Professional Marshalling Box Manufacturer in China

KDM is Your Best Choice to Custom Any Marshalling Box

Premier Marshalling Box Supplier in China

KDM designed a marshalling box that can be adjusted for future expansion required with front and rear access. Our products are precisely designed for long-operational life and sturdy constructed.

KDM manufactures all types of marshalling boxes with different varieties and customizations. We carefully checked our products to make sure it’s functionality and quality. Our marshalling can be applied in power stations, substations, utilities, controls, and instrumentations.

- Over 10 years of marshaling box manufacturing experience

- Complete range of marshaling boxes to meet all requirements

- Top-quality marshaling box manufactured from optimum quality raw materials

- A cost-effective marshaling box can be customized to the required specifications

Send Us An Inquiry!

KDM Marshalling Box Series

KDM manufacture electrical marshaling box in advanced technology tested machinery. We can produce quality finished products with an aim to fully meet expectations.

KDM relay marshalling box comes with advantageous features like flexible structure, compact, reliable and easily installed.

KDM brings you top-of-a-line power transformer marshaling box that conforms to all the highest engineering, designing, and manufacturing standards.

KDM gives a one-stop solution with your stainless steel marshaling box order. We have the full capability to design and develop authentic and innovative products.

KDM is the leading manufacturer of substation marshaling boxes. We can custom-build the cabinet to meet the desired application and project demand.

KDM expertise and knowledge in marshalling junction box production allow us to design up to date product. All items are manufactured to advanced technology.

Send your Inquiry on KDM Marshalling Box

Our company is composed of professional engineers engaged in creating standard marshaling boxes to provide top-of-the-class products. Using the most advanced technology, we have the latest manufacturing process with the latest innovations. With the help of our well-trained workers, we continuously aim to provide products and services that will save our customers’ time and effort. Our main goal is to manufacture marshaling boxes that will satisfy the needs of our customers around the world.

- Boxes feature durability and are resistant to any corrosions

- The strong and shockproof unit fit for any harsh conditions

- Precisely designed for long-operational life and sturdy constructed

- 24/7 team to accommodate any marshaling box request

Related Products of Marshalling Box

KDM Marshalling Box

KDM marshalling box is made of superior quality raw materials. We are one of the leading manufacturers of marshalling box around the world.

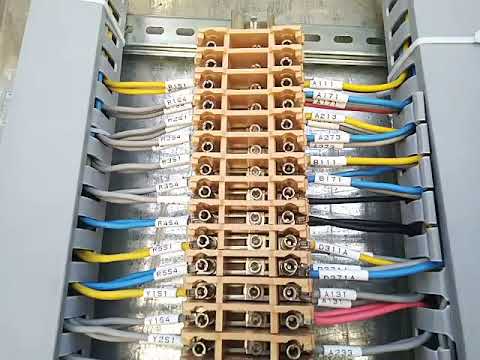

Our marshalling box is created to use as a substation switchyard along with terminal blocks where the control cables are connected. KDM marshalling box features durability and resistance in any corrosions.

We basically manufactured these products strong and shockproof to ensure their’ performance. KDM marshalling box is manufactured as interfaced between dc’s control panels and junction boxes.

These products will absolutely help you identify outputs and inputs easily and you can get an easy diagnosis in trouble shootings. It has an oil temperature indicator, heater switch, fan cooler control and pumps control switch.

KDM manufactures marshalling boxes with world-class quality fit for any outdoor application. We created the marshalling box to bring all relevant components into one control room.

Our main purpose is to make cables and field instruments well-ordered and maintainable. We make sure that our marshalling box is not only durable but also robust, cost-effective and work perfectly.

It can protect all electrical components and wires in different substation plants from any minor and major damages.

KDM marshalling boxes can be made with 2x document holders, 3-point locking handles with padlocks, 2x external breathers, ground fixing points, base gland plates, cable management facilities and double opening doors in both front and back of each box.

We also manufactured fully assembled marshalling boxes. KDM has been manufacturing marshalling boxes for over the years. For over a decade, we hold the needed expertise and records to manufacture the superior quality marshalling box.

KDM exist to manufacture all your needs in this industry. We’ve already established long-term partnerships and managed to provide all their required products.

KDM is eager to help your business grow and manufacture your desired marshalling box. We keep ourselves abreast with the latest technology to make sure we give products efficiently.

Our company is willing to give you your ideal marshalling box at a very affordable price. But, whether you order or not, we are still happy to help you.

We have a team available 24/7 trained to communicate and accommodate our customers.

For further information, be sure to check KDM now!

Marshalling Box: Full FAQ Guide

Complex electrical applications require the use of connected substations that will perform certain functions in the system.

In this case, marshalling boxes and panels play a huge role.

Please, continue further if you want to learn more about this type of electrical equipment.

- What is meant by marshalling box and electronic marshalling?

- Can you name the main types of marshalling boxes?

- Where to use marshalling boxes?

- Is there some difference between marshalling boxes, kiosks, enclosure, and cabinet?

- What is the standard size of marshalling box?

- Can I customize KDM marshalling boxes? What options are available?

- What is the most preferred material for marshalling boxes?

- How to mount a marshalling box?

- What about the wiring of marshaling boxes?

- Where can I find HS code for marshalling boxes?

- Can I use KDM marshalling boxes outdoors?

- Where can I get drawings of the needed marshalling box?

- How can I be sure of the quality of KDM marshalling boxes?

What is meant by marshalling box and electronic marshalling?

Marshalling is the process of grouping I/O (inputs and outputs) together.

Thus, the following groups of electrical panels can be stored inside the marshalling box:

- analog input;

- analog output;

- digital input;

- digital output;

- pulse I/O, etc.

From the marshalling panel, the I/O signals are communicated to the system CPU/Drivers through isolation or signal conditioners.

Can you name the main types of marshalling boxes?

To be fair, the vast majority of marshalling box classifications are independent and made by various entities.

Thus, there is no single classification applied by all marshalling box manufacturers.

We’ve picked the most popular and widespread types of marshalling boxes (all of which can be produced by KDM specialists).

# 1. Single bay marshalling box

Bay is a part of a substation that starts from a bus to a feeder or vice versa.

It consists of a circuit breaker and its associated equipment like isolators, current transformers, earth switches, etc.

Thus, a single bay marshalling box will be used in a single bay electronic scheme.

# 2. Double bay marshalling box

Same as in the previous case, a double bay marshalling box is used in substations.

However, in this case, there would be two separate bays, meaning that the double bay marshalling box has to contain two compartments.

# 3. BMS marshalling box

BMS stands for the battery management system.

Marshalling boxes for BMS help to manage the state of the battery, including protecting the battery from operating outside its safe operating area, monitoring its state, calculating secondary data, reporting that data, controlling its environment, authenticating it and/or balancing it.

# 4. Transformer marshalling box

Transformer marshalling box is needed to eliminate all external connections from the transformer to external switchgear or panel.

Generally, it consists of the following items:

- Oil temperature indicator (OTI) and winding temperature indicator (WTI).

- Terminals for external connection of the Alarms and trips from the OTI and WTI.

- Terminals for transformer neutral CT.

- Motor starters for fans (in case of a forced air-cooled transformer (ONAF).

- Anti-condensation heater.

# 5. Marshalling box for power transformer

In power transformer systems, marshalling boxes do the same, as in the case of simple transformers.

# 6. CT marshalling box

In this case, CT stands for the current transformer.

It is a type of transformer used to reduce or multiply an alternating current.

Basically, CT marshalling boxes are similar to PT cabinets.

# 7. Modular marshalling box

Modular marshalling boxes can store several separate modules to make the connection and wiring clear and simple.

KDM modular boxes can contain as many separate compartments as needed.

# 8. Marshalling box for switchyard systems

Marshalling boxes in power plant switchyards are used for distribution of auxiliary power supply to motors, heating/lighting of various equipment.

Also, they provide terminal blocks for the termination of spare auxiliary contacts from isolators and CBs for further wiring to control/relay panels.

# 9. Relay marshalling box (RMB)

Relay is a switching device used to connect or disconnect a circuit when changing the input current values.

Easy marshalling and cross-wiring inside the box enable last-minute changes to the circuitry.

The relays are plugged in a special socket, making it quick and easy to exchange them, even to change into a timer or latching relay.

# 10. Substation marshalling box

The substation is a set of equipment used to reduce the high voltage of electrical power transmission for consumers’ supply.

# 11. Lighting marshalling box

Marshalling boxes are perfect to store distribution equipment of complex lighting fixtures.

If your application requires the use of long wiring it is better to store additional connections inside marshalling boxes.

Where to use marshalling boxes?

Marshalling boxes are used in a wide range of applications.

Mainly it is used in automation systems where a marshalling box fits in between the junction box and the system cabinet.

Thus, marshalling boxes are common equipment in power plants, manufacturing sites, construction sites, etc.

Is there some difference between marshalling box, kiosks, enclosure, and cabinet?

Yes, there is a slight difference between the above-mentioned fixtures.

Let’s start saying that all of them can be named as an enclosure, which is a general word for all cabinets, kiosks, and boxes.

Some manufacturers even put all these definitions inline, meaning that there is no difference between box, enclosure, or cabinet.

However, we do not like such an approach due to uncertainty.

Thus, at KDM we like to follow the next concept:

- Boxes are small enclosures, including premade equipment like small switching and control panels.

- Cabinets and kiosks are bigger than boxes, however, cabinets typically come empty while kiosks are preassembled with the needed equipment inside.

The aforesaid difference between kiosks and cabinets is not the 100% rule, because kiosks might come empty if needed.

What is the standard size of marshalling box?

There is no single standard adopted by KDM in the case of marshalling box sizes.

In this matter, the exact answer strictly depends on future applications and tasks that might be performed by marshalling boxes.

Also, at KDM we can produce any type of enclosures and additional electrical equipment in any needed size, meaning that we can freely customize the equipment according to your exact specification.

Can I customize KDM marshalling boxes? What options are available?

Yes, you can add extra details and devices to your marshalling box.

First of all, practically every marshalling box in the KDM catalog is equipped with a door.

On one hand, it provides you with the easiest access, and from the other, you can restrict unwanted access to such a device.

To restrict such access, you can use our lockable marshalling box option, that will be equipped with strong locks and latches.

Also, we want to promote you windowed marshalling boxes and enclosures, if you want to have constant visual access to the stored equipment.

The window is made of fiberglass – material that can easily withstand all environmental hazards, typical for the vast majority of industrial applications.

Note: KDM can also help with acquiring such things as:

- Brackets.

- Cable connectors.

- Covers and cable trays.

- Various fittings.

- Holders.

- Racks.

- Correction panels.

- RF shields.

- Cooling fans.

- Wire meshesand so on.

What is the most preferred material for marshalling boxes?

When making electrical enclosures, boxes, and panels, three material categories might be used:

- Metals.

- Plastics.

- Glass and its analogs.

When it comes to metals, KDM uses high-grade stainless steel and aluminum to produce enclosures and various parts of electrical equipment.

The above-mentioned metals are the toughest and can withstand various environmental effects, including humidity, physical impacts, fire, heat, and so on.

Plastics are used in applications where the lightweightness of equipment is a top priority.

Various plastics can provide practically the same level of resistance to water and dust particles, however, they are not so tough as metals when it comes to physical impacts and occasional blows.

However, plastics can be used not only to produce enclosures but for additional details as well.

For example, plastics are the main material for the coating of the wires; various connectors, buttons, and switches are made of plastics.

Finally, enclosures and panels can also contain glass materials, especially fiberglass.

In some cases, the actual glass is used as well, but it is recommended to use reinforced glass or fiberglass to make your application less fragile.

How to mount a marshalling box?

There are no clear limitations when it comes to the mounting of marshalling boxes.

Due to their compact design, they can be easily mounted on walls, poles, DIN rails, etc.

Also, they can come as free-standing items that can be moved when needed.

What about the wiring of marshaling boxes?

Wiring of marshalling boxes is another complex topic.

Marshalling boxes can connect various electrical equipment, thus, wiring schematics will be different in each case.

As we said above, marshalling box fits in between the junction boxes and the system cabinets, connected with field cables.

So, the exact wiring will depend on devices stored inside the aforesaid elements of the electronics system.

Marshalling is usually carried out in one of three ways: cross-wire, fan-out, and half-knit.

# 1. Cross-wire marshalling

Cross-wire marshalling is a method whereby cables are terminated in pair order.

The disconnects, fuses, or termination assemblies are scrambled, and prefabricated cables are used between the disconnects and system cabinets.

This method works best when separate marshalling and system cabinets are used.

Because the prefabricated cables are available in different lengths, it’s not necessary to know the final room layout until much later in the process.

In addition, relays, fuses or isolators can be installed between the field signals and the input/output (I/O) terminals.

Cross-wire marshalling is quick to install and easy to maintain.

The only lack of this method is that it requires additional cabinet space.

# 2. Fan-out marshalling

In this case, field wiring is not terminated in pair order.

Instead, a custom termination per cable is required.

Fan-out marshalling is best suited for situations in which cabinets are connected for testing and then disconnected for shipping.

This happens when they are shipped separately due to the construction schedule – marshalling cabinets are often needed on-site several months ahead of the system cabinets.

Once on-site, the cables are reconnected to the system cabinets.

# 3. Half-knit marshalling

With half-knit marshalling, the field cables are terminated, in pair order, on marshalling blocks.

This is a very efficient method that helps to easily maintain and operate the system.

This type of marshalling is suitable for the following situations:

- Where marshalling and I/O terminals are in different system cabinets, but the cabinets are permanently joined together.

- Where marshalling and I/O terminals are in the same system cabinet.

- Where cross-wiring is done in a remote instrument enclosure (RIE) or on-site.

- Half-knit marshalling is not as suitable in situations where the marshalling and I/O terminals are in separate cabinets that are assembled in different places.

Note: each of the types of marshalling has advantages and disadvantages.

Cross-wire marshalling, for example, offers more flexible scheduling, and it comes with better lifecycle benefits than half-knit or fan-out marshalling.

It is, however, the most costly option.

They all, however, have the same end goal, which is to connect field devices to the control system.

The only real difference is how the multi-core cables are treated in the marshalling cabinets, and how they are connected to the control system.

Where can I find HS code for marshalling boxes?

HS stands for Harmonized System and is used to describe The Harmonized Commodity Description and Coding Systems.

If you want to learn more about this system, please, become familiar with the next guide.

The thing is marshalling boxes can be imported/exported under several HS codes, just like other types of enclosures.

We highly recommend using the following website if you want to figure out what kind of HS code to pick for the marshalling box.

Can I use KDM marshalling boxes outdoors?

Yes, but in this case, you have to be aware of several factors.

First of all, not all KDM enclosures and marshalling boxes fit for outdoor use.

If you need the best protection from environmental influence, we highly recommend picking NEMA/IP rated KDM enclosures.

Speaking of marshalling boxes, the best choice would be picking up aluminum or stainless steel items.

Where can I get drawings of the needed marshalling box?

The smart design of the electrical system is the key to flawless operation in the future.

You can create schematics manually, or use special CAD software.

If you are not able to produce schematics yourself, you can always rely on KDM designers.

Our specialists can produce a complete drawing of your equipment within 1 working day.

Please, send us your specification using the customer support page and we’ll come up with the best solution possible.

How can I be sure of the quality of KDM marshalling boxes?

As a professional manufacturer in China, KDM provides high quality but cost-competitive enclosures.

We operate under strict international standards that refer to enclosures and various electrical devices.

All our items come through complex testing procedures before getting on the market.

If you are still not sure about our capabilities, you can require a sample product from us and conduct your own tests with the help of independent companies.

We can produce you a sample within 3 working days.

https://www.youtube.com/watch?v=80sUaHZDDLw&feature=youtu.be