from those of a Substation.

18. How do you Size Gas Insulated Switchgear?

The sizing of gas Insulated Switchgear depends on the electrical application that you are going to use.

Generally, large electrical equipment will require high voltage Gas Insulated Switchgear.

19. What is Screened Gas Insulated Switchgear?

A screened Gas Insulated Switchgear is a type of switchgear that whose manufacturing process takes into account minimal electromagnetic interference.

This switchgear also produces less noise.

20. How do you Troubleshoot Gas Insulated Switchgear?

SIEMENS GIS

Troubleshooting of Gas Insulated Switchgear depends on the source of the problem.

The following are the some of the ways to troubleshoot your Gas-insulated Switchgear.

· You cannot Lock the Handle

This problem arises from the rusting of the internal locking mechanism or a faulty locking mechanism.

It may also be that you are using the wrong key to open up.

To solve this problem, ensure that you use the correct key.

You need to lubricate the locking mechanism or replace it altogether.

· Internal Noise

the cause of your switchgear producing internal noise is due to the electromagnetic induction screws that are on the partitioning plates.

Cable touching gland plates are another source of the internal noise.

Ensure that you have tightened the screws on the portioning plates and applying a layer of sealant on the cable.

· Overheated Connections

This is a result of having bolts that are overhead and loose.

To solve this, ensure that you use the rated current value.

Also, tighten any loose bolt and replace the busbar if necessary.

· The Switchgear Fails the Dielectric Test or Ground Fault.

Cracked insulators cause switchgear to fail the dielectric test or ground fault.

This. Such insulators are prone to moisture or foreign contaminants.

To solve this, you need to replace the insulators.

You can also clean using an appropriate cleaning agent and dry the moisture parts.

· Shutters not Closing

The main reason why the shutter is not closing is due to damaged shutters.

To solve this, you need to repair the shutters and clean the adjustable parts.

You can also apply a lubricating oil in these parts to facilitate the closing.

· Indicating Light Extinction

Indicating light extinction may be as a result of the following:

Fuse or resistor burnt, Broken bulb filament, faulty limit switch contactor poor contact of the auxiliary switches.

You need to check on the following to fix this: change the bulb, replace the fuse or resistor, cleaning of the auxiliary contacts, or monitor the MCCB of the fuse terminals.

· Poor Control Unit Operation

Poor control unit operation maybe because of unfastened screws of the terminal blocks.

Alternatively, it can be due to an improper connection of the control plug.

You need to tighten the screws for the terminal blocks. You can also connect the control plugs appropriately.

· Shutters are not Opening

If your shutters are not opening, it may be due to poor adjustment of the moving parts or lack of lubricating in these parts.

Also, it can be due to deformed shutters.

To solve this, you need to adjust and lubricate the moving parts and check on the shutters to ensure they are incorrect shape.

21. How many types of circuit Breakers are there?

The following are the main types of Circuit breakers.

· Oil Circuit Breakers

This is a type of switchgear that uses oil vapor, usually to force oil through the arc path.

The oil vapor consists of hydrogen gas.

It is the oldest type of circuit breaker available for use in Gas Insulated Switchgear.

· Air Circuit Breaker

Air Circuit Breaker uses a magnetic force or compressed air to stretch the arc.

The stretched arc automatically exhausts itself since it depends on the voltage available.

· Gas Circuit Breaker

The Gas Circuit Breaker uses a magnetic field to stretch the arc.

It also depends on the SF6 dielectric strength to quench the elongated arc.

· Hybrid Circuit breaker

This type uses both air and gas technology to function.

It features a modular and compact design that consists of different functions in one module.

· Vacuum Circuit Breaker

A vacuum Circuit breaker consists of vacuum interrupters that feature few arcing characteristics.

The reason for this is because the contact material is the only thing necessary for ionization.

This type of circuit breaker is common in gas-insulated switchgear with a voltage range of up to 40,500 volts.

Unlike others, these circuit breakers are unsuitable for direct current faults.

This is because these current lacksthe “current Zero” period.

· Carbon Dioxide Circuit Breakers

Carbon Dioxide Circuit breakers work the same way as Gas circuit breakers.

However, it uses CO2 instead of SF6 gas.

Its main advantage is that its use minimizes greenhouse gas emissions

22. Is the Gas in Gas Insulated Switchgear Harmful to the Environment?

Yes.

The Gas present in Gas Insulated Switchgear is harmful to the environment.

Though an inert gas that does not react with materials, it is a contributing factor to greenhouse gas emissions.

This leads to global warming, which affects the environment.

23. How does Arc Quenching Switchgear Improve Safety?

Arch quenching helps in improving safety by eliminating electrical arcs which are a common occurrence in switchgear.

This is through the use of either SF6 gas or air.

The function of arc quenching includes arc detection, arc transfer, and arc containment.

Arc quenching is essential in switchgear since it helps in minimizing current interruption.

This is through the provision of a quick transition to the current breaking from the current-carrying states of two contacts.

24. How does Disconnecting Switches compare to Earthing Switches in Gas Insulated Switchgear System?

A Disconnecting Switch is a mechanical switch whose function is to de-energize and energize components of an electric circuit.

An Earthing switch helps in earthing components of an electric circuit.