- 最小注文数量はキャビネット1台から

- シングルドア、ダブルドア、マルチドア設計

- IP 65/IP66以上のグレード

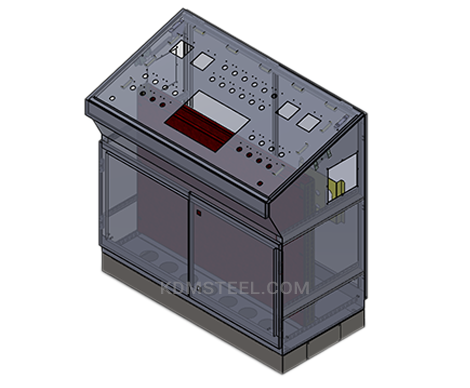

プロジェクトに合わせたカスタム自立型エンクロージャ

20 名を超える専門家で構成される当社のエンジニアリング サポート チームがお客様と緊密に連携し、お客様のアプリケーションに最適なソリューションをご提案いたします。

当社は、過去 17 年間にわたり継続的に開発してきた設計および製造の経験と能力を通じて、サプライヤーとしての役割において卓越した能力を発揮し、お客様の商業または産業用途におけるパートナーとしても機能できると信じています。

- 自立型エンクロージャの設計と製造における10年にわたる経験

- お客様のアプリケーションに特化したオーダーメイドの電気エンクロージャ

- インストールも使い方も簡単

- すべての KDM 自立型エンクロージャは NEMA 規格を満たすように構築されており、電気システムの保護に特化しています。

KDM 自立型エンクロージャシリーズ

KDMフリースタンディングエンクロージャに関するお問い合わせ

当社は、過去 17 年間にわたり、設計および製造能力の向上に全力を尽くしてきました。製品と材料に対する理解が深まれば深まるほど、業界の競争に生き残れる可能性が高くなると信じているからです。

KDM 自立型エンクロージャは、お客様の要件を満たすように細部までカスタムメイドできます。アプリケーションに最適な NEMA または IP 規格を選択し、一連のレイアウト、機能、アクセサリを組み合わせて設計を構成することができます。

- 製造能力

- 購入ガイド

4000W 高性能レーザー切断機、+/- 0.05mm の精度。バリや傷はありません。

多機能フレキシブル溶接装置、高精度、変形なし。

+/- 0.5mmの曲げ精度、曲げ跡のない滑らかな表面。

10 名以上の溶接経験を持つ作業員がおり、全体的な外観は完璧です。

高速かつ高精度の発泡機、高速かつ高品質のガスケット

熟練した組み立てチーム、すべてのKDMエンクロージャで一貫した組み立て品質

KDM: プレミア自立型エンクロージャサプライヤー

KDM 自立型電気エンクロージャ (自立型電気キャビネットとも呼ばれる) は、電気機器に使用され、雨、雪、汚れなどの気象災害や外部からの損傷や汚染から電気機器を保護します。

したがって、この目標を達成するために、すべての KDM 自立型電気エンクロージャは、NEMA 規格とそれに対応する IP コードを満たすように製造されており、電気システムと配線の安全な動作を保証します。

通常、自立型の電気筐体では、平らな床に脚を取り付ける必要はありません。

そのため、設計はシンプルですが、通常は下からアクセスできず、平らな床の電気筐体ほど簡単には移動できません。

移動や移設がそれほど頻繁ではないが、比較的大型の電気機器を収容する必要がある用途に最適です。

KDM 自立型エンクロージャは、炭素鋼、ステンレス鋼 (201、304、316 ステンレス鋼を含む)、および亜鉛メッキ鋼で作ることができます。

過去 17 年間、当社は製品に高品質の素材のみを使用し、最も経験豊富な素材にこだわり続けてきました。

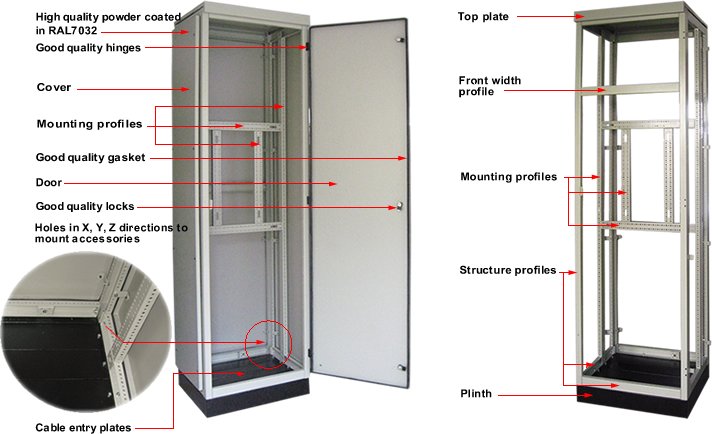

KDM 自立型電気エンクロージャには、シングルドアまたはダブルドアのレイアウトのほか、さまざまなヒンジ、ロックシステム、ラッチ、バックパネル、アイボルト、さまざまな色や表面仕上げなどのさまざまなアクセサリが付属しています。

ヒンジは必要に応じて隠すことができ、取り付けも簡単です。

ロック システムにはさまざまな構成があります。

アイボルトを使用すると簡単に設置できます。

また、背面パネルを取り付けることで、筐体内の壊れやすいコンポーネントや敏感なコンポーネントの操作が容易になります。

通気口、サンシールド、ファンカバー、窓などの追加機能もデザインに追加できます。

当社では何千もの組み合わせをご提供できるほか、お客様独自の設計に基づいてエンクロージャを製造することもできます。

また、会社名やロゴ、安全情報を筐体にシルクスクリーン印刷、陽極酸化処理、または彫刻することもできます。

屋外用自立型エンクロージャ

KDMは製品の設計と製造に努めてまいりました。

通常、リードタイムは 15 日から 30 日程度となります。

今すぐ当社の自立型電気エンクロージャの見積もりをご依頼ください。12 時間以内にご要望にお応えします。

KDM自立型電気エンクロージャは、電気、 電子制御、機器、環境要素のコンポーネント。これらのエンクロージャは、モーター スターター、ドライブ、コンタクタ、PLC を収容する工作機械アプリケーションで使用されているほか、自動車、パルプおよび紙、木材製品、繊維、および類似の産業で使用されるさまざまな電気および電子機器にも使用されています。その他の用途としては、製薬、食品および飲料、包装、水、石油、化学処理産業があります。

KDM 自立型電気エンクロージャは、スチール、304 および 316 ステンレス鋼、亜鉛メッキ鋼など、さまざまな素材で提供されています。非常に大規模な制御システムに対応するために、自立型および床置き型エンクロージャを選択できます。利用可能なモデルには、シングル、ダブル、およびマルチドア構成があります。

KDM の自立型電気エンクロージャは、前面または前面と背面のドア アクセスのいずれかで利用できます。KDM は、エンクロージャの安定性のために、前後に奥行きがあり、ベースが広い自立型キャビネットを設計しています。このエンクロージャは、ほこり、耐候性または防水性、洗浄および腐食性環境からの保護を提供します。すべての自立型電気エンクロージャは、NEMA 1、NEMA 3R、NEMA 4X、および NEMA 12 の NEMA 定格で、さまざまなレベルの環境保護に対応します。

弊社では、標準サイズの自立型エンクロージャに加え、お客様のニーズにぴったり合う自立型電気エンクロージャ キャビネットを設計できるカスタム オプションも提供しています。弊社では、さまざまな材料を使用して自立型キャビネットを製造できます。弊社では、すべてのキャビネットをお客様のご要望に合わせて構築します。

また、オプションのフロアキットも提供しており、標準サイズとカスタムサイズの高さでご利用いただけます。カスタムキャビネットには、切り抜き、断熱材、ヒンジ、ラッチ、またはロックが付属しています。その他のオプションには、透明なポリカーボネートのドア、溶接された窓、およびリクエストに応じて利用可能な顧客固有の穴などがあります。通常、リードタイムは15日から30日です。

自立型エンクロージャはフロアマウント型エンクロージャと非常によく似ていますが、自立型エンクロージャにはフロアサポートキットがありません。自立型エンクロージャは、複数の異なるユニットを結合して 1 つのユニットとして機能させることができます。産業用エンクロージャとして、KDM 自立型エンクロージャは、食品加工から製造、データセンターなど、最も過酷な産業および商業用途で発生するストレスにも耐えることができます。

弊社は製造業における豊富な知識と経験を活かして、幅広い種類の自立型エンクロージャをご提供しています。同時に、あらゆる業界基準を満たす高品質の自立型電気エンクロージャを継続的に開発しています。

KDM は 17 年にわたり自立型エンクロージャの製造に携わってきた経験と、顧客満足への取り組みにより、お客様が必要とするまさにその自立型エンクロージャが見つかると確信しています。当社の専門スタッフと設計チームは、お客様と緊密に連携し、お客様の用途に最適なソリューションを提案いたします。

KDM では、カスタムの自立型エンクロージャを最良の価格で構築します。当社はお客様と協力して、あらゆる業界標準を満たす革新的な新しい自立型エンクロージャとカスタム エンクロージャを開発します。当社が提供する自立型電気エンクロージャについてさらに詳しく知りたい場合は、今すぐお問い合わせください。

自立型電気エンクロージャ: 輸入業者向けの役立つガイド

自立型電気エンクロージャを輸入する場合、このガイドが役立ちます。

これにより、この機器の概要、注意すべき基準、その他多くのことについての知識が広がります。

では、始めましょう。

自立型電気エンクロージャとは何ですか?

自立型エンクロージャは、電気コンポーネントや部品を収容するキャビネットの一種です。

他のエンクロージャと異なる点は、独立して設置できることです。

自立型電気エンクロージャ

バランスを取るために取り付けたり、何らかのサポートを必要としません。

自立型電気エンクロージャが必要な理由

一般的には、 電気筐体 あなた、他のユーザー、および電気部品を環境から保護するためです。

エンクロージャは、その名前が示すように、電気機器や電子機器を囲み、ユーザーをショックなどの電気的リスクから保護します。

これが、自立型エンクロージャが必要な理由についての一般的な考え方です。

電気システムを備えた自立型エンクロージャ

ただし、より具体的に言えば、簡単に移動できるものが必要な場合は、自立型のエンクロージャが必要になります。

明らかに、自立型エンクロージャは簡単に移動できます。

ある場所から別の場所へ簡単に移動できます。

持ち上げて次の場所に移動させるだけです。

また、自立型の電気キャビネットは設置が簡単です。

インストールマニュアルを読むのに何時間も費やしたくない場合は、自立型のエンクロージャを入手するのが理想的です。

このタイプでは、適切な場所を見つけてそこに置くだけです。

他の種類のエンクロージャのインストールに伴う、長時間にわたる肉体的に疲れる作業を省くことができます。

私の意見では、これが自立型の電気筐体が必要な理由のほぼすべてです。

保護性、設置の容易さ、携帯性に優れています。

デザインについては以下をご覧ください。

自立型電気エンクロージャの設計

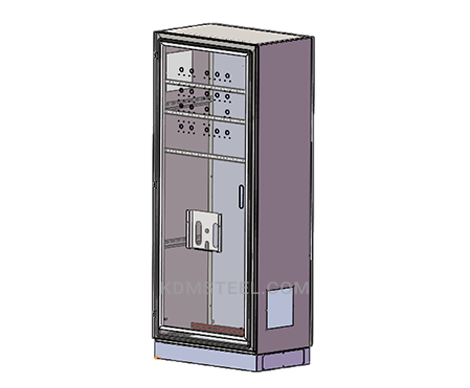

自立型電気エンクロージャには、主に 2 つの構造設計があります。シングル ドア設計とダブル ドア設計です。

· シングルドア自立型電気エンクロージャ

シングルドアエンクロージャには、アクセスドアが 1 つ付いています。

シングルドア電気エンクロージャ

これは、小型の自由電気筐体では一般的です。

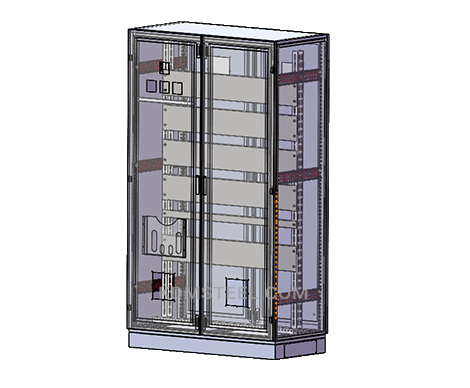

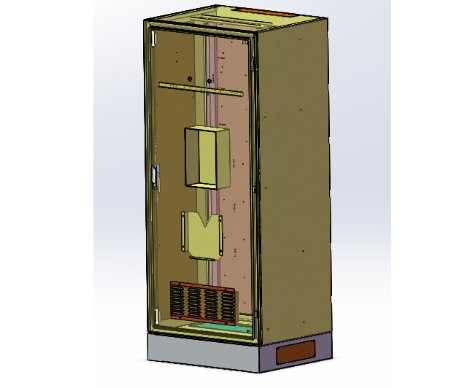

· ダブルドア自立型電気エンクロージャ

繰り返しになりますが、名前が示すように、二重ドアの自立型電気エンクロージャは、2 つのアクセス ドアが組み込まれたエンクロージャです。

これは主に工業用の大型筐体でよく使用されます。

二重扉の自立型電気筐体

最適なデザインを選択する際には、要件に最も適したデザインを選択することをお勧めします。

それでも、コンテンツのアクセシビリティ、インストール設計、ストレージスペース、オープニング設計などを考慮する必要があります。

これらの要素は、特定の用途に適したドアのデザインを決定するのに役立ちます。

自立型電気エンクロージャの品質基準

一般的に、この点で品質基準を適用する目的は、自立型エンクロージャが業界標準を満たしていることをエンドユーザーに保証することです。

内容物は電気製品であるため、安全性を最優先にするためにこれらの規格が制定されています。

したがって、自立型電気エンクロージャを選択して輸入する前に、次のマークを確認して、設定された基準を満たしていることを確認してください。

i. NEMA

あ NEMA 定格 自立型電気エンクロージャ製品が設定された NEMA 仕様に準拠していることを示します。

この場合、NEMA は National Electrical Manufacturers Association (全米電気メーカー協会) の略称です。

メーカーとエンドユーザーにとって最大のメリットとなる具体的なガイドラインを示します。

自立型電気エンクロージャを購入する場合、エンクロージャ タイプに割り当てられた NEMA 定格に注意することになります。

基本的に、NEMA 定格には 13 レベルがあります。レベル 1 ~ 2、3 または 3R または 3S、4、4X、5、6 または 6P、7、8、9、10、11、12 または 12K、および 13。

NEMA 定格

これらはすべて、雨、雪、ほこり、汚れなどの気象条件から筐体を保護するように設計されています。

また、油や水しぶきに対する保護も確保します。

これらの定格の意味を明確に理解することは、自分に合った自立型電気エンクロージャを購入するために不可欠です。

NEMA 定格のエンクロージャを購入すると、輸入プロセスがスムーズに進むことも保証されます。

そうしないと、自国の税関当局との問題に遭遇することになります。

ii. IP 55 または 56

侵入保護(IP)等級 自立型エンクロージャ製品が固体や液体の侵入を防ぐように設計されていることを示します。

基本的に、IP 等級は 2 桁の形式で表されます。

最初の数字は製品が固形物の侵入に対してどの程度保護できるかを示し、2 番目の数字は湿気に対してどの程度保護できるかを示します。

当社では、IP 55 または IP 56 定格の自立型電気エンクロージャが最適です。

IP 55 は、限られた量の粉塵の侵入と低圧の水の噴流から保護します。

IP 56 定格により、限られた量のほこりの侵入や高圧の水の噴流から保護されます。

どちらも限られた範囲で水分の浸入を許容します。

iii. RoHS

安全規格 有害物質の使用制限を意味します。

電気製品における有害物質の使用を制限する要件です。

RoHS 準拠の自立型電気筐体は、その製造において水銀、鉛、カドミウムなどの有害物質を使用していません。

iv. CE

欧州連合地域に自立型電気筐体を輸入する場合は、 CE準拠.

これは、欧州経済領域に定められた健康と安全の保護基準に準拠していることを意味します。

対UL

ULマークは、製品が アンダーライターズ・ラボラトリーズ (UL) 安全性試験分析規格。

これは米国で販売される製品にとって重要な品質要件です。したがって、米国に輸入する場合は、製品にこのマークが付いていることを確認する必要があります。

自立型電気エンクロージャ仕様

各製品の仕様に対する好みは、エンドユーザーごとに異なります。

したがって、自立型エンクロージャを選択する際には、エンド ユーザーのニーズに注意を払うことが重要です。

自立型電気エンクロージャの仕様 – 写真提供: CUBIC

自立型電気エンクロージャを選択する際に考慮すべき主な要素は次のとおりです。

§ 材料

メーカーは、自立型エンクロージャを製造するためにさまざまな材料を使用します。

しかし、そのほとんどは、アルミニウム、スチール、硬くて耐久性のあるプラスチック素材を使用しています。

使用する機器に合わせて木製で作られているものもあります。

適切な自立型エンクロージャは、使用するアプリケーション、環境、場所によって異なります。

この点では、重量、安定性、耐久性、外観、取り付けオプションなどの要素が決定に大きな影響を与えます。

§ フレーム

フレームは、自立型電気筐体の安定性と耐久性を大きく左右します。

したがって、フレームの素材とデザインが自分のスタイルと好みに合っていることを確認してください。

§ ドア

先ほど述べたように、自立型電気筐体には 2 種類のドア デザインがあります。

シングルドアとダブルドア。

小さな筐体ではシングルドアが最も一般的ですが、大きな筐体ではダブルドアがより一般的です。

利用可能なスペース、用途、好みに応じて、目的に最適なドアを選択してください。

重要なのは、ドアが開けやすく、中身に簡単にアクセスでき、耐久性があることを保証することです。

§ ルーフパネル

これは、自立型電気筐体の上部部分にすぎません。

亜鉛メッキ鋼、アルミニウム、または硬質プラスチックから作ることができます。

取り外し可能なものや取り外し不可能なものもあり、ほこりがたまるのを防ぐために少し傾斜しているものもあります。

§ アーシング

アースの連続性を確保するために、自立型電気筐体のすべてのパネルをアースする必要があります。

そうしないと、ユーザーはショックを受け、最悪の場合、火災の危険にさらされることになります。

§ 保護

独立型電気機器は電気機器であるため、考えられるすべての安全基準に準拠する必要があります。

NEMA、IP、UL、CE、および RoHS は、電気筐体に適用される一般的な安全規格です。

したがって、エンクロージャがアプリケーション、場所、および環境での使用に対して適切に評価されていることを確認してください。

§ 寸法

あなたのスペースはどれくらいの広さですか?

購入する正しいサイズを識別するには、自立型エンクロージャを設置する場所を知っておくことが重要です。

自立型電気エンクロージャにはさまざまなサイズがあることを覚えておく必要があります。

したがって、「買いすぎ」や「買い不足」を避けるために、必要なエンクロージャの量を把握しておく必要があります。

§ コンパートメント

どれくらいの量のコンテンツを同封する必要がありますか?

どれくらい離れているのでしょうか?

これらは、アクセスのしやすさとともに、自立型電気筐体を購入する際に自問する必要がある質問です。

1 つ、2 つ、またはそれ以上のコンパートメントを持つエンクロージャに遭遇するでしょう。

その数はエンドユーザーのニーズによって異なります。したがって、選択する際には慎重に行ってください。

KDM 自立型電気

業界には独立型の電気筐体メーカーが数多く存在します。

これにより、信頼できる注目に値するサプライヤーを見つけるのが難しくなります。

しかし、KDM は中国の全鋼製品メーカーであり、最高品質の自立型エンクロージャを供給できます。

当社は高品質で革新的な鋼、ステンレス鋼、 亜鉛メッキ鋼製自立型エンクロージャ.

KDM には、カスタムメイドの自立型電気エンクロージャの設計を支援する専門エンジニアが在籍しています。

詳細な要件を弊社にご連絡いただければ、お客様の仕様通りに正確に納品いたします。

当社がどのような安全対策を適用しているか知りたいですか?

ええ、たくさん。

当社の製品は、NEMA 1、3、3R、3S、4、4X、6P、12、13 などの NEMA 規格に準拠しています。

つまり、汚れ、ほこり、油、氷、水などの厳しい環境から電気部品やコンポーネントを適切に保護します。

一番良かった点は?

当社の価格は非常に競争力があります。いくらか知りたいですか?

0086-13814224925までお電話いただくか、 お問い合わせ オンライン。

結論

自立型電気エンクロージャ溶接

前にも述べたように、自立型エンクロージャにはさまざまなデザインとサイズがあります。

輸入先に応じて、その国で受け入れられる製品デザインを選択してください。

最終目標は、ユーザーと機器を環境から保護することです。

そのため、これを実現するには、LectSteel が提供するような最高品質の自立型エンクロージャのみを選択してください。

私がいつも言っているのは、品質と安全性を優先すること、それ以外はすべておまけだということです。

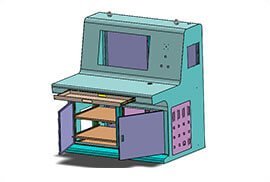

最近の電気筐体設計

自立型電気エンクロージャとは何ですか?

自立型電気エンクロージャは、大型の電子機器や制御装置を保護する、完全に密閉された電気エンクロージャです。平坦で平らな床面に設置して使用します。

対応する脚が付いており、筐体を下から持ち上げて固定します。

複合マウント構成を必要とするシステムで作業する場合は特に、自立型電気機器が最適です。

図1 自立型電気筐体

自立型電気エンクロージャのコア機能は何ですか?

自立型電気エンクロージャの主な機能は、あらゆる破壊的な物体や過酷な環境条件からすべてのシステム機器を保護し、セキュリティを確保することです。

すべての電子機器をスムーズに動作させ、動作の安定性を維持します。

自立型電気エンクロージャの特別な構成は何ですか?

幅広い自立型電気エンクロージャには独自の構成が備わっており、システム全体の外観の基本的な参照として役立ちます。

- 特定の機器の設置ニーズに合わせて取り外し可能なセンターポスト構造に対応する単一または二重のドアを備えています。

- 最適な軸回転と制限のない旋回動作を実現する、耐久性があり取り付けが簡単なヒンジ。

- 別個の留め金とステープルを備えた標準クランプで構成されています。

- 頑丈なハンドルを備えたシンプルな3点ラッチシステム

- 時計回りと反時計回りに回します。

- 完全に溶接された高い脚が底まで立っています。

- 両開きドアの設計に取り外し可能なセンターポストを提供します。

- 取り付けが簡単なバックパネル。

- カスタマイズされたフランジとロック機構。

- 密閉されたドアガスケット。

- 吊り上げ用のアイボルト。

図2 自立型電気筐体

自立型電気筐体の最も一般的な材料タイプは何ですか?

自立型電気エンクロージャは、さまざまな材料タイプで利用できます。

以下は、さまざまな耐久性のある材料を使用した、最も人気のある自立型電気エンクロージャの種類の一部です。

軟鋼製自立型電気エンクロージャ

このタイプの自立型電気エンクロージャは、産業用途に最適です。これは完全に溶接されたエンクロージャであり、あらゆる電子機器に優れた簡単なアクセスを提供します。

ステンレススチール製自立型電気エンクロージャ

これは、より重要なコンポーネントや機器に使用される優れた保護エンクロージャであり、腐食のリスクが高い環境での使用に最適です。

ステンレス鋼製自立型電気エンクロージャの一般的な用途は次のとおりです。

- 油

- ガス

- 食品および飲料

- 製薬

- 屋内と屋外の両方で使用可能

ファイバーグラス製自立型電気エンクロージャ

グラスファイバー製の筐体のほとんどは、価格の割にコスト効率に優れています。特に出費を抑えたい場合には、実用的なソリューションです。

安価であるにもかかわらず、グラスファイバー製の自立型電気エンクロージャには次のような機能もあります。

- 過酷な腐食環境に耐える

- 軽量で優れた衝撃吸収力と耐久性を実現

- 鋼鉄と同等の剛性を実現

自立型電気筐体にはどのような仕上げが施されていますか?

ポリエステル パウダー コート仕上げは、通常、自立型電気エンクロージャに適用されます。エンクロージャの内部と外部の両方の部品に完全に使用されます。

ただし、一部の材料では、カーボン スチール製のエンクロージャには白いポリエステル パウダー コート仕上げ、ステンレス鋼製のエンクロージャには #4 パウダー仕上げなど、異なる仕上げも使用されています。

自立型電気筐体の一般的な寸法は何ですか?

ほとんどの自立型電気エンクロージャは、次のようなさまざまな寸法で利用できます。

- 1000*600*270mm

- 1200*600*350mm

- 1500*600*370mm

- 1500*700*350mm

- 1500*700*370mm

- 1700*700*370mm

- 1800*700*370mm

- 1800*800*370mm

目的や用途に応じてカスタム測定も承ります。

図3 自立型電気筐体

自立型電気エンクロージャの標準的な奥行きの範囲は何ですか?

自立型電気エンクロージャは、以下の深さの範囲でアクセス可能です。 8インチから36インチ、または20.32cmから91.44cm。

自立型電気エンクロージャを使用する理由

多くの電気愛好家は、次のような明白で優れた利点があるため、自立型電気エンクロージャの使用を好みます。

- 高性能でありながら手頃な価格

- 屋内でも屋外でも使用可能

- あらゆる設置が迅速かつ簡単

- あらゆる電子コンテンツに簡単にアクセス可能

- すべての繊細な電気・電子制御とシステムを完全に保護します

- カスタムサイズやその他の仕様もご用意しております

- リバーシブルヒンジドア

- 調整可能な取り付けパネルの深さ

自立型電気エンクロージャはどこで使用できますか?

自立型電気エンクロージャは、次の目的で設計されています。

- 電気端子

- コントロール

- 楽器

- 電子機器

- トランスフォーマー

- システム

図4 自立型電気エンクロージャ

自立型電気筐体に必要な保護等級は何ですか?

すべての自立型電気エンクロージャは、動作中の信頼性と安全性を確保するために、次の製品規格に準拠する必要があります。

NEMA 4 定格

この等級は、自立型電気エンクロージャが耐久性のある防水性を備えているかどうかを決定します。これは、エンクロージャが風雨、水しぶき、ホースからの直接の放水にどれだけ強く耐えられるかを示します。

NEMA 4X定格

NEMA 4x 定格は、自立型電気エンクロージャが主要な保護品質、ガスケット設計、屋内および屋外での使用との互換性に準拠しているかどうかを示します。

NEMA 12 定格

これは、ほこりやその他の液体物質の侵入に対する平均的な屋内保護を必要とするデバイスに使用される最も一般的な NEMA 定格です。ただし、この定格は、自立型電気エンクロージャが不本意な人員接触から保護されている場合にも適用されます。

自立型電気エンクロージャはどのような工業規格を取得する必要がありますか?

の UL そして カルロス 標準。

これらの示された規格により、自立型電気エンクロージャが安全予防規格および適切に構造化された設計に準拠しているかどうかが判断されます。