- Powder Painted Galvanized Enclosure

- Customized Design for Any IP Grade

- Low MOQ from 1 PC

KDM Custom Galvanized Steel Enclosure

- Cost-effective protection option

- High quality galvanized surface

- Long-lasting protection with minimal maintenance

- Abundantcustomization options

KDM Galvanized Steel Enclosure Series

Send your Inquiry on KDM Galvanized Steel Enclosure

KDM provides galvanized steel enclosures in all types, layouts, and sizes. Meanwhile, various design features and accessories, as well as mounting hardware, are also available.KDM’s support team consisting of more than 20 engineers will help you find the design most suitable for your applications.

- Manufacturing Capacity

- Buying Guide

- Enclosure Designs

4000W high-performance laser cutting machine, +/- 0.05mm accuracy. No burr, no scratching.

Multi-Functioning flexible welding equipment, high accuracy, no deformation.

+/- 0.5mm bending precision, smooth surface without bending marks.

10+ welding experienced workers, perfect overall appearance.

High speed and accuracy foaming machines, fast and qualified Gasket

The expert assembling team, consistent assembly quality on every KDM enclosure

KDM: Your Professional Galvanized Steel Enclosure Manufacturer

Galvanizing is the process where a layer of protective zinc coating is applied onto the steel surface so that the steel will become immune to rust.

Therefore, KDM galvanized steel enclosures are a cost-effective alternative to stainless steel while enjoying the mechanical properties of carbon steel.

Galvanized Steel Enclosure

KDM has been manufacturing steel enclosures for almost two decades and has begun to provide the galvanized steel option for years.

Over the years KDM has accumulated a good amount of experience in the use of galvanized steel for manufacturing as well as acquiring high-quality galvanized surfaces.

Compared to the powder coating option, galvanized steel is superior in terms of maintenance.

Because for powder coating, if there are scratches on the surface where the coating layer is worn off, then the entire protection layer becomes almost ineffective instantly.

For the galvanized steel option provided by KDM, on the other hand, if the same scratches are on the surface, the galvanized zinc layer will still protect the steel structure since zinc always reacts with oxygen ahead of steel.

Therefore, even though KDM galvanized steel enclosures come at a slightly higher price compared to powder-coated steel enclosures, for environments where physical damages are more frequent galvanized steel enclosures are the more suitable option that requires much less cost on maintenance.

Galvanized Steel Enclosure: The Ultimate Guide

Nowadays, people use different types of materials to manufacture a wide range of electrical enclosures.

Of course, the nature of the material is a significant concern when looking into the efficiency, performance, and durability of this equipment.

Galvanized Steel Enclosure Accessories

One of the materials that are also getting favorable ratings for manufacturing this unit is galvanized steel.

If you’re buying an electrical enclosure for the first time, then you’re in the right place.

In this guide, I want to tell you all the nitty-gritty revolving around this type of electrical housing.

And hopefully, by the end of reading it, you’ll learn quite a lot of fundamental information surrounding the same.

Now, let’s get straight to the point.

What is Galvanized Steel Enclosure?

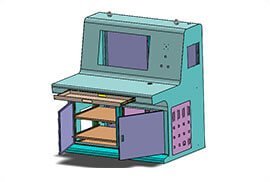

It refers to the type of casing or cabinet made of galvanized steel metal that houses various electronic and electrical components.

It comes in different designs, shapes, and sizes as we’ll come to find out later on in this guide.

Galvanized steel electrical cabinets are important in enhancing productivity, especially within an industrial setting.

And in most cases, you’ll find that these units are used in various types of applications across several industries.

In fact, some of the common areas where they are mostly applicable include traffic control, solar battery, petrochemical, and servers, etc.

But before we dig deeper into the common applications of these units, let’s first see the benefits it has in such applications.

Why You Need Galvanized Steel Enclosure

Galvanized Steel Enclosure Manufacturing

This equipment and any other electrical enclosure for the matter are necessary particularly in an industrial environment.

First, it makes it possible for you to assemble all the different electric and electrical devices and components respectively.

So it becomes quite easy for you to operate all the machines and any other equipment effortlessly.

The other reason why you would need this equipment is that it helps in regulating the temperature of the surrounding.

And by the way, this is so particular in case you’re installing one for indoor use.

Normally, the electrical components tend to generate heat to a certain extent.

When you fail to check most of them, you’ll realize that the condition will be somewhat unbearable to endure.

However, once you keep these devices inside an enclosure, there’s a possibility of having a relatively conducive environment.

These units are fitted with technological mechanisms for regulating the temperatures of these devices.

Another reason is that this unit makes it easy for you to protect all the vital and delicate electrical and control devices.

Most of the time, when you leave such components exposed openly, they tend to damage or on some occasions cause unwarranted inconveniences.

Therefore, it becomes easy for you to safeguard them from potential damages which could arise from physical objects or weather factors.

Galvanized steel enclosures also enable you to safeguard the safety of the users and workers within the premises or surrounding.

And most significantly, you also need this equipment as a way of enhancing efficiency and convenience in various operations.

What happens is that using electrical enclosures helps in increasing overall productivity and subsequent production.

You’ll find that operations become easy, convenient, and relatively fast. And the outcome, of course, is high productivity.

Well, as you can see, this unit provides quite a number of benefits hence making it suitable for you to need it.

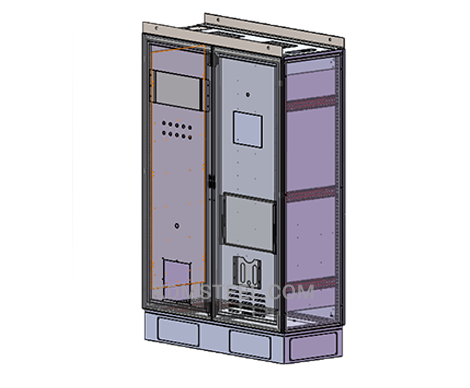

Galvanized Steel Enclosure Designs

Like I’d told you earlier, these types of enclosures come in different designs.

So you’ll find that this variance is essential especially when it comes to selecting a design which suits your needs.

However, the designs for galvanized steel enclosure ordinarily come in two major forms on the basis of a number of doors.

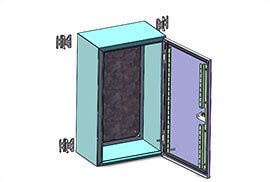

Single-Door Galvanized Steel Enclosure

This simply refers to the type of galvanized electrical enclosure which features one door.

It thus implies that you can only use that one door to access the internal sections of this enclosure.

Single Door Galvanized Steel Enclosure

Moreover, the size of the single-door galvanized enclosures may also vary from small to large ones depending on your needs.

It is nonetheless important to understand that in some of these cabinets, the single doors could be several and located in different sections.

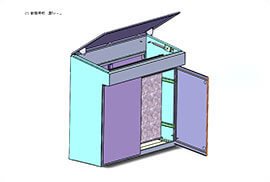

- Double-door Galvanized Steel Enclosure

It refers to the type of galvanized steel cabinet which features two doors for accessing the internal components inside this unit.

Just like single-door design, this one also comes in different sizes ranging from small office one to large industrial one.

Double door electrical enclosure

At the same time, some come with multiple double doors also fitted in different parts of the enclosure for easy accessibility.

Also, you can get customized designs that suit your preferable indoor and outdoor needs.

Quality Standards for Galvanized Steel Enclosure

Well, the definition of how good or bad a product is lies in its quality.

And measuring quality standards is also an equally fundamental task.

The truth is that when it comes to galvanized steel electrical cabinets, quality is an element that you can never compromise.

And in this case, we want to look at some of the key quality standards which outline the suitability and performance levels of these units.

NEMA

This is the group that is responsible for defining the standards of different galvanized steel electrical boxes.

This standard quite often describes the type of grade of such cabinets, and in most cases, it targets the US market.

NEMA necessarily tends to rate these types of enclosures against the various possible environmental vulnerabilities.

Also, NEMA often conveys the ingress progression for enforcing compatibility safety and performance.

IEC 60529

It refers to a quality standard which you use for assessing the performance levels and measures of this enclosure by various elements.

In the European Union region, it’s mostly known as IEC 60529.

The IEC rating for every IP level gives a measurement for a specific quantity of water that should get inside the enclosure.

IEC quality standard also gives a measure for the cabinet about its ability to protect components from dust and moisture.

RoHS

It refers to a quality standard for all types of electronic and electrical components mainly in the European Union zone.

It was formerly known as Directive 2002/95/EC, and it restricts the use of all harmful substances available in electronic devices and components.

What it also primarily does is provide a CE-marking directive for the production of these types of products.

Technical Specifications of Galvanized Steel Enclosures

Selecting the best-galvanized steel cabinet requires quite a thorough knowledge and understanding of its various factors.

Galvanized electrical enclosure

And one of them, which seemingly you have to look into is the technical specifications.

Some of the key ones include the following;

Earthing

This is a low resistance cable that transmits immediate discharge of electrical energy to the earth.

Any type of electrical enclosure including galvanized steel needs to have it.

This device helps to increase the efficiency of the unit and also to enhance the safety of both users and the components of its housing.

Essentially, it prevents high voltage surges and also lightning.

Door

A door, in this case, refers to the section you use to access the interior of this particular enclosure.

They come in different sizes and designs depending on the structure of the cabinet.

And it’s always advisable to go for one which has locks to prevent intruders from accessing the unit.

The door should also fit appropriately on the frame for better functionality of the whole unit.

Structural Design

Of course, this aspect often varies depending on a particular manufacturer as well as your needs.

So if you need one for indoor or small-scale applications, you may need to go for a relatively compact one and vice versa.

The bottom line is that you need to ensure that you choose what you’re certain meets your needs accordingly.

Thermal management

In this case, it is the system of monitoring and regulating temperatures as well as cooling methods within electrical boxes.

So you need to ensure that the ability of the enclosure to manage the temperature to the required standards is appropriate.

Safety protection features

It should also have all the necessary features that guarantee safety to both the users and the devices it is housing.

KDM Steel Galvanized Electrical Enclosures

Listen, if you’re looking for an ideal galvanized electrical enclosure, you need to try some from KDM steel

This manufacturer produces some of the highest quality enclosures for different applications.

And definitely, you can also get your customized unit of course at pocket-friendly rates.

Conclusion

Possibly, you can now figure out the different aspects revolving around galvanized electrical enclosures.

Of course, it’s important because it enables you to make the right decision, especially when importing this type of unit.

But most fundamentally is that you have an ideal manufacturer of this equipment.

And therefore, in case of any challenges, you can merely contact them for further information.

FAQS

What is a Galvanized Steel Enclosure?

Galvanized enclosures made of galvanized steel are robust. It is designed mainly for outdoor usage in harsh environments.

Galvanized steel enclosures are ideal for various sectors, including traffic control, server cabinets, solar battery cabinets, petrochemical, and power generating.

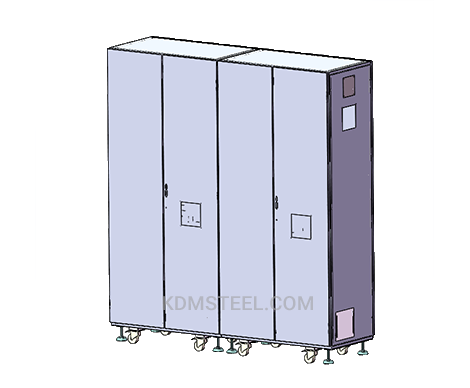

Figure-1 Galvanized Steel Enclosure

Where Does Galvanized Steel Enclosure Use?

They are more affordable than stainless steel and aluminum, which are still the ideal materials for outdoor use.

Besides, it is specifically developed for use in outdoor locations where the weather is harsh.

Given its longevity and strength, it is ideal for nautical, street lighting, and railway line service applications.

Figure- 2 Galvanized Steel Enclosure

What are the Features of Galvanized Steel Enclosure?

Galvanized steel enclosure, constructed of galvanized steel, contains all the required safety features for electrical installations in outdoor facilities.

Zinc coating provides excellent corrosion resistance. Extremely tough and long-lasting. Besides, cost-effective enclosures.

They offer a low-cost, long-lasting solution for a variety of engineering applications.

Construction of an Enclosure.

- 16-gauge galvanized steel.

- Continuous galvanized steel hinge.

- Padlocking hasp included.

- On the front of the door, there are vents.

- On request, a pole mount channel is available.

Finishing the Enclosure

- Only galvanized steel is used.

Sizes of Standard Enclosures

- Size: 12″ H x 12″ W x 6″ D, maximum 12 shunts

- Size: 18″ H x 18″ W x 6″ D, maximum 20 shunts

- Size: 18″ H x 24″ W x 6″ D, maximum 30 shunts

- Size: 24″ H x 24″ W x 6″ D, maximum 40 shunts

- Other sizes that aren’t standard are available.

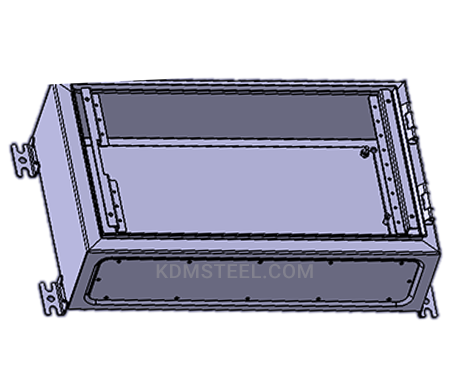

Figure- 3 Galvanized Steel Enclosure

Is Galvanized Steel Enclosure Good for Outdoors?

Galvanized steel enclosure is the most cost-effective option.

That is why it is still extensively used outside.

What is the Expected Lifespan of a Galvanized Steel Enclosure Outside?

Galvanized Steel Enclosure may endure up to 70 years in a variety of conditions.

Enclosures are made of galvanized steel will be exposed to the elements for an extended time.