What is a NEMA Rating?

Association nationale des fabricants d'équipements électriques (NEMA) represents about 325 electrical equipment manufacturers aiming to make safe, efficient, and reliable equipment.

As a leading association of U.S. manufacturers, NEMA promotes standardization of boîtiers électriques.

It outlines the performance criteria of electrical enclosures for different environmental conditions.

Consequently, electrical enclosures are classified as NEMA type 1 to NEMA type 13, depending on the performance criteria in different environments.

Today, NEMA enclosure performance criteria act as a guideline by other organizations such as Laboratoires Underwriters (UL), Canadian Standards Association(CSA), etc.

What is IEC 60529 for Electrical Enclosure?

IEC 60529 standard, also called Ingress Protection, is defined by 2 digits – IP 56, IP 55, etc.

The first digit refers to the degree of protection against solid objects or parts, while the second digit refers to the degree of protection from water.

Although the IEC 60529 standard was mainly associated with the European Union, it has been adopted globally.

Together with the NEMA rating and IEC 60529 standard (IP rating), the two play an integral role in assessing the quality and performance of electrical enclosures in different environments.

Does NEMA Rating Define Enclosure Size Specifications?

No.

The NEMA 250 standard defines performance requirements in different environments by:

- Stating the test requirements

- Construction requirements

However, every NEMA enclosure manufacturer can have their designs and sizes of electrical enclosures.

Electrical enclosure sizes

Can You Submit Electrical Enclosure to NEMA for Approval?

No, the standards are voluntary.

Therefore, NEMA does not test or certify electrical enclosures.

It is upon the electrical enclosure manufacturer to test (within their quality assurance framework) or hire a third-party testing laboratory.

All the tests and quality verifications must conform to the requirements in NEMA 250-2018: Enclosures for Electrical Equipment (1000V max).

You will get electrical enclosure performance criteria for different environments.

The document costs about $145.

How Does KDM Test NEMA Electrical Enclosures?

KDM has its own internal electrical enclosure testing facility.

Besides, we also work with third-party testing laboratories to ensure every enclosure conforms to NEMA standards.

Moreover, KDM electrical enclosure design and fabrication strictly follow the NEMA 250-2018 guidelines.

Are there Construction Requirements for NEMA Type Enclosures?

Generally, NEMA ratings are performance standards.

That is, the focus is more on the degree of protection an enclosure provides.

However, the NEMA 250-2018Enclosures for Electrical Equipment (1000 Volts Maximum), has information about the electrical enclosure construction, especially in section 3.

The section focuses on:

je. Unit of measurement

ii. Material

iii. Corrosion protection

iv. Access to interior

n. Openings

vi. Closing hardware

vii. Mounting mechanism

viii. Conduit connection

ix. Knockouts

x. Hub and fitting

xi. Gasket

xii. Edge sharpness

xiii. Observation windows, etc.

Note: The NEMA 250-2018 document should act as your guideline when fabricating and machining NEMA rated electrical enclosures.

Is KDM a Member of NEMA?

Association nationale des fabricants d'équipements électriques (NEMA) consist of manufacturers from North America.

As a leading manufacturer of electrical enclosures in China, with a large market in North America, KDM conforms to all design, fabrication, and finishing requirements stipulated by NEMA.

All our NEMA enclosures are according to the NEMA 250-2018 Enclosures for Electrical Equipment (1000 Volts Maximum).

We also work with third-party testing laboratories and partners in North America for strict standard compliance. For every electrical enclosure, KDM supplies test results.

What does NEMA 1 Enclosure Mean?

NEMA 1 electrical enclosures are designed for indoor applications where they protect components from falling dirt or foreign solids ingress.

They protect enclosure content from personnel and foreign objects.

Although NEMA 1 enclosure may have a latching door system, there is no gasket sealing system.

Therefore, it implies, NEMA 1 enclosures are suitable where protection from oil or water is not necessary.

What is a NEMA 2 Enclosure?

NEMA 2 enclosures are mainly designed for indoor applications.

They provide limited protection to dirt ingress (falling dirt) and water ingress.

NEMA 2 enclosure will protect equipment only from light splashing and dripping water.

Besides, it will also protect personnel from accessing hazardous parts of the enclosure.

Can You Buy Enclosures from NEMA?

You cannot because NEMA does not manufacture electrical enclosures.

They provide guidelines on performance requirements in different environments.

NEMA Electrical enclosure

What is a NEMA 3 Enclosure?

First, NEMA 3 enclosures are for both indoor and outdoor.

They protect technicians or personnel from accessing hazardous components of the enclosure.

Two, NEMA 3 enclosures protect enclosure equipment from:

- Solid particles or objects – it includes windblown dust or falling dirt ingress

- Water ingress – which takes into account snow, sleet, and snow.

It implies, even if ice forms on NEMA 3 enclosure, it will remain intact.

What Does a NEMA 3R Enclosure Indicate?

You can use a NEMA 3R enclosure for both indoor and outdoor environments.

However, it is common in most outdoor applications where you can use them as junction boxes or other wiring applications.

NEMA 3R enclosures protect technicians and personnel from accessing internal components of the enclosure that may be hazardous.

Besides, NEMA 3R enclosures protect its content from:

- Falling dirt and dust ingress

- Sleet, snow, dripping water and falling rain ingress, hence your component will remain intact with the formation of ice on the external surface of the enclosure

Although some NEMA 3R enclosures may have hasps, they do not have a gasket sealing surface.

The differences between NEMA 3 and 3R enclosure are:

je. Most NEMA 3R enclosures do not have gaskets; however, the standards do not explicitly state this.

ii. NEMA 3R enclosure does not protect against windblown dust.

What is NEMA 3RX?

NEMA 3RX enclosures are for outdoor applications.

However, you can also use NEMA 3RX for indoor applications.

The letter “X” implies an additional corrosion resistance.

Therefore, it implies NEMA 3RX enclosures are suitable for environment with salty water.

Additionally, it protects:

- Technicians or personnel from accessing hazardous components of the enclosure

- Components from sleet, snow, external ice formation, dripping water, and falling rain

- Enclosure components from corrosion

- Enclosure from falling dirt ingress

Although some models have hasps, they don’t have gasket sealing surface.

What Does NEMA 3S Mean?

Although you can use NEMA 3S enclosure for both indoor and outdoor applications, it is suitable for outdoor use.

NEMA 3S enclosure protects equipment from rain, sleet, windblown dust, falling dirt, or snow.

Additionally, it can still operate when laden with ice.

What is NEMA Enclosure Type 3SX?

NEMA Enclosure Type 3SX is similar to NEMA Type 3S Enclosure except that protect components from corrosion. Of course, NEMA Enclosure Type 3SX can also operate when loaded with ice.

Does NEMA Provide Labeling for Enclosures?

No, NEMA does not provide labeling for electrical enclosures.

The manufacturer can go for third-party or self-certify its electrical enclosures to be NEMA compliant.

However, it is important to provide the test results upon request by the customer.

What is a NEMA 4 Enclosure?

You can use the NEMA 4 enclosure for both indoor and outdoor applications.

NEMA type 4 enclosure protects its content from:

- Windblown dust and falling dirt ingress

- Rain, sleet and snow ingress

- Splashing water ingress

- Horse directed water or pressurized stream of water ingress

Furthermore, the formation of ice on the external surface of the NEMA type 4 enclosure cannot cause any damage.

With NEMA 4 enclosure, the door is clamped, and it has a gasket, thereby ensuring maximum sealing.

Normally, NEMA type 4 enclosures are watertight.

Therefore they must prevent not less than 65 GPM of water coming from 1 nozzle from a range not less than ten feet for 5 minutes.

You can use such NEMA type 4 enclosures in dairies, ships, wastewater treatment plant, etc.

What is the Difference Between NEMA 4 and NEMA 4X?

NEMA 4X enclosure provides the same level of protection as NEMA type 4 enclosure.

However, NEMA 4X standard enclosure comes with an additional level of protection against corrosion.

It is for this reason that NEMA 4X enclosures materials such as aluminum, polycarbonate, or stainless steel are a perfect choice.

You can use then in harsh environments where disinfectants or caustic cleaners are common.

Such areas may include petrochemical industries, poultry or meat processing plants, etc.

What Does NEMA Enclosure Type 5 Mean?

NEMA 5 enclosures are suitable for indoor applications.

It provides a degree of protection against:

je. Dripping non-corrosive fluids or liquids

ii. Settling airborne dust

iii. Falling dirt

iv. Fibers and lint

n. Light splashing water

Generally, NEMA enclosure type 5 is dust-tight. Mostly, NEMA 5 enclosures have gaskets and are common in steel mills, powder product processing, cement plants, etc.

What is a NEMA 6 Enclosure?

NEMA 6 enclosures are suitable for both indoor and outdoor use.

These enclosures have the following key features:

je. They can withstand submersion in water and oil (these are oils used in manholes and mining).

However, the submersion is at a limited depth.

Besides, NEMA 6 enclosure will prevent water ingress during temporary and occasional submersion.

ii. The design will depend on prevailing pressure conditions

iii. Protect enclosure components from falling dirt

iv. Protect enclosure components from hose directed water ingress

n. Formation of ice on the surface does not damage the NEMA 6 enclosure

How Does NEMA 6 and NEMA 6P Enclosure Compare?

Both NEMA 6 and NEMA 6P are suitable for both indoor and outdoor use.

Unlike NEMA 6 enclosure, NEMA 6P protects against water ingress in prolonged submersion.

Of course, the depth of immersion is always limited.

However, both the NEMA 6 and NEMA 6P enclosures are not suitable for continuous submersion.

Additionally, NEMA 6P also provides corrosion protection and can withstand the external formation of ice.

Otherwise, all the other degrees of protection of NEMA 6P enclosure is the same as NEMA 6 enclosure.

What is NEMA Type 7 Enclosure?

NEMA type 7 enclosure is suitable for hazardous environments.

They can withstand internal explosions without affecting the surrounding environment.

Type 7 NEMA enclosures are suitable for indoor applications within environments classified by NFPA 70 such as:

- Class I

- Division 1

- Groups A, B, C, or D

How Does NEMA Type 8 Enclosure Compare to NEMA Type 9 Enclosure?

Type 8 NEMA enclosure can prevent combustion when used in oil-immersed equipment.

It is a classified NEMA enclosure for NFPA certified environments such as:

- Class I

- Division 1

- Groups A, B, C, and D

Moreover, NEMA Type 8 enclosure is suitable for both indoor and outdoor applications.

NEMA Type 9 enclosures can prevent combustible dust from the ignition.

They are suitable for indoor or outdoor use in areas NFPA 70 classifies as:

- Class II

- Division 1

- Groups E, F, or G

What is NEMA Type 10 Enclosure?

NEMA type 10 enclosures should meet the specifications of both the Mine Safety and Health Administration, 30 CFR, Part 18.

What is the Difference between NEMA Type 11 Enclosure and NEMA Type 13 Enclosure?

NEMA 11 enclosures are for general purpose applications.

The design of NEMA type 11 enclosure guarantee protection against the effects of corrosive gases and liquids.

On the other hand, NEMA Type 13 enclosures are suitable for general purpose applications.

They provide a degree of protection against non-corrosive coolant seepage, spraying or splashing and spraying or dripping of water.

Besides, NEMA type 13 enclosures are also rust-resistant.

They protect enclosure content from falling and circulating dirt or dust.

Both NEMA type 11 and NEMA Type 13 enclosures are suitable for indoor applications.

What is NEMA 12 Enclosure?

NEMA 12 enclosure protects enclosure content from:

- Drips

- Dripping non-corrosive liquids

- Falling dirt

NEMA Type 12 enclosures have a gasket that completely prevents airborne contaminants ingress, non-pressurized oil, and water ingress.

How Does NEMA 12K Enclosure and NEMA 12 Enclosure Compare?

NEMA 12K enclosures have knock-outs while NEMA enclosure 12 lacks knock-outs.

Knockouts are precut panels you can easily remove using a tool.

Therefore, during the enclosure panel installation, you will only remove important areas.

Knock out in the electrical enclosure

NEMA 12K enclosure offers a reasonable degree of flexibility during cables or wires installation.

Both NEMA Type 12 enclosure and NEMA Type 12K enclosure protect against:

je. Falling and circulating lint, dirt, dust or fibers

ii. Dripping and light splashing of water ingress

iii. Settling dust and dirt

iv. Seepage of coolants and oil

Why is NEMA Mark Missing on KDM Electrical Enclosures?

First, NEMA is neither a conformity assessment or certification mark.

That is why you will not see KDM enclosures with NEMA marks.

Second, NEMA is the National Electrical Manufacturers Association’s trademark.

KDM respects intellectual property; thus, we cannot use it.

However, for our OEM partners in North America, who are members of NEMA, we will use it on their electrical enclosure upon request.

KDM will use it to indicate that the electrical enclosure meets the NEMA design performance requirements for different environments.

But, we will not use it in the same sentence or close to the conformity marks such as CE, UL, etc.

For more clarifications on using NEMA marks on the electrical enclosure, talk to our team today.

NEMA compliant electrical enclosure

What is IP Enclosure Rating?

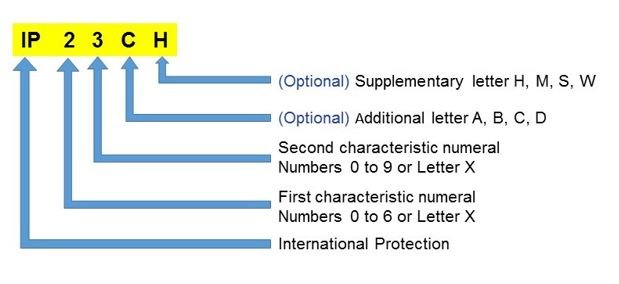

Countries within the European Union use IP code to classify different enclosures depending on the degree of protection.

At times, this code refers to ingress Protection Marking, International Protection Marking, ou IEC standard 60529.

These are enclosure safety standards published by the International Electrotechnical Commission (IEC).

The structure of the IP enclosure rating takes the format:

IP Code – Photo credits: Wikimedia

For instance, you may have IP 45 Enclosure, IP 56 Enclosure, IP 65 Enclosure, etc.

Where the digits or letter show the following degrees of protection:

IP Protection – Photo credits: Flow Star

The first digit refers to the degree of solid particle protection.

While the second digit is liquid ingress protection.

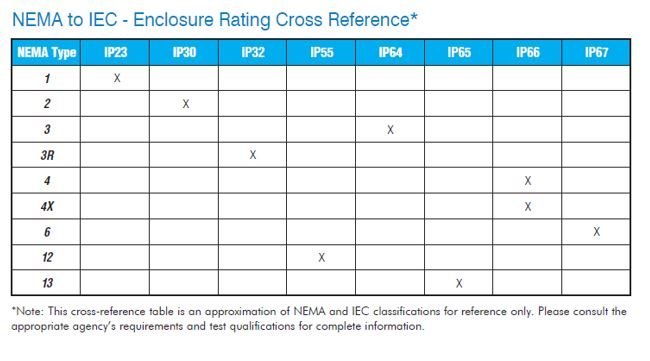

Can You Compare NEMA Enclosure Rating to IP Rating?

Yes, you can.

However, you should note that it is accurate to say that NEMA Type enclosure is equivalent to an IP rated enclosure and not vice versa.

It is because the IP rating focuses on protecting the electrical enclosure from water ingress and solid particles ingress.

However, NEMA designation takes into account other critical aspects such as corrosion resistance, ability to withstand submersion to limited depth and time, among other conditions.

Of course, this is a more comprehensive approach, unlike the IP rating.

Here is a brief comparison between NEMA enclosure and IP enclosure:

NEMA rating to IP rating – Photo credits: Automation Direct

Some Electrical Enclosures Have More than 1 NEMA Type Rating – How is it Possible?

There is nothing wrong with one electrical enclosure having more than 1 NEMA type rating designation.

For instance, you can have an enclosure that is suitable for:

- Both indoor and outdoor applications

- Can withstand submersion and corrosion, etc.

In such a case, after assessment, it is important to list all NEMA type rating designations.

Are KDM NEMA Enclosures Rated for Arc Flash?

NEMA ratings do not have provisions for arc flash protection.

However, our safety instructions and design also conform to NFPA 70E requirements.

At KDM, we give work place the priority.

Does KDM Fabricate Custom NEMA Enclosures?

Oui.

KDM will help you through every stage, from developing the concept, CAD drawing, fabrication, quality testing, and shipping.

Contact us now for your custom NEMA enclosures.